Contents

WHAT TO DO WHEN........................................................................................................................ 1 - 3

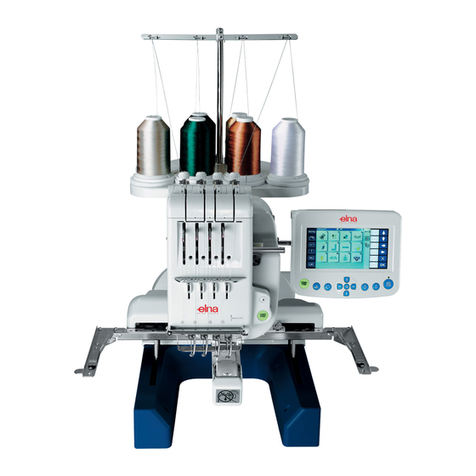

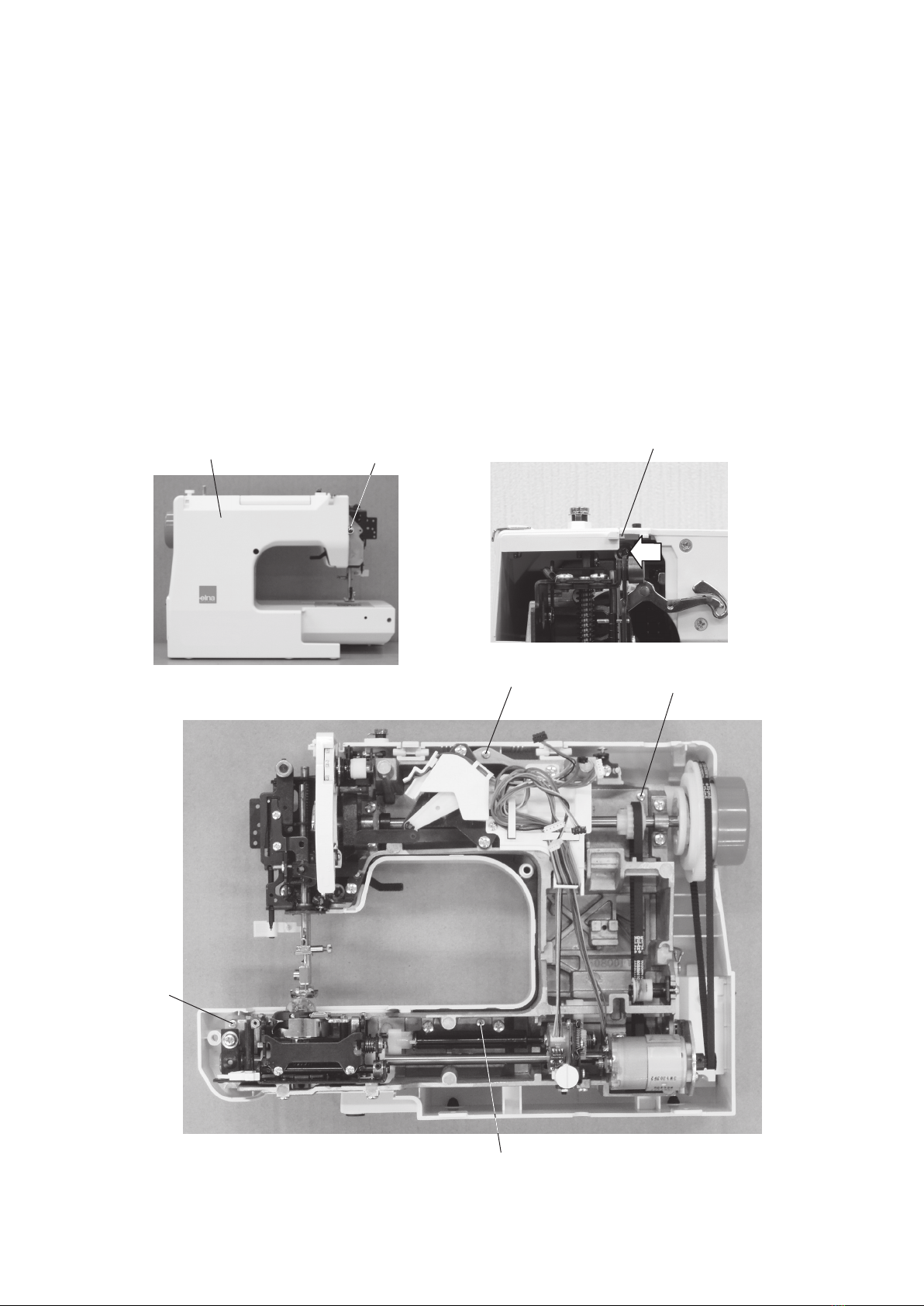

CHANGING EXTERNAL PARTS

FACE COVER .........................................................................................................................................4

BED COVER ...........................................................................................................................................5

FRONT COVER ......................................................................................................................................6

REAR COVER.........................................................................................................................................7

MECHANICAL ADJUSTMENT

PRESSER BAR HEIGHT ........................................................................................................................8

NEEDLE DROP POSITION.....................................................................................................................9

ADJUSTMENT OF HOOK TIMING .......................................................................................................10

ADJUSTMENT OF NEEDLE BAR HEIGHT..........................................................................................11

CLEARANCE BETWEEN NEEDLE AND TIP OF THE ROTARY HOOK ..............................................12

FEED DOG HEIGHT .............................................................................................................................13

BACKLASH BETWEEN HOOK GEAR AND LOWER SHAFT GEAR ...................................................14

TOP TENSION ......................................................................................................................................15

STRETCH STITCH FEED BALANCE ...................................................................................................16

REPLACEMENT AND ADJUSTMENT OF THE NEEDLE THREADER PLATE....................................17

SELF-DIAGNOSTIC TEST

SELF-DIAGNOSTIC TEST.............................................................................................................. 18-22

TO DISPLAY THE VERSION OF THE PROGRAM...............................................................................22

REPLACING THE ELECTRONIC COMPONENTS

PRINTED CIRCUIT BOARD A CONNECTION .....................................................................................23

PRINTED CIRCUIT BOARD A ..............................................................................................................24

PRINTED CIRCUIT BOARD L...............................................................................................................25

DRIVING MOTOR (DC MOTOR) ..........................................................................................................36

SWITCHING REGULATOR UNIT..........................................................................................................27

PARTS LIST.................................................................................................................................... 28-41