Elesa DD52R-E-RF User manual

Electronic position indicators

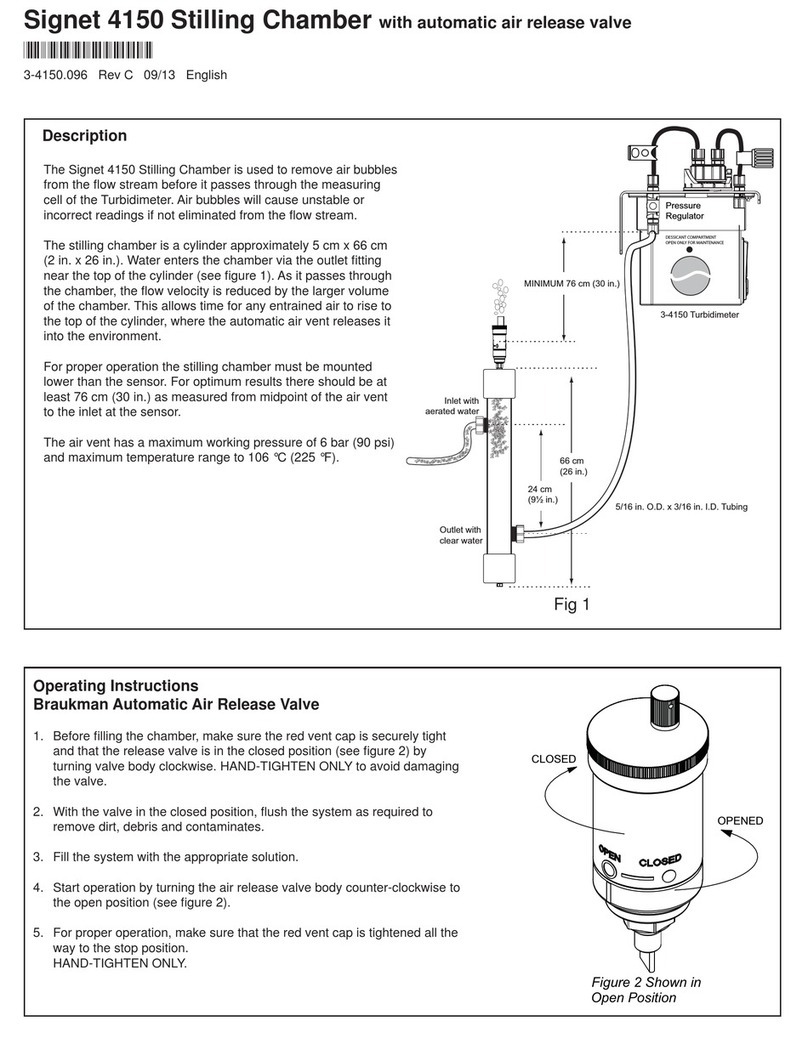

OPERATING INSTRUCTION

DD52R-E-RF

2

EN

DD52R-E-RF Electronic position indicators

Data transmission via radio frequency

Models all rights reserved in accordance with the law.

Always mention the source when reproducing our drawings.

Contents

1. Safety Instructions 3

2. Assembly 5

3. Symbols on the display 5

4. Key function 6

5. Turning on the system 6

5.1 Turning off the system 6

6. Operating mode 7

6.1 System explanation 7

6.2 Programming the network parameter (nEt id)

and the channel parameter (nEt ch) 7

6.3 Targets 7

6.3.1 Target tolerance 8

6.4 Absolute / incremental measuring mode selection 8

6.5 Unit of measure selection 9

6.6 Setting the absolute reference 9

6.7 Direct programming of the absolute reference value

(source) - of the compensation value (offset) - of the

reading after one revolution

10

6.8 Programming target position 10

6.9 Battery replacement 11

7. Programming mode 12

7.1 Programming parameters with numeric values 12

7.2 Programming parameters 12

7.3 Parameters 14

8. Problem solving 17

3

EN

DD52R-E-RF

Electronic position indicators

Data transmission via radio frequency

Electronic position indicators

Data transmission via radio frequency

Models all rights reserved in accordance with the law.

Always mention the source when reproducing our drawings.

1. Safety Instructions

The product has been designed and manufactured in accordance with the current

regulations. The product leaves the factory ready for use and complies with the

safety standards.

To maintain the product in this state, it is necessary that it is assembled and

used properly, in the closest compliance with this instruction manual and with the

following specific safety precautions.

Ensure that the user has read and understood the instruction manual and in

particular the chapter “Safety Instructions”.

In addition to the instruction manual, all the rules of law must be observed, in

regard to accident prevention and environmental protection.

This manual is intended as an indispensable supplement to the existing

documentation (catalogues, data sheets and assembly instructions).

The use without complying with the descriptions / specific

parameters, in combination with systems / machines /

processes to be controlled, it can lead to a malfunction of the

product, causing:

- health hazards,

- environmental hazards,

- damage to the product and its proper functionality.

Do not open nor modify the case of the indicator.

Tampering with this product may endanger the correctness and accuracy of its

operation. In case of malfunction, do not attempt any repairs to the units and

contact Elesa sales office.

4

EN

DD52R-E-RF Electronic position indicators

Data transmission via radio frequency

Models all rights reserved in accordance with the law.

Always mention the source when reproducing our drawings.

Mechanical and electrical characteristics

Power supply Lithium battery CR2477 3.0 V

Battery life 3 years

Display 6-digit LCD of 12 mm height and special

characters

Reading scale -199999; 999999

Number of decimal digits programmable (1)

Unit of measure mm, inches, degrees

programmable (1)

Rotation max. speed 300/600/1000 r.p.m. (2)

programmable (1)

Precision 10.000 impulses/revolution

Protection level IP65 or IP67

Operating temperature 0°C ÷ +50°C

Storage temperature -20°C ÷ +60°C

Relative humidity max. 95% a 25°C

without condensation

Environment indoor use

Altitude up to 2000 m

Interference IEC 61326-1

(1) See paragraph 7.2

(2) Default: 600 r.p.m.

WARNINGS!

Higher rotation speeds to 600 r.p.m. can be maintained for short periods of time.

The value of the max speed affects the battery life.

5

EN

DD52R-E-RF

Electronic position indicators

Data transmission via radio frequency

Electronic position indicators

Data transmission via radio frequency

Models all rights reserved in accordance with the law.

Always mention the source when reproducing our drawings.

2. Assembly

1. Drill a Ø 6x10 mm hole in the body of the machine with a 30 mm centre

distance from the shaft to fit the rear referring pin.

2. Fit the indicator onto the shaft and make sure that the referring pin fits into the

hole.

3. Clamp the bushing to the shaft by tightening the grub screw with hexagon

socket and cup end, according to UNI 5929-85.

3. Symbols on the display

1. Absolute / relative mode

2. Low battey level indicator

3. Unit of measure (mm / inch / degrees)

4. Target position indications

5. Network link indicator

1 2 3 45

6

EN

DD52R-E-RF Electronic position indicators

Data transmission via radio frequency

Models all rights reserved in accordance with the law.

Always mention the source when reproducing our drawings.

4. Key function

FUNCTION

KEY Operating

mode

Programming

mode

Access to the

programming mode

Parameter selection /

Confirm of parameter

change

Displaying target

position / Distance to

go to target position

Digit decrease* /

Scroll for parameters

Absolute or

incremental mode

selection

Digit increase* /

Scroll for parameters

Unit of measure

selection

Programming mode

exit /

Digit selection

*The digit decrease / increase is reversed when the display is in 180° mod.

5. Turning on the system

After you have read and understood the section “Safety Instructions”, proceed by

switching on the indicator.

To turn the indicator on hold then press the key .

The display will light up and the indicator will be ready to be used.

5.1 Turning off the system (only for storage)

To turn the system off enter the programming mode, select the

rESEt

parameter

then press the key . At this point, press the button and then press the

key; the display will turn off and the indicator will go into low power mode

of the battery.

WARNINGS!

The keys’ icons are

conventionally shown with

the display rotation set to

0° (default is 180°).

7

EN

DD52R-E-RF

Electronic position indicators

Data transmission via radio frequency

Electronic position indicators

Data transmission via radio frequency

Models all rights reserved in accordance with the law.

Always mention the source when reproducing our drawings.

6. Operating mode

6.1 System description

DD52R-E-RF, position indicators, with battery power supply, can be used on

passing through shafts in any position to provide the reading of the absolute or

incremental positioning of a machine component.

The system comprises the following components:

- Control unit UC-RF

- Max 36 electronic position indicators DD52-E-RF

The control unit UC-RF is provided with a standard interface (for the most common

industrial busses) to be connected to the PLC and allows the transmission of the

information between the PLC and the DD52R-E-RF position indicators. The UC-RF

exchanges information with the DD52R-E-RF via radio frequency and allows

the setting of the target position and the control of the current position of each

indicators, directly from the PLC.

6.2 Programming the network parameter (nEt id) and the channel parameter

(nEt ch)

The system radio network is defined by the following parameters:

- nEt id: id 00/99

- nEt ch: ch 01/36

These parameters can be configured on the radio menu of the indicator (see cap. 7) and

must be set according to the PLC recipe to guarantee a perfect communication

between UC-RF and DD52R-E-RF.

6.3 Targets

Target positions can be sent from the PLC to the indicators through the control unit.

When a target is set, one of the symbols reported below appears on the top right of the

display, to suggest the direction of rotation of the spindle to get to the target position:

Counter-clockwise rotation. The symbol flashes.

Clockwise rotation. The symbol flashes.

Counter-clockwise rotation. Target position almost reached. The arrow flashes.

Clockwise rotation. Target position almost reached. The arrow flashes.

Target position reached.

Target positions

Current positions

PLC

8

EN

DD52R-E-RF Electronic position indicators

Data transmission via radio frequency

Models all rights reserved in accordance with the law.

Always mention the source when reproducing our drawings.

___0__

The menu function

__0___

allows the customer to choose between the options

d_tArG

or

d_to_GO

(factory detail).

Selecting

d_tArG

, when a new target position is set, the display will keep showing

the present position. If the present position differs from the target an indication will start

flashing. Turn the spindle according to the direction shown by the flashing arrows

or to get to the target position. Press the button

to see the target position

set.

Selecting

d_to_GO

, as soon as the indicator receives a new position from the

PLC, the display starts flashing, showing the distance between the actual and

the target position. To get to the target position, it is necessary to rotate the shaft

following the flashing arrows or until the number on the display becomes

zero. Once the target position is reached, the display will stop flashing showing

the actual position of the indicator. If the spindle is moved and get out of the

desired tolerance, the display will start flashing again. To visualise the actual

position while the display is flashing, keep pressed the button .

6.3.1 Target tolerance

Set the value of

P_toll

parameter to define the tollerance allowed for target (see

cap. 7.3 for detail).

6.4 Absolute / incremental measuring mode selection

Press the key to select the absolute or incremental measuring mode.

The measuring mode selected is shown on the display by the symbols:

-

ABS

: absolute measuring mode

-

REL

: incremental measuring mode

It is possible to change the key function by setting the

parameter

___0__

in the menu (see cap. 7.1).

The available options are:

-

ArCLr

(default): passing from

ABS

to

REL

the counter is set to zero.

-

Ar

: passing from

ABS

to

REL

the counter is not set to zero. In this case, the

counter is set to zero by pressing + .

-

OFF

: the key is disabled and does not allow changing the selected

measuring mode.

To program the parameters listed above, see paragraph 7.2.

9

EN

DD52R-E-RF

Electronic position indicators

Data transmission via radio frequency

Electronic position indicators

Data transmission via radio frequency

Models all rights reserved in accordance with the law.

Always mention the source when reproducing our drawings.

6.5 Unit of measure selection

Press the key to select the unit of measure needed. The options available are

millimeters, inches and degrees.

The measuring mode selected is shown on the display by the symbols:

-

mm

: millimeters -

INCH

: inches -

D

: degrees

It is possible to change the key function by setting the

parameter

_____0

in the menu (see cap. 7.1).

The available options are:

-

ALL

(default): units of measure that can be selected: mm, inch, D

-

nodEG

: units of measure that can be selected: mm, inch

-

OFF

:

the key is disabled and does not allow changing the selected measuring mode.

To program the parameters listed above, see paragraph 7.2.

6.6 Setting the absolute reference

After having selected the absolute measuring mode and stopped the shaft in the

starting position or in the reference position, press the key combination

+the screen will display the last compensation value used (eg

OFFS 0

).

Choose the desired compensation value by pressing the key or , and

then press the key to confirm, this will set the absolute value to the sum of the

values of the parameters

OriGin

(absolute value of reference) and

OFFSET

(compensation value).

The value of compensation (offset) allows you to adjust the value shown on the

display in such a way that takes into account, for example the wear or tool change.

The system allows you to store up to 10 values of compensation.

To program the offset values, see parameter

OFFSET

of paragraph 7.2.

It is possible to change the function of the keys combination

by setting the parameter

0__0__

in the menu (see cap. 7.1).

0__0__

_____0

10

EN

DD52R-E-RF Electronic position indicators

Data transmission via radio frequency

Models all rights reserved in accordance with the law.

Always mention the source when reproducing our drawings.

0_0___

0____0

The available options are:

-

L_OrG

: the reference value and the compensation value are set as shown

above. Choose the desired offset among the 10 available values, then press

the key to confirm;

-

OFF

: the keys combination + is not associated to any function in the

operating mode.

To program the parameters listed above, see paragraph 7.2.

6.7 Direct programming of the absolute reference value (source) - of the

compensation value (offset) - of the reading after one revolution

The function of the keys combination + allows direct access to the

programming of one of the following parameters, depending on the value assigned

to parameter

0____0

(see paragraph 7.1 for the instruction to set values).

It is possible to change the function of the keys combination

by setting the parameter

0____0

The available options are:

-

P_OrG

: direct programming of the absolute reference value (OrG parameter)

-

P_StP

: direct programming of the reading after one revolution (StEP parameter)

-

P_OFS

: direct programming of the compensation value (OFFS parameter)

-

OFF

: the keys combination +is not associated to any function in

the operating mode

For programming the parameters listed above see parameter

0____0

of

paragraph 7.2.

6.8 Programming target position

The function of the keys combination allows, if the parameter

0_0___

has

been set on

tArGEt

, to program or to load one of the 32 target positions (see

paragraph 7.1 for the instruction to set values).

It is possible to change the function of the keys combination

by setting the parameter

0_0___

11

EN

DD52R-E-RF

Electronic position indicators

Data transmission via radio frequency

Electronic position indicators

Data transmission via radio frequency

Models all rights reserved in accordance with the law.

Always mention the source when reproducing our drawings.

The available options are:

-

LOAd_t

: choose one of the 32 available target positions,

then press to confirm

-

PrOG_t

: choose to program one of the 32 available target positions,

then press to start programming

6.9 Battery replacement

The internal lithium CR2477 - 3.0 V battery ensures over 3 years battery life.

The symbol is shown on the display when the battery replacement is required.

The replacement is made by simply removing the front cover without disassembly

of the indicator from the control shaft and keeping unchanged all the configuration

parameters.

To simply remove the battery from the battery compartment, we recommend

the use of a magnet. By replacing the battery in less than 5 seconds, all the

measurement and settings wil not be lost. If more time is required and the display

turns off, the settings of the device have to be set or verified again.

12

EN

DD52R-E-RF Electronic position indicators

Data transmission via radio frequency

Models all rights reserved in accordance with the law.

Always mention the source when reproducing our drawings.

7. Programming mode

Press the key for 3 seconds to enter the programming mode. Depending on

the setting of

PASS

parameter (see table on page 16), the system may require

you to enter a password.

Press the key to scroll through the list of parameters.

Press the key to exit the programming mode. The programming mode is

automatically dropped after 30 seconds of inactivity.

7.1 Programming parameters with numeric values

Press the key to increase* the flashing digit.

Press the key to decrease* the flashing digit.

Press the key to select the next digit.

Press the key to confirm the value and go back to the list of parameters.

*The digit decrease / increase is reversed when the display is in 180° mod.

The numeric values of the parameters must be inserted

taking into account the selected unit of measure.

7.2 Programming parameters

The sequence of the menu elements / parameters shown in programming mod is

as in the following diagram.

13

EN

DD52R-E-RF

Electronic position indicators

Data transmission via radio frequency

Electronic position indicators

Data transmission via radio frequency

Models all rights reserved in accordance with the law.

Always mention the source when reproducing our drawings.

_____0 nodEG

OFF

ALL

StEP 000.01 / 100.00

OriGin -99999 / 99999

dir --o

o--

diSPL 0°

180°

0__0__ L_OrG

OFF

0____0

OFF

P_StP

P_OrG

P_OFS

PASS On

Off

rESEt No

Yes

OFFSET

OFS 0

... -99999 / 99999

OFS 9

SPEEd

300

600

1000

rES mm Inch deg

1

0.1

0.01

1

0.1

0.01

1

0.1

0.01

0.001

___0__ ArCLr

OFF

Ar

rE

P_toll

__0___

0_0___ tArGEt

OFF

0.01 / 9.99

d_tArG

OFF

d_toG0

rAdio

nEt id

nEt ch

00

...

99

ch 01

...

ch 36

14

EN

DD52R-E-RF Electronic position indicators

Data transmission via radio frequency

Models all rights reserved in accordance with the law.

Always mention the source when reproducing our drawings.

7.3 Parameters

The available parameters and their descriptions are listed in the following table.

Parameter Description Available options Standard

value

dir

Rotation

direction

--o

clockwise

o--

counterclockwise

--o

OriGin

Absolute

reference

value

-99999

;

99999

The parameter value depends

on the unit of measure selected.

0000.0

OFFSET

Compensation

values

(Offset)

-99999

;

99999

The system allows you

to store up to 10 compensation

values:

OFS 0

...

OFS 9

The parameter value depends

on the unit of measure selected.

0000.0

StEP

Reading

after one revolution

0.01

;

100.00

001.00

rES

Resolution mm:

1

;

0.1

;

0.01

inches:

0.001

;

0.01

;

0.1

;

1

degrees:

0.01

;

0.1

;

1

mm:

0.1

inches:

0.01

degrees:

1

diSPL

Display orientation

0°

: display right

180°

: display reverse

180°

SPEEd

Reading max speed

[rpm]

300

;

600

;

1000 600

rAdio

Parameters to be

networked to the

UC-RF control unit

via radio frequency.

nEt id: id0...id9

nEt ch: ch01...ch36

id 00

ch01

P_toll

Tolerance of target

position

0.01

;

9.99

The parameter value depends

on the unit of measure selected.

0.10

15

EN

DD52R-E-RF

Electronic position indicators

Data transmission via radio frequency

Electronic position indicators

Data transmission via radio frequency

Models all rights reserved in accordance with the law.

Always mention the source when reproducing our drawings.

Parameter Description Available options Standard

value

_____0

Key function

ALL

: selectable units of

measure: mm, inch, D

nodEG

: selectable units of

measure: mm, inch

OFF

: the key does not allow the

unit of measure conversion

ALL

___0__

Key function

ArCLr

: switching from

ABS

to

REL

the counter is set

to zero.

Ar

: switching from

ABS

to

REL

the counter is not set

to zero.

OFF

: the key is not assigned

to any function in the operating

mode.

ArCLr

__0___

Key function

d_tArG

: during the

positioning press the key

on the display will appear the

target position to reach.

d_toG0

: during the positioning

keep pressed the key on

the display will appear the actual

position of the indicator.

OFF

: the key is not assigned

to any function in the operating

mode.

d_toG0

16

EN

DD52R-E-RF Electronic position indicators

Data transmission via radio frequency

Models all rights reserved in accordance with the law.

Always mention the source when reproducing our drawings.

Parameter Description Available options Standard

value

0____0

Key

combination

function

+

The key combination activates

the direct programming of the

following parameters:

P_OrG

: parameter

OrG

P_StP

: parameter

StEP

P_OFS

: parameter

OFFS

OFF

: the key combination is not

assigned to any function in the

operating mode.

P_OrG

0__0__

Key

combination

function

+

L_OrG

: the key combination

sets the absolute value to

the sum of

OrG

+

OFFS

parameters.

OFF

: the key combination is not

assigned to any function in the

operating mode.

L_OrG

0_0___

Key

combination

function

+

tArGEt

: the keys

combination allows to load/

program on of the 32 target

positions.

OFF

: the key is not assigned

to any function in the operating

mode.

OFF

PASS

Password

ON

: the system requires the

password 22011 to enter the

programming mode.

OFF

: the system does not

require a password to enter the

programming mode.

OFF

rESEt

Setting of

parameters to

standard values

YES

: the parameters are set to

the standard values.

NO

: the parameters maintain the

values set by the user.

NO

rE

Software version The software version is shown on

the display.

F3.E_02

17

EN

DD52R-E-RF

Electronic position indicators

Data transmission via radio frequency

Electronic position indicators

Data transmission via radio frequency

Models all rights reserved in accordance with the law.

Always mention the source when reproducing our drawings.

8. Problem solving

Message on the

display Description Action

_ _ _ _ _ _

Exceeding the

reading scale

(-199999; 999999).

The value cannot

be shown on the

display.

The system

continues

to measure

displacements;

the value will be

shown on the

display again if

re-included in the

reading scale.

S_Err

The shaft speed

has exceeded the

max system speed

(see table on

page 26).

Press to

go back to the

value reading and

re-set the absolute

reference.

Flashing

battery symbol

Low Battery Replace the battery

(see paragraph 6.9).

Other manuals for DD52R-E-RF

3

Table of contents

Other Elesa Measuring Instrument manuals