- 5 -

Electric actuators / Common precautions

Design and selection

Warning

1. Be sure to read the Operation Manual (this manual and the one for the driver: LEC series).

Handling or usage/operation other than that specified in the Operation Manual may lead to breakage

and operation failure of the product. Any damage attributed to the use beyond the specifications is not

guaranteed.

2. There is a possibility of dangerous sudden action by the product if sliding parts of machinery

are twisted due to external forces etc.

In such cases, human injury may occur, such as by catching hands or feet in the machinery, or damage

to the machinery itself may occur. Design the machinery should be designed to avoid such dangers.

3. A protective cover is recommended to minimize the risk of personal injury.

If a driven object and moving parts of the product are in close proximity, personal injury may occur.

Design the system to avoid contact with the human body.

4. Securely tighten all stationary parts and connected parts so that they will not become loose.

When the product operates with high frequency or is installed where there is a lot of vibration, ensure

that all parts remain secure.

5. Consider a possible loss of power source.

Take measures to prevent injury and equipment damage even in the case of a power source failure.

6. Consider behavior of emergency stop of whole system.

Design the system so that human injury and/or damage to machinery and equipment will not be caused,

when it is stopped by a safety device for abnormal conditions such as a power outage or a manual

emergency stop of whole system.

7. Consider the action when operation is restarted after an emergency stop or abnormal stop of

whole system.

Design the system so that human injury or equipment damage will not occur upon restart of operation

of whole system.

8. Never disassemble or modify (including additional machining) the product.

An injury or failure can result. It will cause the loss of the product performance.

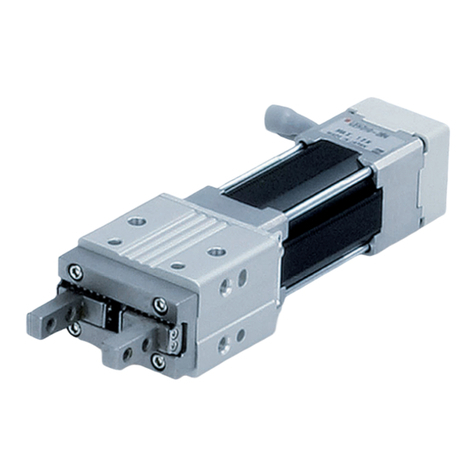

9. When using it vertically, diagonally, or in other conditions with height differences, it is

necessary to build in a safety device (Latches, Movable bolts, Fall prevention devices, etc.).

The rod may fall due to the weight of work. The safety device should not interfere with normal operation

of the machine.

10. Do not exceed product specification, even if workload is supported by external linear guides.

The moment to actuator is reduced by external guide, but required ability for transport (relationship

between speed and workload) is not reduced.

Caution

1. Operate within the limits of the maximum usable stoke.

The product will be damaged if it is used with the stroke which is over the maximum stroke. Refer to the

specifications of the product.

2. When the product repeatedly cycles with partial strokes, lubrication can run out. Operate it at a

full stroke at least once a day or every 1 000 strokes.

3. Do not use the product in applications where excessive external force or impact force is applied

to it. The product can be damaged.

Each component that includes motor is made with accurate tolerance. So even slightly deformed

or miss-alignment of component may lead operation failure of the product.

4. Refer to a common auto switch /matter (Best Pneumatics No 2) when an auto switch is built in

and used.