Page 21000004002 (Rev. A - 08/2017)

4405BF_FTN_AWR, LK4405BF_FTN_AWR

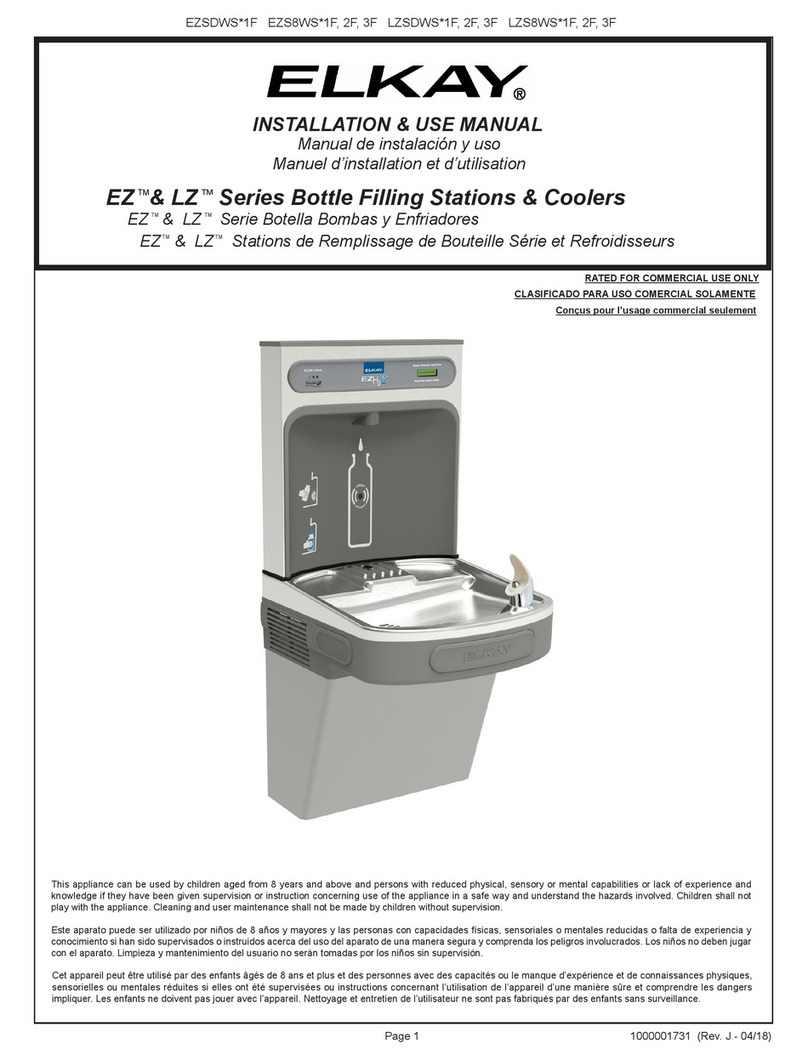

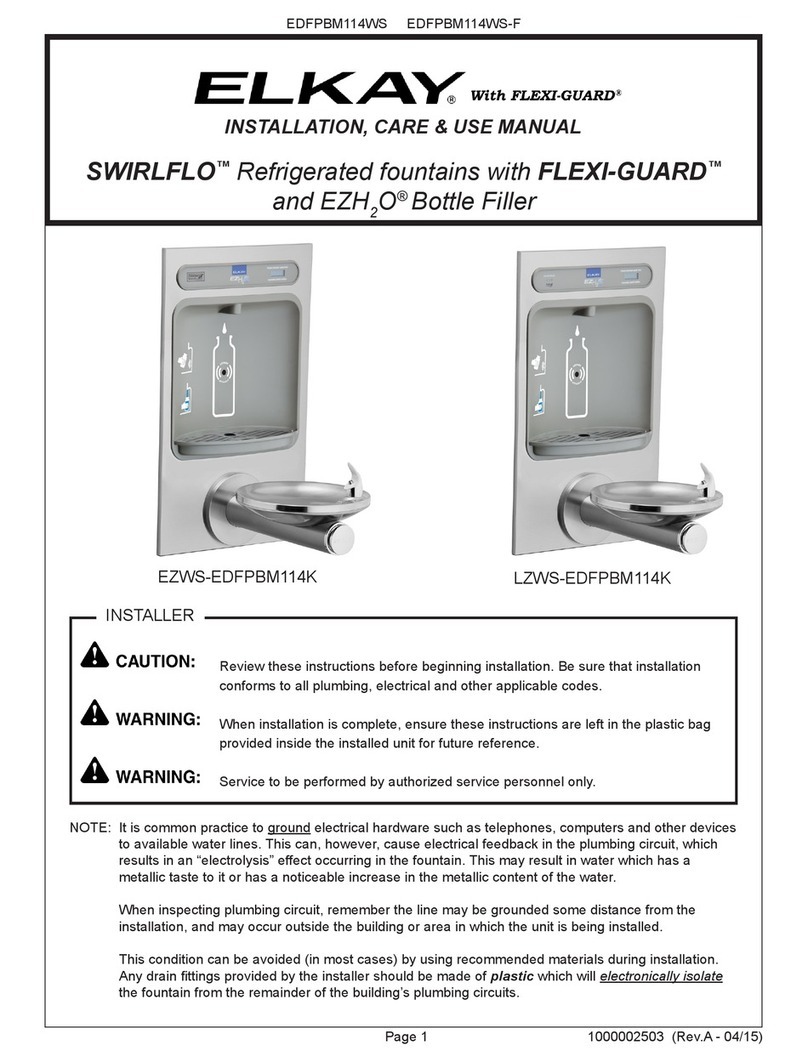

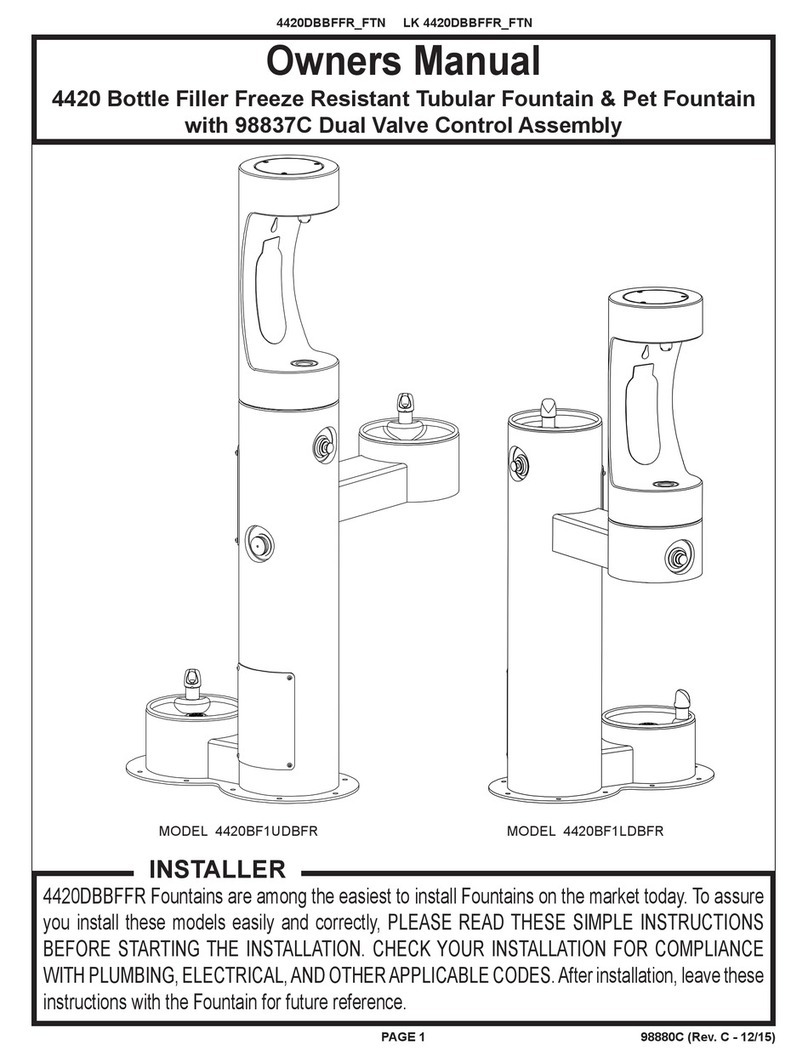

Installation

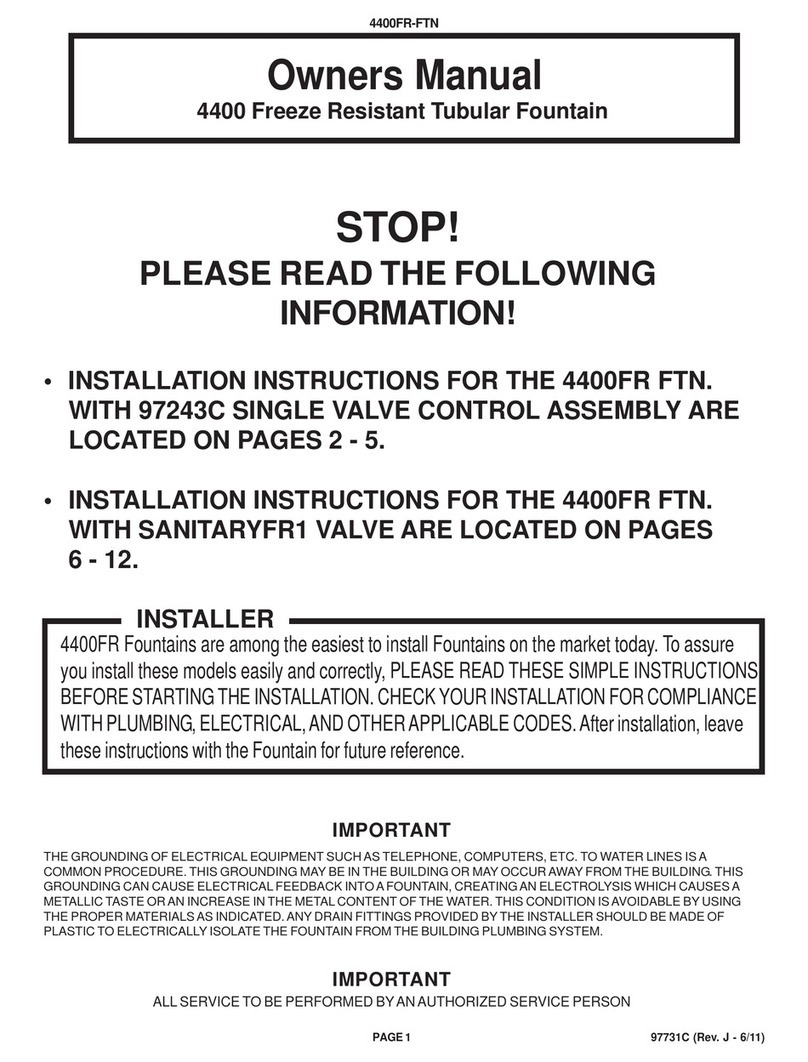

For correct and safe installation, please read these instructions completely.

• All Installation work must be performed by an authorized service personnel.

• Disconnect electrical supply serving the Installation area to reduce risk of electrocution.

• Unit not suitable for installations where water jets could be used.

DANGER

WARNING

• Shut off water supply serving the Installation area to reduce risk of water damage.

• Ensure proper ventilation by maintaining clearance from cabinet louvers to wall on each side of Cooler as specied in installation instructions.

• Never wire compressor directly to electrical supply.

• Thoroughly ush all water lines and ttings of all foreign matter before connecting to Cooler.

• Warranty is void if Installation is not made in accordance with current Manufacturing instructions.

CAUTION

• Hose-sets are not to be used for connecting to water mains.

• If inlet pressure is above 100 psig (0.69 MPa), a pressure regulator must be installed in water supply line. Any damage caused by reason of

connecting this product to water supply line pressure outside it’s rated pressure, is not covered by warranty.

• Tools/Items required but not provided:

Installation

Operation: Start-Up

1. Turn water supply on and inspect for leaks. Fix all leaks before continuing.

2. Connect plug end of International Power Cord Set (sold separately) into electrical outlet and turn on power supply to remote chiller.

Note: The inital dispenses might have air in line which may cause a sputter. This will be eliminated once all air is purged from the line. A steady

stream of water assures all air is removed.

3. Recheck all water and drain connections with water owing through system.

• Water Shut-off Valve with 3/8” (9.5mm) compression outlet.

• Waste Trap (non-metallic)

• Safety Glasses

• Protective Gloves

• 5/16” (8mm) Hex Socket or Flathead Screwdriver

• 3/32” (2.4mm) Hex Key

• Fasteners for wall type

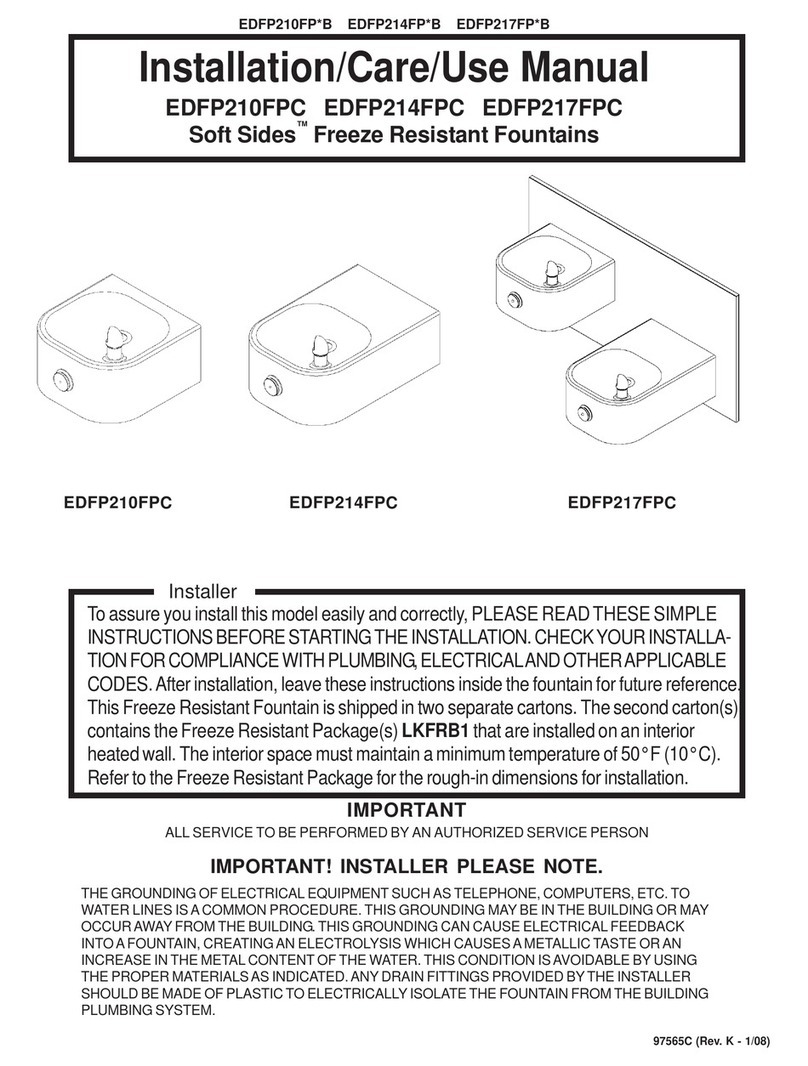

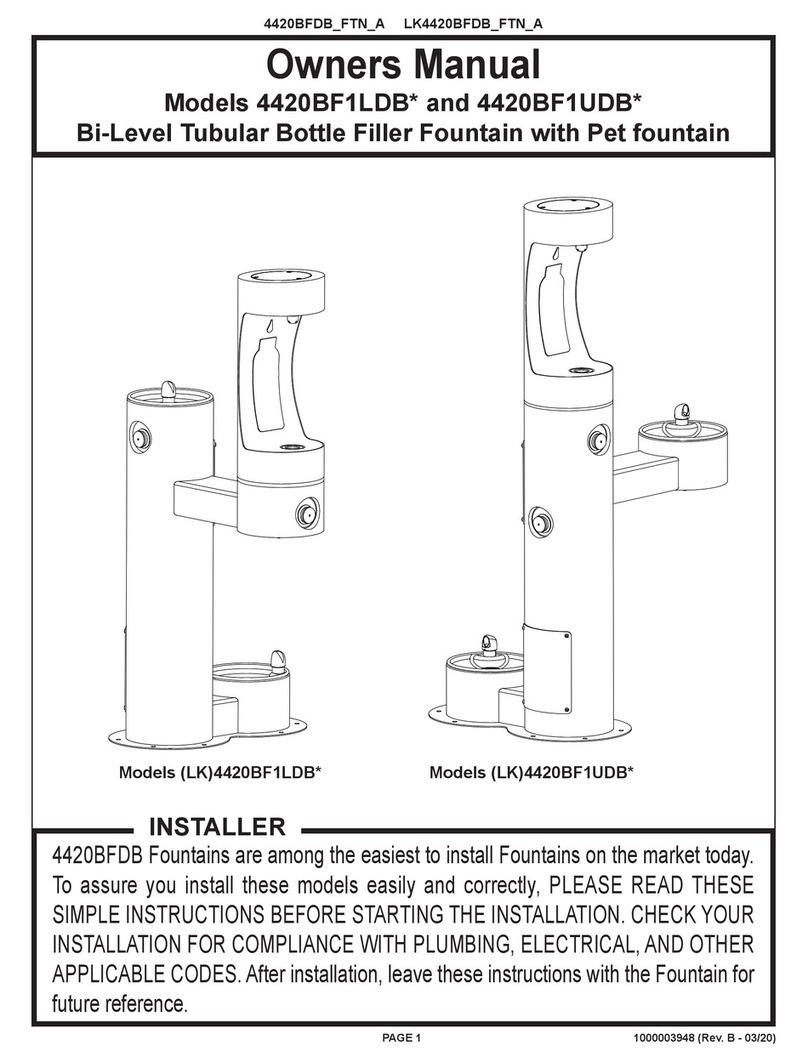

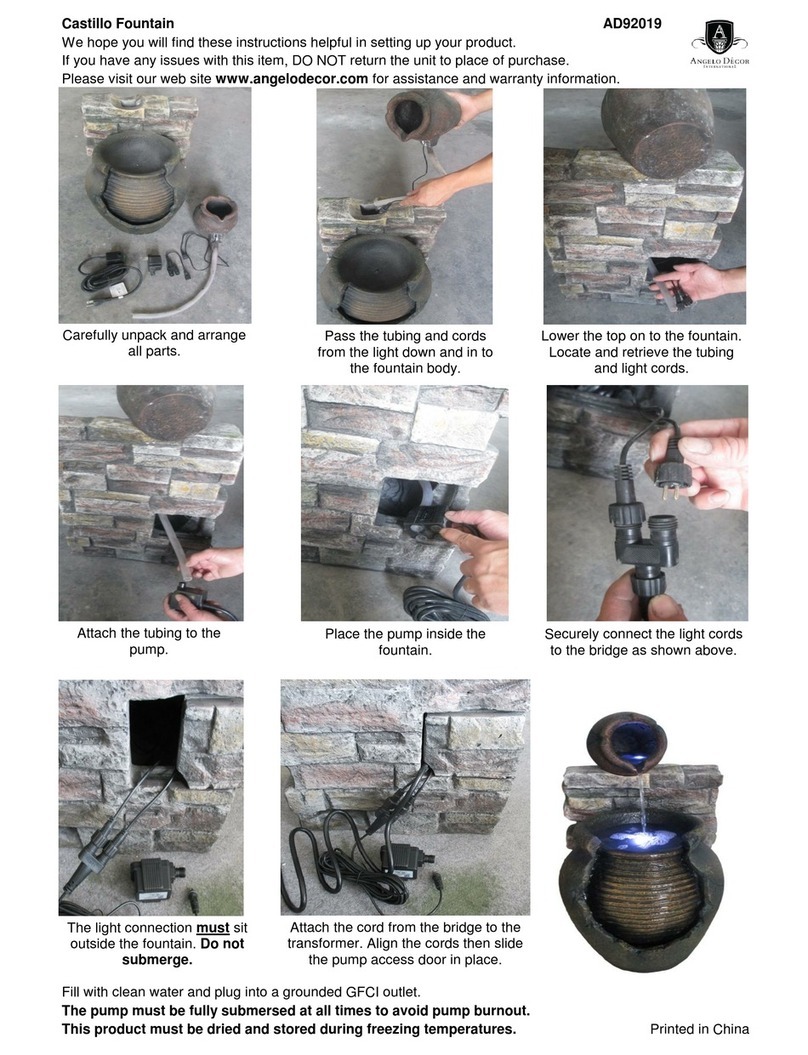

1. This fountain is to be mounted on a smooth, at, nished surface with adequate support structure.

NOTE: Mounting structure must be capable of supporting 300 lb. load on fountain.

2. Refer to rough-in for plumbing.

3. Install shut-off valve on water supply. (Valve not furnished)

4. Locate and install fountain using 3/8" minimum fasteners. (Fasteners not furnished).

5. Prior to installing the bottle ller to the fountain, insert the drain tube (Item # 5) into the arm tunnel and adjust drain to lean to the left side of arm

when facing button. Install bottle ller to fountain being sure drain tube is above mounting plate of ller. Install mounting hardware to secure

ller to fountain.

6. Connect water supply and fountain drain. Water connection and drain must comply with local codes.

7. Turn on water supply and check all connections for leaks.

CAUTION: This fountain is rated for inlet water pressure of 20-105 PSI. A pressure reducing regulator should be used if the inlet water supply

exceeds 105 PSI. Any damage caused by reason of connecting this product to supply line pressures lower than 20 PSI or higher than 105 PSI is not

covered by warranty.

8. Water supply 3/8” O.D. unplated copper tube. Waste 1-1/4” IPS. Contractor to supply waste trap and service stop valve in accordance with

local code.

9. Connecting lines to be made of unplated copper and should be thoroughly ushed to remove all foreign matter before being connected to fountain.

This fountain is manufactured in such a manner that it does not in any way cause taste, odor, color, or sediment problems.

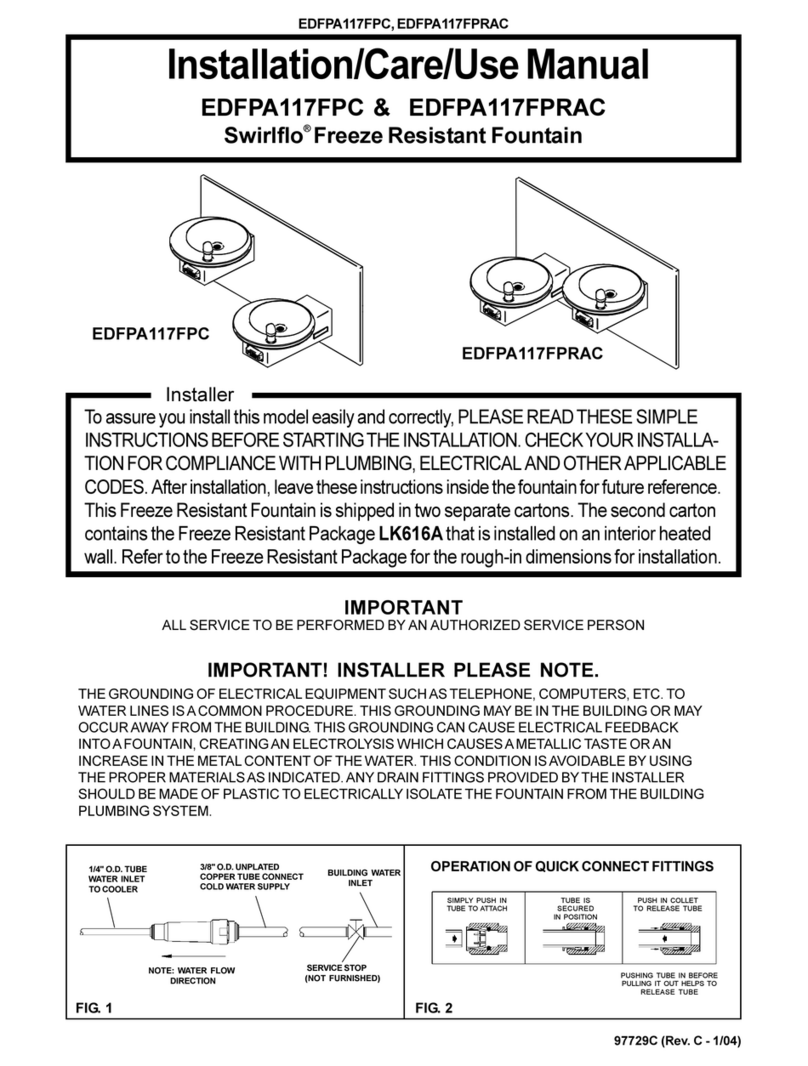

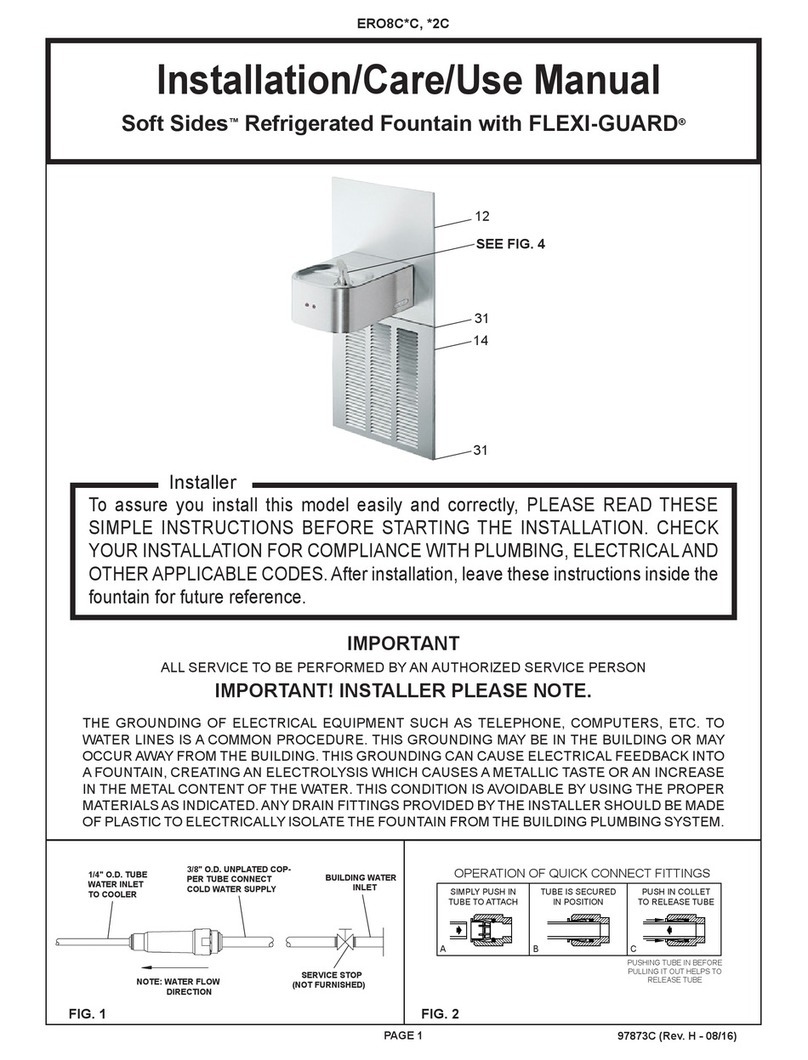

10. Connect fountain to supply line with a shut-off valve and install a 3/8” unplated copper water line between the valve and the cooler. Remove

any burrs from outside of water line. Push the tubes straight into the ttings until they reach a positive stop, approximately 3/4” (See Fig. 2). DO

NOT SOLDER TUBES INSERTED INTO THE STRAINER AS DAMAGE TO THE O-RINGS MAY RESULT.

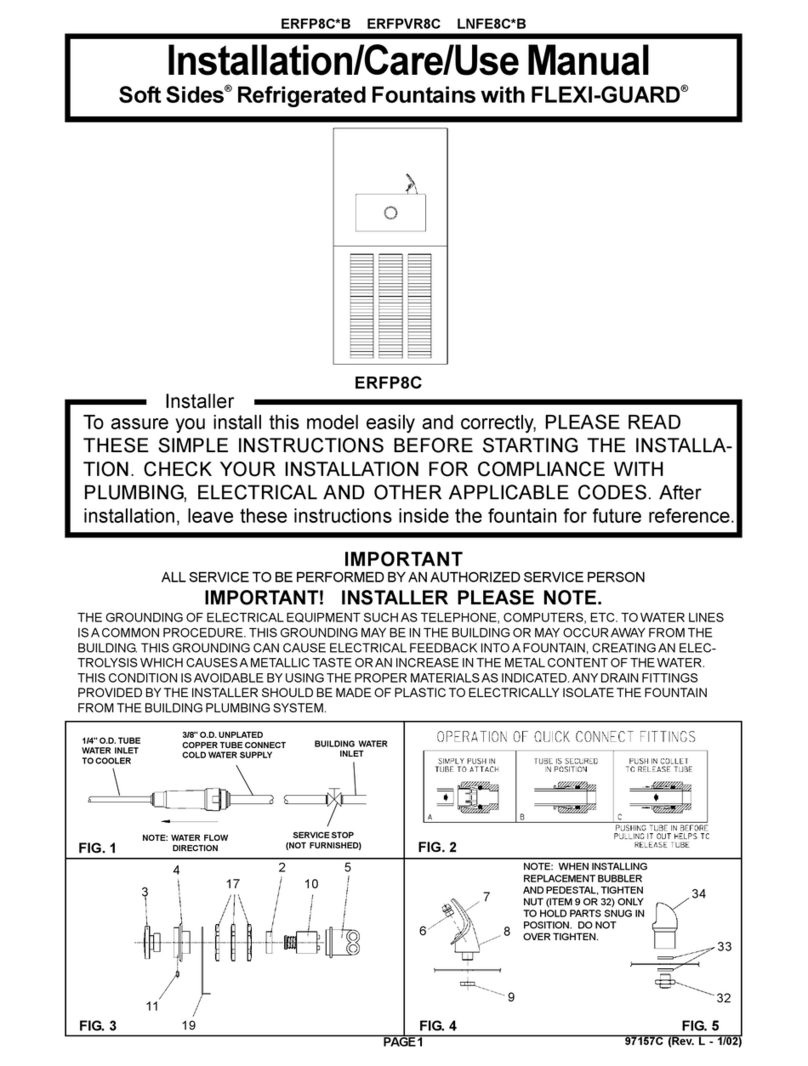

B CA

SIMPLY PUSH IN

TUBE TO ATTACH

TUBE IS SECURED

IN POSITION

PUSH IN COLLET

TO RELEASE TUBE

OPERATION OF QUICK CONNECT FITTINGS

PUSHING TUBE IN BEFORE

PULLING IT OUT HELPS TO

RELEASE TUBE

OPERATION OF QUICK CONNECT FITTINGS

SIMPLY PUSH IN

TUBE TO ATTACH

TUBE IS SECURED

IN POSITION

PUSH IN COLLET

TO RELEASE TUBE

PUSHING TUBE IN BEFORE

PULLING IT OUT HELPS TO

RELEASE TUBE

A B C

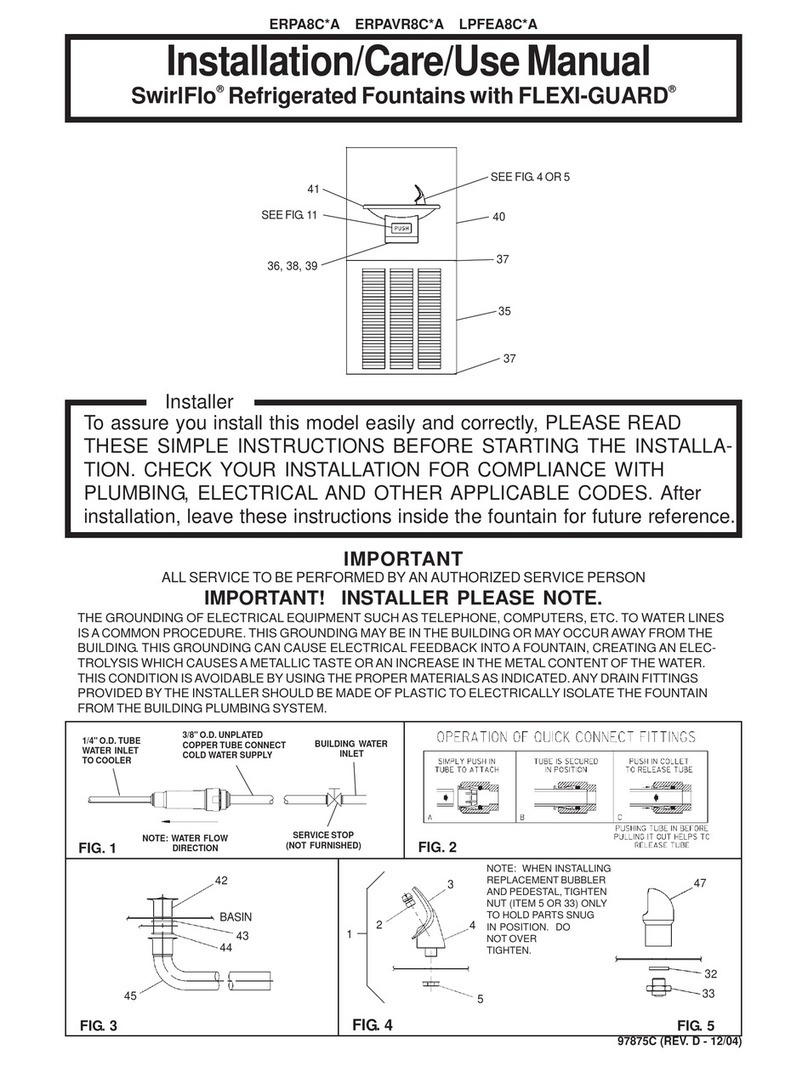

1/4” O.D. TUBE

WATER INLET

TO COOLER

3/8” O.D. TUBE CONNECT

COLD WATER SUPPLY

BUILDING WATER

INLET

NOTE: WATERFLOW

DIRECTION

SERVICE STOP

(NOT FURNISHED)

Figure 1 Figure 2