Elsteam KT Series User manual

924KTE4.01 - 05/2021

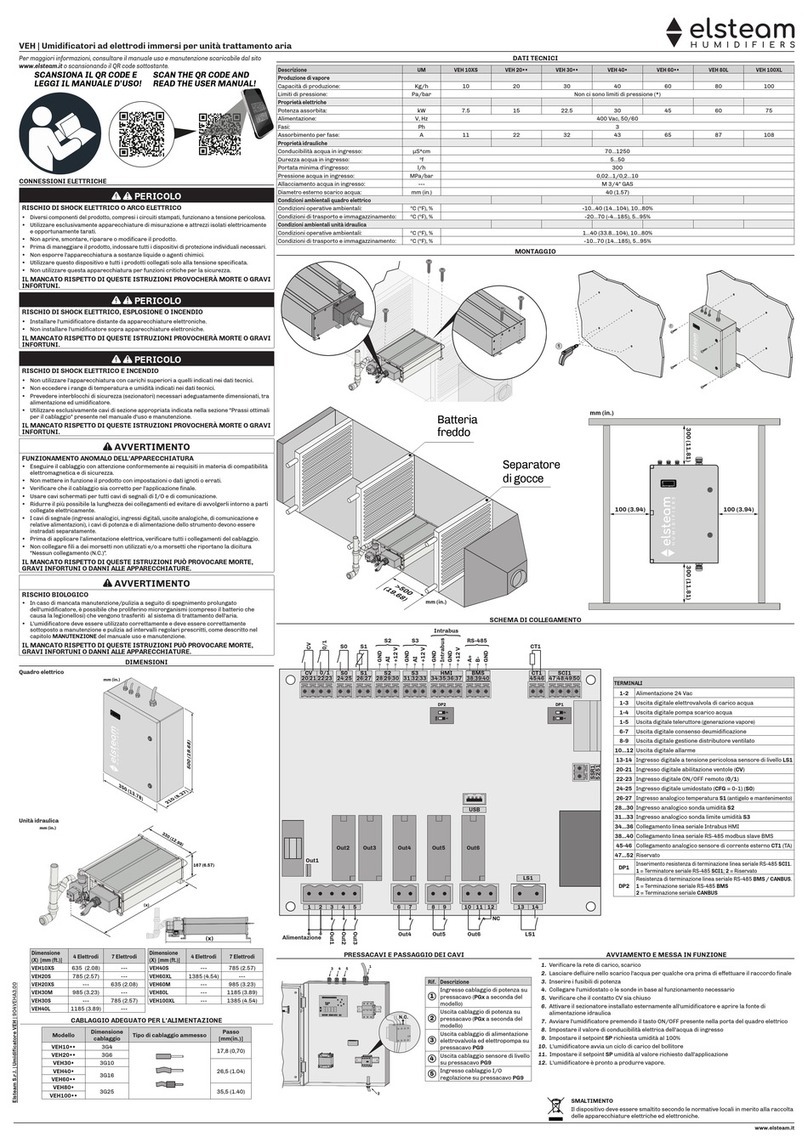

KT Series

Immersed electrode humidiers

CONTENTS

924KTE4.01 - KT series humidiers 05/2021

| 2 |

IMPORTANT INFORMATION.............................................................................................................. 4

IMPORTANT SAFETY INFORMATION................................................................................................ 5

SAFETY INFORMATION RELATING TO THE PRODUCT..................................................................... 6

1. INTRODUCTION............................................................................................................................... 7

1.1 Description.............................................................................................................................................. 7

1.2 Applications ............................................................................................................................................ 7

1.3 Main features ......................................................................................................................................... 7

1.3.1 Features of electronic control...................................................................................................................7

1.4 Accessories ............................................................................................................................................ 8

2. TECHNICAL DATA............................................................................................................................ 9

2.1 Technical specications........................................................................................................................ 9

3. DELIVERY OF PRODUCT................................................................................................................ 10

3.1 Checking the packaging.......................................................................................................................10

3.1.1 Opening the packaging..............................................................................................................................10

3.1.2 Checking the contents ..............................................................................................................................10

4. DIMENSIONS AND MECHANICAL ASSEMBLY........................................................................... 11

4.1 Dimensions............................................................................................................................................11

4.2 Minimum installation distances..........................................................................................................11

4.3 Installation............................................................................................................................................12

4.3.1 Installation instructions...........................................................................................................................12

5. INSTALLATION .............................................................................................................................. 13

5.1 Humidier parts ...................................................................................................................................13

5.1.1 Top ..............................................................................................................................................................13

5.1.2 Bottom ........................................................................................................................................................13

5.2 Water connections...............................................................................................................................13

5.2.1 Characteristics of water ..........................................................................................................................13

5.3 Water discharge system......................................................................................................................13

5.3.1 Characteristics of tting ..........................................................................................................................14

5.4 Steam distribution in an AHU or duct .................................................................................................14

5.4.1 Permitted positioning of the distributor in the duct ..............................................................................15

5.4.2 Examples of distributor installation in the duct .....................................................................................16

5.4.3 Distributing steam in the room ................................................................................................................17

6. ELECTRICAL CONNECTIONS........................................................................................................ 18

6.1 Before starting .....................................................................................................................................18

6.2 Connection best practices ..................................................................................................................18

6.2.1 Wiring best practices................................................................................................................................18

6.2.2 Replacing fuses - Fuse holder ..................................................................................................................20

6.2.3 Replacing fuses - Control board...............................................................................................................21

CONTENTS

924KTE4.01 - KT series humidiers 05/2021

| 3 |

6.3 Wiring diagrams ...................................................................................................................................22

6.3.1 Connection with ON/OFF humidistat .......................................................................................................22

6.3.2 Connection with humidistat with voltage output, ON/OFF and proportional......................................22

6.3.3 Connection with humidistat with resistive output .................................................................................23

6.3.4 Connection with humidistat which suspends humidication when ventilation is suspended...........23

7. USER INTERFACE AND INITIALISATION ................................................................................... 24

7.1 How the LEDs work...............................................................................................................................24

7.2 Switching on and starting up...............................................................................................................25

8. OPERATION.................................................................................................................................... 26

8.1 Regulating and calibrating the potentiometers ................................................................................26

8.2 Manual water discharge .....................................................................................................................26

9. MAINTENANCE.............................................................................................................................. 27

9.1 Introduction..........................................................................................................................................27

9.2 Periodical cleaning of the product and parts....................................................................................28

9.3 Cleaning the boiler ...............................................................................................................................29

9.4 Cleaning the optional stainless steel drain tank (accessory) 29

9.5 Replacing the boiler .............................................................................................................................29

9.6 Installing the boiler..............................................................................................................................29

10. SPARE PARTS .............................................................................................................................. 30

10.1 Hydraulics...........................................................................................................................................30

10.2 Electrics ..............................................................................................................................................31

11. WHAT TO DO IF............................................................................................................................ 32

12. WIRING DIAGRAMS................................................................................................................... 33

12.1 Models KT3 .........................................................................................................................................33

12.2 Models KT5-400..................................................................................................................................34

12.3 Models KT10-230 ...............................................................................................................................35

12.4 Models KT10-400 / KT20-400 ...........................................................................................................36

12.5 Models KT20-230 ...............................................................................................................................37

12.6 Models KT30-400 ...............................................................................................................................38

12.7 Models KT40-400 / KT60-400 ...........................................................................................................39

924KTE4.01 - KT series humidiers 05/2021

| 4 |

IMPORTANT INFORMATION

Liability and residual risks

ELSTEAM assumes no liability for any damage caused by the following (by way of example; this is not an exhaustive list):

• Installation/useforpurposesotherthanthosespeciedand,inparticular,notadheringtothesafetyprovisionssetout

by current regulations in the country in which the product is installed and/or contained in this manual;

• Useinappliancesthatdonotguaranteesufcientprotectionagainstelectricshocks,wateranddustwithinthe

installation conditions created;

• Useinappliancesthatallowaccesstohazardouspartswithouttheuseofakeyedortooledlockingmechanismwhen

accessing the instrument;

• Tampering and/or modifying the product;

• Installation/use in appliances which do not comply with current regulations in the country in which the product is

installed.

The customer/manufacturer is responsible for ensuring their machine complies with these regulations.

ELSTEAM’s responsibility is limited to the correct and professional use of the product in accordance with regulations and the

instructions contained in this manual and other product support documents.

TocomplywithEMCstandards,observealltheelectricalconnectioninstructions.Asitdependsonthewiringconfigurationas

wellastheloadandtheinstallationtype,compliancemustbeverifiedforthefinalmachineasspecifiedbytherelevantproduct

standard.

Disclaimer

This document is the exclusive property of ELSTEAM. It contains a general description and/or a description of the technical

specifications for the features offered by the products listed herein. This document should not be used to determine the

suitability or reliability of these products in relation to specific user applications. Each user or integration specialist should

conducttheirowncompleteandappropriateriskanalysis,inadditiontocarryingoutaproductevaluationandtestinrelation

to its specific application or use. Users can send us comments and suggestions on how to improve or correct this publication.

Neither ELSTEAM nor any of its associates or subsidiaries shall be held responsible or liable for improper use of the

information contained herein.

ELSTEAMhasapolicyofcontinuousdevelopment,thereforereservestherighttomakechangesandimprovementstoany

product described in this document without prior notice.

The images in this document and other documentation supplied with the product are provided for illustrative purposes only and

may differ from the product itself.

The technical data in this manual is subject to change without prior notice.

Terms and Conditions of use

Permitted use

The device must be used for humidification only.

Thedevicemustbeinstalledandusedinaccordancewiththeinstructionsprovidedand,inparticular,hazardouslivepartsor

high pressure water must not be accessible under normal conditions.

The device must be suitably protected from water and dust with regard to its application and must also only be accessible with

the aid of a tool.

Only qualified personnel may install the product or perform technical support procedures on it.

The customer must only use the product as described in the documentation relating to that product.

Prohibited use

Any use other than those described in the "Permitted use" section and in the product support documentation is prohibited.

Disposal

The device must be disposed of according to local regulations governing the collection of electrical and

electronic equipment.

Consider the environment

Thecompanystrivestorespecttheenvironment,takingaccountofcustomerrequirements,technological

innovations in terms of materials and the expectations of the community to which we belong. ELSTEAM places great

importanceonrespectingtheenvironment,encouragingallassociatestobecomeinvolvedwithcompanyvaluesand

guaranteeingsafe,healthyandfunctionalworkingconditionsandworkplaces.

Please consider the environment before printing this document.

924KTE4.01 - KT series humidiers 05/2021

| 5 |

IMPORTANT SAFETY INFORMATION

Readthisdocumentcarefullybeforeinstallationandtakeallprecautionsbeforeusingthedevice.Onlyusethedevicein

accordance with the methods described in this document. The following safety messages may be repeated several times in

thedocument,toprovideinformationregardingpotentialhazardsortoattractattentiontoinformationwhichmaybeusefulin

explaining or clarifying a procedure.

SYMBOLS

Thissymbolisusedtoindicateariskofelectricshock.

Itisasafetyindicationandassuch,shouldbeobservedtoavoidpotentialaccidentsorfatalities.

Thissymbolisusedtoindicateariskofseriouspersonalinjury.

Itisasafetyindicationandassuch,shouldbeobservedtoavoidpotentialaccidentsorfatalities.

Thissymbolisusedtoindicateariskofseriouspersonalinjury/burns.

Itisasafetyindicationandassuch,shouldbeobservedtoavoidpotentialaccidentsorfatalities.

SAFETY MESSAGES

DANGER

DANGER indicatesasituationofimminentdangerwhich,ifnotavoided,will result in death or serious injury.

WARNING

WARNING indicatesasituationofimminentdangerwhich,ifnotavoided,may result in death or serious injury.

CAUTION

CAUTION indicatesapotentiallyhazardoussituationwhich,ifnotavoided,could cause minor or moderate injury.

NOTICE

NOTICE indicates a situation not related to physical injuries but which

,ifnotavoided,

could damage the equipment.

N.B.:Themaintenance,repair,installationanduseoftheequipmentmustonlybeentrustedtoqualifiedpersonnel.

QUALIFIED PERSONNEL

Only suitably trained and experienced personnel capable of understanding the content of this manual and all documentation

regardingtheproductareauthorisedtoworkonandwiththisequipment.Furthermore,thepersonnelmusthavecompleted

coursesinsafetyandmustbeabletorecogniseandpreventtheimplieddangers.Thepersonnelmusthavesuitabletraining,

knowledgeandexperienceatatechnicallevel,andbecapableofanticipatinganddetectingpotentialriskscausedbyusing

theproduct,aswellaschangingthesettingsandmodifyingthemechanical,electricandelectronicequipmentfortheentire

systeminwhichtheproductisused.Allpersonnelworkingonandwiththeproductmustbeentirelyfamiliarwiththerelevant

standardsanddirectives,aswellassafetyregulations.

924KTE4.01 - KT series humidiers 05/2021

| 6 |

SAFETY INFORMATION RELATING TO THE PRODUCT

Beforecarryingoutanyworkontheequipment,readtheseinstructionscarefully,makingsureyouunderstandeverything.

DANGER

RISK OF ELECTRIC SHOCK, EXPLOSION OR ELECTRIC ARC

• Only use electrically insulated measuring devices and equipment.

• Do not install the equipment while the power supply is connected.

• Switchoffallequipment,includingconnecteddevices,beforeremovinganycoversorhatchesandbeforeinstallingor

uninstallinganyaccessories,hardware,cablesorwires.

• Usetherequiredsafetyinterlocks(disconnectors)ofasuitablesizebetweenthepowersupplyandthehumidifier.

• Alwaysuseacorrectlycalibratedvoltmetertocheckthesystemisswitchedoff.

• Themaintenance,repair,installationanduseoftheequipmentmustonlybeentrustedtoqualifiedpersonnel.

• Do not touch the unshielded components or the terminals while they are live.

• Donotopen,disassemble,repairormodifytheproduct.

• Do not expose the equipment to liquids or chemicals.

• Makesuretheequipmentisproperlyearthed.

• Before applying voltage to the equipment:

• Makesureallprotectiveelements,suchascovers,hatchesandgrilles,arefittedand/orclosed.

• Checkallwiringconnections.

DANGER

RISK OF ELECTRIC SHOCK AND FIRE

• Do not use the device with loads greater than those indicated in the technical specifications.

• Do not exceed the temperature and humidity ranges indicated in the technical specifications.

• Usetherequiredsafetyinterlocks(disconnectors)ofasuitablesizebetweenthepowersupplyandthehumidifier.

• Only use cables with a suitable cross-section as indicated in the section “Wiring best practices”.

WARNING

MALFUNCTIONING OF THE EQUIPMENT

• Performthewiringcarefully,incompliancewithelectromagneticcompatibilityandsafetyrequirements.

• Carry out a full start-up test.

• Makesurethewiringiscorrectforthefinalapplication.

• Minimise the length of the connections as much as possible and avoid winding the cables around electrically connected

parts.

• Beforeapplyingthepowersupply,checkallthewiringconnections.

• Do not connect wires to unused terminals and/or to terminals labelled “No connection “(N.C.)”.

Thehumidifierproducessteamat100°C(212°F)anddischargeswaterwithatemperatureofapproximately98°C(208.4°F).

WARNING

HOT STEAM

Do not touch the equipment when it is in operation.

WARNING

RISK OF BURNS

Beforecarryingoutanyworkonthesystem,disconnectthehumidifierandwaituntilithascooleddown(<50°C(122°F)).

WARNING

REGULATORY NON-COMPLIANCE

Makesurealltheequipmentusedandthedesignedsystemscomplywithcurrentlocal,regionalandnationalregulationsand

standards.

924KTE4.01 - KT series humidiers 05/2021

| 7 |

1. INTRODUCTION

1.1 Description

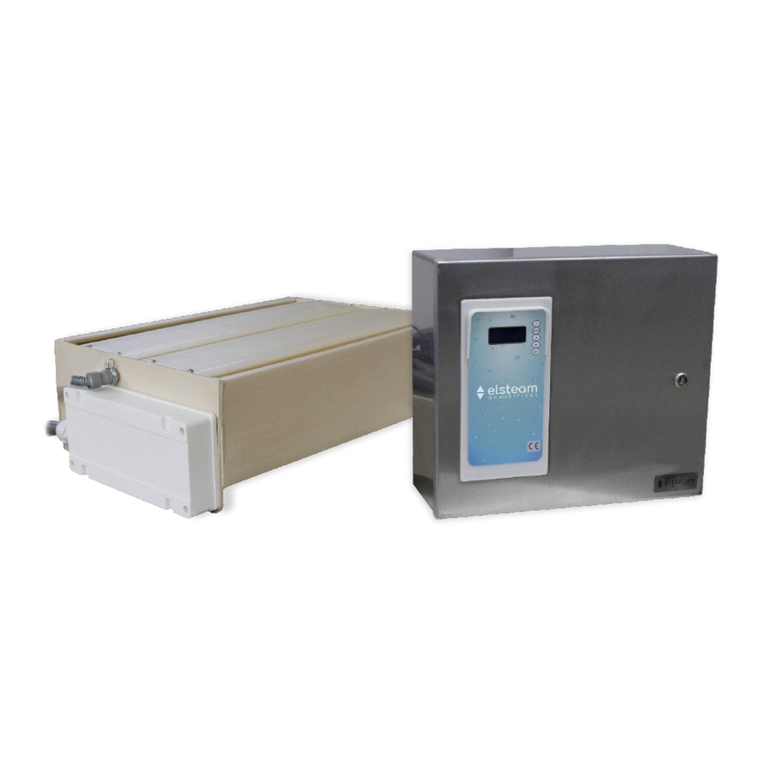

The KT series is a range of immersed electrode humidifiers by ELSTEAM.

The humidifiers in the KT series generate humidity (steam) when a current is applied to two or more electrodes immersed in tap

water,causingthewatertoboil.

Thesteamiscontrolledbymodulatingtheintensityofthecurrenttransferredtothewaterbytheimmersedelectrodes,soby

indirectly controlling the boiling water.

Steam is introduced into the room through a special flexible hose and a steam distributor in stainless steel and engineering

plastic (steam introduced into an AHU - air handling unit or an air conditioning duct) or a steam blower (steam introduced into

room).

1.2 Applications

The KT seriesismainlyusedwhensterilesteamisneeded,suchasin:

• Hospitals;

• Healthcare facilities;

• Commercialbuildings(ofces,factories,etc...)or;

• Wellness centres.

1.3 Main features

• Isothermalhumidier;

• Sterilesteam(atatemperatureofapprox.100°C(212°F));

• Automatic boiler cleaning;

• Automatic descaling of electrodes and boiler (reusable);

• Variablesteamoutput(3...60kg/h);

• Built-inelectroniccontrolusingON/OFFsignalor0...10V(proportional);

• Protectionagainstwaterescapingonthesteamside(oatingballwhichstopswaterleakingintothesteamsupplypipe);

• Stainlesssteeldrainagetankavailableonrequest.

1.3.1 Features of electronic control

• Proportional (logarithmic) control of steam production:

• Highlyefcient;

• Quickresponsetochangesinrequest;

• Accurate control of steam production.

• Automatic electrode and boiling cleaning system (international patent):

• Less maintenance required;

• High performance;

• Prolongs the life of the electrodes and boiler.

• Automatic boiler drainage:

• Removes any limescale which collects in the manifold sleeve;

• Prolongs the life of the boiler.

• LED signalling of operating status:

• Operating status always under control;

• Automatic fault analysis.

924KTE4.01 - KT series humidiers 05/2021

|8|

1.4 Accessories

The following accessories are available for the immersed electrode humidifiers in the KT series:

P/n Description

EHSD040 Linearsteamdistributor,400mm(15.75in.)

EHSD060 Linearsteamdistributor,600mm(23.62in.)

EHSD080 Linearsteamdistributor,800mm(31.49in.)

EHSD100 Linearsteamdistributor,1000mm(3.28ft)

EHSD130 Linearsteamdistributor,1300mm(4.26ft)

EHSD160 Linearsteamdistributor,1600mm(5.25ft)

EHSD200 Linearsteamdistributor,2000mm(6.56ft)

EHSDSP0 Linearsteamdistributor,lengthonrequest

EHSDY00

Yfitting,diameter38mm

EHSR0107

Steam blower for room

TV Special pipe fitting that connects the humidifier and distributor

VI Waterdrainagetank

EVHP523 Humidity probe 4-20 mA

EV3411M7 Universalcontrollerwith1outlet,powersupply230Vac

EVTPNW30F200 NTCtemperatureprobe,IP68

0031000048 Female3/4"Gflexiblehosetofeedwater

1240000004 Alarm electronic board

924KTE4.01 - KT series humidiers 05/2021

|9|

2. TECHNICAL DATA

2.1 Technical specifications

Description M.U. KT3 KT10-230 KT20-230 KT5 KT10 KT20 KT30 KT40 KT60

Steam production

Production capacity kg/h 3 10 20 5 10 20 30 40 60

Maximum pressure

MPa

(mmH2O)

0.002 (200)

Pipe connection external

diameter mm (in.) 40 (1.57)

Steam distribution

Number of linear distributors

that can be connected --- 1 1 2 1 1 1 1 2 2

Number of steam blowers that

can be connected --- 1 1 / 1 1 / / / /

Electrical properties

Power consumption kW 2.25 7.5 15 3.75 7.5 15 22.5 30 45

Power supply Vac,Hz 230V,50Hz 400V,50Hz

Phases Ph 1 3 3 2 3 3 3 3 3

Current per phase A 10 19 38 9 11 22 32 43 65

Water properties

Inlet water quality --- See "5.2.1 CHARACTERISTICS OF WATER" ON PAGE 13

Inlet water conductivity μS*cm 70…1250

Inlet water hardness °f 5...50

Inlet water pressure

MPa/bar

0.2...1/2...10

Inlet water connection --- 3/4"GAS

Water drain external dimensions

mm (in.) 42 (1.65)

General characteristics

Dimensions mm (in.) See "4.1 DIMENSIONS" ON PAGE 11

Weight kg 15 25 15 25

Hydraulic unit IP protection --- 20

Regulation

Type of controller --- Built-in

Command signal --- Proportional(0-10V)orON-OFF

Compliance

CE certification --- √

924KTE4.01 - KT series humidiers 05/2021

| 10 |

3. DELIVERY OF PRODUCT

3.1 Checking the packaging

• Checkthepackagingisintact;

• Checkthehumidierisintactupondeliveryandimmediatelynotifythecarrier,inwriting,ofanydamagethatmaybedue

to careless or improper transport (accept the goods subject to inspection).

3.1.1 Opening the packaging

• Movethepackagingtowherethehumidieristobeinstalled;

• Openthecardboardpackagingandremovetheprotectivepolystyrenecorners;

• Pullthehumidierout.

3.1.2 Checking the contents

Thepackagingcontains:

• KT serieshumidier;

• Operation and maintenance manual;

• Pipettingthatfeedswaterfromthemainstothehumidier’swaterloadsolenoidvalve;

• Hexkeytoopenthecabinet.

924KTE4.01 - KT series humidiers 05/2021

| 11 |

4. DIMENSIONS AND MECHANICAL ASSEMBLY

4.1 Dimensions

680 (26.77)

210 (8.26)

610 (21.01)

370 (14.57)

210 (8.26)

680 (26.77)

mm (in.)

KT40 400

KT60 400

KT10 ...KT5

KT10...KT3

KT5

Fig. 1. Dimensions

4.2 Minimum installation distances

WARNING

MALFUNCTIONING OF THE EQUIPMENT

• The humidifier must be installed where the minimum distances from all nearby structures and equipment can be

guaranteed,asshowninthismanual.

• Install all the equipment in accordance with the technical specifications given in the respective documentation.

mm (in.)

KT40 400

KT60 400

KT10 ...KT5

KT10...KT3

KT5

300 (11.81)

>1000 (39.36)

>1000 (39.36)

300 (11.81)300 (11.81) 300 (11.81) 300 (11.81)

300 (11.81)

Fig. 2. Minimum installation distances

924KTE4.01 - KT series humidiers 05/2021

| 12 |

4.3 Installation

2

1

3

4

2.2

2.1

56

Fig. 3. Installation instructions

N.B.: Installation of models KT40 / KT60 is the same as above.

4.3.1 Installation instructions

DANGER

RISK OF ELECTRIC SHOCK, EXPLOSION OR ELECTRIC ARC

Makesuretheequipmentisproperlyearthed.

NOTICE

IRREGULAR INSTALLATION

Usebracketswithaminimumload-bearingcapacityof80kgwheninstallingthehumidifier.

• OpenthepanelsofthehumidierbyremovingtheheadlessscrewswiththeSW2.5hexkey;

• Removethepanelsoneatatime,pullingthemtowardsyoufromthebottomandliftingthemup;

• Removethehumidierfromthepolystyrene;

• Hookthehumidierontothebracketsonthewallusingtheslotsattherearofthehumidier.

924KTE4.01 - KT series humidiers 05/2021

| 13 |

5. INSTALLATION

5.1 Humidifier parts

5.1.1 Top

• Steam outlet;

• Male3/4"GASconnectorforwatersupply.

5.1.2 Bottom

• Water outlet to connect to sewer system;

• Strain relief cable gland for power supply wiring;

• Strain relief cable gland for wiring of regulation board.

5.2 Water connections

You will need the following components to plumb in the humidifier:

• An intercept tap;

• Asupplementaryltertotheonealreadyinthesolenoidvalve;

• A pressure reducer (if the pressure of the mains water exceeds 1 MPa (10 bar)).

N.B.:Ifapressurereducerisused,makesureitiseffectiveanddoesnotcauseadrasticreductioninpressurewhenthemains

pressure is very low.

NOTICE

MALFUNCTIONING OF THE EQUIPMENT

• The feed water must have a minimum pressure of 0.2 MPa (2 bar).

• Connect the solenoid valve to the mains using the flexible hose supplied to reduce water hammers in the hose to the

humidifier.

• Duringinstallation,becarefulnottodamagetheplasticthreadofthesolenoidvalve.

• Whenmakingthewaterconnections,itmustalwaysbepossibletoaccessthemechanicalfilterinthewaterloadsolenoid

valve for cleaning.

5.2.1 Characteristics of water

• Water pressure between 0.2...1 MPa (2...10 bar);

• Temperaturebetween1...50°C(33.8...122°F);

• Conductivitybetween75...1250μS/cm;

• Maximum water hardness between 5...50 °f.

N.B.:Ifwaterisharderorifthereismoreorganicresidueinit,thehumidierwillstilloperatecorrectlybutitmustbeserviced

more regularly.

Dos

• Flushwaterintothedrainforacoupleofhoursbeforemakingthenalconnection.

• Checktheconditionoftherubbercouplingregularlytopreventproblemsandwaterleakingintotheroom.

Don’ts

• Softenthewater.Ifthewaterhardnessisabove50°forifitissuchthattheboilerrequiresregularmaintenance,use

demineralisedwatermixedwithtapwaterinapercentagethatensuresaminimumconductivityof200μS/cmanda

hardness of at least 10 °f.

NOTICE

MALFUNCTIONING OF THE EQUIPMENT

• Do not use softened water.

• Oncethehumidifierhasbeeninstalled,flushthepipeswiththeremainingwatertopreventblockingthefilter.

• Checkallthepartsofthehumidifierareintact.

• Ifevenonepartofthehumidifierisdamaged,suspendinstallation.

5.3 Water discharge system

Asthishumidifierhasanautomaticboilercleaningfunction,thewateroutletmusthaveacapacityofatleast10litresinafew

seconds (maximum 1 l/s).

NOTICE

MALFUNCTIONING OF THE EQUIPMENT

Sizetheoutletpipetopreventobstructionsorblockagesduringtheautomaticcleaningcycle.

924KTE4.01 - KT series humidiers 05/2021

| 14 |

5.3.1 Characteristics of fitting

• Minimum diameter 40 mm (1.57 in.);

• Maximumradiusofcurvature300mm(0.98ft.);

• Minimum average slope of 45° with no siphons.

Ifthesecharacteristicscannotberespected,abasinmust

be placed at the bottom of the humidifier to collect water and

limescale (p/n VI) (contact ELSTEAM’s sales office for more

information).

Features of basin

• Drainage pipe with siphon to collect limescale.

NOTICE

MALFUNCTIONING OF THE EQUIPMENT

Ifthewaterisharderthan40°f,thebasinmustbechecked

and cleaned at least twice a year.

Minima 45°

Fig. 4. Drainage pipe

If the water hardness is the same as indicated in the section "5.2.1 CHARACTERISTICS OF WATER" ON PAGE 13,

,thebasincanbe

cleaned once a year.

Ifthedrainagesystem-orthebasin-ismadeofanelectricallyconductivematerial,asasafetymeasureitmustbeconnected

to the earthing of the electrical system.

DANGER

RISK OF ELECTRIC SHOCK

Ifthebasinismadeofanelectricallyconductivematerial,eartheitherthebasinorthedrainagesystem.

Theoutletwatercanreachatemperatureof98°C(208.4°F)orhigher.

WARNING

RISK OF BURNS

• Beforedrainingwater,makesureyouarewearingallthenecessarypersonalprotectiveequipment(PPE).

• Do not touch the equipment during draining.

5.4 Steam distribution in an AHU or duct

The humidifier must be connected to a stainless steel steam distributor with a fixing flange in engineering plastic in order to

distribute steam in the ventilation system.

The steam distributor must be installed:

• Vertically;

• At least one metre from the top of the duct;

• At the bottom of the duct (so the steam can mix properly with the air);

• Higherthanthehumidieroutlet;

• Ascloseaspossibletothehumidier(topreventreducedefciency).

Thesectionoftheductwherethesteamdistributorisinstalledmustbeinsulated,waterproofandhaveadrainatthebottom.

The insulated pipe fitting between the humidifier and the distributor must not be fitted with siphons and must always slope

down towards the humidifier to ensure the condensate runs freely in the machine.

WARNING

MATERIAL DETERIORATION

• The special steam piping must be fixed to the boiler and stainless steel ramp with stainless steel ties.

• Only use material suitable for the intended use.

924KTE4.01 - KT series humidiers 05/2021

| 15 |

5.4.1 Permitted positioning of the distributor in the duct

Horizontal installation

Fig. 5. Horizontal installation - 1 distributor

Fig. 6. Horizontal installation - 2 distributors

Vertical installation

Fig. 7. Vertical installation - 1-2 distributors

924KTE4.01 - KT series humidiers 05/2021

| 16 |

Horizontal installation - Wide duct

Fig. 8. Horizontal installation with wide duct - 2 distributors

5.4.2 Examples of distributor installation in the duct

Description Example

Installation example no. 1

Distributorisinstalledinahorizontalduct,positioned

higher than the humidifier.

Direction of air flow is not relevant.

Installation example no. 2

Distributor is installed in a vertical duct.

Direction of air flow is not relevant.

Installation example no. 3

Distributorisinstalledverticallyinahorizontalduct,

positioned higher than the humidifier.

Direction of air flow corresponds to the slope of the

ramp.

924KTE4.01 - KT series humidiers 05/2021

| 17 |

Description Example

Installation example no. 4

Distributorisinstalledinahorizontalduct,positioned

lower than the humidifier.

Example of incorrect installation

Itisimportanttoavoidcondensationpocketsinthe

supply pipe.

5.4.3 Distributing steam in the room

A steam blower p/n ESR010700 mustbeinstalledifsteamistobedistributedintheroomwithoutusingventilationducts.For

moreinformation,visitwww.elsteam.it.

Thesteamblowermustbepositionedhorizontally,withthedistributionholesaimedupwards,atleastonemetrefromthe

ceiling and walls.

WARNING

RISK OF BURNS

The steam blower must be installed so it is accessible to qualified personnel only.

WARNING

HOT STEAM

Do not touch the equipment when it is in operation.

Itmustbepositionedatleastonemetrefromtheceiling(3.28ft.).

Steam blower power supply

Steam blowers:

• Single-phase 230 Vac models: Powered directly by the fuse holder.

• Three-phase models: Powered directly by the 230 Vac mains voltage.

924KTE4.01 - KT series humidiers 05/2021

|18|

6.1 Before starting

Read this manual carefully before installing the equipment.

Inparticular,thesafetyinstructions,electricalrequirementsandcurrentregulationsforthemachineortheprocessinwhich

this device is involved must be observed.

The use and application of the information contained herein require experience in the design and installation of humidification

systems.Onlytheuser,systemintegratorormachinebuildercanbeawareofalltheconditionsandfactorspresentduringthe

installation,configuration,operationandmaintenanceofthemachineorprocess,andcanthereforedeterminetheassociated

automationequipmentandtherelatedsafetiesandinterlockswhichcanbeeffectivelyandproperlyused.Whenselecting

automationandcontrolequipmentandanyotherrelatedequipmentorsoftwareforaparticularapplication,alwaysconsider

alltheapplicablelocal,regionalornationalstandardsand/orregulations.

DANGER

RISK OF ELECTRIC SHOCK, EXPLOSION OR ELECTRIC ARC

• Only use electrically insulated measuring devices and equipment.

• Do not install the equipment while the power supply is connected.

• Switchoffallequipmentandremovethepowerfuses,includinganyconnecteddevices,beforeremovinganycoversor

hatches,orbeforeinstallingoruninstallingaccessories,hardware,cablesorwires.

• Usetherequiredsafetyinterlocks(disconnectors)ofasuitablesizebetweenthepowersupplyandthehumidifier.

• Alwaysuseacorrectlycalibratedvoltmetertocheckthesystemisswitchedoff.

• Themaintenance,repair,installationanduseoftheequipmentmustonlybeentrustedtoqualifiedpersonnel.

• Do not touch the unshielded components or the terminals while they are live.

• Donotdisassemble,repairormodifytheproduct.

• Do not expose the equipment to liquids or chemicals.

• Makesuretheequipmentisproperlyearthedandifitisnot,earthit.

• Before applying voltage to the equipment:

• Makesureallprotectiveelements,suchascovers,hatchesandgrilles,arefittedand/orclosed.

• Checkallwiringconnections.

WARNING

REGULATORY NON-COMPLIANCE

Makesurealltheequipmentusedandthedesignedsystemscomplywithcurrentlocal,regionalandnationalregulationsand

standards.

6.2 Connection best practices

6.2.1 Wiring best practices

DANGER

RISK OF ELECTRIC SHOCK AND FIRE

• Do not use the device with loads greater than those indicated in the technical specifications.

• Do not exceed the temperature and humidity ranges indicated in the technical specifications.

• Usetherequiredsafetyinterlocks(disconnectors)ofasuitablesizebetweenthepowersupplyandthehumidifier.

• Only use cables with a suitable cross-section as indicated in the section “Wiring best practices”.

Whenwiringthehumidifiers,observethefollowinginstructions:

• Makesuretheoperatingenvironmentandconditionsfallwithinthespeciedvalues.

• Usecablesofthecorrectdiameter,suitedtothevoltageandcurrentrequirements.

DANGER

LOOSE WIRING CAN RESULT IN ELECTRIC SHOCK AND OVERHEATING

Tighten connections in compliance with the technical specifications for torque values.

WARNING

MALFUNCTIONING OF THE EQUIPMENT

• Performthewiringcarefully,incompliancewithelectromagneticcompatibilityandsafetyrequirements.

• Carry out a full start-up test.

• Makesurethewiringiscorrectforthefinalapplication.

• Minimise the length of the connections as much as possible and avoid winding the cables around electrically connected parts.

• Beforeapplyingthepowersupply,checkallthewiringconnections.

• Do not connect cables to unused terminals and/or to terminals labelled “No connection “(N.C.)”.

6. ELECTRICAL CONNECTIONS

924KTE4.01 - KT series humidiers 05/2021

|19|

WARNING

REGULATORY NON-COMPLIANCE

Makesurealltheequipmentusedandthedesignedsystemscomplywithcurrentlocal,regionalandnationalregulationsand

standards.

Suitable wiring for power supply

Pitch 17,8 mm (0.70 in.)

Ø 3.5 mm (0.14 in.)

mm2

AWG

No. of conductors

2.5 2.5 2.5

13 13 13

3

mm

in.

7

0.28 C2,5

22.12

N•m

lb-in

Fig. 9. Suitable wiring for power supply - KT3

Pitch 17,8 mm (0.70 in.)

Ø 3.5 mm (0.14 in.)

mm2

AWG

No. of conductors

1.51.5 1.5

15 15 15

4

mm

in.

7

0.28 C2,5

22.12

N•m

lb-in

Fig. 10. Suitable wiring for power supply - KT5

Pitch 17,8 mm (0.70 in.)

Ø 3.5 mm (0.14 in.)

mm2

AWG

No. of conductors

4

mm

in.

7

0.28 C2,5

22.12

N•m

lb-in

2.5 2.5 2.5

13 13 13

Fig. 11. Suitable wiring for power supply - KT10 400 V

Pitch 17,8 mm (0.70 in.)

Ø 3.5 mm (0.14 in.)

mm2

AWG

No. of conductors

6

9

6

9

6

9

4

mm

in.

7

0.28 C2,5

22.12

N•m

lb-in

Fig. 12. Suitable wiring for power supply - KT10 230 V

Pitch 17,8 mm (0.70 in.)

mm2

AWG

No. of conductors

16

5

4

16

5

16

5

mm

in.

7

0.28

KT20 400

KT20 230 V / KT30

Ø 3.5 mm (0.14 in.)CN•m

lb-in

Ø 3.5 mm (0.14 in.)C3

26.55

N•m

lb-in

2,5

22.12

Fig. 13. Suitable wiring for power supply - KT20 400 V / KT20 230 V / KT30

Pitch 17,8 mm (0.70 in.)

mm2

AWG

No. of conductors

25

7

4

25

7

25

7

mm

in.

7

0.28

KT40

Ø 3.5 mm (0.14 in.)C4

35.40

N•m

lb-in

Fig. 14. Suitable wiring for power supply - KT40

Pitch 17,8 mm (0.70 in.)

Ø 3.5 mm (0.14 in.)

mm2

AWG

No. of conductors

35 + 25 35 + 25 35 + 25

2 + 32+ 32 + 3

3 (35) + 1 (25)

mm

in.

7

0.28 C4

35.40

N•m

lb-in

Fig. 15. Suitable wiring for power supply - KT60

N.B.: For models KT3 / KT5 / KT10 / KT10 230 / KT20wiringisdirectlyatthefuseholder,whilefortheothermodelsitis

directly at the disconnector.

924KTE4.01 - KT series humidiers 05/2021

| 20 |

Suitable protective devices for power supply

DANGER

RISK OF ELECTRIC SHOCK

• Switchoffallequipment,includinganyconnecteddevices,beforeremovinganycoversorhatches,orbeforeinstallingor

uninstallingaccessories,hardware,cablesorwires.

• Alwaysuseacorrectlycalibratedvoltmetertocheckthesystemisswitchedoff.

Current

KT3KT5 KT10

Type

Dimension

16 16 16

Fast FastFast

10x38 10x38 10x38 10x38 10x38

KT20

32

Fast

KT10 230 V

32

Fast

Fig. 16. Overload protection devices according to model

6.2.2 Replacing fuses - Fuse holder

12

34

5

Fig. 17. Overload protection devices

N.B.: Only for models KT3/KT5/KT10/KT10 230/KT20 400.

This manual suits for next models

9

Table of contents

Other Elsteam Humidifier manuals

Elsteam

Elsteam VEH Series Installation and operating instructions

Elsteam

Elsteam VEH Series User manual

Elsteam

Elsteam MISTRAL User manual

Elsteam

Elsteam HPN Series Operating instructions

Elsteam

Elsteam ZEPHYR EHKT003M2 User manual

Elsteam

Elsteam AHU-VEH User manual

Elsteam

Elsteam REH4 Installation and operating instructions

Elsteam

Elsteam UH06-OEM Operating instructions

Elsteam

Elsteam KT User manual

Elsteam

Elsteam VEH20 Series User manual