CONTENTS

WHAT TO DO WHEN .................................................................................. 1-3

SERVICE ACCESS (1) FACE COVER........................................................... 4

SERVICE ACCESS (2) TOP COVER ............................................................. 5

SERVICE ACCESS (3) BELT COVER ........................................................... 6

SERVICE ACCESS (4) BED COVER & BASE............................................... 7

SERVICE ACCESS (5) FRONT COVER........................................................ 8

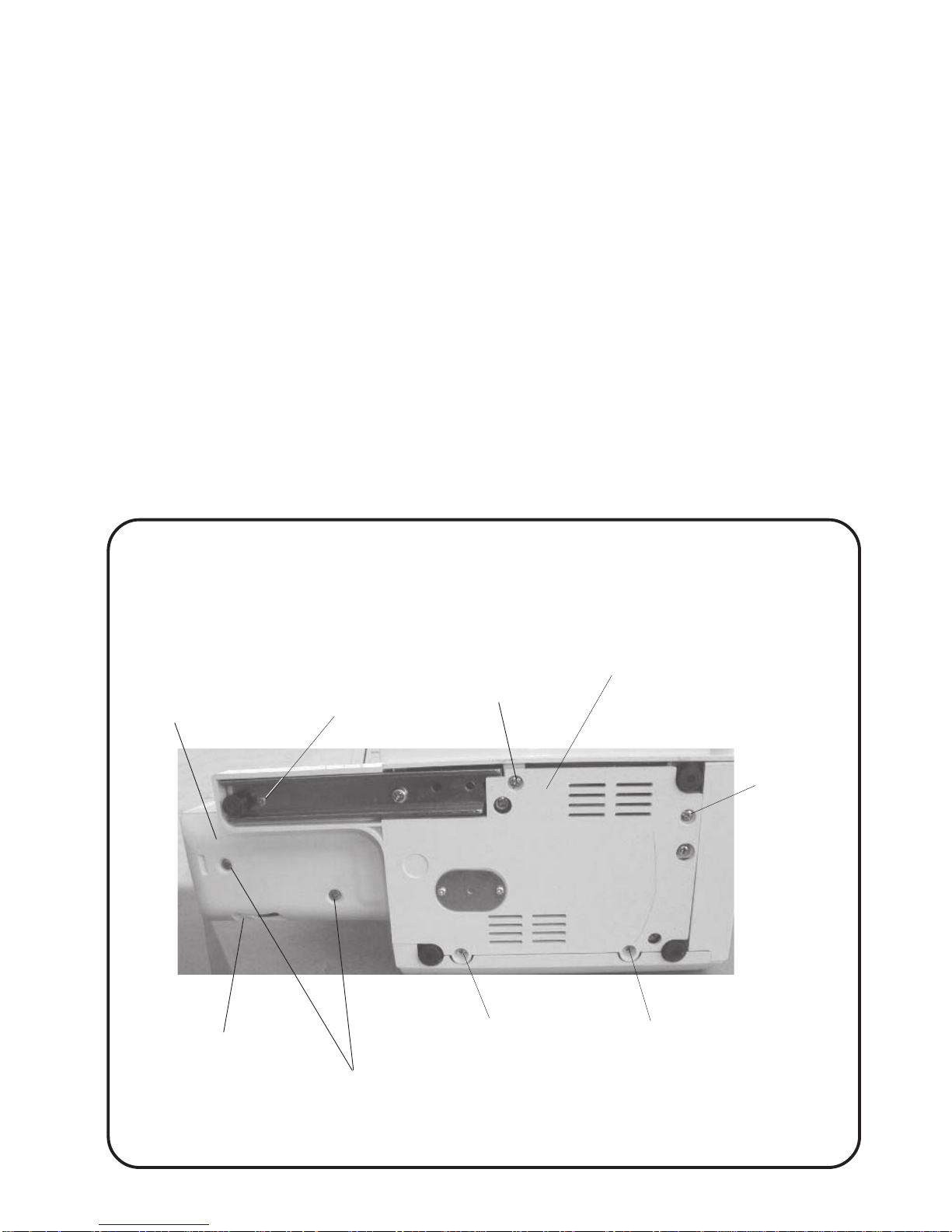

SERVICE ACCESS (6) REAR COVER .......................................................... 9

ADJUSTING PRESSER FOOT HEIGHT AND ALIGNMENT ....................... 10

NEEDLE DROP POSITION ALIGNMENT .................................................... 11

ADJUSTING HOOK TIMING ........................................................................ 12

ADJUSTING NEEDLE BAR ......................................................................... 13

ADJUSTING CLEARANCE BETWEEN NEEDLE AND HOOK .................... 14

ADJUSTING BACKLASH BETWEEN HOOK DRIVE GEAR

AND LOWER SHAFT GEAR ............................................................... 15

FEED DOG HEIGHT ADJUSTMENT ........................................................... 16

ZIGZAG SYNCHRONIZATION..................................................................... 17

NEEDLE THREAD TENSION ...................................................................... 18

STRETCH STITCH FEED BALANCE .......................................................... 19

REPLACEMENT AND ADJUSTMENT

OF THE NEEDLE THREADER PLATE................................................ 20

CONNECTOR DIAGRAM............................................................................. 21

SELF DIAGNOSTIC TEST ...................................................................... 22-25

REPLACING PRINTED CIRCUIT BOARD “A” ............................................. 26

REPLACING PRINTED CIRCUIT BOARD “K” AND “F” ............................... 27

REPLACING DC MOTOR AND ADJUSTING MOTOR BELT TENSION...... 28

REPLACING THE FUSES............................................................................ 29

REPLACING MACHINE SOCKET (UNIT).................................................... 30

REPLACING THE TRANSFORMER ............................................................ 31

REPLACING THE ZIGZAG WIDTH MOTOR ............................................... 32

REPLACING FEED STEPPING MOTOR..................................................... 33

ADJUSTING BUTTONHOLE LEVER POSITION......................................... 34

ADJUSTING THE BOBBIN WINDING SWITCH .......................................... 35

OILING ......................................................................................................... 36