Elka ES 50 User manual

Installation and operating instructions

Barriers

ES 50 – ES 80

with MO 63

Translation of original operating manual

D-ID: V7_0 – 07.17

ES 50 – ES 80

1

Contents

1Preface ............................................................................................................................ 3

1.1General notes ................................................................................................................... 3

1.1.1Symbol explanation .......................................................................................................... 4

1.2Copyright .......................................................................................................................... 4

1.3Information regarding installation instruction .................................................................... 4

2Safety ............................................................................................................................... 5

2.1General notes on safety ................................................................................................... 5

2.2Notes on safety for the operation ...................................................................................... 5

2.3Safety notes for the operation with radio remote control .................................................. 5

2.4Intended use of barriers .................................................................................................... 5

2.5Improper use .................................................................................................................... 5

2.6Intended use – vehicle traffic, pedestrian traffic impossible .............................................. 6

2.7Intended use - vehicle traffic, pedestrian traffic not impossible ........................................ 6

2.8Danger, which could emanate from the site of operation .................................................. 7

2.9Non-factory technical alterations and extensions ............................................................. 7

2.10Personnel requirements – professional skills, knowledge and qualifications .................... 7

2.11Personal protective equipment ......................................................................................... 8

3Transportation and storing ............................................................................................ 9

3.1Transportation inspection ................................................................................................. 9

3.2Storing .............................................................................................................................. 9

3.3Lifting heavy loads ............................................................................................................ 9

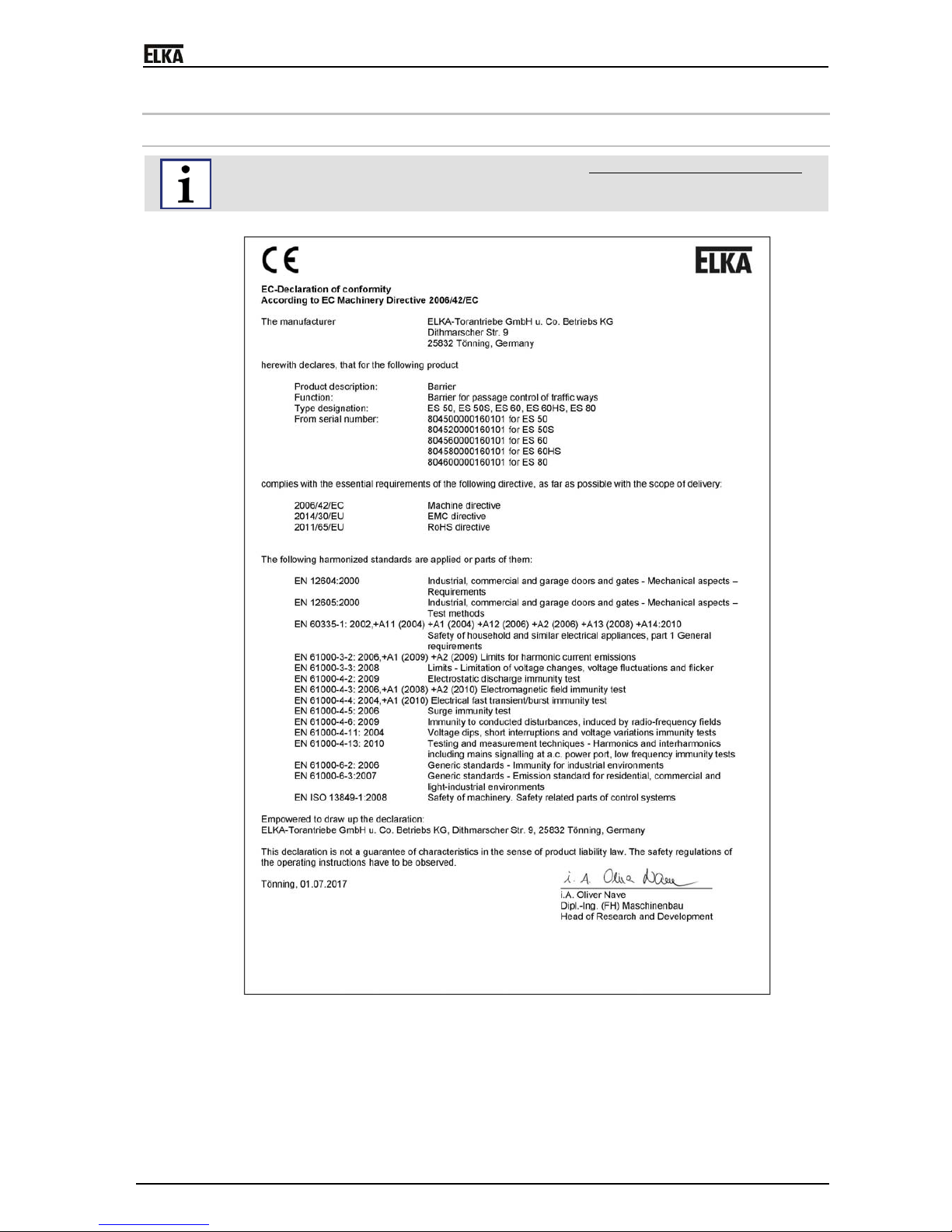

4Declaration of conformity ............................................................................................ 10

4.1Barrier ES 50-80 – pedestrian traffic impossible ............................................................. 10

4.2Barrier ES 50-80 – pedestrian traffic not impossible ....................................................... 11

4.3Declaration of conformity – complete system ................................................................. 12

4.4Name plate ..................................................................................................................... 12

4.5Performance declaration ................................................................................................ 12

5Function description .................................................................................................... 13

6Technical data ES 50 – ES 80 ...................................................................................... 14

6.1Operation - Safety – Wind load class ............................................................................. 15

7Measurements ES 50 – ES 80 ...................................................................................... 17

8Installation ES 50 – ES 80 ............................................................................................ 18

9Controller MO 63 ........................................................................................................... 23

9.1Connections .................................................................................................................... 24

9.2Further connections ........................................................................................................ 24

9.3Visual indication .............................................................................................................. 25

9.4Operating mode controller .............................................................................................. 25

9.4.1Pre-warning before opening (VWA) ................................................................................ 25

9.4.2Pre-warning before closing (VWZ) .................................................................................. 25

9.4.3Automatic closure (ZLA) ................................................................................................. 26

9.4.4Reversal on hitting obstacles (REV) ............................................................................... 26

9.4.5Counting (ZÄHL) ............................................................................................................. 26

9.4.6Reversal during opening (SZ) ......................................................................................... 26

9.4.7Automatic closure by photo-cell (LSA) ............................................................................ 26

9.4.8Photo-cell test (LSTST) .................................................................................................. 26

9.5Photo-cell test ................................................................................................................. 26

9.6Programming .................................................................................................................. 27

9.6.1Running time and automatic closure .............................................................................. 27

ES 50 – ES 80

2

9.6.2Personal code for radio remote ...................................................................................... 27

10External connections ................................................................................................... 29

11Layout in the barrier ..................................................................................................... 31

12Fault finding .................................................................................................................. 32

12.1The closed barrier doesn’t react to a signal to open ....................................................... 32

12.2The open barrier doesn’t react to signals to close .......................................................... 33

12.3Fault finding continued ................................................................................................... 34

12.4Error code ....................................................................................................................... 35

13Examples for use of loop detectors ............................................................................ 36

14Maintenance and cleaning ........................................................................................... 38

14.1Maintenance ................................................................................................................... 38

14.2Cleaning ......................................................................................................................... 38

14.2.1Cleaning – outer sides of the barrier housing ................................................................. 38

14.2.2Cleaning- inside of the housing ...................................................................................... 39

15Decommissioning ......................................................................................................... 40

15.1Disposal .......................................................................................................................... 40

16Extra equipment ........................................................................................................... 41

16.1Swinging support for ES 50 – 80 .................................................................................... 41

16.2Fixed support with electromagnet ................................................................................... 42

17Layout (exploded drawing) .......................................................................................... 43

17.1Layout ES 50 - 80 ........................................................................................................... 43

ES 50 – ES 80

3

1 Preface

1.1 General notes

These operating instructions must be available on site at all times. It should be read thoroughly by all

persons who use, or service the appliances. Improper usage or servicing or ignoring the operating

instructions can be a source of danger for persons, or result in material damage. If the meaning of any

part of these instructions isn’t clear, then please contact ELKA-Torantriebe GmbH u. Co. Betriebs KG

before you use the appliance.

This applies to all setup procedures, fault finding, disposal of material, care and servicing of the

appliance. The accident prevention regulations and applicable technical regulations (e.g. safety or

electrical) and environment protection regulations of the country in which the appliance is used also

apply.

All repairs on the appliances must be carried out by qualified persons. ELKA-Torantriebe GmbH u. Co.

Betriebs KG accepts no liability for damage which is caused by using the appliance for purposes other

than those for which it is built.

ELKA-Torantriebe GmbH u. Co. Betriebs KG cannot recognise every possible source of danger in

advance. If the appliance is used other than in the recommended manner, the user must ascertain that

no danger for himself or others will result from this use. He must also ascertain that the planned use

will have no detrimental effect on the appliance itself. The appliance should only be used when all

safety equipment is available and in working order. All faults which could be a source of danger to the

user or to third persons must be eliminated immediately. All warning and safety notices on the

appliances must be kept legible.

All electrical periphery equipment which is connected to the appliance must have a CE Mark, which

ensures that it conforms to the relevant EEC regulations. Neither mechanical nor electrical alterations

to the appliance, without explicit agreement of the manufacturer, are allowed. All alterations or

extensions to the appliance must be carried out with parts which ELKA-Torantriebe GmbH u. Co.

Betriebs KG have defined as suitable for such alterations, and be carried out by qualified personnel.

Please note that with any alteration of the product, no matter whether mechanical or electrical, the

warranty expires and the conformity is revoked. Only the use of ELKA accessories and original ELKA

spare parts is allowed. In case of any contravention ELKA disclaims liability of any kind.

INFORMATION!

The operation of the system within CEN countries must also be conformant with the European safety-

relevant directives and standards.

We reserve the right to make technical improvements without prior notice.

ES 50 – ES 80

4

1.1.1 Symbol explanation

WARNING!

Remarks regarding the safety of persons and the gate opener itself are marked by special

symbols. These remarks have to be absolutely observed in order to avoid accidents and

material damage.

DANGER!

…points to an imminent dangerous situation, which can cause death or serious injuries if it is

not avoided.

WARNING!

…points to a potentially dangerous situation, which can cause death or serious injuries if it is

not avoided.

ATTENTION!

…points to a potentially dangerous situation, which can cause minor or slight injuries if it is not

avoided.

ATTENTION!

…points to a potentially dangerous situation, which can cause property damage if it is not

avoided.

REMARK!

Important notice for installation or functioning.

1.2 Copyright

The operating manual and the contained text, drawings, pictures, and other depictions are protected by

copyright. Reproduction of any kind – even in extracts – as well as the utilization and/or communication

of the content without written release certificate are prohibited. Violators will be held liable for damages.

We reserve the right to make further claims.

1.3 Information regarding installation instruction

This document is to be used as installation instruction for partly completed machinery (according to

machinery directive 2006/42/EG, article 13, (2)).

ES 50 – ES 80

5

2 Safety

2.1 General notes on safety

The valid regulations and standards have to be observed during installation and operation, e.g. DIN EN

13241, DIN EN 12445, DIN EN 12453 etc.

Only the use of spare parts made by the original manufacturer is allowed. Do not put a defective gate

opener / barrier into operation.

After set-up (installation) every user of the equipment has to be instructed about the operation and

function of the gate opener / barrier.

In order to reduce the risk potential related to the movement of the barrier boom, additional optical

and/or acoustical warning devices should be installed.

2.2 Notes on safety for the operation

Children from the age of 8 years and persons with reduced physical sensory or mental capabilities or

lack of experience and/or knowledge may use these devices, provided they are supervised or have

been instructed in the safe use of the device, and have understood the hazards involved. Children

must not play with the device.

No persons, objects, or animals are allowed within the range of the gate movement / barrier movement

during opening or closing.

Never reach into moving parts of the gate operator, gate or barrier.

Drive through the gate system /barrier only after complete opening.

The gate system / barrier has to be secured depending on the type of usage, corresponding to the valid

standards and regulations (e.g. safety at the main and secondary closing edges).

The safety devices have to be checked regularly for functioning according to the standards and

regulations, at least once a year.

2.3 Safety notes for the operation with radio remote control

The radio remote control should only be used, if the area of movement of the gate / barrier is always

completely visible by the operator and thus it is assured, that no person, object, or animal is present

within this range of movement.

The radio remote control transmitters have to be carefully kept, so that an unintentional use is

impossible.

Radio remote controls should not be operated at radio-technical sensitive locations, like airports or

hospitals.

Interferences by other (properly operated) radio communication installations, which are used within the

same frequency range, cannot be ruled out.

2.4 Intended use of barriers

The vehicle barriers model ES 50-80 are exclusively intended for controlling access to and exit of

certain road vehicles in or from certain areas.

The barrier is either controlled by a person in manual operating modes or by access control systems in

automatic operating modes and monitored by induction loops and/or safety facilities.

WARNING!

Danger through improper use!

Each improper use can lead to dangerous situations.

Any use above and beyond the expressly described intended use is prohibited.

Definition - vehicles, when using the barrier models ES 50-80

Vehicles are all vehicles which are used for the carriage of persons or goods and which participate in

road traffic.

Road vehicles need to have sufficiently large metal areas in the vehicle floor area to enable

detection by induction loops. The induction loop function is significantly dependent on this

metalarea.

For all other road vehicles other or complementary safety facilities must be installed.

In general additional safety facilities must be installed for motorcycles and bicycles.

2.5 Improper use

The regulation of pedestrian traffic with the vehicle barriers ES 50-80 is contrary to the intended use.

ES 50 – ES 80

6

The barriers model ES 50-80 are no railway crossing gates and must not be used at railway crossings.

The barriers are not approved for bicycles or animals.

The barriers must not be used in explosive environments.

WARNING!

Danger through non-intended use!

Every non-intended use can lead to dangerous situations.

Any use above and beyond the above mentioned use is prohibited and constitutes improper use.

2.6 Intended use – vehicle traffic, pedestrian traffic impossible

The operational safety can only be ensured when the barrier is used as intended.

After installation, the barriers of the series ES 50-80 serve as passage control of vehicle paths.

Notes for danger area, when pedestrian traffic is impossible:

WARNING!

Danger of impact and crushing in the danger area!

Keep people away from the danger area in which the barrier with pedestrian traffic impossible use

is being used!

WARNING!

Danger of impact and crushing in the danger area!

Entering the danger area can cause death or serious injuries!

Mark the danger area by prohibition signs.

Set up barriers such as fences and railings.

Set up separate passageway for persons and bicycles outside the danger area.

Observe county-specific regulations (regulations and laws).

CAUTION!

Risk of injury by entering the danger zone!

With inadequate safety measures the movement of the barrier boom can cause injuries.

In order to reduce the risk potential related to the movement of the barrier boom, additional at least

one additional optical presence detection or safety features (e.g. photoelectric barriers) must be

installed if the barrier is installed in public areas.

The controller is a product component and serves to control the barrier.

Any use above and beyond the above mentioned use is prohibited and constitutes improper

use.

2.7 Intended use - vehicle traffic, pedestrian traffic not impossible

The operational safety can only be ensured when the barrier is used as intended.

After installation, the barriers of the series ES 50 – ES 80 serve as passage control of vehicle paths.

Any use above and beyond the above mentioned use is prohibited and constitutes improper

use.

Through the installation of suitable safety devices ELKA-barriers of the types ES 50 - 80 can

also be used where passenger traffic cannot be excluded.

Notes to the danger area pedestrian traffic not impossible:

WARNING!

Danger of impact and crushing in the danger area!

People could be present in the danger area of barriers where personal traffic cannot be excluded!

CAUTION!

Danger of impact and crushing in the danger area!

Entering the danger area can cause serious personal injuries.

Mark the danger area by prohibition signs.

Observe county-specific regulations (regulations and laws).

CAUTION!

Danger of impact and crushing in the danger area!

Safety measures for vehicles and trucks cannot protect bicycles, motorcycles and other vehicles.

For bicycles, motorcycles and other road vehicles other or complementary safety facilities must be

installed.

ES 50 – ES 80

7

Notes for the barrier boom specification:

WARNING!

Danger of impact and crushing!

Through additional installations on the barrier boom, e. g. swinging support, force at the main closing

edge outside the permitted range can arise.

Additional installations on the barrier boom are not allowed.

For the different barrier models the only use of the original specified ELKA barrier booms is

allowed.

Notes on safety:

CAUTION!

Risk of impact or crushing!

With inadequate safety measures the movement of the barrier boom can result in impact or crushing

points between the boom and solid objects within the movement area.

Suitable safety devices for the protection of persons must be installed.

In order to reduce the potential danger during the barrier boom movement, additional optical

and/or acoustic warning devices should be installed.

2.8 Danger, which could emanate from the site of operation

The barriers ES 50 – ES 80 operate with moving parts.

WARNING!

Rotating and/or linear movable components can cause serious injuries.

Do not reach into moving parts or handle any moving components during operation.

Turn the appliance off before any maintenance work, repair work or other work and secure it

against unintentional restarting.

2.9 Non-factory technical alterations and extensions

Non-factory technical alterations and/or extensions may result in hazards as well as interfere with the

function of the barrier.

DANGER!

Danger through voltage!

Risk of death by electric shock!

Technical alterations may only be performed by skilled personnel and only according to the

manufacturer’s instructions.

CAUTION!

Danger of injury through defective components!

Mechanical and electrical alterations can influence the functioning of the barrier!

Technical alterations may only be performed by skilled personnel and only according to the

manufacturer’s instructions.

CAUTION!

Malfunctioning of the barrier!

Mechanical and electrical alterations can influence the functioning of the barrier!

Technical alterations may only be performed by skilled personnel and only according to the

manufacturer’s instructions.

2.10 Personnel requirements – professional skills, knowledge and qualifications

WARNING!

Risk of injury through inadequate qualification!

Improper handling during installation, maintenance, repair work or dismantling can result in personal

injury and/or property damage.

Work during installation, maintenance, repair and dismantling must be performed by skilled

personnel only.

Specialist - is a person with suitable professional training, knowledge and experience, who can

recognize and avoid danger.

Instructed person - is a person, which was instructed in the operation and use.

ES 50 – ES 80

8

2.11 Personal protective equipment

During installation, maintenance, repair work and dismantling of the barrier suitable personal protective

equipment must be worn.

CAUTION!

Bruising/jamming/driving over (e.g. by material handling equipment, industrial trucks) the feet,

contusion by falling heavy objects, cutting injuries by stepping into pointed/sharp objects.

Foot injuries

Wearing of suitable safety shoes during the installation, maintenance, repair work and dismantling

protects against serious foot injuries with long-lasting consequences.

CAUTION!

Falling heavy objects hitting the head

Head injuries

Wearing of a suitable safety helmet during the installation, maintenance, repair work and

dismantling protects against serious head injuries with long-lasting consequences.

CAUTION!

Cutting injuries resulting from pointed/sharp objects

Hand injuries

Wearing of suitable safety gloves during the installation, maintenance, repair work and dismantling

protects against serious hand injuries with long-lasting consequences.

CAUTION!

Injuries resulting from drilling chips or saw dust

Eye injuries

Wearing of suitable safety goggles during the installation and repair work protects against serious

eye injuries with long-lasting consequences.

ES 50 – ES 80

9

3 Transportation and storing

3.1 Transportation inspection

The shipment has to be inspected for transportation damage immediately after receipt. In case of any

damage record the type and extent on the delivery receipt or refuse acceptance.

Inform ELKA-Torantriebe immediately in the event of damage.

In case the above points are not observed claims will be denied due to insurance regulations.

3.2 Storing

The barrier has to be stored as follows:

Do not expose the barrier to aggressive substances.

Do not expose the barrier to heat sources.

Storage temperature -20°C to +70°C.

3.3 Lifting heavy loads

WARNING!

Risk of injury by lifting heavy loads!

Lifting heavy loads may cause serious injuries.

Never lift the barrier single-handedly.

To lift the barrier, use a suitable lifting device.

Wear suitable safety shoes.

ES 50 – ES 80

10

4 Declaration of conformity

4.1 Barrier ES 50-80 – pedestrian traffic impossible

The declaration of conformity below is valid for barriers where pedestrian traffic can be excluded.

Drawing 1

ES 50 – ES 80

11

4.2 Barrier ES 50-80 – pedestrian traffic not impossible

The declaration of conformity below is valid for barriers where pedestrian traffic cannot be excluded.

Drawing 2

Suitable safety devices for the protection of persons must be installed. Only with the (on site)

installation of suitable safety devices for the protection of persons the barrier is confirm with EN 13241.

ES 50 – ES 80

12

4.3 Declaration of conformity – complete system

After the installation an EG-declaration of conformity according to EC-machinery directive 2006/42/EG

for the complete system has to be issued by the person responsible for the integration (according to

product standard DIN EN 13241).

4.4 Name plate

The name plate of the barrier is attached at the inside front of the barrier housing.

4.5 Performance declaration

The performance declaration (pursuant to EC Machinery Directive No. 305/2011) is attached to the

product as a special annex.

ES 50 – ES 80

13

5 Function description

Barriers serve as passage control of vehicle paths. By raising and lowering of the barrier boom the

passage is granted or obstructed.

For a boom length of 4,000mm and longer we recommend the use of a fixed or swinging support, for a

boom length of 5,000mm and longer the use of a fixed or swinging support is mandatory.

The controller offers the possibility to activate the barrier by radio remote control.

The controller is able to observe the max. permitted force which was set before in the learning

sequence. If during the closing movement more force is needed, the barrier reverses. Additionally

several different safety features, e.g. photoelectric barriers, can be connected.

Safety devices (photoelectric barriers, light curtains etc.) must be installed on site. The safety devices

and induction loops must ensure that the barrier danger area is clear before the barrier closes.

ES 50 – ES 80

14

6 Technical data ES 50 – ES 80

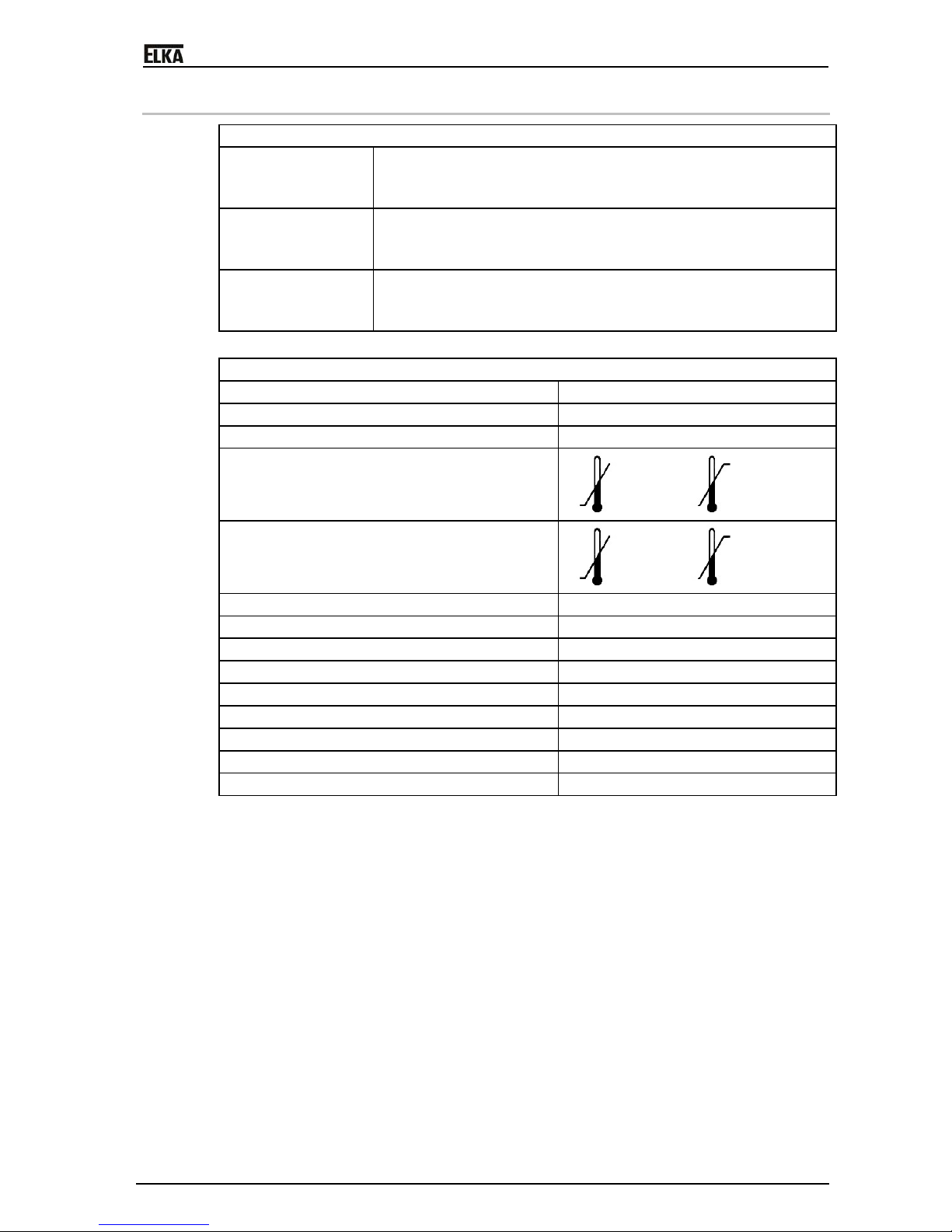

Operative range

Application for… Parking area, parking garage

Company entrance

Safety area

Drive pulse from… Push-button, card reader, key switch, desk top panel etc.

remote control

Induction loop

Safety Reversing on obstacle

Best protection against vandalism

Ergonomic emergency release

Table 1

General data

Mains supply 230V / 50Hz

Max. current 10A (max.)

Duty cycle 100%

Ambient temperature range

-20°C to +70°C

Storage temperature range

-20°C to +70°C

Relative humidity max. 95%, non-condensing

Controller MO 63

Measurements (w/l/h) 400x450x1.100mm

Foundation (frost-proofed) 600x650x800mm

Boom connector central

Housing aluminium

Mechanical parts steel, zinc coated

Sound pressure level (distance 1m) ≤ 60 dB(A)

Degree of protection IP 44

Table 2

ES 50 – ES 80

15

Typical Data ES 50 ES 50S ES 60 ES 60HS ES 80

Drawn power [kW] 0.26 0.37 0.26 0.37 0.26

Opening and closing time

[s]

approx. 4.0 approx. 4.0 approx. 5.5 approx. 4.0 approx. 8.5

Max. boom length [mm] 5,000 5,000 6,000 6,000 8,000

Effective length [mm] 5,140 5,140 6,140 6,140 8,140

Fixed support / swinging

support

required required required required required

Reversing on obstacle selectable selectable selectable selectable selectable

Boom weight [kg] 10 10 16.5 16.5 23

Boom weight (round boom,

optional) [kg]

9 9 11 11 18.5

Barrier weight [kg] approx. 116 approx. 116 approx. 124 approx. 124 approx. 138

Table 3

The barriers ES 50 to ES 80 are for vehicle-traffic only!

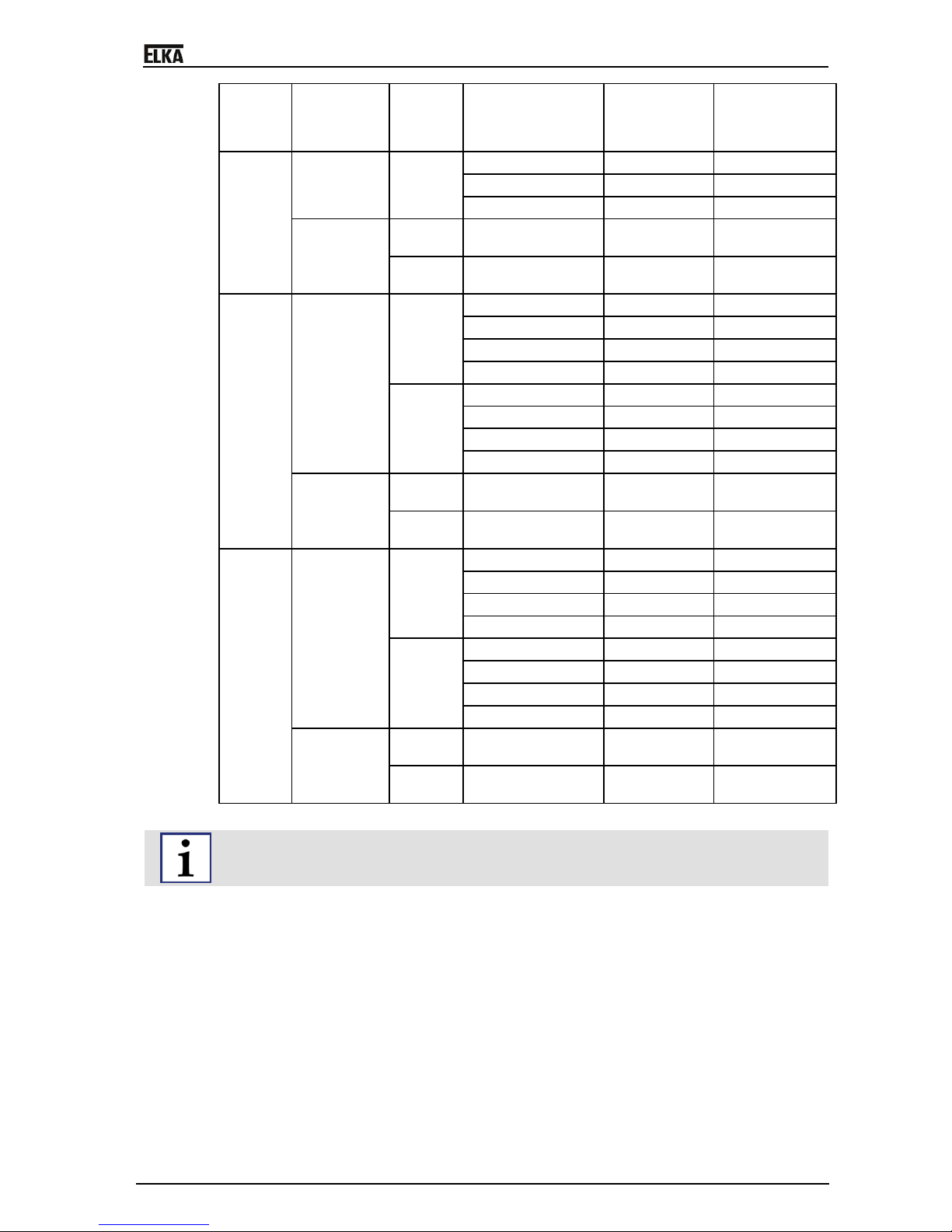

6.1 Operation - Safety – Wind load class

WARNING!

Risk through high wind loads!

The barrier use during high wind loads can lead to barrier boom damage and/or damage to the boom

connector.

The barrier use during higher wind loads as shown in the table below is prohibited.

The figures below refers to the closed barrier and not to the ability to open and close the barrier

during high wind loads.

During high wind loads the barrier boom must be secured or dismantled!

Type Barrier

boom

Swinging

support /

Fixed

support

Folding skirt

or

top and bottom

skirt

max. permitted

wind load

class

Windspeed

(km/h)

ES 50 Standard

boom

Swinging

support

without 4 up to max. 133

HG 75 2 up to max. 90

Fixed

support

without 4 up to max. 133

HG 75 3 up to max. 117

Round

boom

Swinging

support

without 4 up to max. 133

Fixed

support

without 4 up to max. 133

ES 50 S Standard

boom

Swinging

support

without 4 up to max. 133

HG 75 2 up to max. 90

Fixed

support

without 4 up to max. 133

HG 75 3 up to max. 117

Round

boom

Swinging

support

without 4 up to max. 133

Fixed

support

without 4 up to max. 133

ES 60 Standard

boom

Swinging

support

without 4 up to max. 133

HG 75 3 up to max. 117

HG 150 (max. 4.5m) 4 up to max. 133

SG 150 (max. 4.5m) 4 up to max. 133

Fixed without 4 up to max. 133

ES 50 – ES 80

16

Type Barrier

boom

Swinging

support /

Fixed

support

Folding skirt

or

top and bottom

skirt

max. permitted

wind load

class

Windspeed

(km/h)

support HG 75 4 up to max. 133

HG 150 (max. 4.5m) 4 up to max. 133

SG 150 (max. 4.5m) 4 up to max. 133

Round

boom

Swinging

support

without 4 up to max. 133

Fixed

support

without 4 up to max. 133

ES 60HS Standard

boom

Swinging

support

without 4 up to max. 133

HG 75 3 up to max. 117

HG 150 (max. 4.5m) 4 up to max. 133

SG 150 (max. 4.5m) 4 up to max. 133

Fixed

support

without 4 up to max. 133

HG 75 4 up to max. 133

HG 150 (max. 4.5m) 4 up to max. 133

SG 150 (max. 4.5m) 4 up to max. 133

Round

boom

Swinging

support

without 4 up to max. 133

Fixed

support

without 4 up to max. 133

ES 80 Standard

boom

Swinging

support

without 3 up to max. 117

HG 75 2 up to max. 90

HG 150 (max. 6m) 2 up to max. 90

SG 150 (max. 6m) 2 up to max. 90

Fixed

support

without 4 up to max. 133

HG 75 4 up to max. 133

HG 150 (max. 6m) 4 up to max. 133

SG 150 (max. 6m) 4 up to max. 133

Round

boom

Swinging

support

without 4 up to max. 133

Fixed

support

without 4 up to max. 133

Table 4

The wind speeds are statistic maximum values.

ES 50 – ES 80

17

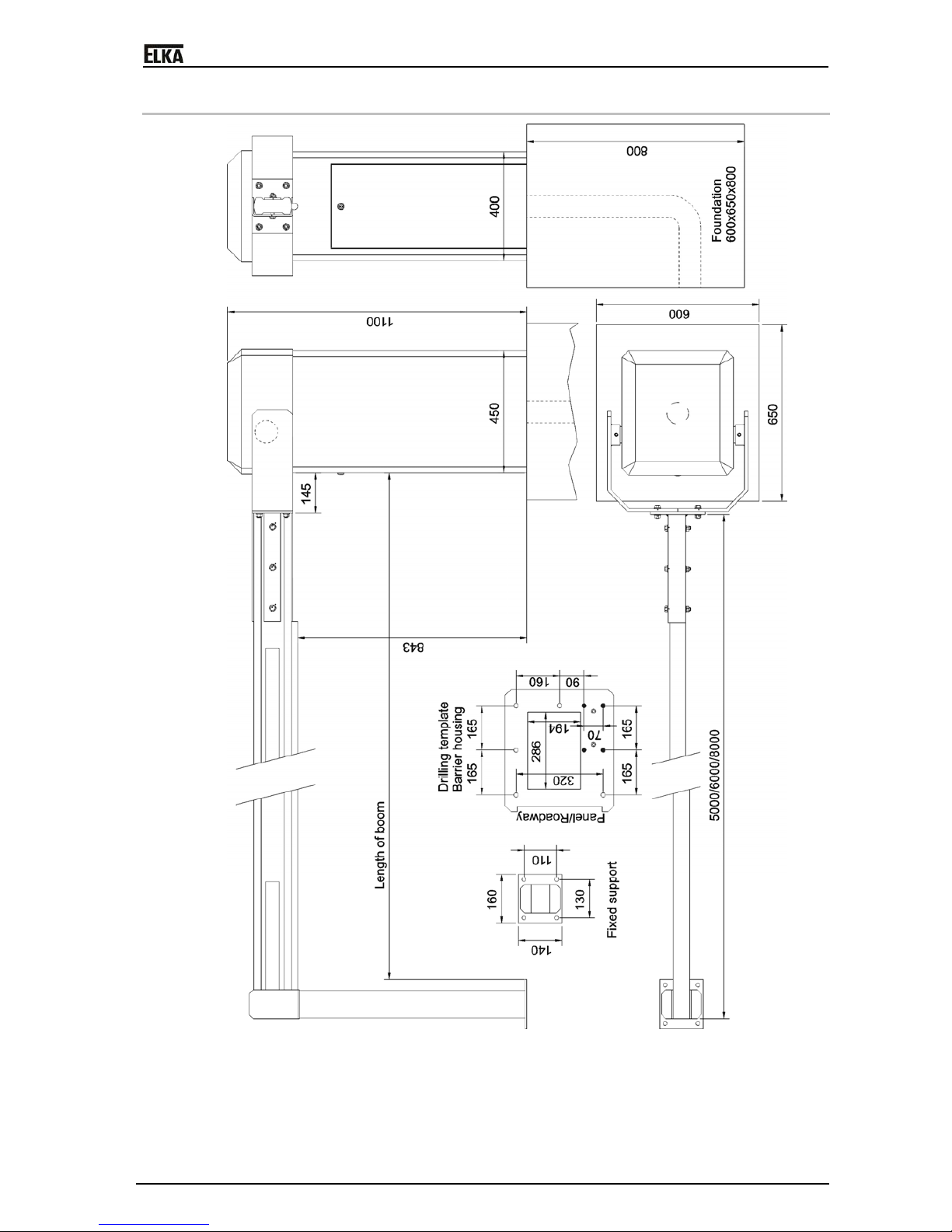

7 Measurements ES 50 – ES 80

Drawing 3

ES 50 – ES 80

18

8 Installation ES 50 – ES 80

Basic requirements

Keep a safety distance of min. 500mm between all moving barrier parts and surrounding objects

like walls, fences etc.

When preparing the foundation consider the alignment and distance related to a (optional) fixed

support.

The installation of barriers in flood areas is prohibited.

REMARK!

For the barrier foundation we recommend a concrete strength class of C20/25 (or higher) and the use

of chemical dowels (M12).

WARNING!

Risk of injury by insufficient fastening!

Tilting barrier housings can result in severe injuries.

Before installation ensure a safe stand oft he barrier housing.

Do not lean the barrier boom against a wall or similar before isntallation. Store the boom

horizontally only.

Install the barrier housing as specified.

Use the recommended heavy duty anchor bolts M12, at least M10 is required.

During maintenance check the housing for a correct fasenting on the foundation.

1. Before preparing the foundation lay enough underground cable (provide for a sufficient number of

wires) or a plastic cable conduit for a later cable installation. The foundation has to be absolutely

frost-free and with a horizontal surface of 600 x 650mm (if possible, at least 30mm higher than the

surrounding ground).

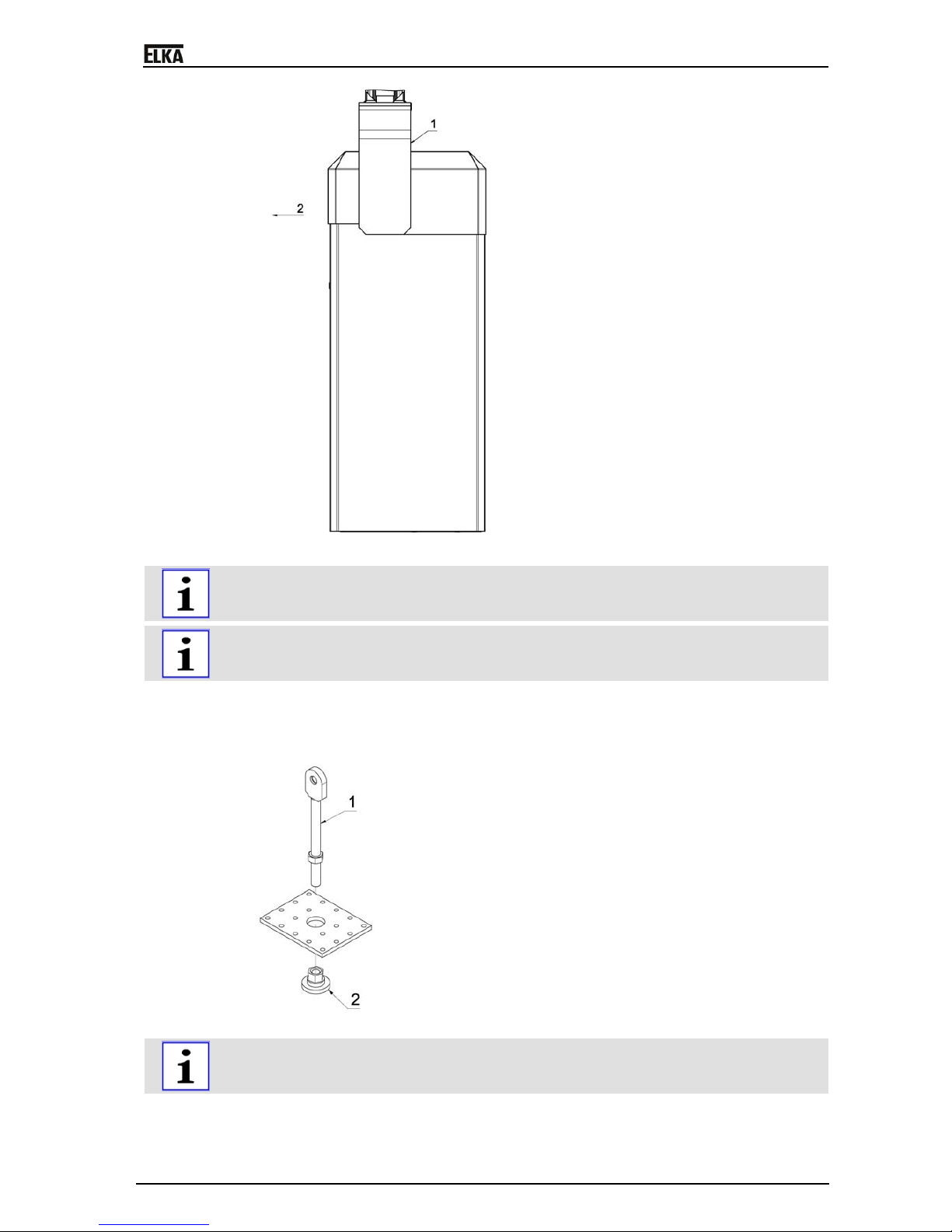

Drawing 4

2. Using the provided template you can either grout bolts (min. 12mm) into the foundation at the

appropriate positions or drill holes into the hardened concrete for heavy-duty fixings. Secure the

barrier on its foundation. For a correct functioning make sure the barrier housing is in a

perpendicular position.

A

nchor the spring assembly with all four fastening points through the housing into the foundation (see

drilling template ).

3. To open (release) the barrier boom during installation and current failure, pull the release lever

(2). The barrier can now be opened manually. In the vertical position the bolt (1) engages

automatically. To close (reposition) the barrier boom pull the lever again and move the boom

manually downwards.

ES 50 – ES 80

19

Drawing 5

The barrier is open when delivered, i.e. the boom connector wings have to be mounted vertically

upwards. During mounting the larger hub distance has to point in direction to the access panel (2).

Please also observe the stickers at the boom connector wings („OBEN-TOP-HAUT”).

The wings (1) for the boom connectors are different for the left and right side.

The wings are numbered (on the carton) in pairs and each pair is assigned for a certain barrier

mechanics.

4. Connect the wings for the boom connector to both ends of the main shaft. 4 of the 16 tapped holes

are numbered in handwriting and the inserted grub screws have to be tightened in the

corresponding order.

5. Secure the boom holder on the assembly. The two parts are then joined together.

Drawing 6

For the above drawing the tension springs were graphically removed. Do not loosen the tension

springs from the spring plate during installation / disassembly of the spring assembly.

6. Remove the adjusting nut from the spring assembly. If the boom is to be shortened reduce the

number of springs. The following table shows approximate values, check that the balance is as

described under f). The springs must be divided equally between the back and the front. One

This manual suits for next models

4

Table of contents

Other Elka Control System manuals

Popular Control System manuals by other brands

Extron electronics

Extron electronics TouchLink TLC Pro 526M Series user guide

Strand

Strand Vision.net RS232 user manual

DANHAG

DANHAG APP-control operating manual

Niles

Niles WVC100 Specifications

ENTRYPASS

ENTRYPASS EP.MINI Wiring guide

tbs electronics

tbs electronics H64 Installation instructions & user manual