ELTRA ON-900 User manual

0

0.1

2002 by ELTRA GmbH Germany – January 2002 – Service Manual OH 900 / ON 900 / ONH 2000

0.1-2

The analysers ON - 900, OH - 900 and ONH – 2000 are of equal design.

The service manual is therefore common for all three types.

The only difference between them is the tubing and the chemicals. See 4.3

NOTE :

Servicing should only be done by a person with profession, who has mastered the

servicing and maintenance of this device, as well as having further qualifications,

especially in the field of electronics and physics.

We ask the users of this Service Manual to inform us about any possible mistakes.

We would also appreciate any suggestions for supplements and improvements to this

Service Manual.

CAUTION !

Before opening this device, always unplug the main power !

2002 by ELTRA GmbH Germany – January 2002 – Service Manual OH 900 / ON 900 / ONH 2000

0.1-3

SERVICE MANUAL ON / OH-900 and ONH-2000

0.1 Overview of the ON/OH-900; ONH-2000 modifications………………………..…0.1-5

1 FAULTS

1.1 IR cell test displays ++++ see 2. 3 .............................................................................1.1-1

1.2 No gas flow.....................................................................................................................1.2-1

1.3 The flowrate is not stable .............................................................................................1.3-1

1.4 The base line of the TC cellcannot be adjusted to zero............................................1.4-1

1.5 Analysis time too long....................................................................................................1.5-1

1.6 High blank value.............................................................................................................1.6-1

1.7 Erratic results..................................................................................................................1.7-1

1.8 The LED for the temperature regulation of the infrared cell or the thermoconductivity

cell does not flash...........................................................................................................1.8-1

1.9 No analysis start.............................................................................................................1.9-1

1.10 The message "No Water Flow" appears on the display..........................................1.10-1

1.11 Furnace temperature too high.....................................................................................1.11-1

1.12 The base line of the TC cellis negative, see 2.12 ...................................................1.12-1

1.13 No furnace power during the analysis........................................................................1.13-1

1.14 The sample drop motor does not rotate.....................................................................1.14-1

1.15 Faulty electronic drivers...............................................................................................1.15-1

1.16 Noise or drift of the infrared baseline .........................................................................1.16-1

1.17 Furnace cut-off during analysis...................................................................................1.17-1

1.18 Beeper responding.......................................................................................................1.18-1

1.19 Saved data is lost.........................................................................................................1.19-1

1.20 The upper electrode becomes dark............................................................................1.20-1

1.21 The chopper motor doesn`t rotate..............................................................................1.21-1

1.22 The samples make bubbles........................................................................................1.22-1

1.23 Spare parts kits ............................................................................................................1.23-1

1.24 Unstable current...........................................................................................................1.24-1

2 ADJUSTMENTS, TEST AND FUNCTION EXPLANATION

2.1 Gas flowcontroller adjustment and jumper settings ...................................................2.1-1

2.2 Pressure switch..............................................................................................................2.2-1

2.3 Infrared zero-baseline, control and adjustment...........................................................2.3-1

2.4 IR-source voltage setting...............................................................................................2.4-1

2.5 Temperature regulation of the IR-cell...........................................................................2.5-1

2.6 Pneumatics for furnace lift............................................................................................2.6-1

2.7 Flow rates .......................................................................................................................2.7-1

2.8 Furnace lift adjustment..................................................................................................2.8-1

2.9 Linearization ...................................................................................................................2.9-1

2.10 Balance programming:.................................................................................................2.10-1

2.11 .......................................................................................................................................2.11-1

2.12 TC zero baseline adjustment......................................................................................2.12-1

2.13 Diagnostic printout .......................................................................................................2.13-1

2.14 Temperature regulation of the TC Cell.......................................................................2.14-1

2.15 Water flowand furnace temperature sensing board ON21......................................2.15-1

2.16 The furnace control board PW13...............................................................................2.16-1

2.17

2.18 Sample drop motor and the motor switch adjustment..............................................2.18-1

2.19 Hot extraction upgrade ................................................................................................2.18-1

2002 by ELTRA GmbH Germany – January 2002 – Service Manual OH 900 / ON 900 / ONH 2000

0.1-4

3 SERVICE

3.1 IR-paths, cleaning and replacing....................................................................3.1-1

3.2 IR-source......................................................................................................3.2-1

3.3 Infrared electronics........................................................................................ 3.3-1

3.4 Infrared power supply.................................................................................... 3.4-1

3.5 Chopper ++++ see 3. 2................................................................................ 3.5-1

3.6 Infrared temperature regulation..................................................................... 3.6-1

3.7 Leak checking...............................................................................................3.7-1

3.8 Replacing the EPROMS................................................................................ 3.8-1

3.9 Clearing memory........................................................................................... 3.9-1

3.10 Electronic reset........................................................................................... 3.10-1

3.11 Coding of the IR-ranges.............................................................................. 3.11-1

3.12 Adding new IR-ranges................................................................................. 3.12-1

3.13 Cleaning the solenoid valves....................................................................... 3.13-1

3.14 Replacing the flow sensor ........................................................................... 3.14-1

3.15 Installing an AC power stabilizer.................................................................. 3.15-1

3.16 Replacing the gas pump.............................................................................. 3.16-1

3.17 Additional safety features for furnace pneumatics (optional)......................... 3.17-1

3.18 230V / 400 V operation................................................................................ 3.18-1

3.19 Upgrading of analysers with electronic rack for using the

new Windows software................................................................................ 3.18-1

4 MISCELLANEOUS

4.1 Ordering numbers.........................................................................................4.1-1

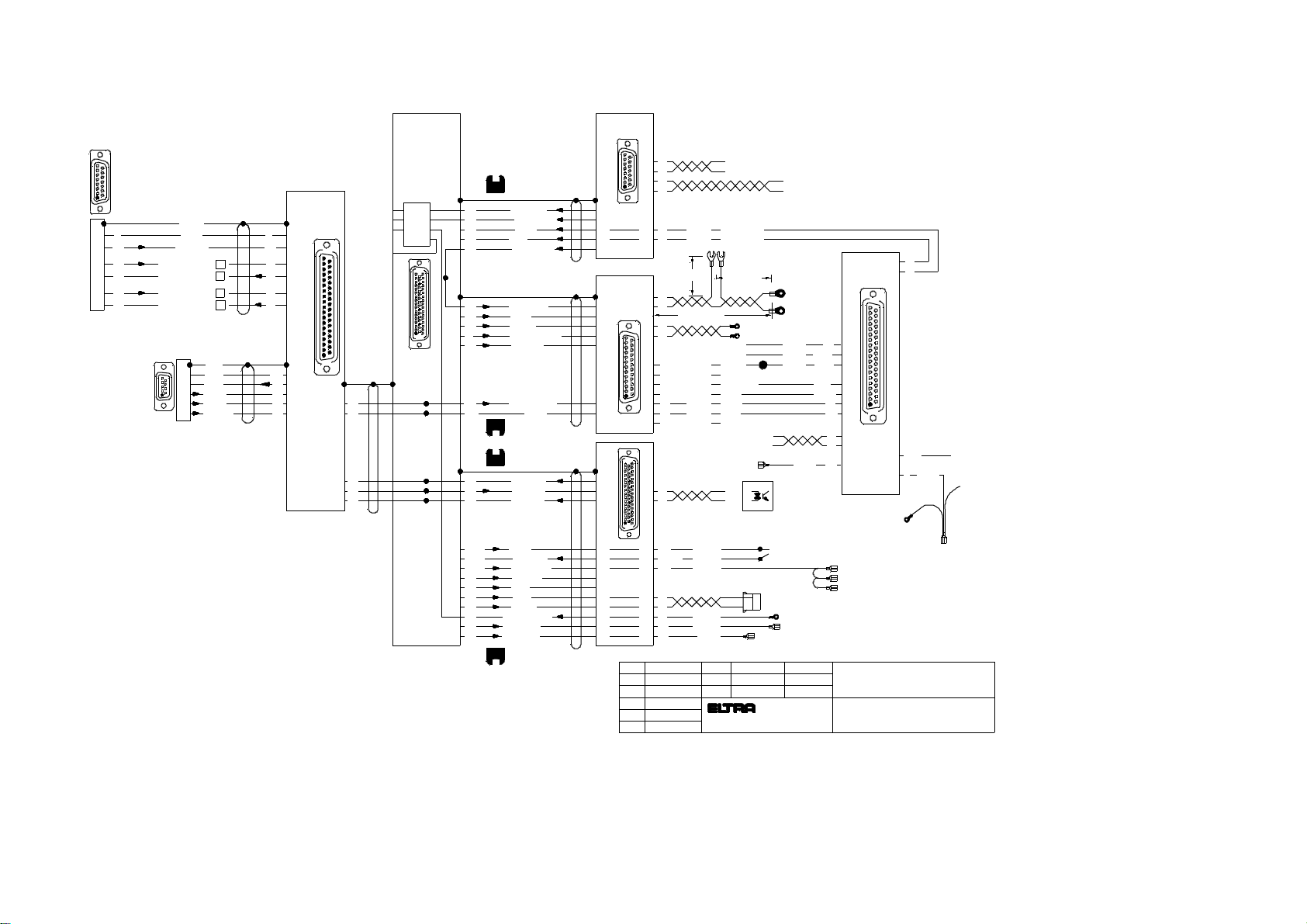

4.2 Wiring diagrams............................................................................................ 4.2-1

4.3 Water and gas flow diagrams, analysis sequence.......................................... 4.3-1

4.4 Purging of the chopper..................................................................................4.4-1

4.5 Maintenance OH- 900, ON- 900....................................................................4.5-1

2002 by ELTRA GmbH Germany – January 2002 – Service Manual OH 900 / ON 900 / ONH 2000

0.1-5

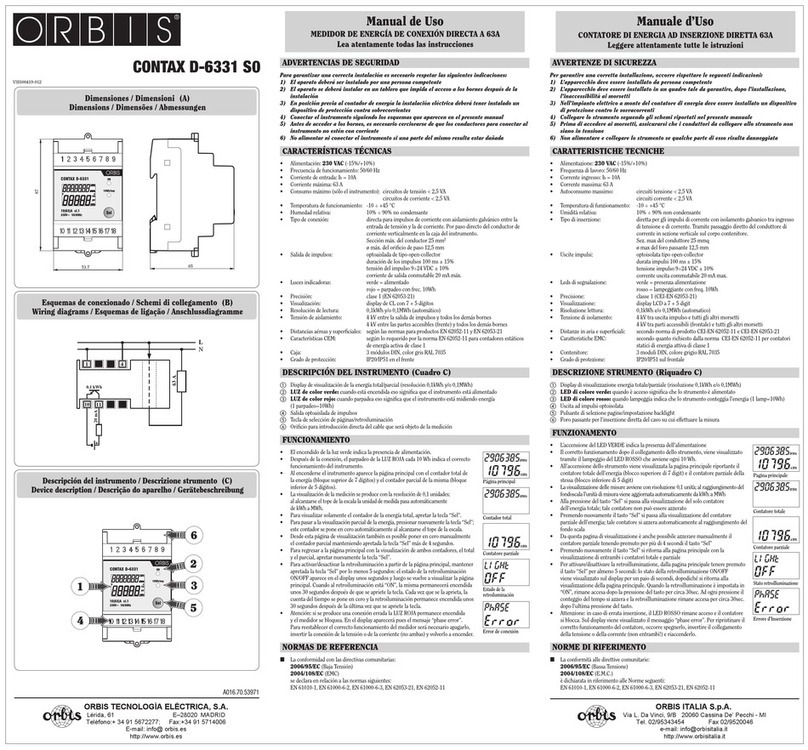

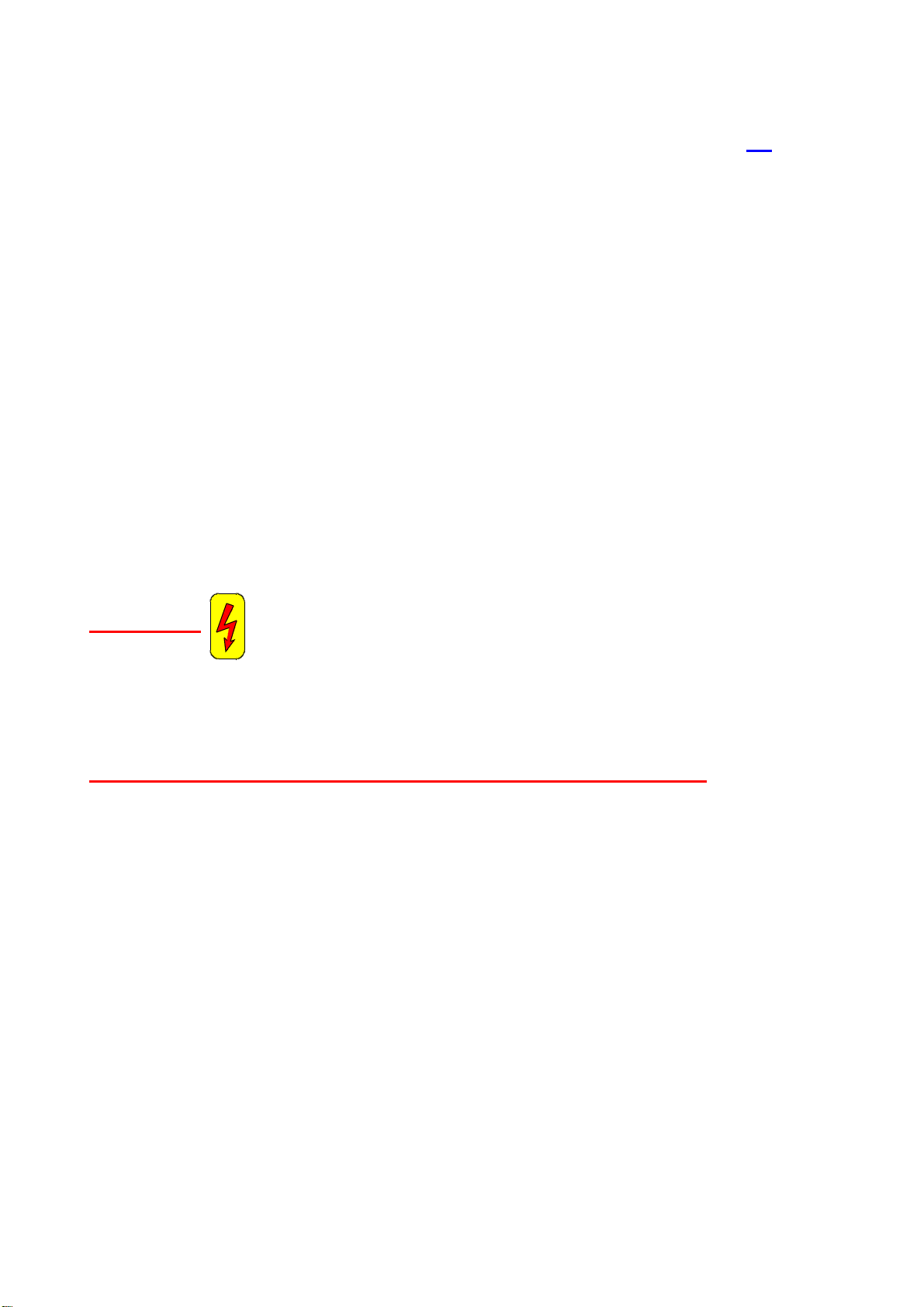

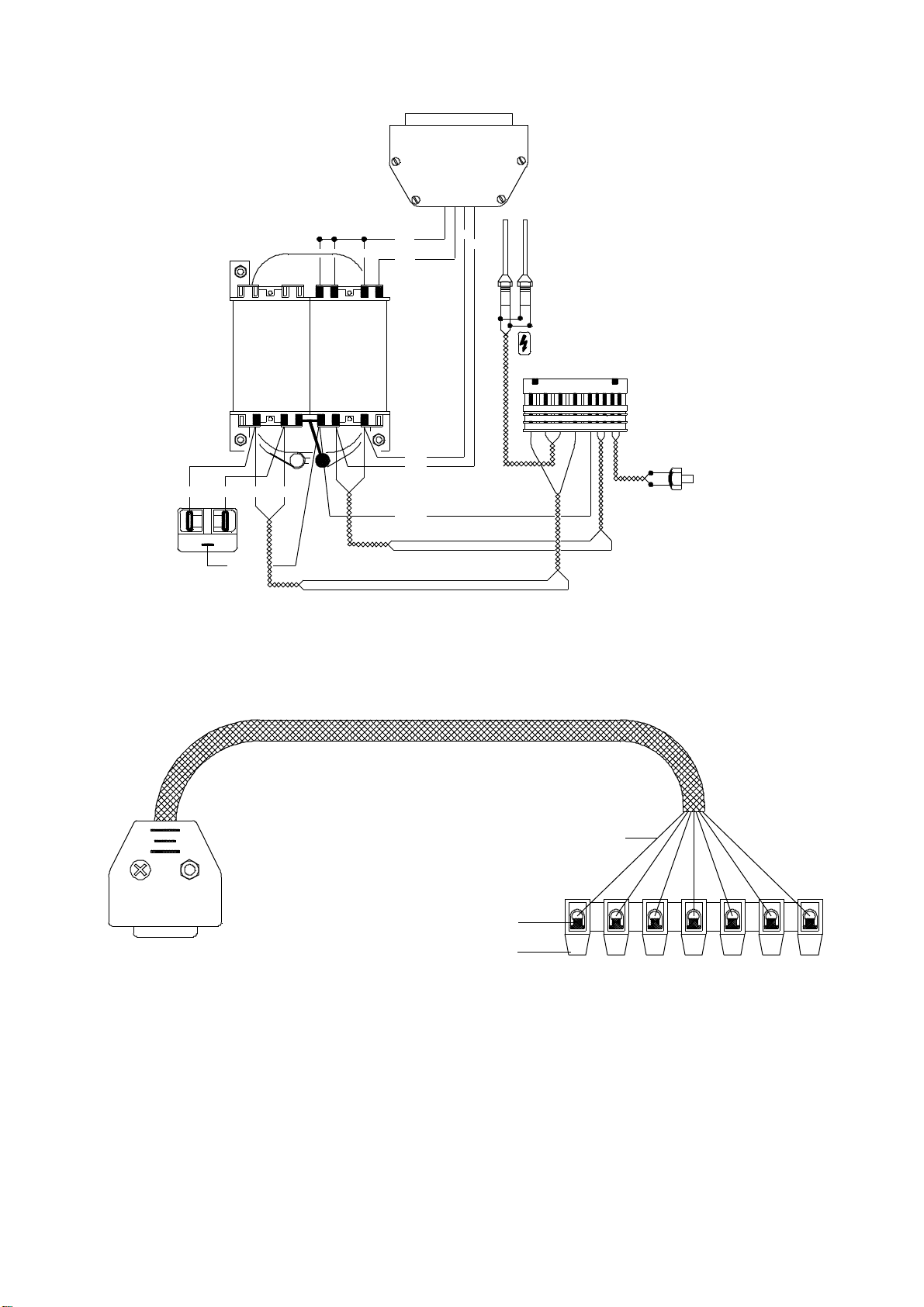

0.1 Overview of the ON/OH-900; ONH-2000

modifications:

Up to S/N 1500xxxxxx

The electronic unit is replaced by the board UNI 1.3 and the electronic rack is removed.

The corresponding wiring diagram is 32007.

The modification took place in the second half of 2004.

12

1

13

9

6

5

4

3

ws

br

15

gr

23

9

17

18

48

45

2

49

12

47

sw

rs

ws

rt

br

50

46

ws

br

9

10

14

gn

ge

gr

10

19

35 20br 19

ws

2

1

6

5

gn

bl

ge

rt

18 33

34 50

17

1

8rs

7

ge

+15V

-15V

GND

GND

24+25

12+13

21

8

1 13

14 25

vi 43

8bl

+24V 22ac

GND 24ac

ge

gn

br

ws

br

gn

gr

ge

100 cm

100 cm

42 cm

Overheat

Water flow

+24V

GND

Water flow

Trigger

Power ON/OFF

Motor

+24V

Power (1V/kW)

Gas pump

Flow rate

Gas flow

GND

+24V

TC cell

Purge valve

Pneumatic

7

15

Pump control

3

2

ws/gn

bl

sw

rs/gr

13x 0.14²x105 cm abgeschirmt

GND

Flow rate

gr

br

br

gr

gn

ge

rt

gn

gn

bl

bl

49 cm

49 cm

10 GND 24acgn/rt

15

31

27

18

11 br/gr

3 ws/br

Motor

Phase

ws/gn

gn/rt

bl

sw

vi

vi

1

21

rt

bl/ws

33

7rt

Pneumatic valve 11380

Purge valve 01160

Pressure switchrs

13

11

28gr

ws/br

ws/br50 cm

50 cm

50 cm

Phase

115cm

115cm

105cm

Pressure switch

10cm

160cm Motor

20

19

1

37

Furnace current

9x 0.25²

60 cm

10x 0.25²

NR32

15038

65 cm Water temp.

ON21-32210

81

159

PW13-32066

6x 0.25²

sw

6

30 cm

140 cm

40 cm

40 cm

40 cm

40 cm

30 cm

FC21

15098

50 cm Furnace voltage

2x 0.75²

15c m

2x 0.75²

50c m

NK31- 16100

130 cm Furnace temp.

30 sw

5rt

gr

abgeschirmt

D50-Buchse-Lötseite D25-Buchse-Lötseite D15-Buchse-Lötseite

D37-Buchse -Lötseite -

8

2

4

5

1

110cm

N (Hi)

N (Lo)

GND

GND

3

33

zero

TC temp.

6 9

5

1

D9-Buchse Lötseite

Auto zero signal

2

PIN

1 TC Temp.

Low N output signal

High N output signal

4

5

2

2

GND8 GND9

TC CELL

sample drop

24V AC

GND

current sense

85cm Motor

blue

bro wn

yellow

gre y

gre en

ora nge

pink

red

blac k

vio lett

wh ite

bl

br

ge

gr

gn

or

rs

rt

sw

vi

ws

36

38

40

35

37

39

or

gn/ws

bl 100 cm

100 cm

100 cm

gr/rs

bl/rt

ws/gn

GND

H/N code

Gas saveing

C1

C3

Purge valve

H/N code switch

25500

01160

11430

11435

Gas save valves

50 cm

50 cm

5x 0.14²x25 cm

abgeschirmt

grgr

br

1

O(Lo) auto zero

2

ge

O(Lo) IR-signal

gn

ge

2

2

1br

5

1

O(Hi) IR-signal

O(Hi) auto zero

gn

6

ws ws

GND

IR temp.

14

9

81

159

IR-Cell D15-Socket solder side

GND14

PIN

9IR Temp.

High O output signal

4High O auto zero signal3

2

Low O output signal2

2

Low O auto zero signal1

2

ws

2

44

3 vi

rt 60 cm

rt

vi

5

11

4

1

20

19

37

15

14

17

34

16

13

Shield

D37-plug solderside

rs rs

18 33

34 50

17

1

FD50-Socket solder side

11

gr Water flow

6x 0.14²x130 cm

abgeschirmt

34

27

18

14

16 1

5

3

ULN

7x 0.14²x120 cm

42

36

18

39

28

37

26

20

50

41

38

40

geändert am:

D-41469 Neuss

Mainstr. 85 Block 20

Zeichnungs-Nr.:

Datum

gez.:

gepr.:

Sanda

Polemitis

Name

19.07.2004

19.07.2004

Bez.:

32007

a 21.07.2004

ON900/OH900 + ONH 2000

-UNI 1.3+1.4 Version

Signal and control cable

Benennung:

6x 0.14²x65cm

Abschirmung

5x 0,14²x55cm

b 02.12.2004

c 03.12.2004

9

15

17

16

29

13

UNI 1.3+1.4

UNI 1.3+1.4

Pressure switch

d 07.12.2004

NC

2

e 08.12.2004

2002 by ELTRA GmbH Germany – January 2002 – Service Manual OH 900 / ON 900 / ONH 2000

0.1-6

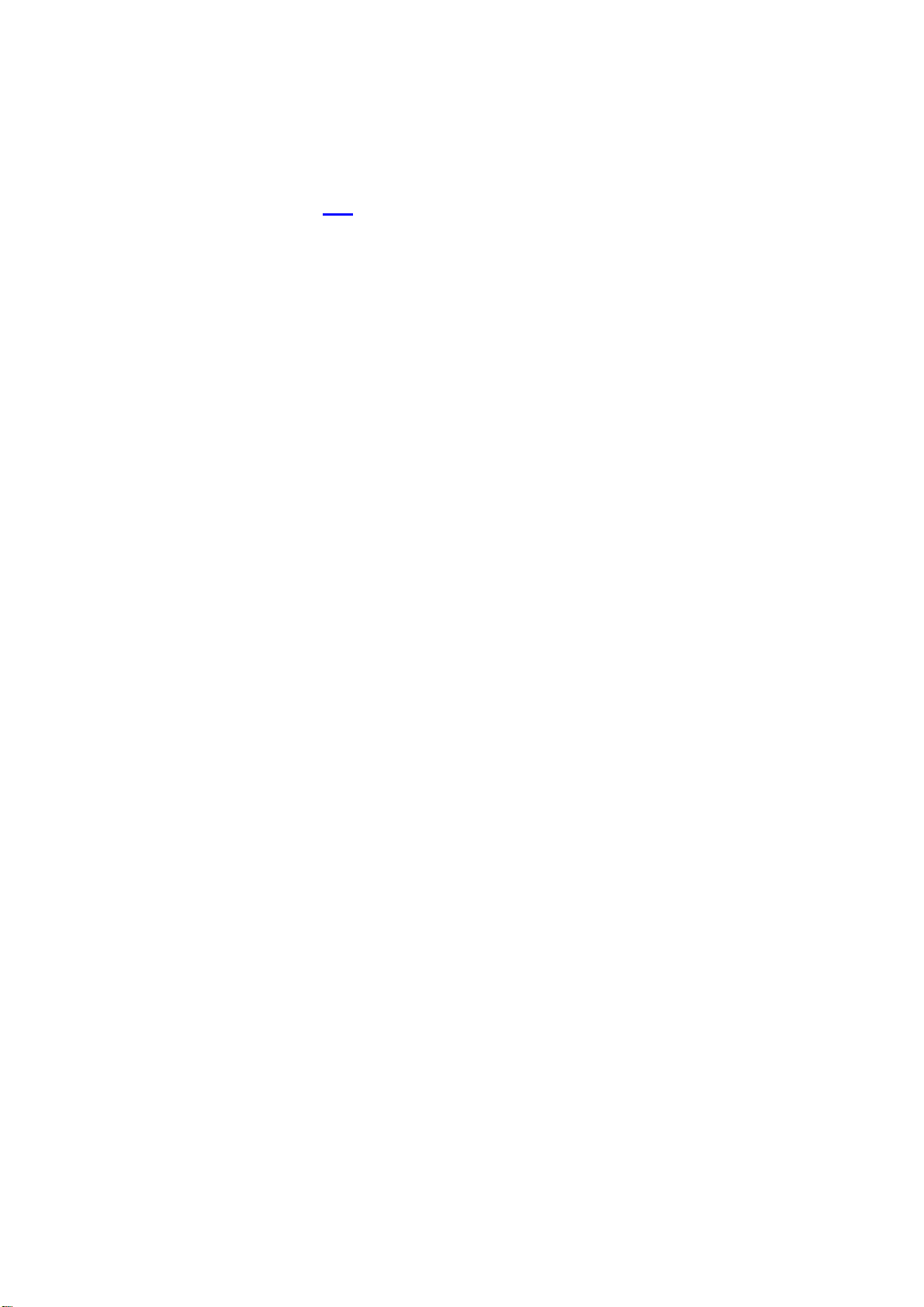

Pump 15266

Pump plate-15262

Pump control board PC1-15268

T1

BF418

100µ/350V

1765432

T5

4007

ZY200

ZY200

D8 D9 D10

D12D11

7824

T4

T3

1 2k /9 W

R5

R1

33/5W

4

3

2

5

6

7

8

TP1 TP2

TP3

TP4

50k

1 00 k

4148

56k

18k

68k

10k

220k 100k

R3

R4

R7

R8 R9

10k

1k8

1k8

T2

4007

D1

D2

C1

R2

4148

ZD33

IC1

R10

R11

R12

1k

10k

150k

150k

120k

39k

12k

15k

10k

33k

33k

47k47k

39k

R26

R16

TP7

R17

D5

D3

C7

10n 0,1

47 µ

6 3V

10n

C6

C4

TP6

4148

D6 R18

IC2

4 N 3 5

3k3

C2 R 6

ZD15

4007

P2P1

G

IRF820

TP8

TP9

NR 32

IRF820

J2

A B

1

R13

R14

R15

R19

R20

R21

R22

R23

R24

R25

R27

4007

S

C5

OP270

1k

10n/500V

+

TP5

1µ

C 3

D7

D

+

IRF820

G

S

D

- pol ige S tiftle is te a b gew in ke lt5 0

50

17

33 1

18

34

D 9 -B u c hs e

+

+ + + +

1 0µ 47µ

1 0µ 47 µ 4 7µ 1 0 0 µ

O P 4 7 0

P1 P2 P3 P4

1 2 k / 5 W

TR 1

TP3

J 1

5

9 6

1

K1

7 812782 0

TR 2

F B R 2 2 1

+

47µ

47 µ

+

F C 2 1

MD-50

To pum control board

To pum control board

Adapter 32910

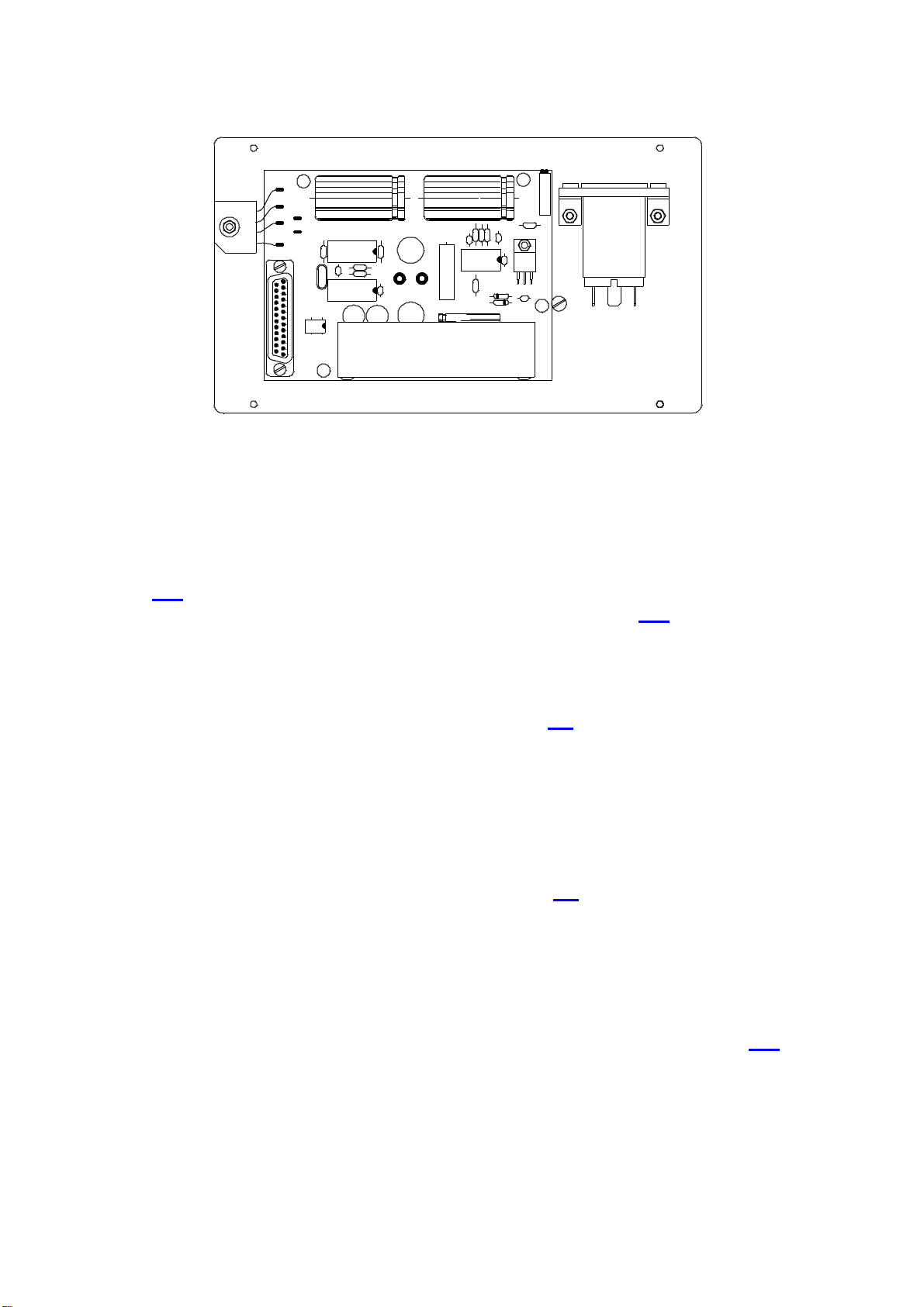

ON-900 from S/N 1738xxxxxx

OH-900 from S/N 1811xxxxxx

ONH-2000 from S/N 1771xxxxxx

The pump has changed along with a pump control board and a adapter as shown below.

The boards FC21 and NR32 are replaced by the board 15268.

2002 by ELTRA GmbH Germany – January 2002 – Service Manual OH 900 / ON 900 / ONH 2000

0.1-7

ON-900

OH-900

ONH-2000

09270 old pump

Oldpumpout

-po l i ge S t iftl e i st e ab ge w i nk el t5 0

5 0

1 7

33 1

18

3 4

D 9 -Bu c h se

+

+ + + +

10µ 47µ

10µ 47 µ 47 µ 100 µ

O P 4 7 0

P1 P2 P3 P4

12 k/ 5 W

T R 1

TP3

J1

5

9 6

1

K1

78127820

T R2

F BR 2 2 1

+

47µ

47 µ

+

F C 2 1

T1

BF418

100µ/ 350V

1765432

T5

4007

ZY 200

Z Y200

D8 D9 D1 0

D1 2D11

7824

T4

T3

12 k/9W

R5

R1

33/5W

4

3

2

5

6

7

8

TP 1TP 2

TP3

TP4

5 0k

1 00k

4148

5 6k

18k

68k

10k

220k 100k

R3

R4

R 7

R8 R9

10k

1 k8

1k8

T2

40 07

D1

D2

C1

R2

4148

ZD33

IC1

R10

R11

R12

1k

10k

1 50k

150k

120k

39k

12k

1 5k

10k

33k

33k

47k47k

39k

R26

R1 6

TP7

R17

D5

D3

C7

10n 0,1

4 7µ

63V

10n

C6

C4

TP6

4148

D6 R18

IC 2

4 N3 5

3k3

C2 R 6

ZD15

4007

P2P1

G

IR F820

TP8

TP9

NR 32

IRF82 0

J 2

A B

1

R13

R14

R15

R19

R2 0

R2 1

R22

R23

R24

R25

R27

4007

S

C5

OP270

1k

10n/500V

+

TP5

1 µ

C 3

D7

D

+

IRF820

G

S

D

Two

boards

out

NR-32

FC-21

15266 pump

15268 electronic

board

15264 supporting

panel

Newpumpin

withboard+panel

Adapterin

32910 adapter

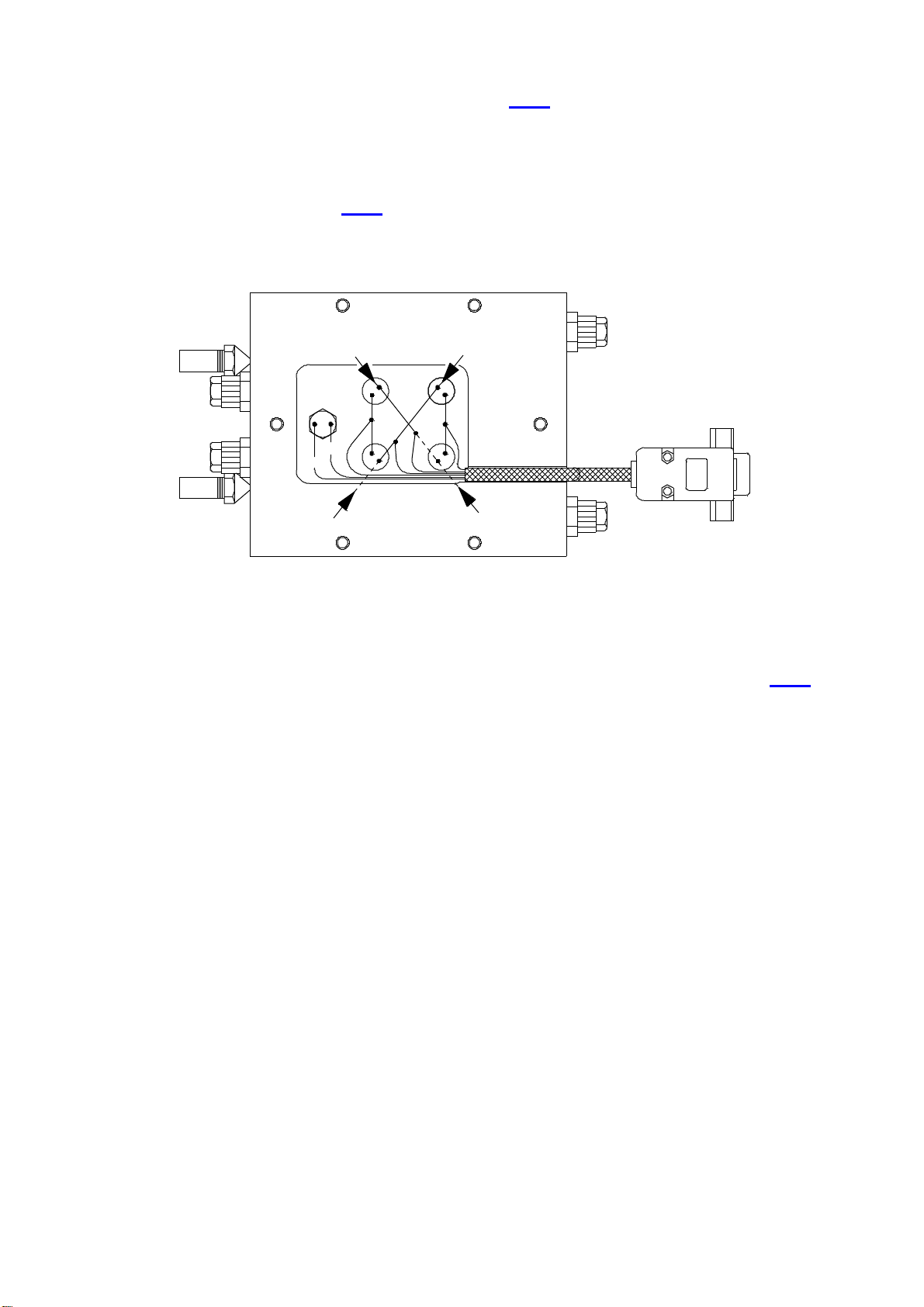

The old pump is change with the new pump as shown below.

Ordering numbers:

15264-Pump plate

15266-Pump

15268-Pump control board PC1

32910-Pump adapter

2002 by ELTRA GmbH Germany – January 2002 – Service Manual OH 900 / ON 900 / ONH 2000

0.1-8

60250

60525

60552 60552

upwards

downwards

60500 silver

60500 nature

60234

60525

60513

60522

60236

60566

60500 blue

72010

2,5bar

60566

60500

green

60500 blue(L=3cm)

60531

60566

From end of the year 2007 the ON/OH-900 and ONH-2000 are equipped

with the new pneumatics.

2002 by ELTRA GmbH Germany – January 2002 – Service Manual OH 900 / ON 900 / ONH 2000

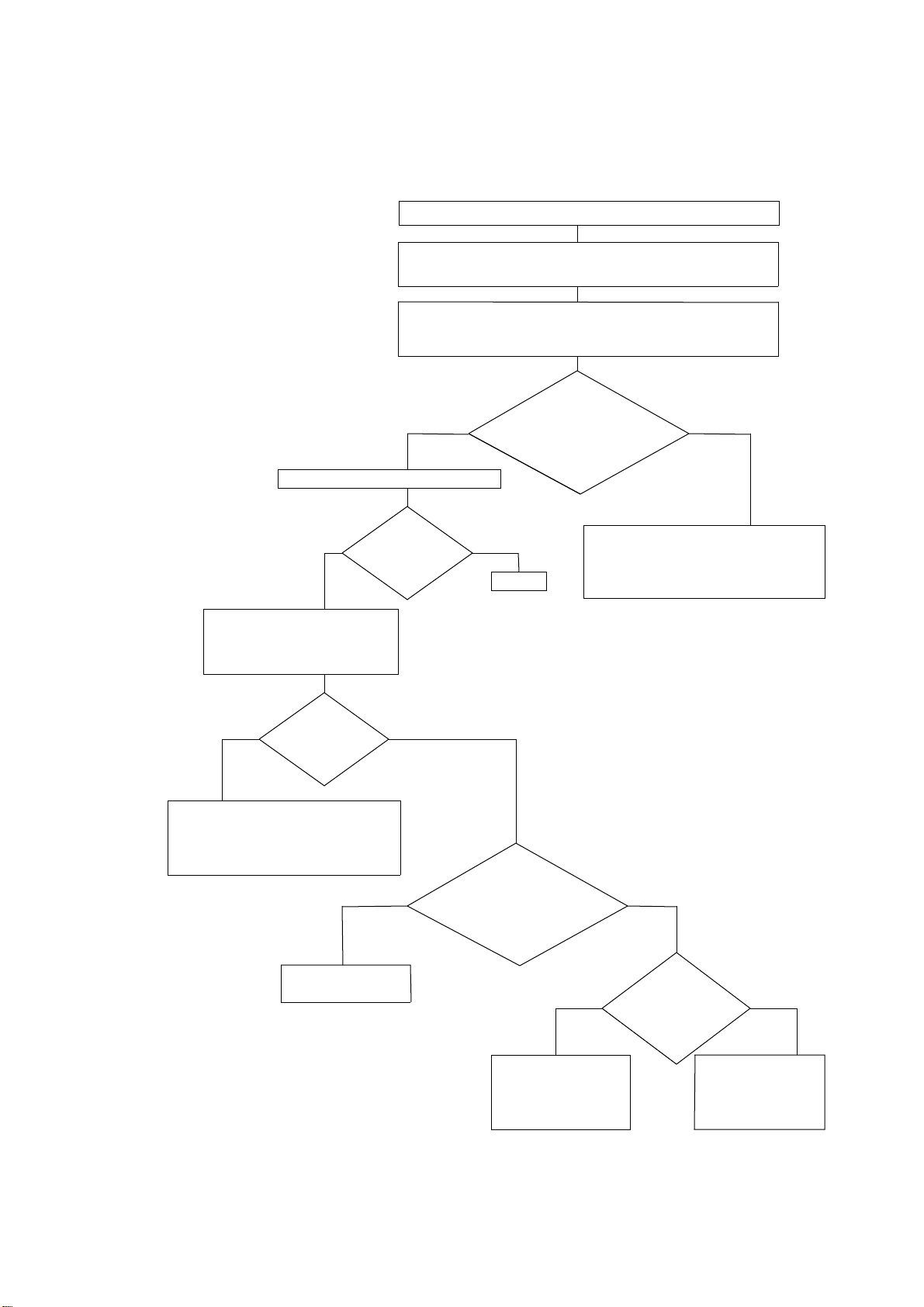

1.1-1

1

1

FAULTS

1.1

1.1

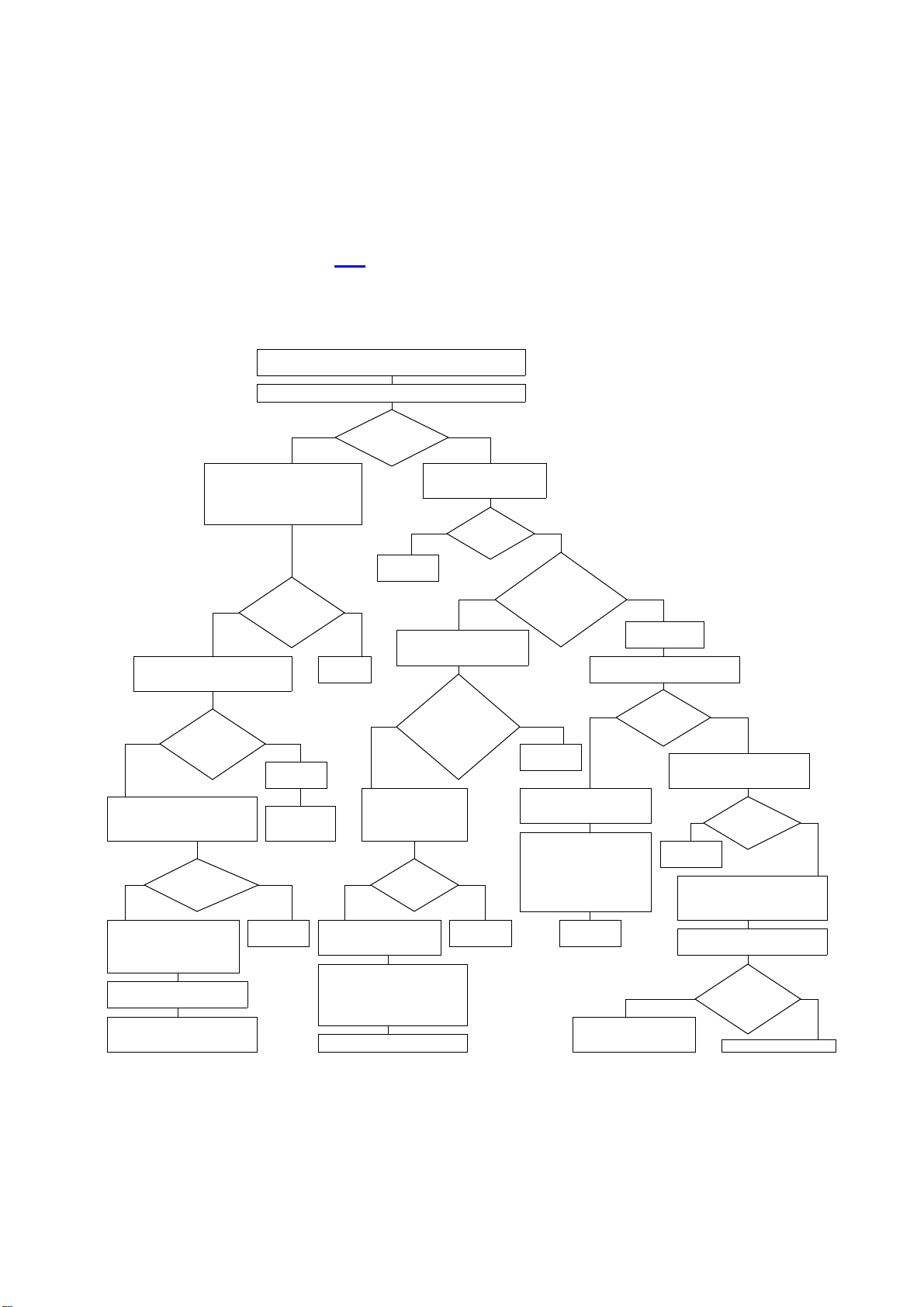

IR-cell test displays: ++++ see 2. 3

also after five minutes of oxygen flow:

If the range is higher than

10 V ++++

then the problems are as follows:

1) Too much contamination:

There are one or more

indication ranges and they

are too high.

2). The IR–sources:

The sources are bent or

de-adjusted through

transport. See Remark:

3).Chopper:

The chopper is not running

although the path is not

contaminated and the IR-source´s

is ok.

Remark:

In most cases the problem is

in the IR-sources or in the

power supply. During a rough

transportation the IR-sources

may be bent causing the

problem. See 3.2. We

experienced that this is very

popular for the new IR-detector

and preamplifiers.

We can only help if you send

us a copy of the flow diagram of this chapter, after drawing a line along the path you

followed according to the condition you found.

Asking for detectors, preamplifiers and boards without following this diagram, is useless.

P1

06421 IR13

I R1 3 0 64 2 0

1

1 - 1- 2

Check the IR

source voltage

see

Check the chopper.

For this,

remove the

IR Path. see

Ceck the position

of the IR-sources

see

< Menu > < Cal > displays ++++

Replace the

power supply.

see

IR Source

is defective.

see

Is the

rectifier

warm

yes

no yes

Feel the rectifier (1)

no

Adjust the

IR Source

voltage see

Adjust the zero

see Check if there

is 1-1,5 VAC

on TP1,board IR21

see

Still

faulty

Does the

chopper

run

no

Replace the

spring see

Replace the

chopper motor

see

no yes

yes

no yes

Replace the

IR21 board

see

Voltage

correct

1-1 S

Too

low or

zero

Zero

Replace path

see

Check for

contaminated

IR - path

Too low

Replace the

IR preamplifier

see and

Check for proper

Cable connection

to IR21 board

Replace the

IR detector, see

Attention!

Consider the detector

only as a last resort!

If after replacing the

detector the fault still

exists, then reinstall

the old detectors

Is there

any

voltage

?

3.1

3.2

2.4

?

3.4 3.2 ?

3.5 2.4

3.5

?

2.3

2.3

?

?

3.1

3.3

2.3 3.1

3.1

2002 by ELTRA GmbH Germany – January 2002 – Service Manual OH 900 / ON 900 / ONH 2000

1.1-2

Touch the rectifier ( 1 ) of the IR-cell, it should feel warm ( about 45°C ).

( The analyser does not need to be turned off, nor must the infrared rack be removed ).

If the rectifier is cold ( room temperature ), you should check the IR-source voltage,

see 2. 4 .

If there is no IR source voltage, replace the power supply, see 3. 4

If there is IR source voltage, but the rectifier ( 1 ) is cold, then the IR source is

defective.

Since the IR sources are connected in series, the rectifier is cold, even when just one

of the IR sources is defective.

Open the infrared rack, remove the IR source ( see 3.2 ), and identify the defective

part by resistive measurement.

Non defective IR sources have a resistance of only 1 Ohm, while defective ones have

a much higher or unmeasurable resistance.

CAUTION!

When setting new IR sources, CO2can be produced during the first warming up.

Therefore, all points of the adjustment instructions ( see 2.3 ) should be carefully followed

through.

If the rectifier ( 1 ) is warm, then check if the chopper motor is at a standstill. To do

this, an IR path must be unscrewed.

Through the bore holes in the chopper motor housing, the chopper blades should be

be visibly rotating.

The cause for a chopper motor that doesn't run are usually the springs ( see 3. 5 ) that

were built in before September 1993 .

Exchange the spring-type for a newer type. The motor itself should turn anyway, even

when the chopper blade is not mounted. If not, the motor is defective.

Theoretically, the circuit board IR21 may also be at issue. This is, however, very

unlikely if more than one channel is not functioning in a multi-channel device.

P1

06421 IR13

I R 13 0 6 4 20

1

1- 1 - 2

2002 by ELTRA GmbH Germany – January 2002 – Service Manual OH 900 / ON 900 / ONH 2000

1.1-3

TC-cell check displays ++++ or -9.99 ( see 2 .12 )

If the test of the TC-cell still shows ++++ or - 9.99 after 5 minutes of carrier gas flow,

check the flow rates first ( see 2 .12) .

If they are OK, watch the zero baseline of the nitrogen channels and adjust them if

necessary.

If it is not possible to get a straight baseline by using the jumper and trimmer ( see 2 .12 ),

check the resistance of the thermistors.

Unplug the connector of the TC-cell and open the metal block of the TC-cell.

Connect an ohmmeter across each thermistor ( don't open any connection ).

The expected reading should be approximately 5-6 KOhm.

In case you should measure more than 14 KOhm across one specific thermistor, then that

thermistor is faulty and must be replaced.

CAUTION :

The thermistor is a small part inside of the glass ball, in the middle of the wire.

br

bl

Pair1

Pair2

Pair1

Pair2

rs

ws ge gn

1-1-3

2002 by ELTRA GmbH Germany – January 2002 – Service Manual OH 900 / ON 900 / ONH 2000

1.2-1

1.2

1.2

No gas flow

C h e ck th e p re s s u re

S e e 4 .2

s

w

itc h . S e e 2 .2

C h e c k th e m a in s p o

w

e r.

h ig he r o r lo

w

e r

?

of the p um p vo lta g e

the re a d in g

Is

O n th e b o ard F C 2 1 .

z e ro

o k o r

?

Is th e

v o lta g e

1 2 V D C

?

th e v o lta g e

Is

R e p la ce th e

flo

w

s e n s o r

R e p la c e th e

b o a rd F C 2 1

A d

j

u s t F C 2 1

S e e 2 .1

R e p la c e th e

b o a rd N R 3 2

A d

j

u s t N R 3 2

S e e 2 .1

Zero

L o

w

e r H ig h e r

Higher

o .k .

Y e s

o .k .

ab ou t 1 2 V D C on T P 4

M e a s u r e a t le a s t

2 0 V D C o n T P 5 ,

?

w

h e n n o flo

w

th a n 0 .6 V D C

on TP1 much higher

o n T P 2 z e ro

o r

Zero

A d

j

u s t th e flo

w

s e e 2 .1

N o

?

ad

j

ustab le

flo

w

Is th e

12VDC

th an 1 0 0

Voltages

C h a n g e th e c h e m ic a ls .

T h e g a s flo

w

is b lo cke d .

S e e 1 .2

T h e p u m p is

w

o rn o u t.

0.6 VDC

1 -6 -E

M e a s u re th e pu m p v o lta g e b e t

w

e e n

T P 1 a n d T P 2 (G N D ) o f th e b o a rd N R 3 2 ,

s e e 2 .1

C h e c k th e o xy g e n p r e s s u re o n th e

fro n t p a n e l g a n g e to b e 1 ,5 ba r (2 2 ps i)

N o g a s fl o

w

o n th e u p p e r flo

w

m e te r

2002 by ELTRA GmbH Germany – January 2002 – Service Manual OH 900 / ON 900 / ONH 2000

1.3-1

1.3

1.3

The flow rate is not stable

Please note: The gas flow in consideration is read on the right-side flow meter.

Vibrations of the ball inside of the flow meter is not a sign of an unstable flow rate. This is

an effect of the weight of the ball and the compressibility of the carrier gas in a small tube.

The flow rate is only unstable, if the average position of the ball becomes higher or lower.

First check the vacuum at the inlet of the electronic flow controller. It should be higher than

50 mbar. If it is not, check the tubes from furnace to flow controller.

If the vacuum is higher than 50 mbar, check the tubes following the flow controller.

Check the complete tubing from the furnace outlet up to the analyser outlet.

Otherwise change the flow controller.

Caution:

It has happened several times already, that the outlet of the furnace was blocked by

silicon grease. Due to an excessive greasing of the surface of the O-ring ( 4 ) of the lower

furnace closure, some of the grease can land onto the furnace outlet hole ( 1 ), causing its

blockage.

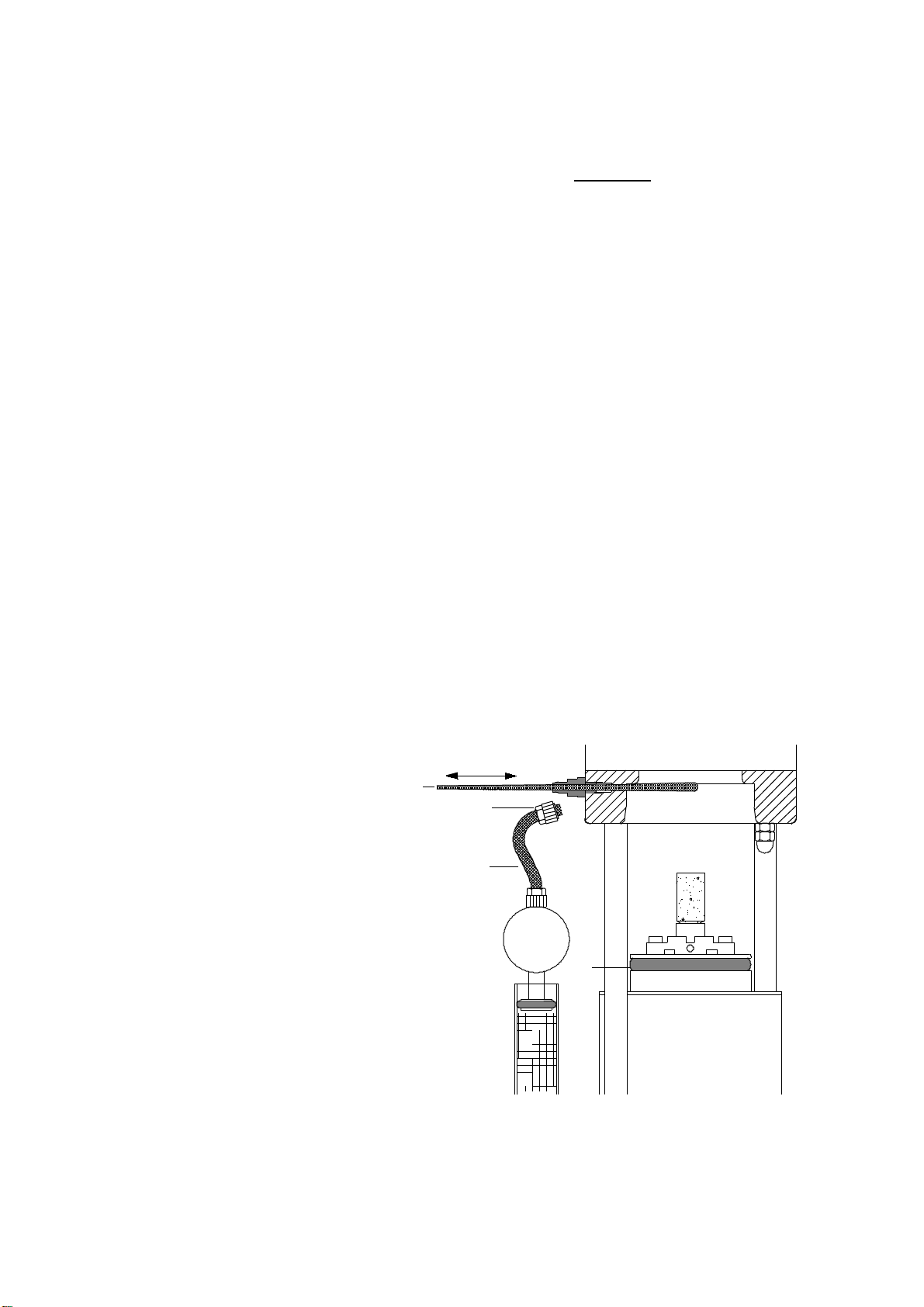

In this case open the furnace,

remove the tube ( 2 ) from the furnace outlet ( 1 )

and pass a pipe cleaner ( 3 ) through the

fitting ( 1 ) into the furnace area to

make sure that the hole is

completely free.

3

2

1

1-3

1

4

2002 by ELTRA GmbH Germany – January 2002 – Service Manual OH 900 / ON 900 / ONH 2000

1.4-1

1.4

1.4

The base line of the TC cell cannot be adjusted to zero

The baseline control of the TC-cell is different from the one for the IR-cell.

The values for the "low" and the "high" nitrogen ( or hydrogen, depending on the

instrument ) channels are produced by two different gain stages within one amplifier

connected to the TC detection cell.

The automatic base line control regulates the zero signal of the "high nitrogen" gain stage.

Only the high channel zero value appears on the display .

If the zero value of the "low nitrogen ( hydrogen )" channel is out of range, the electronic

board cannot control this signal to zero. In this case check the "high nitrogen (hydrogen)"

signal with

If the signal of the high channel is higher than ±0.4V, the low channel is out of range.

CAUTION :

Look for the reason of this drift! Adjust the flow rates or the thermostabilization, if

necessary.

If there is no fault, adjust the signal of the "high nitrogen ( hydrogen )" channel to zero

manually, see 2 .12

2002 by ELTRA GmbH Germany – January 2002 – Service Manual OH 900 / ON 900 / ONH 2000

1.5-1

1.5

1.5

Analysis time too long

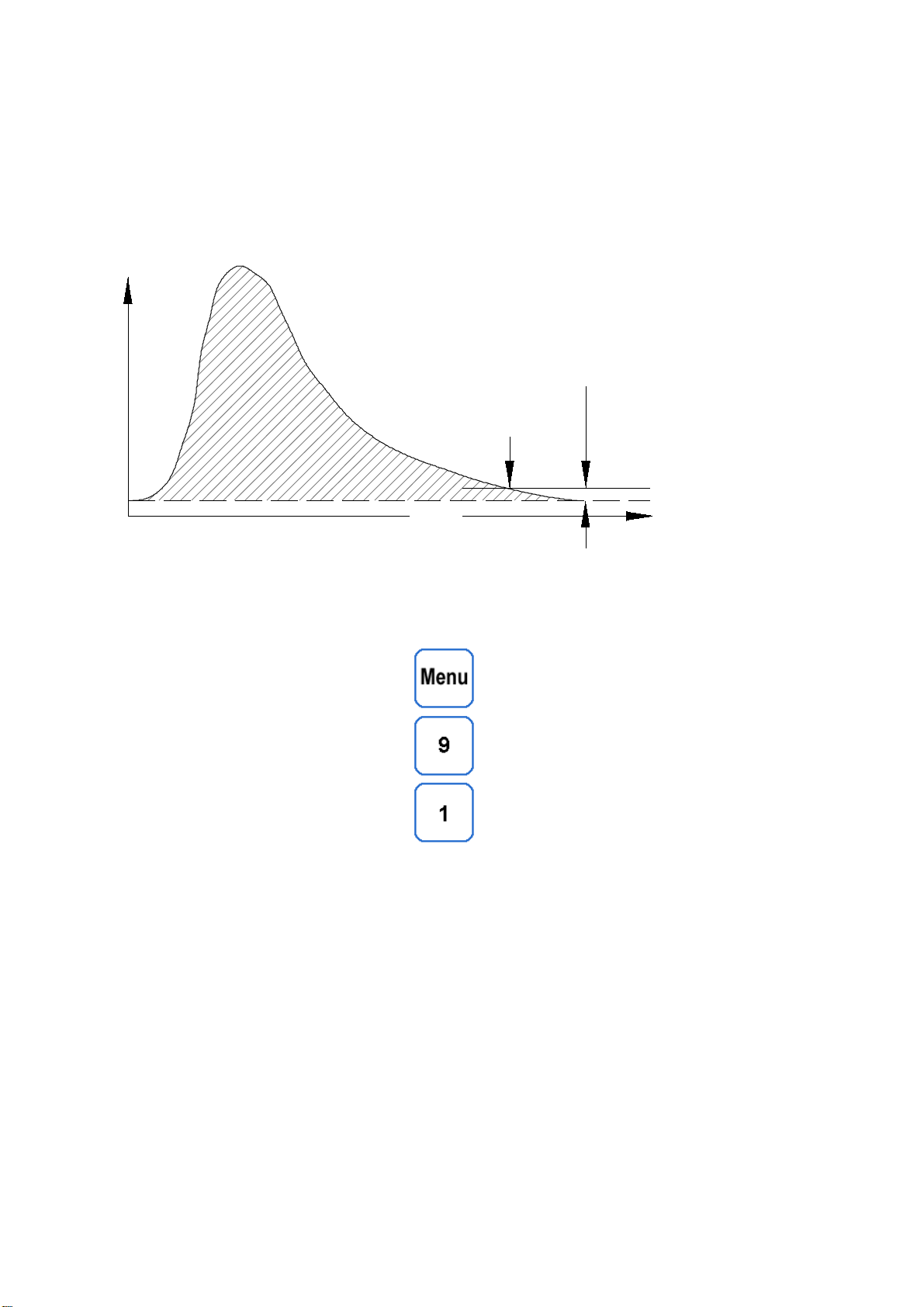

The instrument stops the analysis automatically, once the peaks of all activated ranges

have descended to the comparator level, ( see drawing below ).

The comparator level is an artificial zero level which can be adjusted and it is normally just

above the baseline.

If after a preset time, the signal stays higher than the comparator level, the analyser stops

and calculates the result. But this result may be inaccurate, because the peak wasn't

completely recorded.

With

you enter the menu for setting the comparator level.

The standard values for sensitive channels are 250 to 300 for the "low channel",

and 50 to 100 for the "high channel".

Before increasing the values check the following:

Thermostabilisation

Flow rates

Blank value ( a large blank value is a sign for a physical or chemical fault )

Check for gas leakage.

If above functions are OK, it is possible to increase the comparator level by 100 units.

time

Comparator level

Stop

IR output

2002 by ELTRA GmbH Germany – January 2002 – Service Manual OH 900 / ON 900 / ONH 2000

1.6-1

1.6

1.6

High blank value

It is impossible to avoid blank values, because oxygen and nitrogen are contents of the

air. But this blank value should not be higher than 5 to 10ppm.

Otherwise try the following :

Increase the flow rates to 40 / 70 l/h

Fasten the electrodes

Clean the furnace

Use a gas precleaning furnace, filled with copper

Connect a computer to watch the blank value peak and start an analysis without any

sample.

In some cases a small air volume remains in the threads under the lower electrode.

Screw the lower electrode out and fill a small amount graphite powder in. Screw the

electrode in. Repeat this procedure until it needs some force to screw the electrode

complete in.

If the base line of the detectors is unstable due to insufficient mains voltage

( less than 200V AC ), connect a voltage stabilizer ( see 3.14 ).

2002 by ELTRA GmbH Germany – January 2002 – Service Manual OH 900 / ON 900 / ONH 2000

1.7-1

1.7

1.7

Erratic results

The only way to check the repeatability, is to analyse standards. Watch the standard

deviation attested in the certificate of the standards.

Self-made standards are a cheap option to check the calibration in the user’s range.

The following faults cause erratic results :

Insufficient flow rates

Wrong or highly inconsistent blank value of the carrier gas

Damaged electrodes

Bad contact – see 1. 24

Check the electrodes and the flow rates first.

Delete the blank value as follows

Enter the channel number as required

Start analysis

To abort the blank value analysis press

Run five analyses cycles without sample, by entering 1000 mg manually.

The blank value should be 5 to 10 ppm. Otherwise see 1. 6.

Analyse a standard sample 5 times.

The standard deviation should be better than 1% or ± 3 ppm, whichever is higher.

2002 by ELTRA GmbH Germany – January 2002 – Service Manual OH 900 / ON 900 / ONH 2000

1.8-1

1.8

1.8

The LED for the temperature regulation of the infrared cell or the

thermoconductivity cell does not flash :

A ) IR - Cell

For detailed explanation, see 2. 5

Is it

higher or

lower than

5.25VDC? Replease

the TH61

Check the DC voltage

between Pin4 and Pin5

of the NR32 see 2.5 Check the

cable

see 1.8

Check the voltage

on the TP1 of NR32

See 2.5

Replace

the NR32

Adjust

see 2.5

Replace the

temperature sensor

200VDC

between Pin

4 and 5

of the NR32?

See 2.5

Replace

the TH61

Check the cable

connecting NR32 to

TH 61. See 1.8

220 VACZERO

Is it

220VAC

or zero?

Measure the AC

supply voltage to

of the NR32 (6-7)

see 2.5

Is it

around 200VDC

or zero?

20 0 VDC

Replace

the NR32

Replace the sensor when

the resistance is lower

than 6 kOhm

Is it

still always

on or off?

The LED of the IR Cell thermostatization

does not flash

YES

ZERO

NO YES

Check the DC voltage

between TP2 and TP1

on the TH 61 see 2.5

NO

Check the DC voltage

between TP2 and TP3

of the TH 61. See 2.5

Adjust around 5.25VDC

See 2.5

Check the cable

connecting NR32 to

TH 61. See 1.8

Check the 13 Pin plug

of the TH61. See 1.8

Remove the plastic cover

and check the cable

connections

Check the wiring see 4.2

Check the 13 Pin plug

of the TH61.

See 1.8

Remove the plastic

cover and check

the cable connections

Is the

voltage on

the capacitor

over 250VDC

or is it almost

zero?

NO

Measure the DC voltage

between TP2 and TP1

of the TH 61. See 2.5

Is

the LED

still always

off ?

200VDC

on the

heaters?

NO YES

Check the voltage of the

heaters see 2.5

The board

NR32 is ok

Is it

higher than

5.25V?

Is the

resistance

much lower than

6 kOhm?

Replace the TH61

NO

Replace

the TH61

Replace

the NR32

Measure the resistance

of the sensor

Check the connection

of the temperature

sensor in the 13 Pin

plug. See 1.8

>2 5 0VDCZERO

LO WER HIGHER

YES

YES

Measure the resistance

of the sensor

Check the connection

of the temperature

sensor in the 13 Pin plug.

See 1.8

Measure the voltage

on the capacitor 100µF

on the NR32 see 2.5

Adjust P1 on the TH61 board see 2.5

z e ro 20 0 VDC

About

200VDC or

zero?

O FF ON

Replace

the NR32

1-14

2002 by ELTRA GmbH Germany – January 2002 – Service Manual OH 900 / ON 900 / ONH 2000

1.8-2

Check that the cable is well connected to the plug, and that there are no short circuits

between the contacts in the 13 pin plug.

Inspect the spring contact ( 2 ) on the connector ( 1 ).

One of the contact threads ( 2 ) could have failed, or one of the connections ( 3 )

could be disconnected.

A look inside the plug ( 4 ) is recommended.

2

3

4

1-14-2

1

rt

sw

sw

123

6

4

3 4 8

ge/gn

ge/gn

swsw

2+15

3+16

25

22

bl

bl

1 5

1

3

5

7

9

10

11

12

1 3

gn

br

Temperature

sensor

200 VDC as long

as the LED is on.

No voltage as long

as the LED is OFF.

Heaters

13 Pin plug.

Remove the

plastic cover

and check the

cable connections.

PRI SEC

vi

sw

sw

rt

rt

vi

*

1-8-3

2 7

blue

brown

yellow

grey

green

orange

pink

red

black

violett

white

bl

br

ge

gr

gn

or

rs

rt

sw

vi

ws

2002 by ELTRA GmbH Germany – January 2002 – Service Manual OH 900 / ON 900 / ONH 2000

1.8-3

B ) TC - Cell

The set point is adjusted with trimmer No.1, turn clockwise to increase the temperature.

If the LED is not flashing 2 minutes after increasing the set point, exchange the cable to

the board TH 61 with the cable to the IR cell.

Check the board TH61 as described for the IR cell.

CAUTION :

The temperature's influence on the baseline of the TC cell is very high. Wait until the

baseline is stable before analysing. Use a computer to check the baseline.

TC CELL

312

2-12

04000

Other manuals for ON-900

1

This manual suits for next models

2

Table of contents

Other ELTRA Measuring Instrument manuals

ELTRA

ELTRA CS-2000 User manual

ELTRA

ELTRA CS-i User manual

ELTRA

ELTRA CS-800 User manual

ELTRA

ELTRA Thermostep TGA User manual

ELTRA

ELTRA ELEMENTRAC CS-i User manual

ELTRA

ELTRA ELEMENTRAC ONHp2 User manual

ELTRA

ELTRA CS-580A User manual

ELTRA

ELTRA CSi/d User manual

ELTRA

ELTRA CS-580A User manual

ELTRA

ELTRA CS-2000 User manual