Elsteam HPN Series Operating instructions

HPN SERIES

HIGH PRESSURE PROPORTIONAL HUMIDIFIER

CENTRAL UNITS, SOLENOIDS CARDS AND

DISTRIBUTION RACK

USER, INSTALLATION AND MAINTENANCE GUIDE

Ver. 21.1.EN

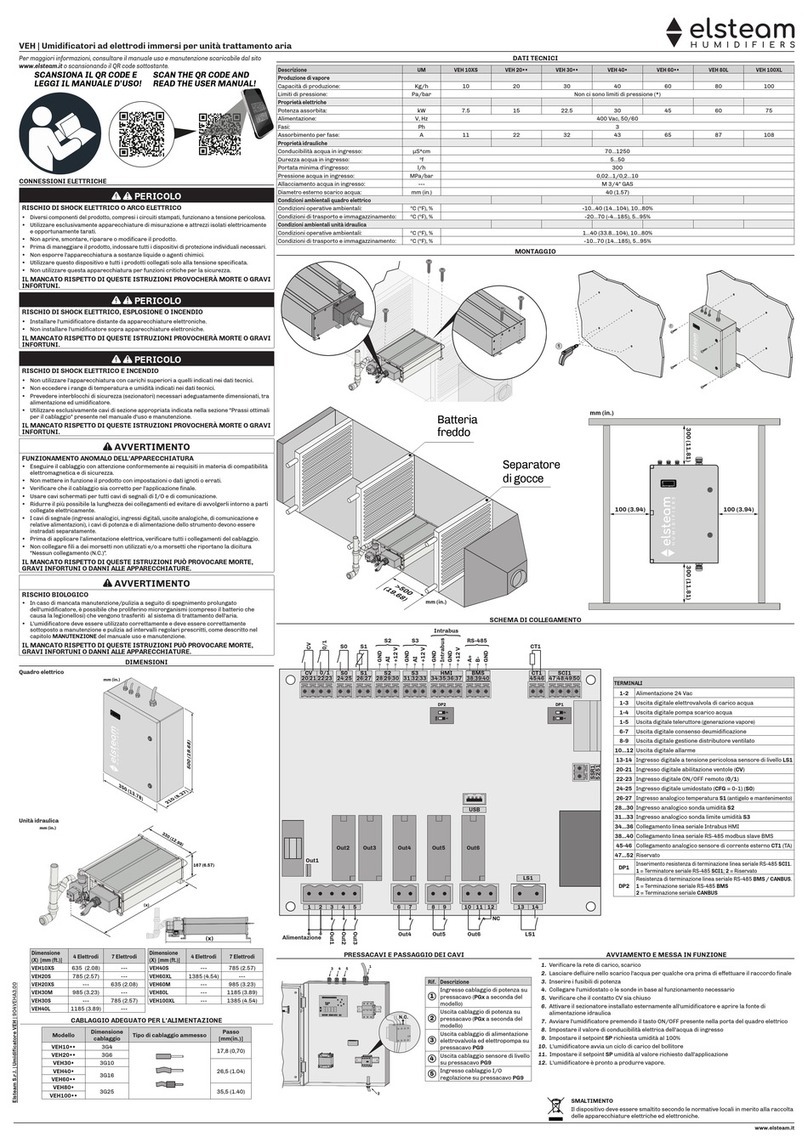

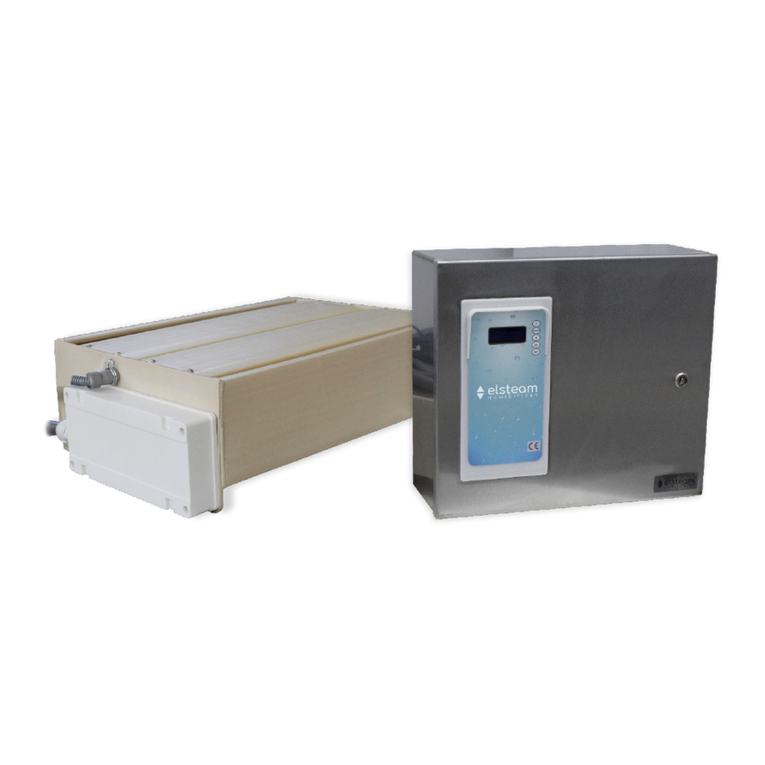

MAIN UNIT

HPNCTRL

DISTRIBUTION RACK

HighPressure Humidifier - Constant Pressure

21.1.EN

2

Elsteam S.r.l - via E.fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it - Web: http://www.elsteam.com

TOC

1PACKAGE CONTENT..................................................................................................................................................... 3

2SAFETY MEASURES..................................................................................................................................................... 3

2.1 GROUND CONNECTION ......................................................................................................................................................3

2.2 THERMO-HYGROMETRIC CONDITIONS OF THE INSTALLATION ..........................................................................................3

2.3 ELECTRICAL CONNECTIONS ..............................................................................................................................................3

2.4 HYDRAULIC CONNECTIONS ...............................................................................................................................................3

2.5 WASTE DISPOSAL .............................................................................................................................................................4

2.6 WARRANTY........................................................................................................................................................................4

3MANUFACTURER ......................................................................................................................................................... 4

4WORKING PRINCIPLE.................................................................................................................................................. 5

5CHARACTERISTICS ..................................................................................................................................................... 6

6INSTALLATION PRINCIPLES...................................................................................................................................... 7

7INSTALLATION.............................................................................................................................................................. 8

7.1 MAIN UNIT ........................................................................................................................................................................8

7.2 HPNCTRL ........................................................................................................................................................................8

7.3 DISTRIBUTION RACK .........................................................................................................................................................8

7.4 DROPLET SEPARATOR........................................................................................................................................................9

7.5 HYDRAULICS CONNECTIONS..............................................................................................................................................9

7.6 ELECTRICAL CONNECTIONS ........................................................................................................................................... 10

7.7 SETTING OF THE BYPASS CONTROL VALVE ..................................................................................................................... 11

8MAINTENANCE ...........................................................................................................................................................11

9ELECTRONIC CONTROLLER .....................................................................................................................................12

9.1 NORMAL OPERATION DISPLAY .................................................................................................................................... 12

9.2 ELECTRONIC CONTROLLER BASIC PROGRAMMING ........................................................................................................ 12

9.3 ELECTRONIC CONTROLLER ADVANCED PROGRAMMING (ONLY FOR MAINTENANCE/FITTER) ....................................... 14

10 ALARM MESSAGES................................................................................................................................................16

11 CONNECTIONS DIAGRAM ....................................................................................................................................17

HighPressure Humidifier - Constant Pressure

21.1.EN

3

Elsteam S.r.l - via E.fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it - Web: http://www.elsteam.com

Please before using your equipment read this guide carefully, by noting all the precautions and safety

instructions reported in it. Keep your equipment in good operative conditions.

Familiarize with the working and security instructions related to the operation of your apparatus before

trying to make it function. Keep this guide and any other booklet provided with your apparatus to be able

to refer to them later.

1Package content

The High Pressure Humidifier package is composed of:

◊The high pressure humidifier central unit

◊This user guide

◊The high pressure pump user manual

◊The inverter user manual

◊A yellow cap for the pump oil to replace the red one (to be used only for transport)

2Safety measures

People who are not familiar with this type of apparatus or which did not read attentively this guide do not

have to be authorized to use the humidifier.

The humidifier is designed to be used on alternative 220Vac 50/60 Hz only. Do not try to connect it to a

different type of supply. Check that the sector supply voltage corresponds to that of the apparatus.

The humidifier must always be switched-off before any maintenance operations.

All operations of maintenance and repairs must be carried out by the manufacturer, his technical service

or any other qualified personnel to avoid any problem.

Do not cover any opening of the humidifier and do not insert objects in the openings

2.1 Ground Connection

The first operation of each installation is the correct ground connection for the equipment, following the

safety regulations of the state and at the time when the equipment is installed.

2.2 Thermo-hygrometric conditions of the installation

Check that the environmental conditions of the place where the installation is carried out are always

compatible with the requirements of the product as indicated in this manual. ELSTEAM products cannot

be installed exposed to weather conditions or frost, unless different conditions explicitly expressed in

countersigned documents.

2.3 Electrical Connections

ELSTEAM equipment must be connected to the power supply by carefully following the local regulations

and the specifications on the plates of the equipment.

In particular, it is mandatory that the power supply lines have a correct section and are equipped with a

standard disconnecting switch with differential safety (life-saving device) capable of protecting the user

not only against the device, but also against the power lines installed.

2.4 Hydraulic Connections

ELSTEAM equipment needs to be connected to the water supply. Supply water shall comply with

microbiological requirements of the German Drinking Water Ordinance (TrinkwV). Only ELSTEAM HPN

DEMI humidifier complies with VDI6022 certification when using reverse osmosis water (not in contact

with drinking-water mains). Should the unit be installed using normal water the installer must use a VDI

6022 non return valve to be still compliant.

It is necessary to strictly comply with the local actives regulations (for installation) and make sure that

any breakages or water leaks deriving from the installation or from the units itself cannot cause damage

to the environment or to third parties. Do not install the equipment on passageways or over dangerous or

susceptible objects and always provide special drainage systems that can evacuate any spilled water

HighPressure Humidifier - Constant Pressure

21.1.EN

4

Elsteam S.r.l - via E.fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it - Web: http://www.elsteam.com

correctly.

2.5 Waste Disposal

Directive 2002/96 / EC of the European Parliament and the related national regulations impose the

obligation not to dispose of WEEE as urban civil waste, but to prepare a special collection for outdated

parts of the humidifier.

The purchaser has the right to return the disused humidifier to ELSTEAM srl in case of purchase of an

equivalent humidifier. ELSTEAM will arrange for its own disposal or through its appointees.

The disposal of electrical or electronic components in an abusive manner and not in compliance with

current regulations involves penalties.

2.6 Warranty

ELSTEAM Srl recognizes on its products the legal guarantees in force at the time of sale of the product.

Incorrect use and lack of maintenance entail the automatic forfeiture of any form of guarantee.

3Manufacturer

Manufacturer

ELSTEAM S.r.l.

Via ENRICO FERMI 496, 21042 CARONNO PERTUSELLA (VA) - ITALY

Contact

Tel.: (0039) 029659890

Fax: (0039) 0296457007

Email: info@elsteam.it

Web: www.elsteam.com

HighPressure Humidifier - Constant Pressure

21.1.EN

5

Elsteam S.r.l - via E.fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it - Web: http://www.elsteam.com

4Working principle

The high-pressure humidifier performs an adiabatic humidification by atomization of softened water or

standard water at high pressure.

The system is composed by a central unit, a network control unit (HPNCTRL), a distribution rack and the

droplet separator (at the end of the humidification section, only for AHU installation).

The central unit maintains the pressure in the distribution network at a constant value (established based

on the model of nozzles used) as the number of active network sections varies.

The HPNCTRL, for proportional control of the distribution network, is installed in the environment to be

humidified or inside the AHU, managing section solenoids to make proportional production and

feed/drain solenoids to activate/empty the distribution network. One HPNCTRL must be installed for each

zone to control. The HPNCTRL card receive proportional or ON/OFF signal from the controlling system

and provide signals to the distribution networks solenoids and to the central unit. The HPNCRTL unit

opens the drain solenoid to empty the distribution rack when the control signal is 0.

The droplet eliminator is used to stop the droplets of water that are not completely evaporated before

they enter in the duct.

5Characteristics

TECHNICAL DATA

Code

HPN2L

DEMI

HPN3L

DEMI

HPN4L

DEMI

HPN5L

DEMI

HPN6L

DEMI

HPN7L

DEMI

HPN8L

DEMI

HPN9L

DEMI

HPN11L

DEMI

HPN14L

DEMI

SPRAY PRODUCTION

Max. Capacity

[l/h]

120

180

240

300

360

420

480

540

660

840

Max Pressure

[Mpa/bar

]

8/80 8/80 8/80 8/80 8/80 8/80 8/80 8/80 8/80 8/80

DISTRIBUTON RACK

Code

HPN2RA

CKxxx

HPN3RA

CKxxx

HPN4RA

CKxxx

HPN5RA

CKxxx

HPN6RA

CKxxx

HPN7RA

CKxxx

HPN8RA

CKxxx

HPN9RA

CKxxx

HPN11R

ACKxxx

HPN14R

ACKxxx

Max. Nozzles

(8l/h)

[n]

15

22

30

37

45

52

60

67

82

105

ELECTRICAL CONNECTIONS

Power [kW]

[kW]

1.5

1.5

1.5

1.5

1.5

1.5

2.2

2.2

4

4

Phases

[Vac, Hz]

1

3

Voltage

[n]

230V, 50/60Hz

400V, 50/60Hz

HYDRAULIC CONNECTIONS

Inlet water quality

---

Supply water shall comply with microbiological requirements of the German Drinking Water

Ordinance (TrinkwV). Supply water must be totally or partially demineralized by drinking water.

Should the unit be installed using normal water, the installer must use a VDI 6022 non-return

valve to be still compliant.

Inlet water

conductivity

μS*cm

0...100

Inlet water

hardness

°F

0...5

Input Pressure

[MPa/ba

r]

0,02...0,7 / 0,2...7

Water inlet

connection

---

M 3/4"GAS

Water drain

connection

---

M 1/4"GAS

HUMIDIFIER CONTROL

Control

---

Integrated on hydraulic module, remote on distribution rack

Control Signals

---

4…20mA (internal controller), 0-10V or ON-OFF (external signal)

MECHANICAL DATA

Dimensions

(WxHxD

[mm])

515x480x335 615x480x335

Weight (kg)

[kg]

50

IP protection

(Main Unit)

---

20

IP protection

(Distribution Rack)

---

40

Droplet Separator

HPNDROPxxx (optional)

CONFORMITY

CE

---

√

√

√

√

√

√

√

√

√

√

VDI6022

---

√

√

√

√

√

√

√

√

√

√

6Installation Principles

The figure below shows the basic working principle of the proportional humidifier. The output signal of

the humidistat (0-10V) controls the solenoids controlled card (for proportional working mode) as well as

the activation (threshold set at 1V) of the high pressure system.

The following figure shows instead an implementation of an installation with the network of nozzles split in

three sections with 33% and 66% thresholds.

HighPressure Humidifier - Constant Pressure

21.1.EN

8

Elsteam S.r.l - via E.fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it - Web: http://www.elsteam.com

7Installation

7.1 Main unit

The cabinet of the humidification system must be installed in a ventilated and protected place. It must be

placed on a flat and stable surface. For a correct use and operation, as well as for an easy maintenance,

leave enough free space around the machine. To enable the correct ventilation of the unit is necessary to

ensure a free space of at least 20 cm close to the perforated panel for ventilation, which is located on the

right wall of the machine.

Do not place the machine in dangerous and/or explosive/inflammable places.

After installation the red cap of the oil tank, used for the transport, must be replaced by the yellow one,

used for normal working operation, provided with the system.

The access internal parts of the cabinet remove screws that secure the top and side panels.

7.2 HPNCTRL

The HPNCTRL card must be installed close to the distribution rack.

Electrical connections scheme is reported at the end of the document. Electrical connections to the high-

pressure solenoids (section, feed and drain) and main unit must be realised respecting local regulation.

The HPNCRTL card receives the regulation signal (ON/OFF or Proportional).

The HPNCRTL unit opens the drain solenoid to empty the solenoids lines when the control signal is 0.

7.3 Distribution rack

The case of the rack must be installed external to the AHU and fixed using dedicates holes. Hydraulic

connections to the rack (high pressure water input and drain) are respectively on the top and bottom of

the case. Three holes must be realised into the sandwich panel to let nozzles lines enter the AHU. When

mounting the nozzle lines a slope towards the case must be realised. This slope allows the lines to empty

totally when the system is off.

The rack must be installed in direct contact (thermally connected) to the HEATING COIL, to let the rack dry

when it is not used.

When shutting down the system for long periods, the humidifier must be switched-off before the

ventilation system, so to assure that the humidifier chamber is dry before complete shutdown.

During the first installation and all the operations of maintenance

please take care

of the

temperature sensor installed at the exit of high pressure pump.

Its damage may cause the breakage of the high pressure system.

Before first switch

-On replace the RED transport cap with the YELLOW cap having

a

built

-in dipstick provided.

The control signal mu

st be 0 in case of ventilation system failure or system shut off

HighPressure Humidifier - Constant Pressure

21.1.EN

9

Elsteam S.r.l - via E.fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it - Web: http://www.elsteam.com

The nozzle lines must be connected in thermal contact with heating batteries in AHU, to be sure the

stainless steel pipes are always at drying temperature when the humidifiers is not working. This will dry

the empty network avoiding all possibilities of microbes growth and proliferation.

When installing the distribution rack (inside the AHU) the holes opened in the panel of the

must be closed using permanent elastic sealant that fulfils the requirement of the standard

VDI 6022-1.

7.4 Droplet separator

The “droplet separator” is made of stainless steel frame and glass fiber panel. It must be installed (only in

AHU) at minimum 150cm from the distribution network. It is care of the AHU manufacturer to make

stainless steel frame avoiding sharp edges and all corner than can allow dust deposits. Permanent elastic

sealant must be used in such a way to avoid dirt accumulation (make surfaces as smooth as possible).

The droplet separator must be easily removable to perform maintenance operation or unit replacing. As

the droplet eliminator is not intended to be cleaned, it must be replaced at end of its lifetime.

When installing the droplet separator (inside the AHU) the holes opened in the panel of the

must be closed using permanent elastic sealant that fulfils the requirement of the standard

VDI 6022-1.

7.5 Hydraulics connections

The connection between the pump and distribution network must be realized using pipes which supports

nominal pressure of 100bar (minimum), due to the high pressure (80 bar) in the network. It is preferable

to use stainless steel material.

Hydraulic connections are positioned on side panels of the cabinet. Input water connection is 3/4" and is

on the right side of the case; output is 3/8" and is on the left side.

A shut-off valve must be installed upstream (and nearby) humidifier for maintenance and

safety reasons operations.

Before installing the nozzles, it is mandatory to carry out a cleaning phase of the pipes

installed to

remove

all deposits in the pipes.

HighPressure Humidifier - Constant Pressure

21.1.EN

10

Elsteam S.r.l - via E.fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it - Web: http://www.elsteam.com

Only HPNxxDEMI models complies with VDI6022 standards.

The High Pressure Humidifier can work with standard or demineralised water. Different pumps materials

(STAINLESS STEEL for reverse osmosis water, BRASS for normal tap water) are used in the two versions.

The water pressure at the input must not be lower than 1bar.

For proper operation in according to VDI standards, stagnation of water in supply lines shall be avoided.

When shutting down the system for long periods particular care must be taken to empty supply lines or

keep active water treatment systems.

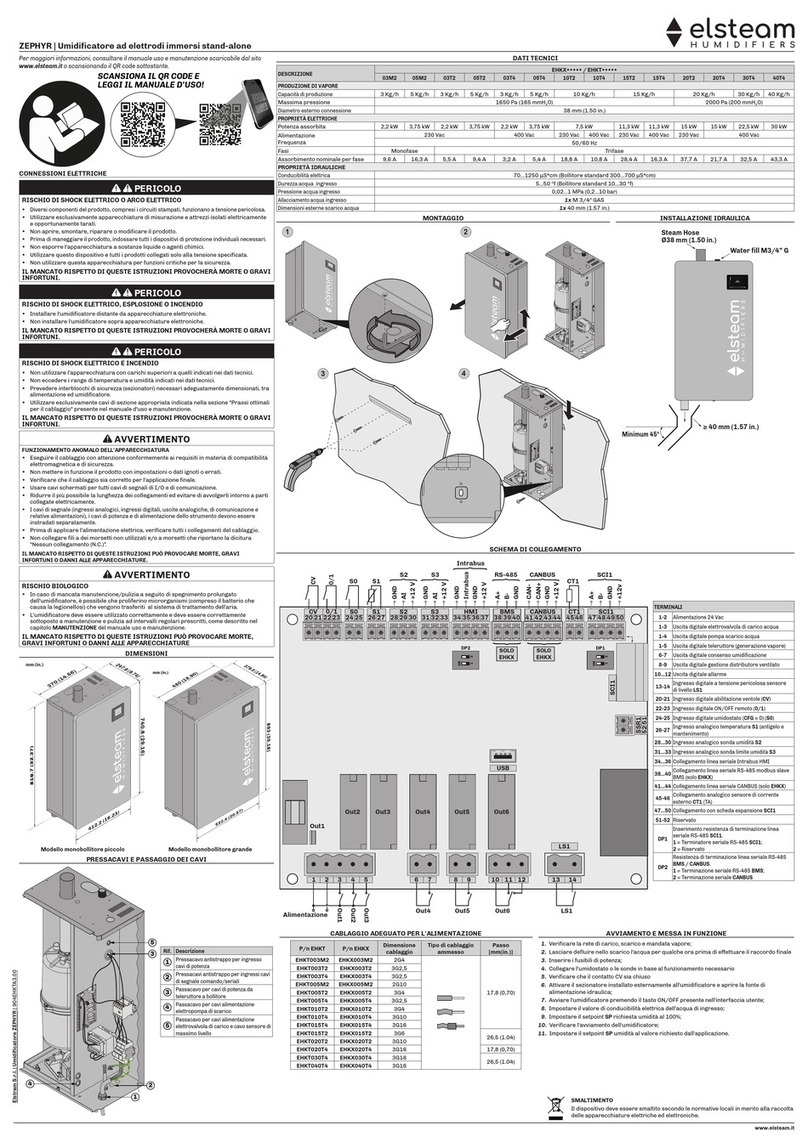

7.6 Electrical Connections

Before starting installation:

◊Check that the supply voltage and the frequency correspond to those indicated on the rating plate.

◊The dimensions of the supply cable must suit the machine absorption and comply with the current

regulations.

◊Put the cable in the relevant cable passage hole and then tighten.

Connectors for electrical connections are located inside the upper part of the cabinet (to access it you

need to remove the upper panel of the cabinet). It is recommended to isolate the machine from the mains

before each intervention and in any case in absence of protective covers (dangerously live electrical

parts are present inside).

The power supply line must be connected to the input of the circuit breaker, for the ground connection

there is a special yellow-green terminal, the hole for the cables is located on the rear of the cabinet.

Controls and alarm signals are found in the card connectors (to access it, remove the upper panel of the

cabinet) and the opening for these cables is also in the rear of the cabinet.

Controller Terminal Block

All operations of electrical installation MUST be performed by qualified personnel (

eg

electrician or staff with appropriate training) only.

The customer is responsible for the use of qualified personnel.

Prior to carrying out any inspection or service on the machine, it is necessary to

disconnect it from the main electrical supply. Make sure, that nobody can reconnect it

during the technical service.

Every installed electrical and electronic equipment or basic structure must be

earthed.

HighPressure Humidifier - Constant Pressure

21.1.EN

11

Elsteam S.r.l - via E.fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it - Web: http://www.elsteam.com

N°

Name

Description

3

ALARM

Alarm

Normally opened contact. (Max. 2A, 230V).

4

ALARM

5

REQ

NOT USED

6

REQ

7

0 V

Ground reference voltage (0V)

8

REG

Input Control Signal (0-10V)

9

V+

Positive Reference Voltage (12V)

10

RTH

NOT USED

11

ACOUT

NOT USED

All connections between the controller and the solenoid card are made at the factory. The user must

connect the output signal of the humidistat to the terminals 7 (-) and 8 (+) taking care of polarities.

For ON/OFF driving connect the wires to terminals 8 and 9.

The HPNCTRL card proportional or ON/OFF control signal must be shut off in case of ventilation failure or

AHU shutdown to stop mist entering into the AHU without airflow.

7.7 Setting of the bypass control valve

The high-pressure system has a bypass valve for regulating the output pressure. At first power on is

necessary to control the adjustment of this valve.

In the case of a successful installation, you can adjust the maximum pressure (turning clockwise the

valve). It is advisable to adjust the output pressure up to a pressure of about 80 bar.

It's also possible to reduce the output pressure in case “Etb” message is displayed on the inverter display

(lower limit for output pressure is 30bar).

8Maintenance

A high pressure humidification system requires some periodic maintenance operations for its proper

operation:

•Change the oil pump every 500 hours, as indicated on the attached manual pump, closing

the inlet water and removing the top caps and bottom as shown in figure

•Periodically check the wear of the nozzles. The nozzles worn may cause the blocking of the

machine due to an excessive reduction of output pressure

•Check periodically pump oil level:

HighPressure Humidifier - Constant Pressure

21.1.EN

12

Elsteam S.r.l - via E.fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it - Web: http://www.elsteam.com

If oil level is not within zone, add or remove oil in the tank. Check for oil leaks.

NOTE

The high pressure humidifier presents a thermal protection for the pump system. Be extremely careful

not to damage the temperature sensor mounted on the pump.

9Electronic Controller

All operation of the high pressure humidifier are managed by a micro controller based board. All

information is provided through a 16 characters by 2 lines display. Its main functions are:

•Switch On/Off of the system

•Check the real working time of the system

•Provide information about replacement of spare parts and pump oil.

•Display information about parameters

•Provide different alarms

9.1 Normal operation DISPLAY

During normal operation the electronic controller display show on the first line main parameters of the

system:

: System State:

•“u” : indicates proper operation of the system

•“!” : indicates temperature protection intervention

•“x” : indicates that no request is present

: Pump temperature indication bar

: Minimum operating time of the pump. At startup/shutdown of the pump “t” character is displayed.

During the inhibit time (factory setting: 60 s). During this period system shutdown or startup is

inhibited.

“W” character indicates that input water solenoid is opened

“i” character indicates that input water flow is sufficient for system operation. If “i” is not shown, there is

a problem in input water flow or pressure.

The second line indicates the pressure value in the nozzles network.

9.2 Electronic controller basic programming

To enter the basic programming mode press the SET button for 2 seconds, until the following message is

displayed:

During the first programming of the controller is advisable to disconnect the control

signals (Pin 8 of the terminal) to avoid that the humidifier is put into operation.

H P NT Wi

Pou t = x x . x b a r

HighPressure Humidifier - Constant Pressure

21.1.EN

13

Elsteam S.r.l - via E.fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it - Web: http://www.elsteam.com

Humidify System

-- Enabled --

To modify the value of a field or to move between fields use + and - buttons. During value changing, the

value of the field blinks.

To end the programming of a field press the OK button to set the new value, CANC button to cancel

modification or OK , SET or CANC for more than 3 seconds to exit programming phase.

Programming phase automatically ends without current parameter update if no button is pressed for 3

seconds.

Note: To save updated values do not abandon programming pressing CANC button.

HighPressure Humidifier - Constant Pressure

21.1.EN

14

Elsteam S.r.l - via E.fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it - Web: http://www.elsteam.com

Basic menu programming fields are:

Display

Description

Humidify System

Enable or disable the humidifier

"

Enabled

", System on

"Disabled", System off

Life Time

Display the effective working time of the system

This field is read only. Cannot be modified by the user

Change Oil Timer

Display the remaining time before pump oil change

c. Cannot be modified by the user

9.2.1 Counter of the remaining time before pump oil change

The high pressure pump requires changing the oil every 500 hours of operation (the first oil change

should be made after 50 hours of operation). Use SAE 15W40 mineral oil. The quantity of oil needed

depends on the pump flow. Please refer to the pump system manual for details.

The controller counts the time remaining for the next oil change. At the end of that period the message

"ChangeOil xxxxxh" is displayed to inform user that oil must be changed. After this message there is still a

period of 50 hours before the controller BLOCKS the system.

If oil is changed before scheduled time (before the controller blocks the system), the oil counter must be

reset by pressing SET and OK buttons. When the message “Pump Oil has been changed” is displayed,

press OK button to confirm and reset the counter. By pressing CANC button the counter is not reset and

the system will stop at counter expiration.

At expiration of extended period the system will stop working and following message will be displayed

“System Failure - Change the Oil of the Pump”.

Once the oil is changed do not forget to reset the oil counter by pressing OK button. When the message

“Pump Oil has been changed” is displayed, press OK button to confirm and reset the counter. By pressing

CANC button the counter is not reset and the system will remain blocked.

9.2.2 Display of the remaining time

During normal working operation the user can display remaining time before oil change pressing -

button.

9.2.3 LCD Contrast change

If necessary the user can modify the value of the display contrast pressing CANC button and one of +

or

- button.

9.2.4 Display of Firmware version

User can display the installed firmware version pressing + and - buttons.

9.3 Electronic controller advanced programming

(only for maintenance/fitter)

Advanced programming mode allows maintenance people and fitters to modify additional parameters

depending on the working conditions of the HPN system.

To enter the advanced programming mode press SET and + buttons for 2 seconds, until the following

message is displayed:

Humidify System

-- Enabled --

HighPressure Humidifier - Constant Pressure

21.1.EN

15

Elsteam S.r.l - via E.fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it - Web: http://www.elsteam.com

Advanced menu programming fields are:

Display

Description

Humidify System

Enable or disable the humidifier

"

Enabled

", System on

"Disabled", System off

Life Time

Display the effective working time of the system

This field is read only. Cannot be modified by the user

Change Oil Timer

Display the remaining time before pump oil change

This field is read only. Cannot be modified by the user

Pump Rate

Set the system flow rate

Indicates the nozzle system flow rate, not the pump one. In the

current version must be set to minimum value. Will be used to

provide information about real water consumption.

Minimum External

Signal xxx/100%

Minimum value of external controller signal (only proportional

controller)

This value is expressed in percentage of 10V. In case of noise on the

external signal line, parameter value can be increased. (Default

value 10%)

Output Pressure

Timeout= xxx sec

Max time to reach standard pressure in the nozzles network

If within this period from system start, pressure in the nozzles pipe

has not reached the default value, the embedded controller stops

the system providing the following error message “

Low Output

Pressure

”.

To restart the system after failure solution, press

OK

. (Default value

60 sec)

Minimum On/Off

Time = 000 sec

Minimum System On/Off time

To avoid frequent stop and start of the pump (that can damage it) a

minimum period is set by electronic controller. During this period

switch on and off of the system is inhibited unless the circuit

breaker is used (NOT RECOMMENDED).

In cases of frequent starting and stopping of the pump, increase the

value. (Default Value : 60 sec)

Std Pressure

xxx bar

Standard value of pressure

This parameter allows the fitter to modify the default value of the

pressure in the nozzles network. (Default Value: 80bar)

4..20mA Coeff. P

P= xx.xbar)yyyyy

Pressure transducer Coefficient

On the second line of the LCD display the pressure value and probe

coefficient are showed.

(Default Value: 8850)

To

confirm the changes made to a field, use SET or OK. To exit the

advanced

programming mode,

press SET or OK. To store the changes

in the FLASH memory

of the microcontroller

press SET or OK for more than 3 seconds. Using the

CANC

key

changes to a field will not be stored in FLASH and new values will be valid

until

the next

switch off the humidifier (using circuit breaker).

HighPressure Humidifier - Constant Pressure

21.1.EN

16

Elsteam S.r.l - via E.fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it - Web: http://www.elsteam.com

10Alarm Messages

To remove alarm conditio0n and restart the system press OK key.

Message

Insufficient Water

Cause

Lack of input water

Inverter security error

Possible Solution

Check input water flow.

Check inverter display for error messages. If “Etb

” message is displayed the output

pressure security pressure switch stopped the system. Check the output bypass valve.

Turn it counterclockwise to reduce output pressure.

Remove one nozzle from the network and try the system. Press OK key to remove

alarm condition and restart the system.

If the alarm condition stops:

•Replace nozzle and restart the system

If the system is still in alarm, please contact ELSTEAM or your distributor for input flow

meter replacement part.

Message

Check Load Valve Driver

Cause

Driving of input water solenoid failure

Possible Solution

If “W” character is displayed in the first line, check solenoid connections and voltage

(12V). Press OK key to remove alarm condition and restart the system.

If the system is still in alarm, please contact ELSTEAM or your distributor for part

replacement.

Message

NTC failure

Cause

The pump temperature probe is damaged.

Possible Solution

Contact ELSTEAM or your distributor for part replacement.

Message

Low Output Pressure

Cause

The pressure in the nozzle pipe cannot reach the default value within the set period.

Possible Solution

Check distribution network and output connection pipe for draining.

Check the output bypass valve. To increase the output

pressure turn clockwise the

valve.

Message

Pump Overheating, check atomizers

Cause

Pump temperature high.

Possible Solution

Check the output bypass valve. Turn it counterclockwise to reduce output pressure.

CAUTION

The controller stores the status of the humidifier in a FLASH memory.

Turning the system off and on to remove alarm conditions has no effect

HighPressure Humidifier - Constant Pressure

21.1.EN

17

Elsteam S.r.l - via E.fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it - Web: http://www.elsteam.com

Connections Diagram

Other manuals for HPN Series

1

This manual suits for next models

11

Table of contents

Other Elsteam Humidifier manuals

Elsteam

Elsteam VEH20 Series User manual

Elsteam

Elsteam VEH Series User manual

Elsteam

Elsteam VEH Series Installation and operating instructions

Elsteam

Elsteam UH06-OEM Operating instructions

Elsteam

Elsteam REH4 Installation and operating instructions

Elsteam

Elsteam KT Series User manual

Elsteam

Elsteam MISTRAL User manual

Elsteam

Elsteam ZEPHYR EHKT003M2 User manual

Elsteam

Elsteam KT User manual

Elsteam

Elsteam AHU-VEH User manual