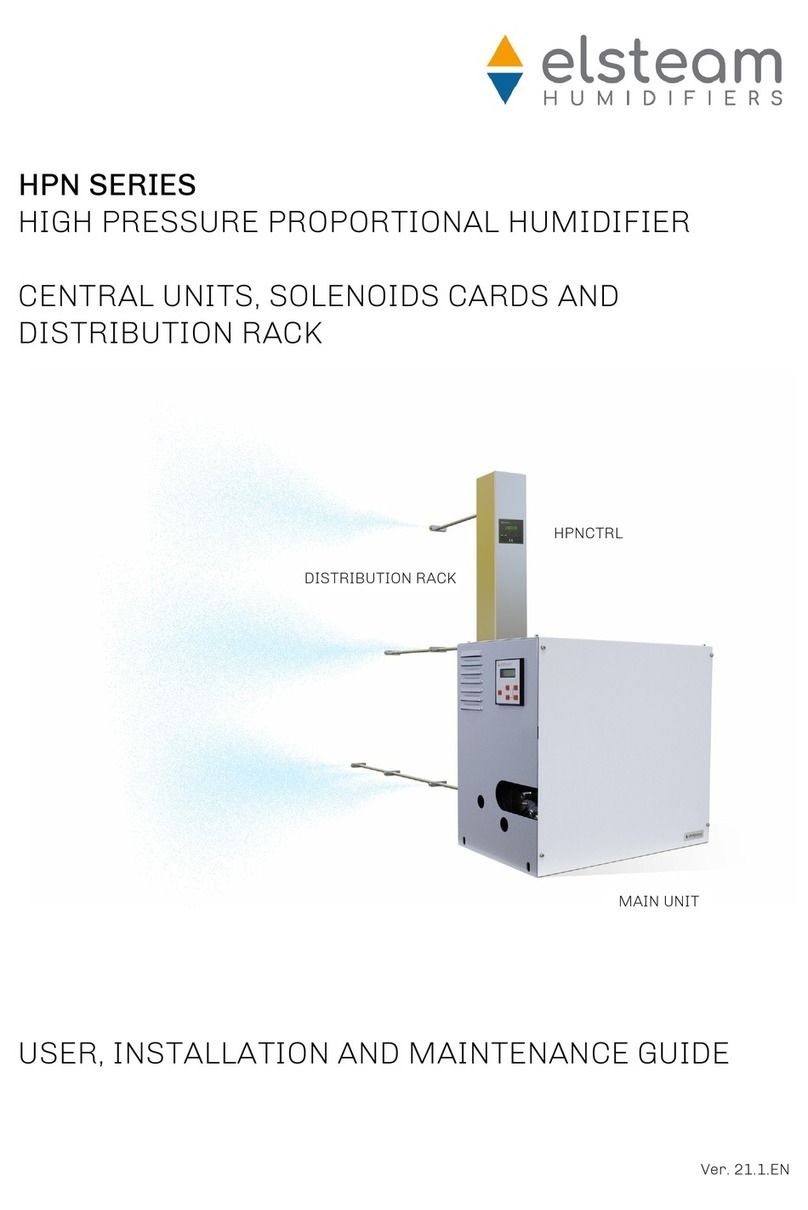

Elsteam REH4 Installation and operating instructions

AIR HANDLING UNITS

RESISTORS HUMIDIFIER: REH

Installation, use and maintenance guide

Rel. 21.2.EN

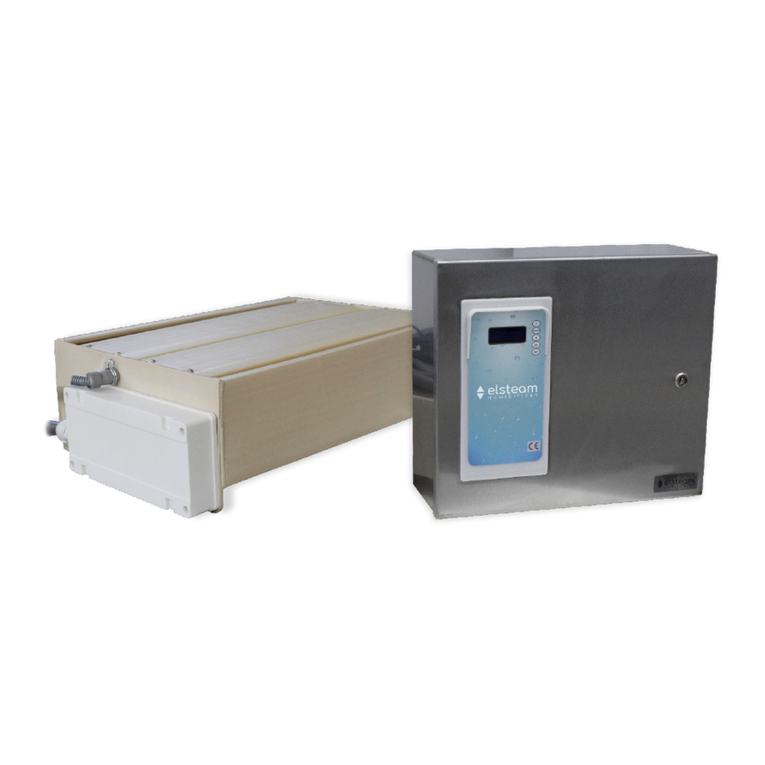

Kettle body to

in

stall

in

the AHU

Control

Unit

AHU Resistors Humidifier - REH 21.2.EN 2

Elsteam S.r.l - via E. Fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it Web: http://www.elsteam.com

TOC

1SAFETY RULES ...........................................................................................................................................................3

1.1 GENERAL RULES .....................................................................................................................................................3

1.2 CONDITIONS THERMO HYGROMETRIC (INSTALLATION)......................................................................................................3

1.3 POWER SUPPLY ......................................................................................................................................................3

1.4 WATERCONNECTIONS .............................................................................................................................................3

1.5 WASTE DISPOSAL....................................................................................................................................................3

1.6 WARRANTY...........................................................................................................................................................4

2MANUFACTURER DATA.............................................................................................................................................4

3GENERAL CHARACTERISTICS OF THE HUMIDIFIER .....................................................................................................4

4STRUCTURE OF REH HUMIDIFIER ..............................................................................................................................4

5WORKING PRINCIPLE.................................................................................................................................................5

6CHARACTERISTICS.....................................................................................................................................................5

7HUMIDIFIER INSTALLATION.......................................................................................................................................7

7.1 WATERCONNECTION...............................................................................................................................................7

7.2 DRAIN ANDOVERFLOW HYDRAULIC CONNECTION............................................................................................................7

7.3 ELECTRICAL CONNECTION..........................................................................................................................................8

7.4 ENABLECONTACT ...................................................................................................................................................8

7.5 DRAINING BLOCKMANUAL CALIBRATION.......................................................................................................................8

8WORKING PRINCIPLE...............................................................................................................................................10

9MENU AND PARAMETERS.......................................................................................................................................10

9.1 ON/OFFMODE ..................................................................................................................................................10

9.2 LANGUAGE..........................................................................................................................................................10

9.3 HUMIDITY SELECTION.............................................................................................................................................10

9.4 NOMINALCURRENT ..............................................................................................................................................10

9.5 DRAIN TIME.........................................................................................................................................................10

9.6 WATER FILL TIME..................................................................................................................................................11

9.7 PURGE TIME........................................................................................................................................................11

9.8 HEATING TIME .....................................................................................................................................................11

9.9 TACOEFFICIENT. ..................................................................................................................................................11

9.10 LEVEL SENSOR......................................................................................................................................................11

9.11 PRESSURE THRESHOLD ...........................................................................................................................................11

9.12 MINIMUM 0-10VINPUT CALIBRATION ......................................................................................................................11

9.13 WATERCHANGE INTERVAL ......................................................................................................................................11

10 ALARMS ..............................................................................................................................................................12

11 CONNECTIONS.....................................................................................................................................................13

11.1 USED AND AVAILABLE CONNECTIONS..........................................................................................................................13

12 SCHEMATIC DIAGRAM.........................................................................................................................................17

AHU Resistors Humidifier - REH 21.2.EN 3

Elsteam S.r.l - via E. Fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it Web: http://www.elsteam.com

Read this manual carefully, observing all the safety measures listed in it for the correct use of the humidifier.

Keep the humidifier in good working condition. Look closely at all the tips for the installation and use of your

humidifier before operating it. It 'made absolute obligation for installers to go through the installation manual

of this unit: Elsteam srl declines any responsibility for damages caused to third parties or to the product

resulting from the missing or partial application of the rules contained in it.

Keep this manual and all the documentation that came with your humidifier in a safe place for future reference

further.

1Safety Rules

1.1 General Rules

People who are not familiar with this type of equipment or do not have carefully read this manual should not

be allowed to use the humidifier.

Your humidifier is designed to be used with AC 230V 50/60Hz. Do not attempt to use the humidifier with a

different kind of tension. Check that the mains voltage corresponds to the humidifier target value.

The humidifier must always be switched off before any maintenance operation.

The kettle contains boiling water. BEFORE TOUCHING THE HOUSING MAKE SURE THAT THE TEMPERATURE

IS DROPPED.

All maintenance and repair work must be performed by the manufacturer, its service agent or qualified per-

sonnel.

Do not scotch the output socket steam humidifier and do not insert any object into any opening.

1.2 Conditions thermo hygrometric (installation)

Make sure that the environmental conditions of the place where the installation is carried out are always

compatible with the requirements of the product as required in this manual. Each Elsteam product cannot be

installed in places exposed to weather conditions or frost, unless different terms are explicitly expressed in

documents countersigned.

1.3 Power supply

The Elsteam equipment must be connected to the power supply strictly following the regulations and specifi-

cations stamped on equipment labels.

In particular, it is mandatory that the supply lines are of the correct section and equipped in accordance with

safety switch (RCD) that can protect user.

1.4 Water connections

Elsteam equipment may need to be connected to the water network. In this case it is necessary to strictly

comply with the regulations and make sure that any fault or water leakage resulting from the installation or by

the equipment cannot cause harm to the environment or to third parties. Do not install the unit on walkways

or above dangerous objects or susceptible to damage and always provide proper drainage systems that can

properly evacuate any water leakage.

1.5 Waste disposal

Directive 2002/96/EC of the European Parliament and the national rules impose an obligation not to dispose of

WEEE as unsorted municipal civil, but to set up a special collection of obsolete parts of the humidifier.

The buyer has the option to return the humidifier into disuse at Elsteam srl in case of purchase of an equivalent

(o superior) humidifier. Elsteam will take care of disposal directly or through its agents.

The disposal of electrical or electronic components in an abusive manner and not complying with the legislation

entails sanctions.

AHU Resistors Humidifier - REH 21.2.EN 4

Elsteam S.r.l - via E. Fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it Web: http://www.elsteam.com

1.6 Warranty

ELSTEAM Srl recognizes on its products the legal guarantees in force at the time of sale of the product. Incorrect

use and lack of maintenance entail the automatic forfeiture of any form of guarantee.

2Manufacturer Data

Manufacturer

ELSTEAM Srl

Via ENRICO FERMI 496, 21042 CARONNO PERTUSELLA (VA) - ITALY

Contacts

Tel.: (0039) 029659890

Fax: (0039) 0296457007

Email: infocomm@elsteam.com

Web: www.elsteam.com

3General characteristics of the humidifier

The humidifier REH is a range of humidifiers based on electric immersion heaters specifically designed for

installation inside air handling units.

Normally in these applications, the humidifier is installed externally to the air handling unit and the steam is

conveyed through pipes inside the units and distributed through stainless ramps that allow the steam mixing

with air.

This solution has numerous drawbacks and additional costs:

-The construction of a technical compartment exterior to protect the humidifier

-An antifreeze device which ensures that the water in the humidifier does not freeze in the absence of

a request for production

-The use of expensive and bulky rubber tubes for the conveyance of steam-

-The use of steel distributors within the UTA

-The formation of condensation inside the tubes and distributors with decreased performance

-The need to install the pipes avoiding traps and depressions that would prevent the steam to flow

properly

-The loss of heat to the outside through both tubes, but especially in the humidifier itself exposed to

low temperatures.

The family of REH humidifiers, as well as the VEH (electrodes) and SSH (steam heat exchanger) families, is able

to overcome all these problems, greatly simplifying the installation costs and increasing the performance of

the product compared to the corresponding humidifiers usually on the market.

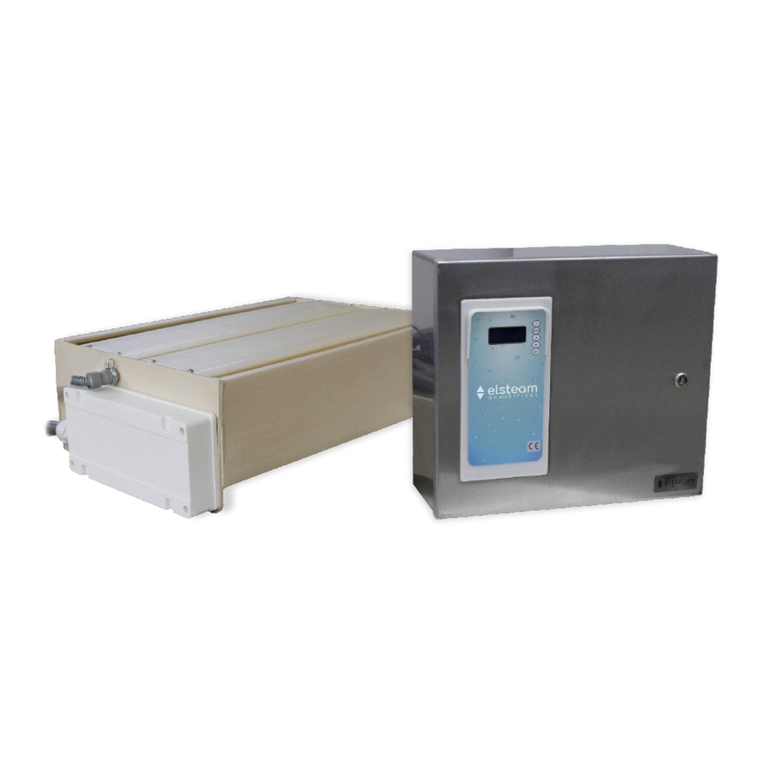

4Structure of REH humidifier

The humidifier REH consists of two units electrically connected to each other: the hydraulic unit and the mi-

croprocessor-based control unit. The hydraulic unit is installed inside the AHU, lying on the condensate drain

pan immediately downstream of the cooling coil. The control unit can be positioned into the AHU electric panel

or on the AHU panels.

The hydraulic unit is constituted by a kettle of stainless steel with dimensions 52 cm x 80 cm x 15 cm in height.

Figura 1 – REH humidifier hydraulic unit

AHU Resistors Humidifier - REH 21.2.EN 5

Elsteam S.r.l - via E. Fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it Web: http://www.elsteam.com

Inside the hydraulic units are arranged longitudinally the heaters (special stainless steel resistor with protec-

tion) connected to the electrical power supply phases and easily removable.

Figura 2 – heaters elements inside kettle

On top cover are present longitudinal slits that allow the output of the produced steam. Due to the positioning

of the unit inside the AHU, the steam can mix with air flow along the unit section.

This solution prevents the formation of condensate in the piping and also prevents any increase of the steam

pressure in the boiler due to obstructions in the steam conveying tubes.

On one side of the kettle (the easiest to access once installed) you have:

-Level switch

-Drain block

The drain block has been specially designed to empty the tank from water

and limestone pieces without having to block and having to be able to work

without pressure.

It is essentially constituted by a valve having a free passage of 32 mm in

diameter, closed by a damper operated by an electric motor and a cam.

Grafted rigidly on the pivot motor is an electronics rotation sensor, which,

communicating with the microprocessor control is able to manage the cor-

rect operation of the system and communicate any faults that appear in the

display.

5Working Principle

When switched on, the humidifier performs a complete drain of kettle, thus ensuring to operate with clean

water. If the humidistat requires steam production, the humidifier starts to fill with water until it reaches the

level of exercise. If the time required to reach that level is greater than a predetermined value, the humidifier

stops and indicates an alarm (possible causes are lack of power or breaking of level switch). Upon reaching the

water level, the control unit switches the control system of the heater elements (resistors).

The resistors are connected to three contactors so as to allow the production to be proportional to the request.

The control unit will maintain production at the set value with additions or discharges of water.

The maximum temperature of the boiler is controlled by NTC sensors (max value set at 125°C) with humidifier

stop and signalling in case of alarm. Each heater element has an intrinsic supplementary safety system consti-

tuted by a thermistor fuse that opens when the resistor temperature exceeds 150°C.

At regular intervals, the humidifier makes also small purges, so as to ensure that the salt content in the water

is not too high and thus avoiding an excessive deposit of limestone.

At much longer intervals (default value 4h) the control system will make complete draining of the boiler to

remove limestone deposits.

If the humidistat request is zero for a long period, the control unit provides to empty all the water contained

in the kettle so as to avoid health problems due to rotting in the water tank.

6Characteristics

AHU Resistors Humidifier - REH 21.2.EN 6

Elsteam S.r.l - via E. Fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it Web: http://www.elsteam.com

Models REH4 REH12 REH24 REH36 REH48

PRODUCTION

Steam Capacity [Kg/h] 4 12 24 36 48

Max Pressure [mm H2O/bar] no limits under normal conditions within the AHU

ELECTRICAL DATA

Power [kW] 3 9 18 27 36

Supply [Vac, Hz] 230, 50 400, 50

Phases [n] 1 3

Max Current per Phase [A] 13 13 26 39 52

HIDRAULIC DATA

Input Water Quality

Complies with the microbiological requirements defined for drinking water by

the regulations in force in the area of use; the use of totally or partially demin-

eralized water is recommended to reduce the frequency of maintenance

Input Water Conductibility μS*cm 0...1250

Input Water Hardness °Fr 0...50

Input Water Pressure [MPa/bar] 0,02...1/0,2...10

Input Water Connection M 3/4” G

Drain Water Connection [mm] 42

GENERAL DATA

Control Unit Dimensions (HxWxD [mm]) 350x400x150

Hydraulic Unit Dimensions (HxWxD [mm]) 150x250x950 150x250x950 150x280x950 150x365x950 150x520x950

Weight [kg] 18 23 28 33 41

IP Hydraulic Unit 20

IP Control Unit 44

REGULATION

Control Controllore Interno (sonda umidità 4-20mA), segnale esterno (0-10V, ON-OFF)

AHU Resistors Humidifier - REH 21.2.EN 7

Elsteam S.r.l - via E. Fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it Web: http://www.elsteam.com

7Humidifier installation

The hydraulic part is simply placed inside the compartment of humidification of the AHU on the condensate

drain pan immediately downstream of the cold battery, with the control group placed on the sides of the AHU

where inspection is easier.

If the AHU is subjected to shock and transport, secure it with screws.

During the humidifier installation carefully follows these points:

•The opening and the closing of the power electronic control box takes place through 4 screws

•Since water is discharged at a temperature of 100 ° C, it is necessary to connect the drain witha plastic

tube of greater length possible (at least 1 meter)

•The model listed aboveare only for operation in OEM application within AHU

•As above said the humidifier of these families cannot be installed in direct contact with people and

objects

7.1 Water connection

The humidifier must be connected to the water supply through a solenoid valve driven by the control unit. Such

a solenoid valve is connected to the hydraulic unit through a flexible tube that can withstand pressure shocks,

which allows, moreover, a rapid disassembly for inspection and cleaning of the solenoid filter. The solenoid

valve has female fitting ¾-inch.

We recommend the use of totally or partially demineralized water, in order to significantly reduce the mainte-

nance and cleaning of limescale deposits, however the use of drinking water and softened water is allowed,

according to the data in paragraph 6 - Characteristics

Input pressure must be between 2 and 10 bars.

7.2 Drain and overflow hydraulic connection

The humidifier is equipped with an automatic drain unit (managed by

the control unit). The drain unit has an outlet pipe with an external

diameter of 42mm. The drain must be brought outside the AHU with a

tube that can support 90 ° C of water drain. This connection prevents

the condensate collection tank from being clogged with limestone

discarded by the humidifier during the tank washing and production

phases,. This drain pipe must be equipped with a slope towards the

outside and provided with a siphon (outside the AHU) to avoid the re-

entry of odors into the AHU.

An overflow fitting is present on the drain side of the kettle. The overflow drain (external diameter 25mm)

must be brought outside the AHU and connected to the drain pipe before the siphon. If the connection is not

possible, the overflow drain ust be equipped with a siphon.

THE OPERATION OF THE HUMIDIFIER MUST ALWAYS BE SUBJECT TO THE WORKING

OF THE AHU FAN AND ONLY IF INSTALLED INTO A AHU

The resistances cables must be arranged and fixed so that they

not contact any

part of the kettle, being at an elevated temperature (100 ° C)

The kettle contains boiling water. BEFORE TOUCHING THE HOUSING MAKE

SURE

THAT THE TEMPERATURE IS DROPPED.

AHU Resistors Humidifier - REH 21.2.EN 8

Elsteam S.r.l - via E. Fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it Web: http://www.elsteam.com

7.3 Electrical connection

You need to connect the control unit to the power supply making sure that the cables sections comply with the

regulations and that a circuit breaker is installed upstream.

You do not need the neutral and ground lines.

Before starting ensure the following conditions:

The size of the power cables must be convenient to the maximum current that must pass through

them.

7.4 Enable Contact

This connection should be made only for humidifiers placed in centralized and ducted ventilation systems. It

allows stopping the steam production each time the air ventilation in the channels stops. If production is not

stopped it would create a steam accumulation in the channels and a subsequent condensation with water leaks.

To obtain this enable, you must bring a connection between the auxiliary contact of the fan contactor (voltage

free contact) to terminals J5-6 and J17-8 the humidifier electronic board.

If you do not use such enable, left the contact shorted (J5-6 and J17-8 terminals) as received from Elsteam.

7.5 Draining block manual calibration

The drain block is calibrated in the best closed position during the testing phase. In case this position were to

vary with time (you see the high losses of the draining pipe), it should proceed to a new adjustment of the

closure of the draining block.

This procedure must be carried out with the full water kettle to allow the search of the optimal closed position.

Please proceed as following:

1) Switch the humidifier OFF

2) Press and hold SET and OK simultaneously while providing voltage. The word "DISCHARGE SETTING"

appears on the display.

3) 3) Press the + and - buttons to adjust the position of the drain block until you no longer see leaks from

the drain.

4) Press OK.

All operations related to electrical installation MUST be carried out by

qualified

personnel (eg electrician or staff with appropriate training). The customer is

responsible for the use of qualified personnel.

Before any maintenance and installation power connection should be dis-

continued and protected against any accidental connection.

Before performing the electrical connections make sure that the voltage

available is equivalent to that of the humidifier.

AHU Resistors Humidifier - REH 21.2.EN 10

Elsteam S.r.l - via E. Fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it Web: http://www.elsteam.com

8Working Principle

a) At power-up, the humidifier performs an emptying of the tank by opening the drain for the time

value set in "T. Emptying".

b) If the request for production is greater than zero, water is charged for the time value set in "T. Load

Water". If it is the first load of water, and then the tank is empty, the charging time will be twice

the set value.

c) Follows a period of waiting to heat water, the duration of which is set by the parameter "T. Heat-

ing".

d) At the end of heating time, the system tries to balance production with the request, in the following

way: if production is less than the request, it returns to step b. If, however, the production is higher

than the required heating phase continues until the output value becomes not less than the re-

quested value.

e) If, at the end of the heating period, the current is still zero, a lack of water alarm is set.

f) During normal operation, there is an active system for changing the water: after one hour of opera-

tion, the system provides to the discharge of a small part of water and the relative refilling. Every 4

hours, is, instead, a total change of the tank water.

g) If the demand of production remains at zero for a period of more than 4 hours, the tank will be emp-

tied, to avoid the formation of bacteria.

9Menu and Parameters

Pushing the "SET" button, you can access the configuration menu of the system. The buttons "+" and "-

" allow increasing and decreasing the parameter value. Click "OK" to confirm the new parameter

value and passes to the next. The modifiable parameters are:

9.1 ON/OFF Mode

During normal operation (not in alarm) by pressing the "RESET" button for 5 seconds, the humidifier

goes into OFF mode disconnecting the contactor. To resume operation press the "RESET" button for 5

seconds (ON mode).

9.2 Language

Set the menu and messages language:

a. Italian (default).

b. English.

c. French.

d. German (not yet implemented)

9.3 Humidity selection

Set the source of humidity sensor:

a. Internal: in this case it is proposed to set the desired humidity value between 0 and 100%.

Internal controller uses a humidity probe 4-20mA connected at

J17.pin5 = +V

J17.pin4 = IN

J17.pin8 = GND (if needed)

b. External: in this case you have to select the type of used humidistat:

I. On-Off type

II. Proportional 0-10V type

III. Proportional 4-20mA type

Default: Extern humidistat. Proportional 0-10V type

9.4 Nominal Current

Set the rated current of the humidifier.

Default 20A

9.5 Drain time.

Set the time during which the drain system remains open to allow emptying of the tank. The time is

in seconds, from 1 to 250.

Default 120”.

AHU Resistors Humidifier - REH 21.2.EN 11

Elsteam S.r.l - via E. Fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it Web: http://www.elsteam.com

9.6 Water fill time

Set the time during which the inlet valve is open water. The time is in seconds, from 1 to 250.

Default 10”.

9.7 Purge Time.

Set the purge time during which the drain system remains open to allow a small discharge of water.

The time is in seconds, from 1 to 250.

Default 1”.

9.8 Heating time

Set the waiting time during which the water in the tank is heated by the passage of the current. The

time is in seconds, from 1 to 1200 (= 20min.).

Default 80”.

9.9 TA coefficient.

Set the coefficient for the TA mounted in the humidifier. It is a number from 10 to 9999, modified in

steps of 10.

Default 750.

9.10 Level sensor

Set the type of level sensor connected. Can be chosen among:

HV Level switch (High Voltage). Input IN-DIG0

Contact with float on input IN-DIG1 (jumper JP2 must be closed):

a. N.C. = normally closed.

b. N.O. = normally open.

Default HV Level switch

9.11 Pressure threshold

2000Pa

9.12 Minimum 0-10V Input Calibration

This parameter allows varying the minimum threshold for intervention in the case of using an external

controller with different voltages from 0-10V.

9.13 Water change interval

It indicates the interval between complete changes of water in the kettle.

(Default 4h)

AHU Resistors Humidifier - REH 21.2.EN 12

Elsteam S.r.l - via E. Fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it Web: http://www.elsteam.com

10 Alarms

DISPLAY Description Resolution

A L A R M

NTC KO NTC open

Damaged element or low temperature

Check NTC element

Check heater connections

Check contactors

A L A R M

RESISTOR T. Heater element temperature above 125°C The humidifier stops for some minute to lower tempera-

ture, and then restarts, so to avoid damaging of heaters

A L A R M

LACK WATER No water in the kettle Check the input solenoid

Check the electrical connections of the solenoid

A L A R M

DRAIN MOTOR The drain motor is not closed within the al-

lotted time. (Timeout of closing)

Check the electrical connections of the motor

Check that there are no blocks of limestone or objects

blocking the closure

A L A R M

CLOGGED DRAIN limestone blocks draining block Check the amount of scale in the kettle/draining block.

Perform manual cleaning of kettle/draining block

AHU Resistors Humidifier - REH 21.2.EN 13

Elsteam S.r.l - via E. Fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it Web: http://www.elsteam.com

11 Connections

11.1 Used and available connections

J1 –TA Input

1 Phase-R –

2 Com ---

3 Phase-S –

4

Com

---

J17

Analogues

Inputs

J5

Digital

Inputs

J1 – TA inputs

J13 – Add-On supply

J6 – Motors with po-

tentiometers

J16 – TRIAC connec-

tions

J15 – HV opto input

J10 – RS485

J3

Proportional

Output 0-10V

J8 – Opto outputs

J4 – Relay outputs

J2 – Transistor out-

puts

Unit internal connections

J12 –AC input 12V

J9

–

Keyboard

con-

nector

User available connections

AHU Resistors Humidifier - REH 21.2.EN 14

Elsteam S.r.l - via E. Fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it Web: http://www.elsteam.com

J17 Analogue

Inputs

1 Vcc –

2 +NTC0 –

3 –NTC0 –

4 – CLOOP –

5 + CLOOP –

6 IN-AN0 –

7 IN-AN1 –

8 GND –

Humidistat

0-10V

J2

–

Transistor

Outputs

1 Out1 + -

2 GND –

3 Out2 + -

4 GND –

I

nlet

solenoid

valve

J16 –TRIAC

Connections

1 +R –

2 - R –

3 + S –

4 – S –

5 + T –

6 – T –

J15 –HV Opto

Input

1 IN-DIG0+ -

2 IN-DIG0- -

J5

–

Opto

Inputs

1 IN-DIG1+ -

2 IN-DIG1- -

3 IN-DIG2+ -

4 IN-DIG2 –

5 IN-DIG3 +

6 IN-DIG3 -

Float level sensor (N.C

or

N.O.).

Alternative to the HV sensor.

Jumper JP2 closed

3 available analogue

inputs

1 available output

2 available opto inputs

Humidistat

ON-OFF

J6 - 8 – V_Aux+

AHU Resistors Humidifier - REH 21.2.EN 15

Elsteam S.r.l - via E. Fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it Web: http://www.elsteam.com

J12

–

12V

AC

Input 1 –

2 –

Supply

230/400 - 12Vac

J17

Analogue

INputs

8 GND

–

J6 – Motor with

Potentiometer

1 – Mot1_A –

2 – Mot1_B –

3 – V_Aux + -

4 – In_Pot1 –

5- GND –

6 – Mot2_A –

7 – Mot2_B –

8 – V_Aux+ -

9 – In_Pot2 –

Drain motor

with position

potentiome-

ter.

-

Mot

+ Mot

+ V pot

Pot

- Pot

1 available motor control with potenti-

ometer

J4

–

Relays Out-

puts

1 – Relay 1 A –

2 – Relay 1 B –

3 – Relay 2 A –

4 – Relay 2 B –

5 – Relay 3 A –

6 – Relay 3 B –

7 – Relay 4 A –

8 – Relay 4 B –

9 – Relay 5 A –

10 – Relay 5 B –

Relay alarm signal.

Enable contact

(Active if closed)

CONTACTOR1

CONTACTOR2

CONTACTOR3

AHU Resistors Humidifier - REH 21.2.EN 16

Elsteam S.r.l - via E. Fermi, 496 - 21042 Caronno Pertusella (va) - Tel.+39 02 9659890 - Fax +39 02 96457007

E-mail: info@elsteam.it Web: http://www.elsteam.com

Available 0 – 10V proportional output.

J3

-

0

-

10V

Proportional

Output

1 – Out + -

2 Gnd –

J10

–

RS485

1 – A –

2 – B –

3 – Gnd –

J8

–

Opto

Outputs

1 – Out 2 C –

2 – Out 1 E –

3 – Out 2 E –

4 - Out 1 C –

Available RS485 line.

2 available optocoupled outputs

This manual suits for next models

4

Table of contents

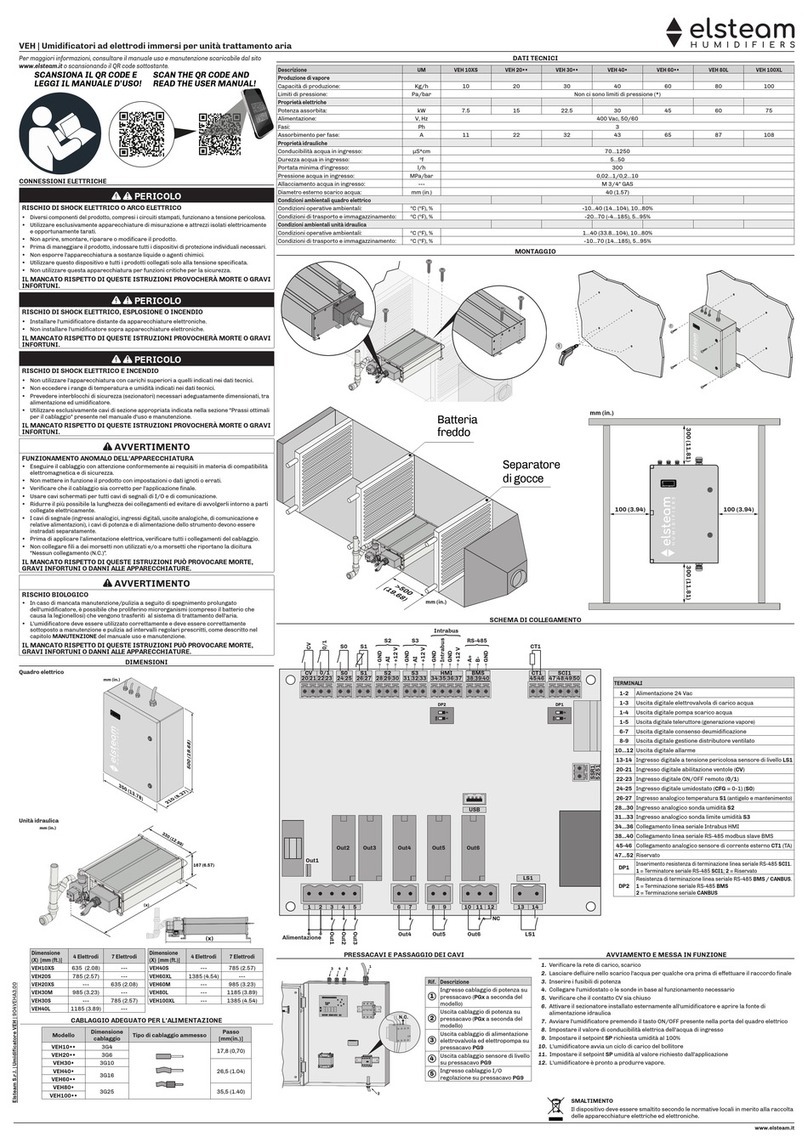

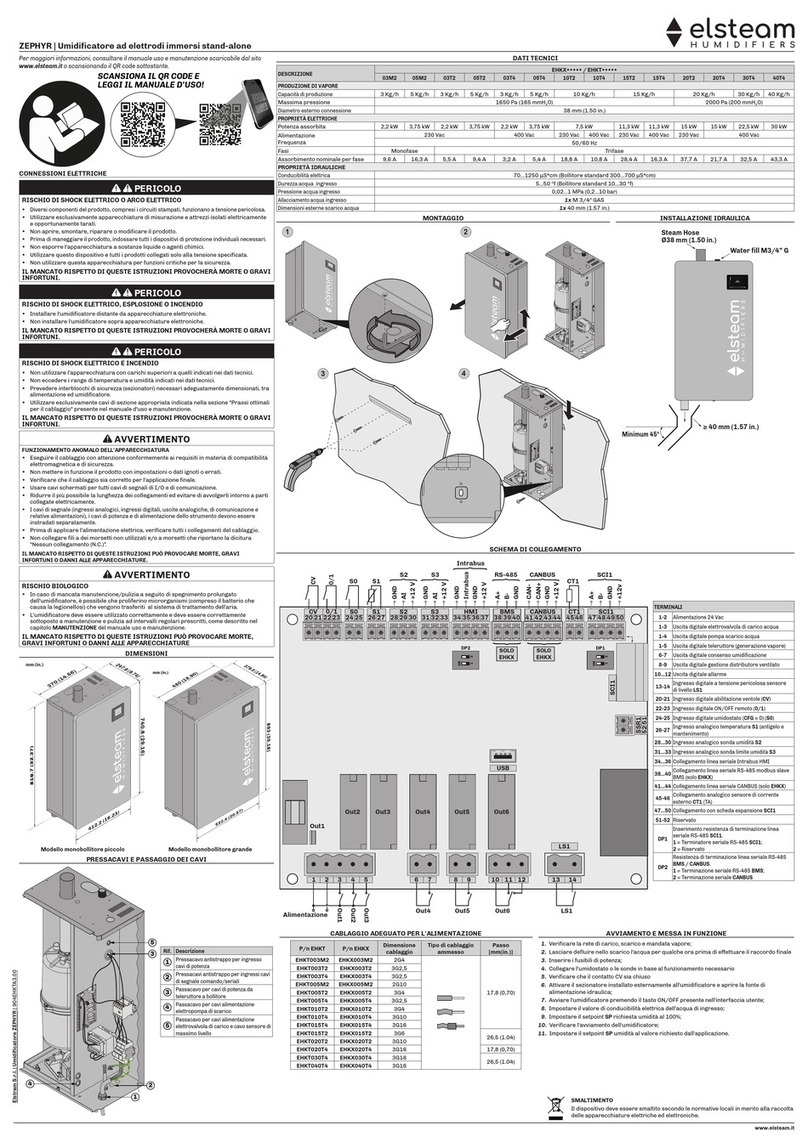

Other Elsteam Humidifier manuals

Elsteam

Elsteam VEH20 Series User manual

Elsteam

Elsteam ZEPHYR EHKT003M2 User manual

Elsteam

Elsteam KT User manual

Elsteam

Elsteam VEH Series Installation and operating instructions

Elsteam

Elsteam AHU-VEH User manual

Elsteam

Elsteam MISTRAL User manual

Elsteam

Elsteam HPN Series Installation manual

Elsteam

Elsteam KT Series User manual

Elsteam

Elsteam VEH Series User manual

Elsteam

Elsteam HPN Series Operating instructions