97559C (REV. B - 1/00)

HRC4-19-1B HRC4-19-2B

ITEM

NO. PART NO.

1

2

3

4

5

6

7

8

9

10

11

12*

13

14

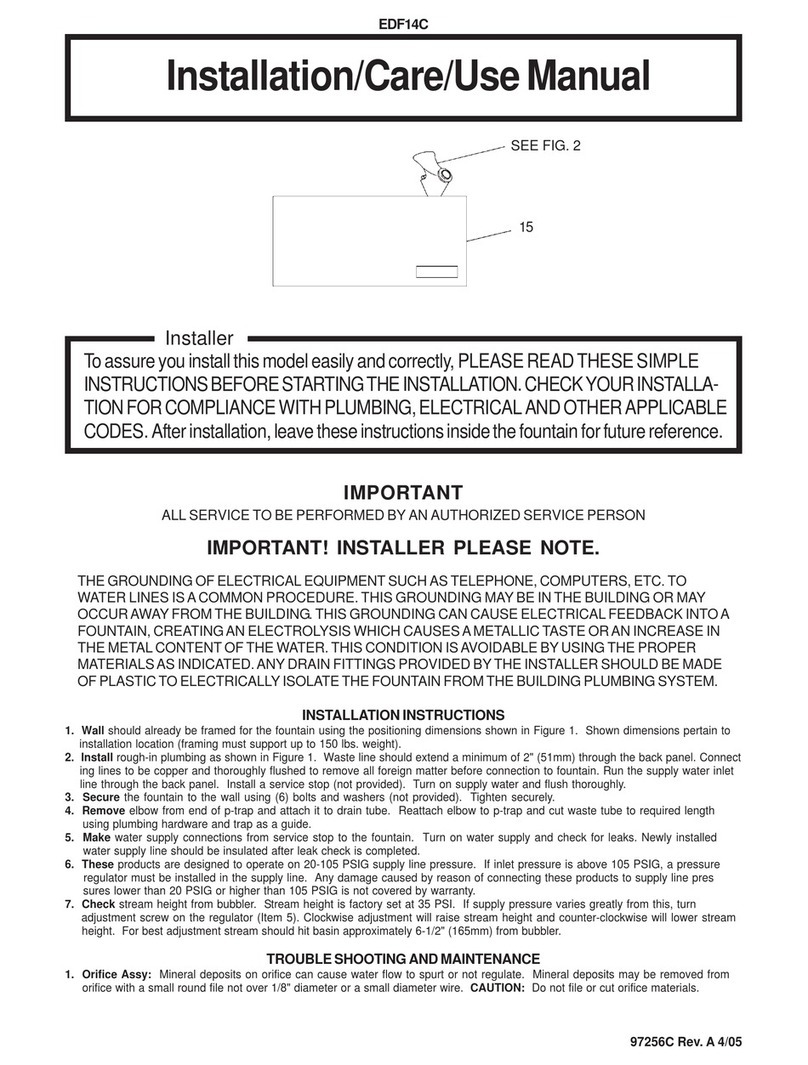

15

16

17

18

19

20

21

22

23

24

25

26

27

NS

23089C

35882C

35895C

31757000

30502C

41991000

70018C

70009C

32824000

32817000

35977C

35986C

35880C

30234C

30233C

30235C

19037000

100806740570

66563C

27597C

70772C

27197C

27844C

23100C

23101C

23104C

23103C

27198C

ITEMIZED PARTS LIST

DESCRIPTION

*INCLUDES RELAY & OVERLOAD. IF UNDER

WARRANTY, REPLACE WITH SAME COMPRESSOR

USED IN ORIGINAL ASSEMBLY.

NOTE: All correspondence pertaining to any of the

above water cooler or orders for repair parts MUST

include model number and serial number of cooler, name

and part number of replacement part.

Terminal Box Cover

Cold Control

Cold Control (Freeze Protect)

Fan Motor

Fan Blade

Fan Bracket

Fan Nut

Motor Mounting Screw

Condenser

Shroud

Capacitor

Compressor Serv Pak (115v)

Overload

Clip Compressor

Overload Spring

Terminal Cover

Clip

Grommet

Evaporator Assy

Insulation Box Cover

Drain Plug

Grill (Front)

BaseAssy

Insulation Box Panel (Rear)

End Panel

Insulation Box (Front)

Terminal Box

Grill (Rear)

24

20

26

19

1, 27

2311

4, 5, 6,

7, 8

9, 10

12

13, 14, 15,

16

25

21 22 23 19,20

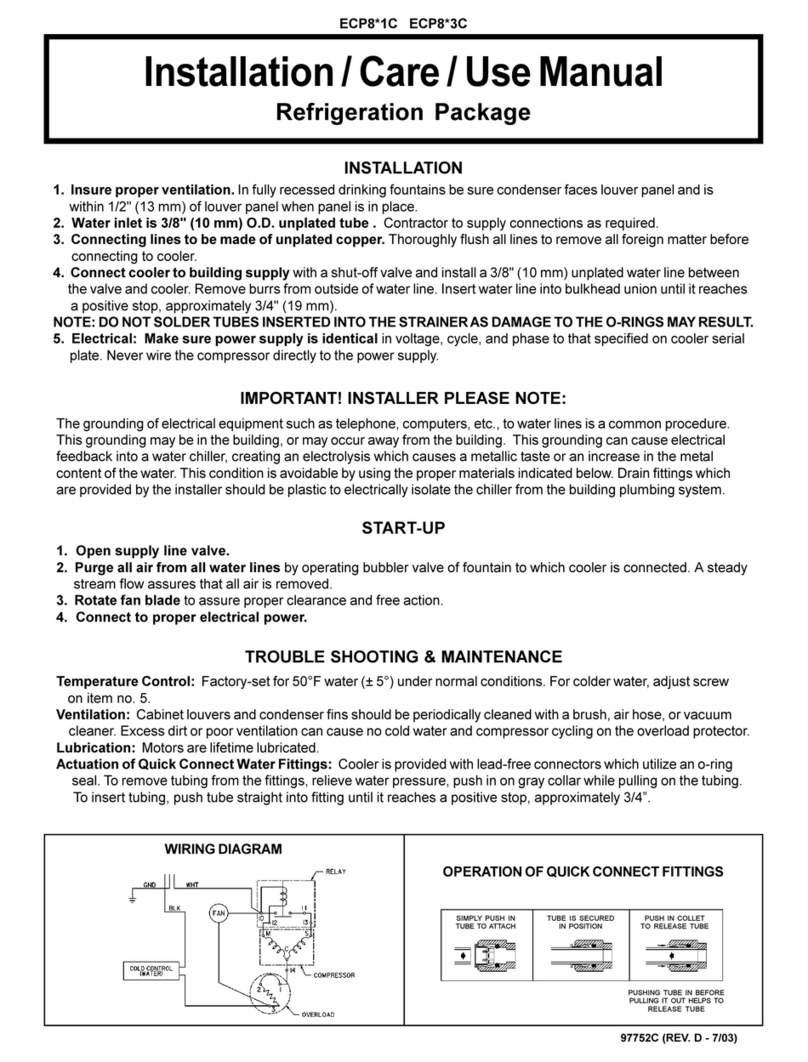

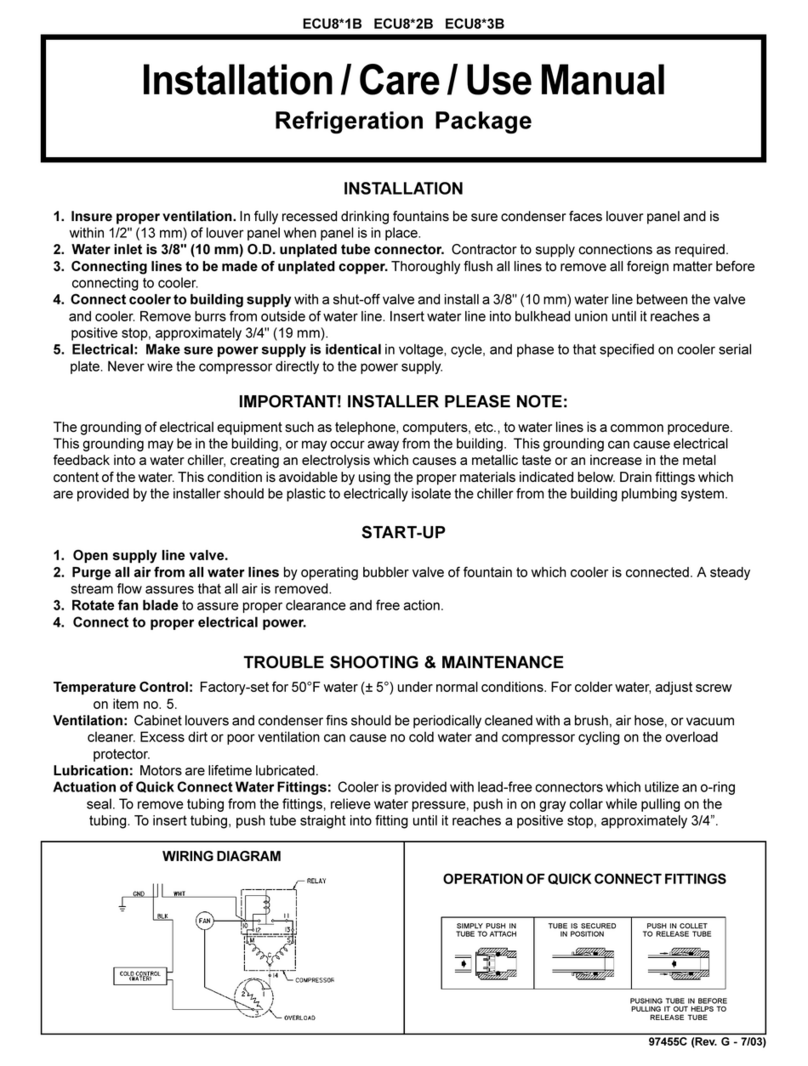

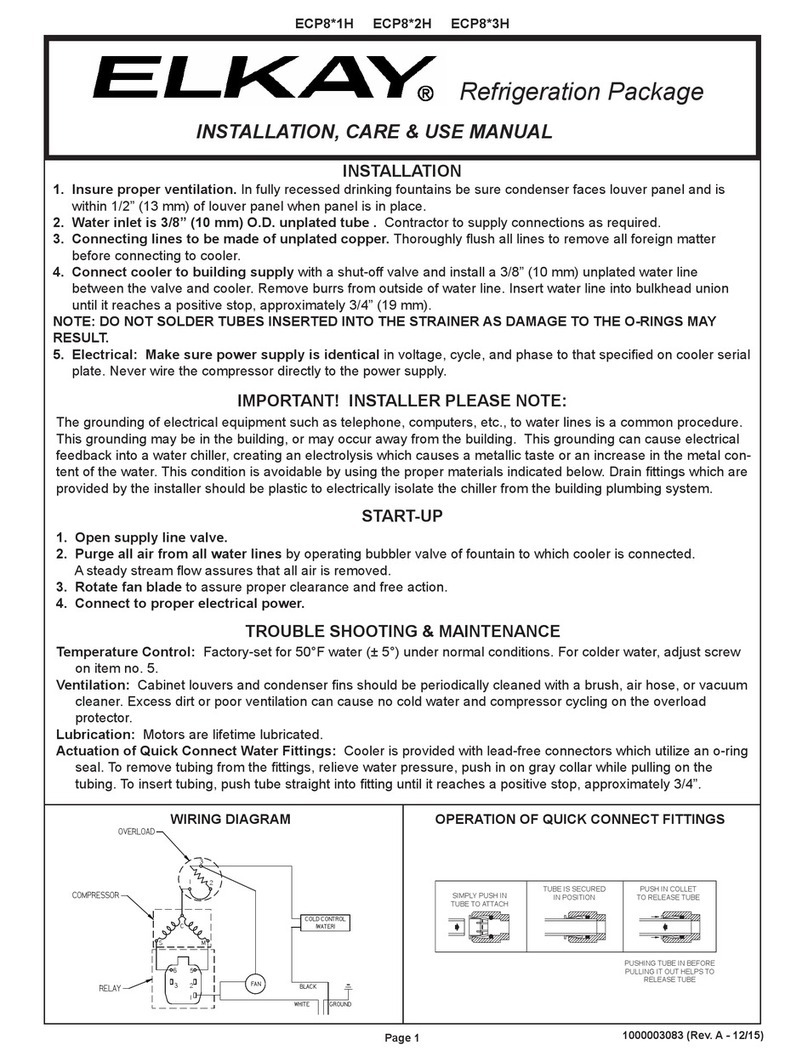

WIRING DIAGRAM

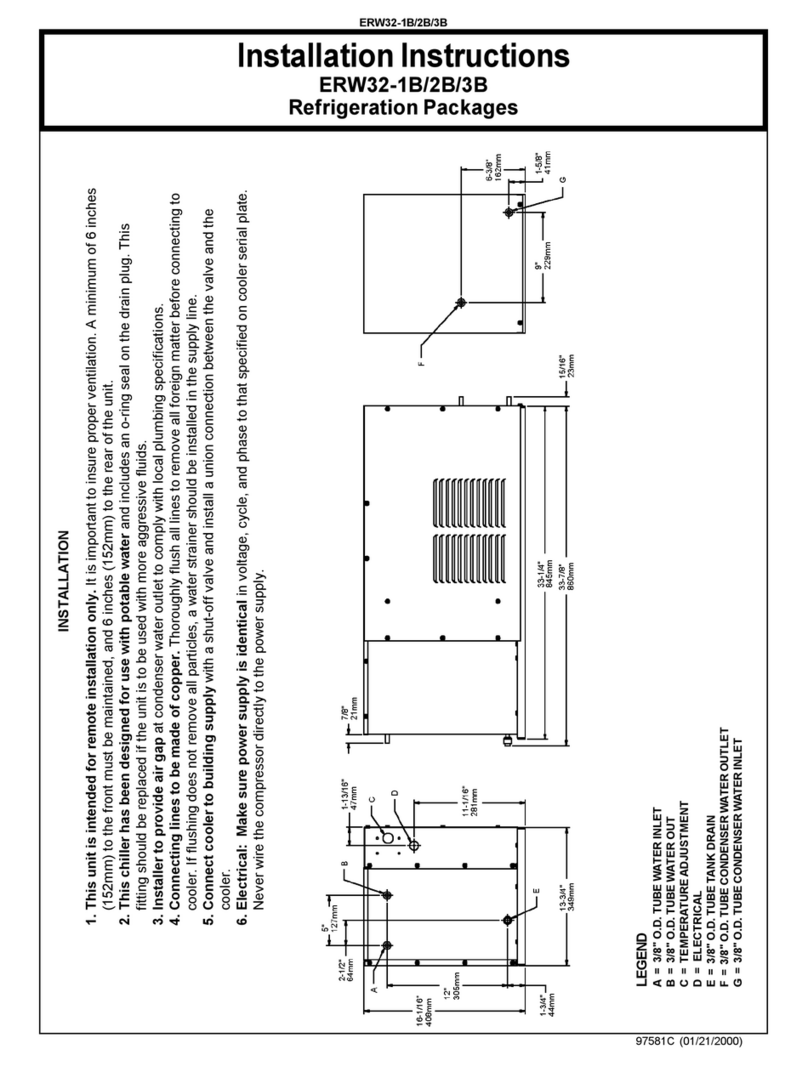

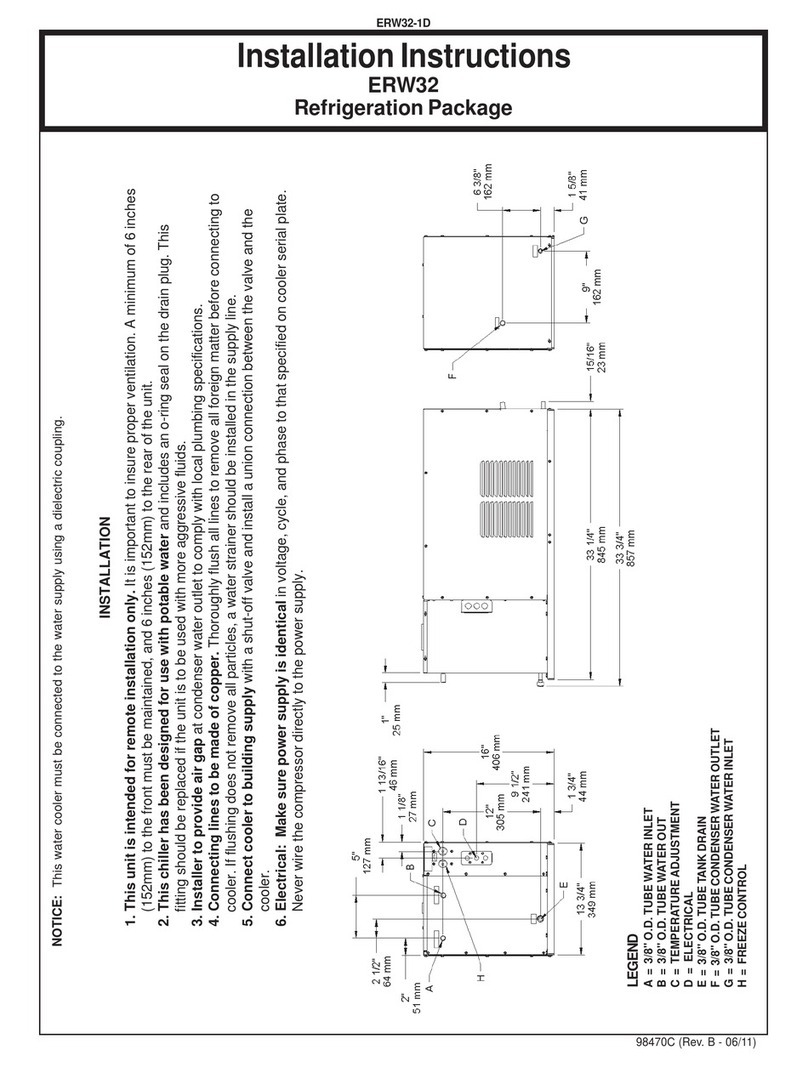

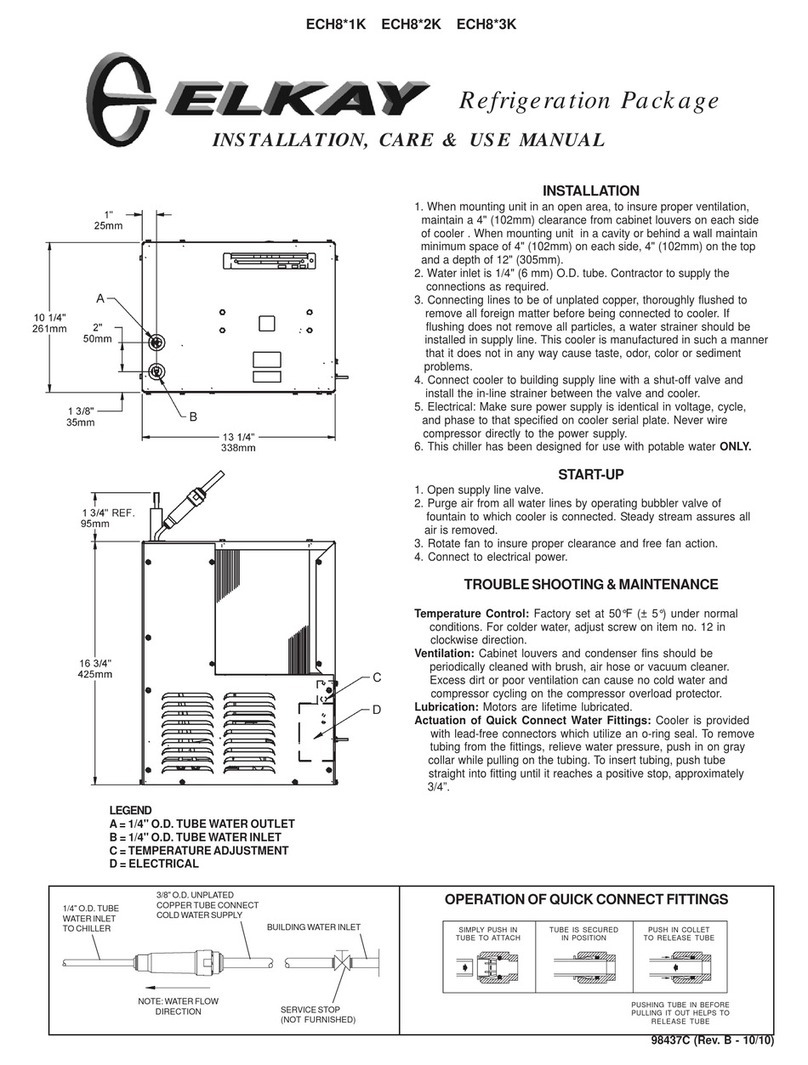

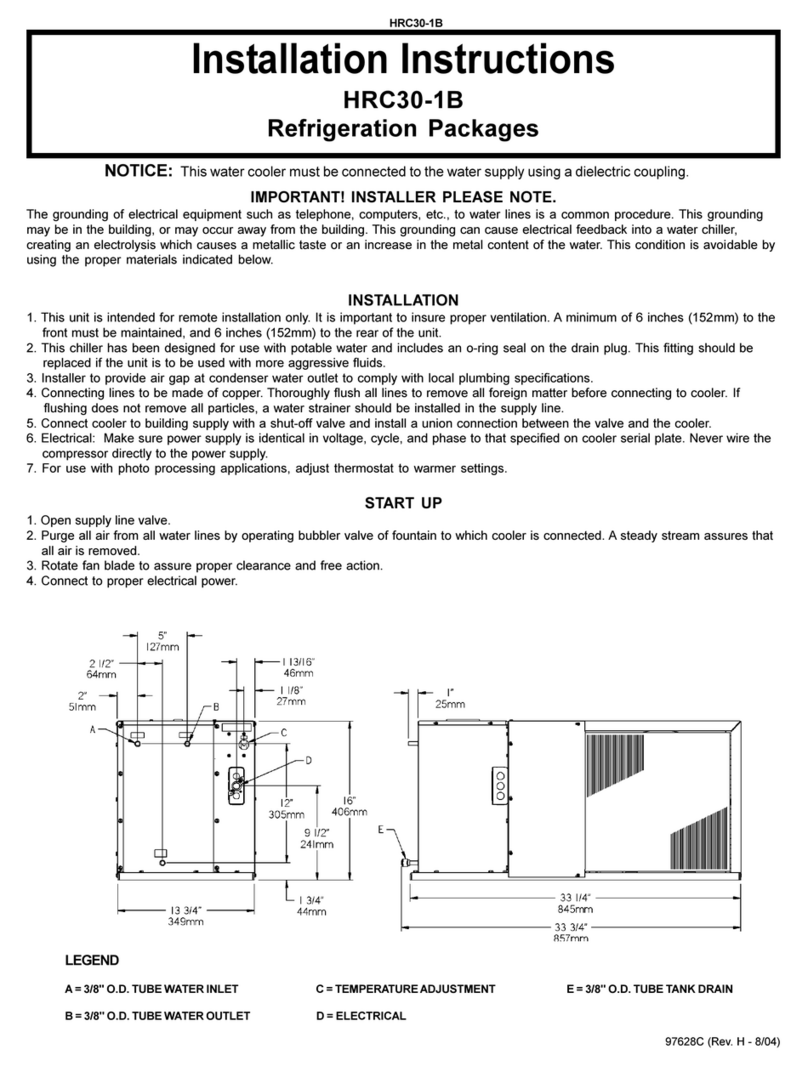

INSTALLATION

1. Potable water inlet and outlet are 3/8" (9 mm) O.D. tube located on

top of unit. Contractor to supply connections as required.

2. Connecting lines to be of copper, thoroughly flushed to remove all

foreign matter before being connected to cooler. If flushing does

not remove all particles, a water strainer should be installed in supply

line.

3. Connect cooler to building supply line with a shut-off valve and install

a union connection between the valve and cooler.

4. Electrical: Make sure power supply is identical in voltage, cycle, and

phase to that specified on cooler serial plate. Never wire compressor

directly to the power supply.

START-UP

1. Open supply line valve.

2. Purge air from all water lines by operating bubbler valve of fountain.

3. Connect to electrical power.

TROUBLE SHOOTING & MAINTENANCE

Temperature Control: Factory set for 50° F water (+/- 5°) under normal

conditions. For colder water, adjust screw on item no. 2 CW.

Ventilation: Cabinet louvers should be periodically cleaned with brush,

air hose or vacuum cleaner. Excess dirt or poor ventilation can cause

no cold water and compressor cycling on the compressor overload

protector

Lubrication: Motors are lifetime lubricated.

ITEM

NO. PART NO.

HRC41950 - 220/240V, 50 HZ

DESCRIPTION

4

11

11A

12*

13

15

16

23

-

-

36015C

36000C

36003C

36002C

35997C

35998C

30560C

27981C

36001C

35999C

Fan Motor

Capacitor (run)

Capacitor (start)

Compressor Serv Pak

Overload

Overload Spring

Terminal Cover

Base Assy

Relay

Gasket