AD

B

C

2

The eLine Brand

Congratulations on choosing your eFlex underoor heating product from the eLine

range of underoor heating solutions.

The eLine range has been manufactured to exceed all relevant standards and

expectations considering ease of installation and usability through the lifetime of the

product.

The eFlex Product

The eFlex is a thin (4mm) twin conductor, 10w per linear metre constant wattage

heating cable, with a pre-terminated 2.5m cold tail (power cable) attached.

Twin conductor product design ensures a simple installation for either a warm oor or

total heating solution.

The xing strip provided with the eFlex kit, allows installation of the eFlex at variable

spaces (minimum 50mm) consequently altering the heat output to your own

requirements.

Tools needed for installation

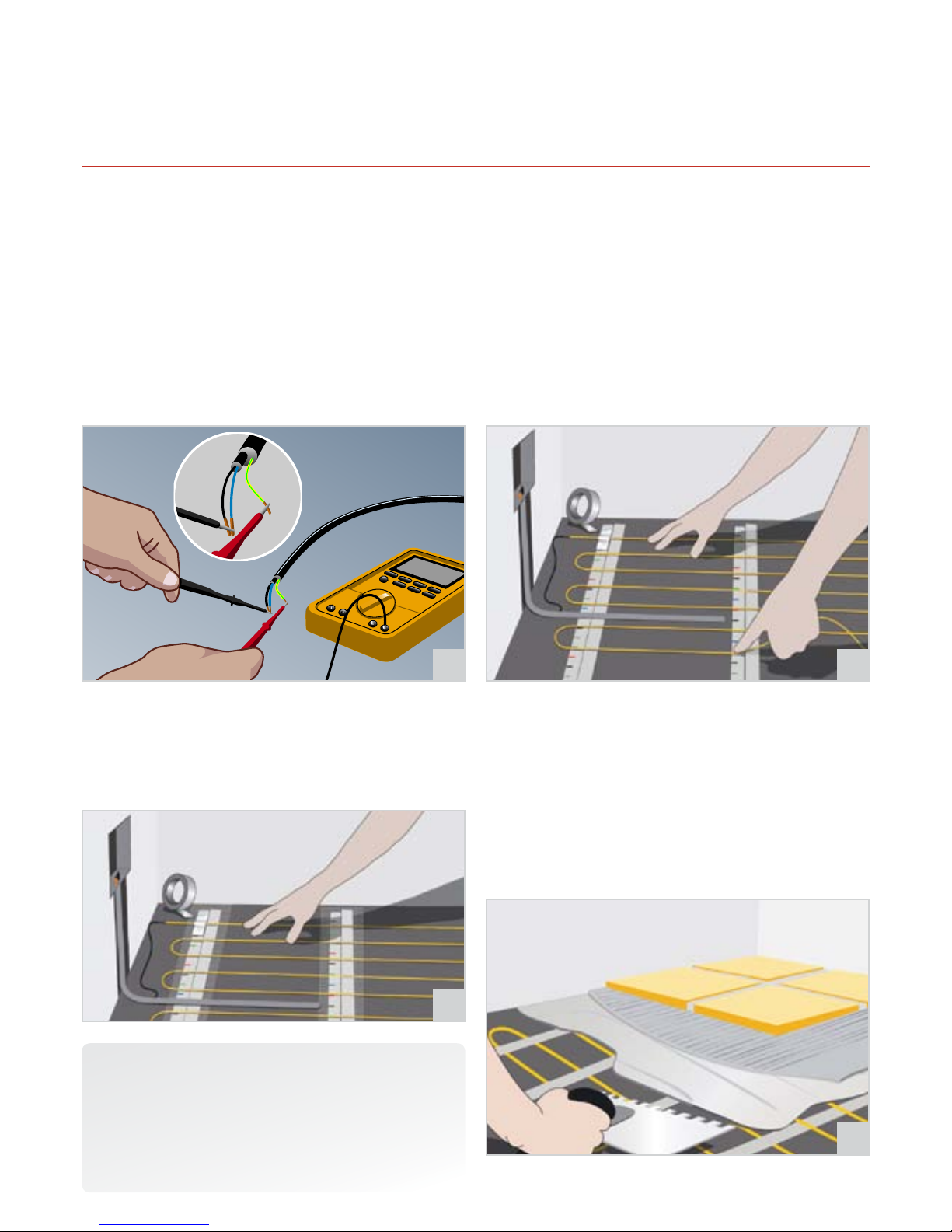

You will require the following items to install and test the eFlex system:

• Tapemeasuredrawingpadandpencil

• Cablestrippersandscrewdriver

• Resistancetester(multimeter)

The complete eFlex system

• Heatingcable •eGaugemeasuringtape

• Sensortube •eFixdoublesidedtape

• Installationinstructions •eMesh

• Warranty

The following pages contain all the information you will need about the eFlex.

Please take time to study this information thoroughly before you attempt to install

this product.

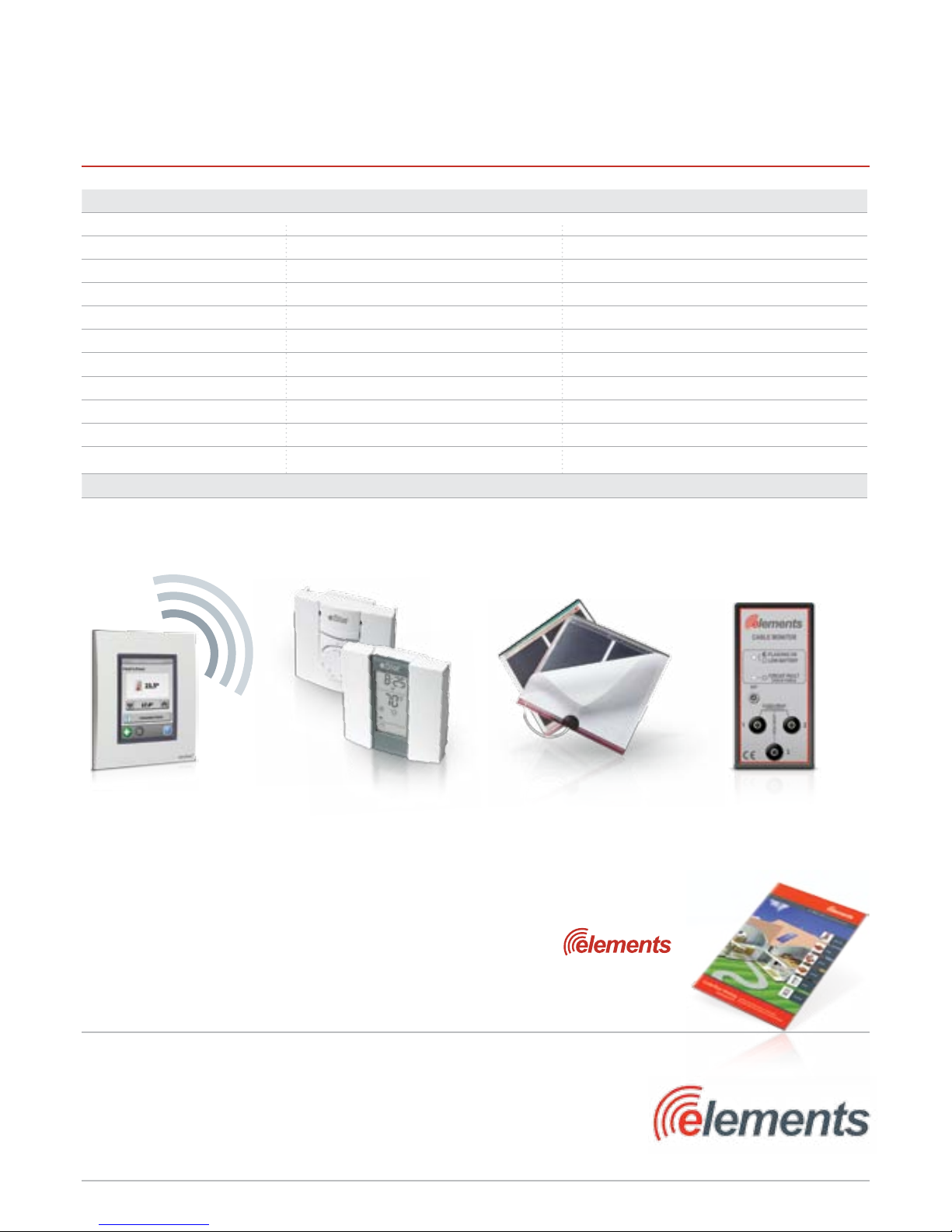

Glossary of Terms

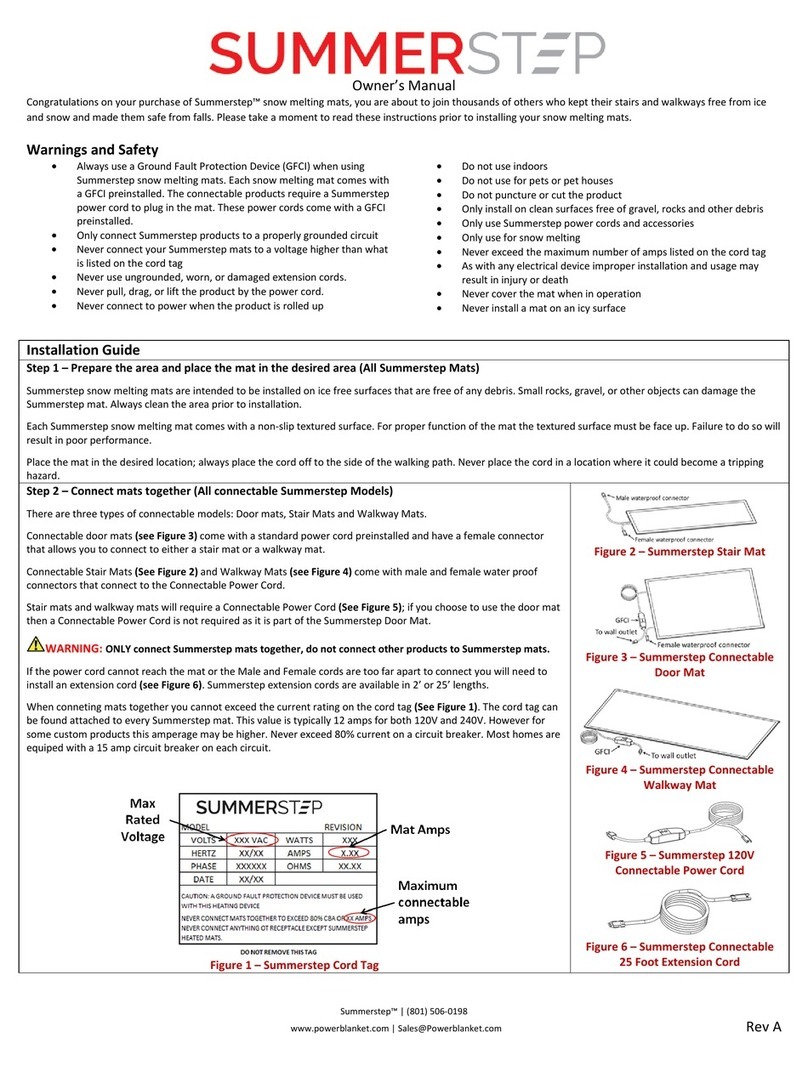

A– Heating element

B– Factory made cold tail joint

C– Cold tail power lead

D– End termination joint

Do’s & Don’ts

Do

Carefully read this instruction manual before starting your installation and

follow the testing procedure as detailed on page 6.Throughout your installation:

• Takesometimetoplanyourcablelayoutconsideringallobstaclese.g.drain

covers, kitchen units, bathroom sinks etc.

• Ensuretheoorsensorthermostatisinsertedwithintheexibletube

provided, with the oor end of the exible tube properly sealed (to ensure

easy removal of the oor sensor after installation if required).

• Maintainaminimumof50mmspacingbetweentheheatingelementruns

at all times.

• Takecarenottodamagetheheatingcableandcoldtail(powercable)whilst

screeding the oor area.

• Ensurealltheyellowheatingelementiscoveredwiththetileadhesive

or exible self levelling compound.

• Ensuretheoorsurfaceiscorrectlypreparedbeforeinstallation(seepage4).

• Ensuretheentireyellowheatingelementisinstalledwithintheoor.

• WhenusingmorethanoneeFlexfromasinglesupply,coldtailsmustbe

connected in parallel.

• Whenusingfoilfacedinsulationensureallinsulationjointsareproperly

taped to prevent the eFlex from slipping in-between insulation panels.

• EnsuretheeFlexisevenlyspacedacrossyourcompletefreeoorarea.

Don’t

• Cutorshortentheyellowheatingcable.

• Crossortouchtheyellowheatingcablestogether.

• Switchyourunderoorheatingsystemonforaminimumof7daysafter

tiling to allow correct curing of tile adhesives and grouts.

• Connecttheheatingelementtothepowersupplywhilststillrolledup.

• Leaverolledupsurpluscableunderkitchenunitsorbathspaces.

•

CommenceinstallationofyouroorsurfacebeforetestingyoureFlex.Seepage7.

• Tileoverdamagedortwistedcables.

• Installheatingcablescloserthan50mm.

Introduction

Importantnotes,pleasereadcarefullybeforeproceedingwithinstallation