1000001747 (Rev. B - 05/16) Page 4

LMABFD*B LMABF8*1C

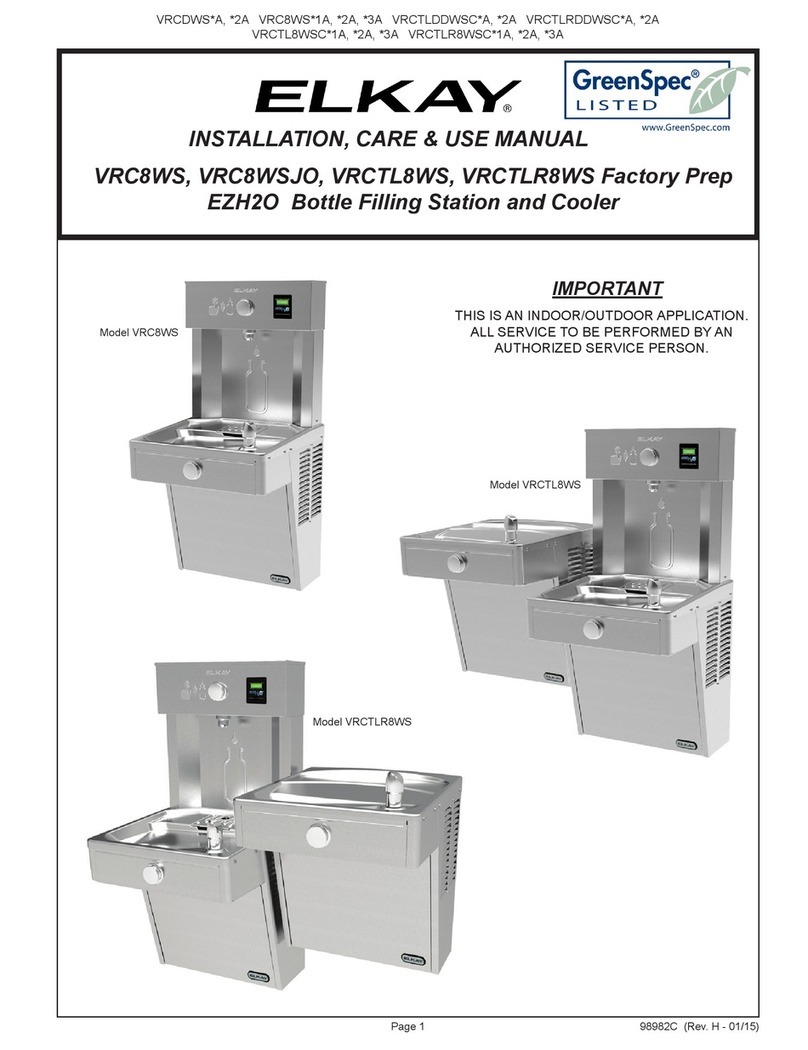

IMPORTANT

ALL SERVICE TO BE PERFORMED BY AN

AUTHORIZED SERVICE PERSON

HANGER BRACKETS & TRAP

INSTALLATION

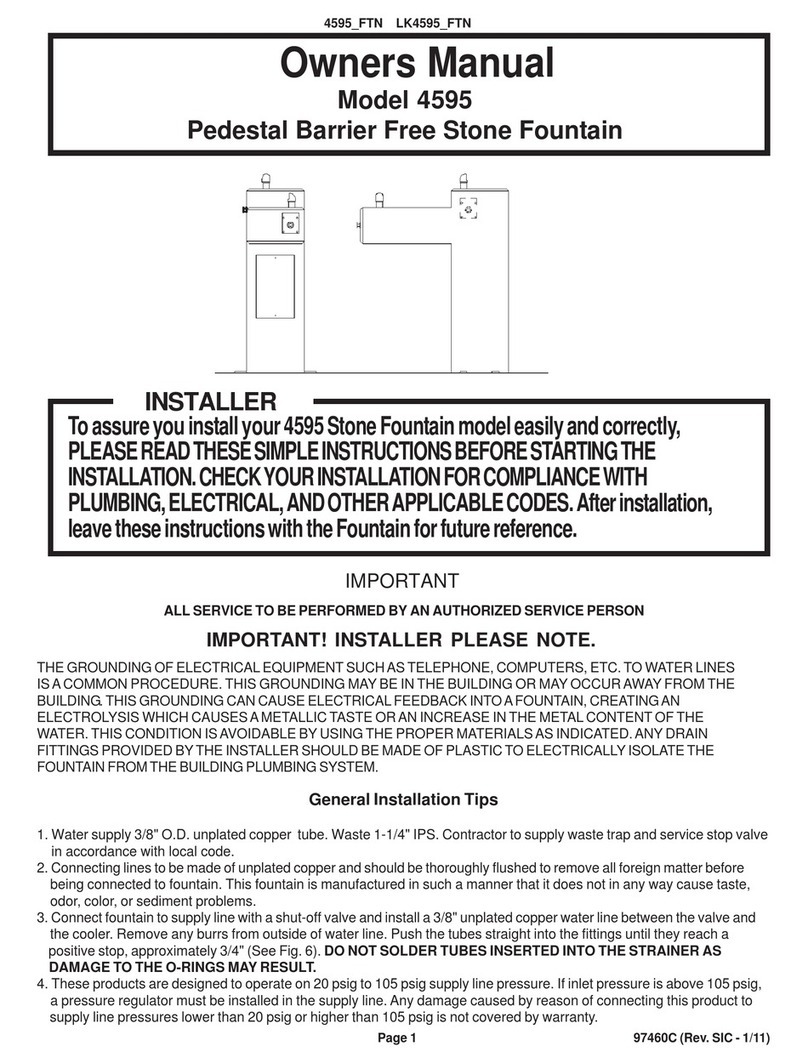

1) Remove hanger bracket fastened to back of

cooler by removing one (1) screw.

2) Mount the hanger bracket and trap as shown in

Figure 2.

NOTE: Hanger Bracket MUST be supported

securely.Addxturesupportcarrierifwallwill

not provide adequate support.

IMPORTANT:

• 6 1/4 in. (159mm) dimension from wall to

centerline of trap must be maintained for proper

t.

• Anchorhangersecurelytowallusingallve(5)

5/16" dia. mounting holes.

3) Install straight valve for 3/8" O.D. tube.

INSTALLATION OF COOLER

4) Hang the cooler on the hanger bracket. Be

certain the hanger bracket is engaged properly

in the slots on the cooler back as shown in Fig.

3.

5) Loosen the two (2) screws holding the lower front

panel at the bottom of cooler base and two (2)

screws at the top. Remove the front panel and

set aside.

6) Connect water inlet line--See Note 4 of General

Instructions.

7) Remove the slip nut and gasket from the trap and

install them on the cooler waste line making sure

thatthe endof thewastelinetsinto thetrap.

Assemble the slip nut and gasket to the trap and

tighten securely.

START UP

Also See General Instructions

8) Stream height is factory set at 35 PSI. If supply

pressure varies greatly from this, adjust screw,

accessible by removing front push panel (Item

7, Fig. 5). CW adjustment will raise stream and

CCW adjustment will lower stream. For best

adjustment, stream should hit basin

approximately 6-1/2” (165mm) from bubbler.

9) Replace the front panel and secure by

retightening four (4) screws.

10) If a taste, odor or sediment problem is

prevalent,tryinstallingourwaterltermodule.

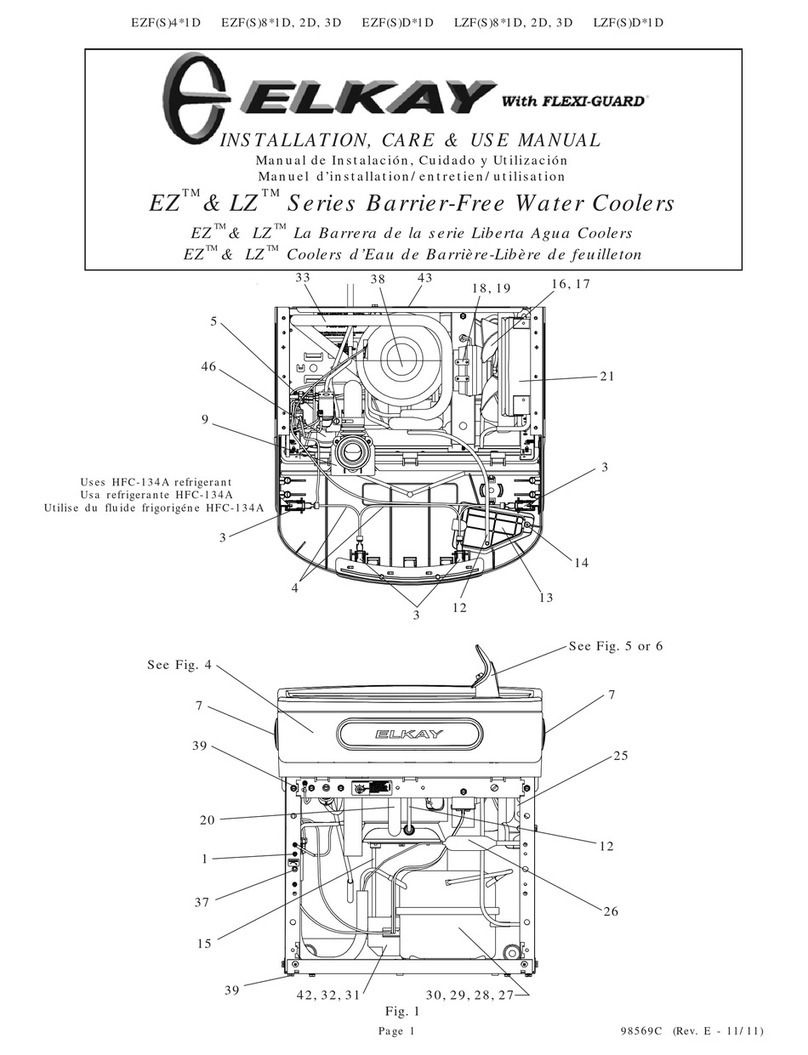

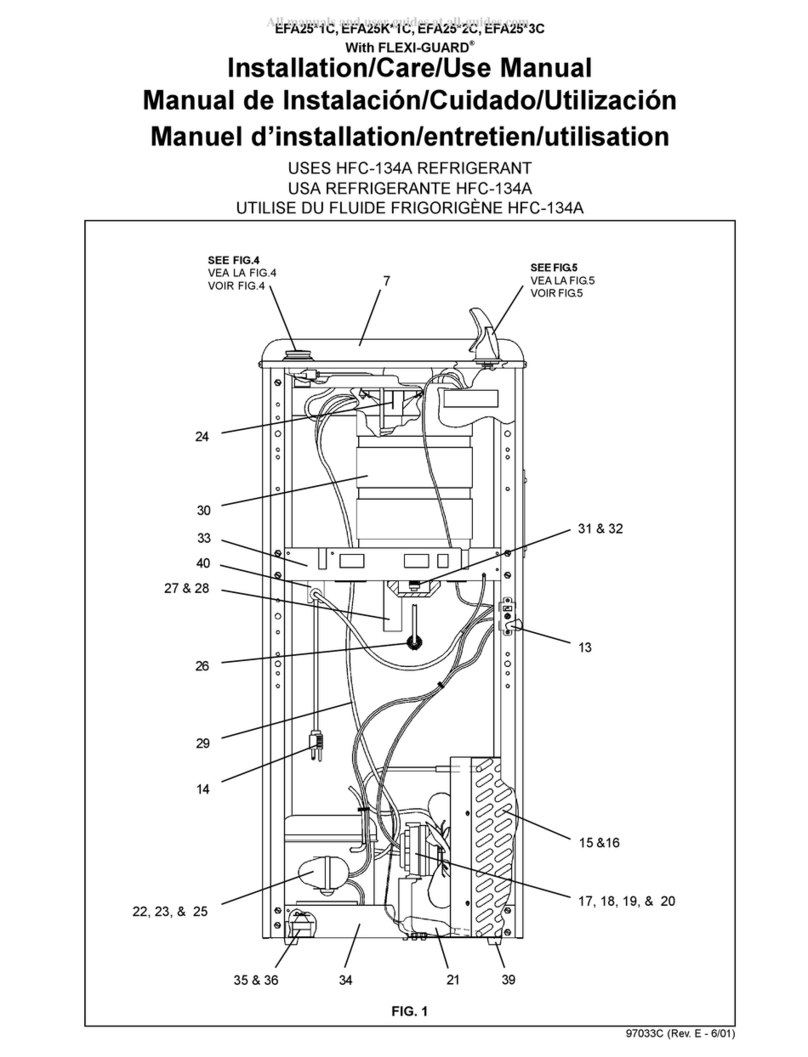

COOLER BACK

HANGER BRACKET

FIG. 3 FIG. 4

17

34

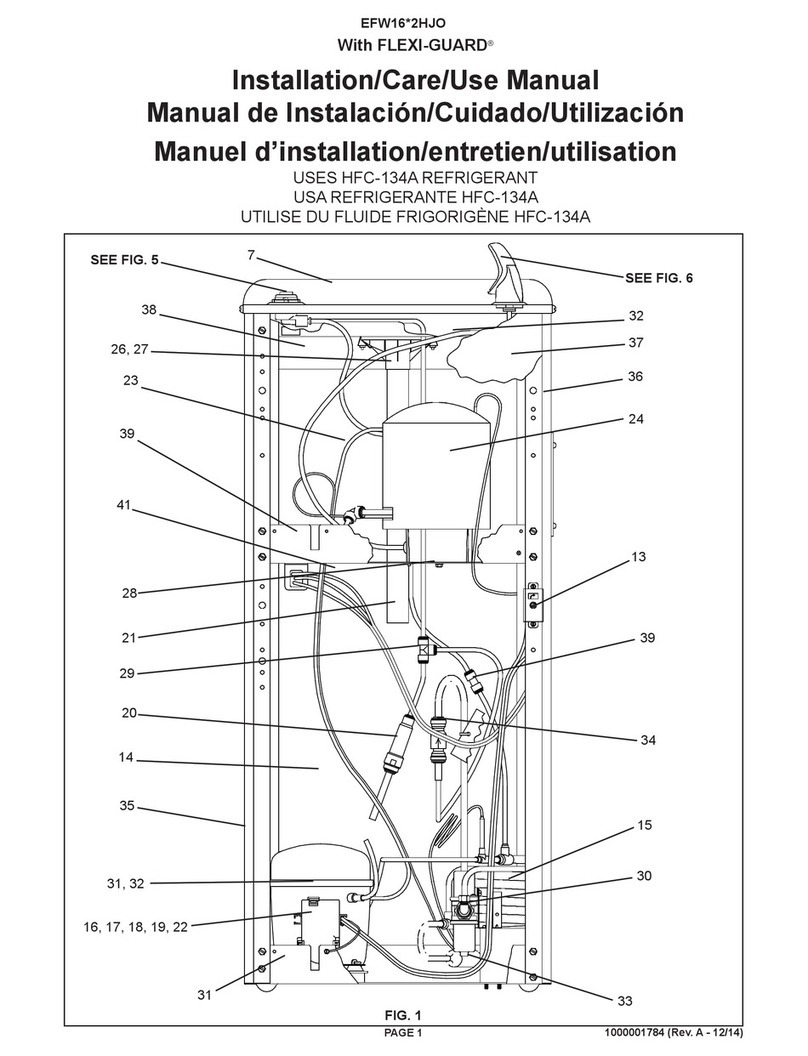

FIG. 5

3

6

4

4

7

2

3

4

4

C

3

4

5

3

4

2

2

1

15

14

13 15

15

A

18 - B

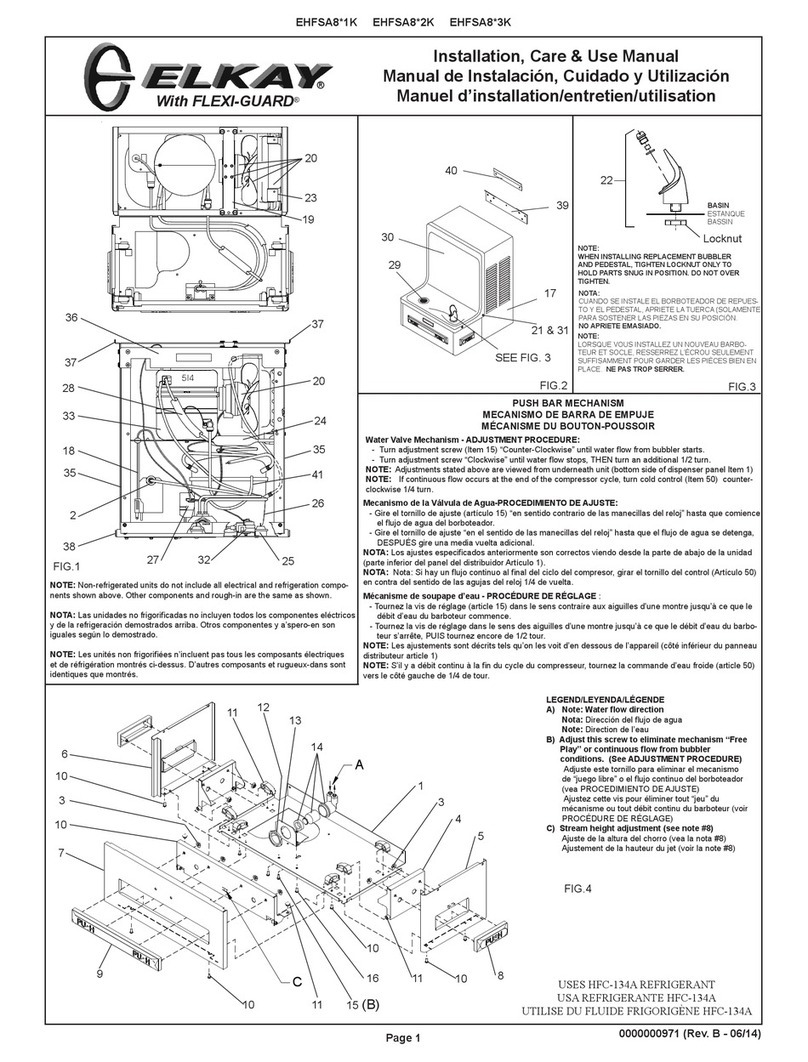

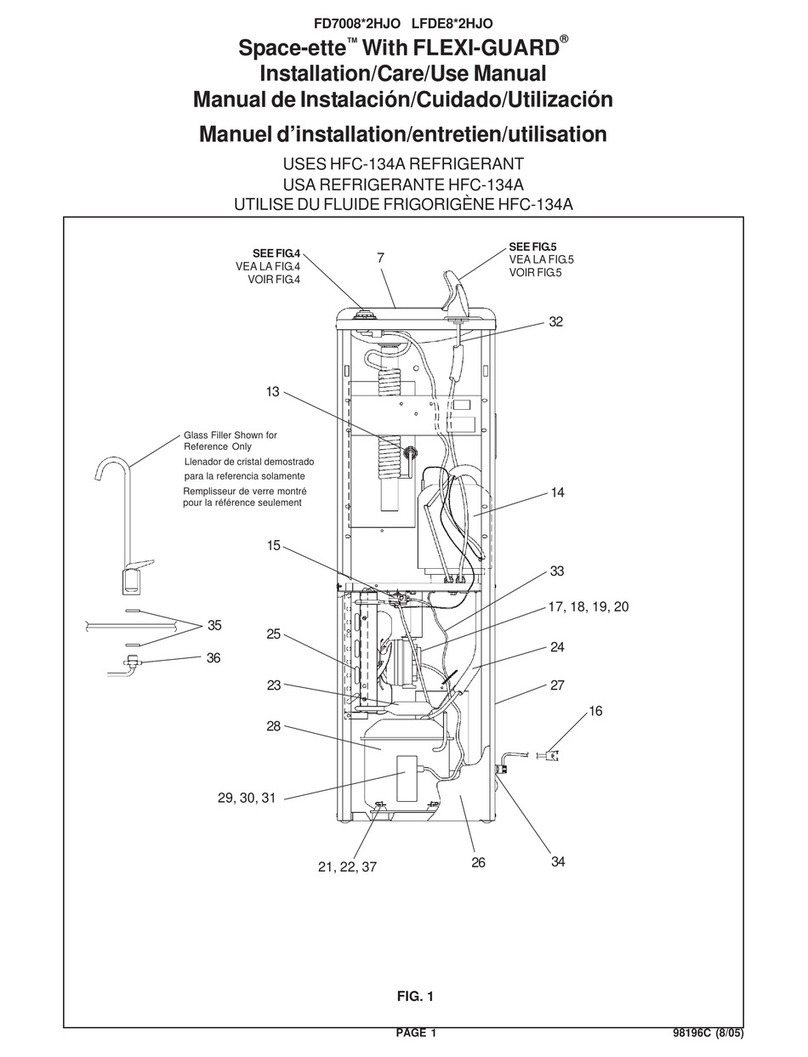

PUSH BAR MECHANISM

LEGEND

A) Note: Water ow direction

B) Adjust this screw to eliminate mechanism

“Free Play” or continuous ow from bubbler

conditions. (See ADJUSTMENT PROCEDURE)

C) Stream height adjustment (see note #8)

Water Valve Mechanism - ADJUSTMENT PROCEDURE:

-Turnadjustmentscrew(Item18)“Counter-Clockwise”untilwaterow

from bubbler starts.

-Turnadjustmentscrew“Clockwise”untilwaterowstops,THENturn

an additional 1/2 turn.

NOTE: Adjustments stated above are viewed from underneath unit

(bottom side of dispenser panel Item 1)

NOTE: Ifcontinuousowoccursattheendofthecompressorcycle,turn

cold control (Item 31) counterclockwise 1/4 turn.

3

2

2

23

11

3

4