IMPORTANT SAFETY INSTRUCTIONS P2

IMPORTANT SAFETY INSTRUCTIONS

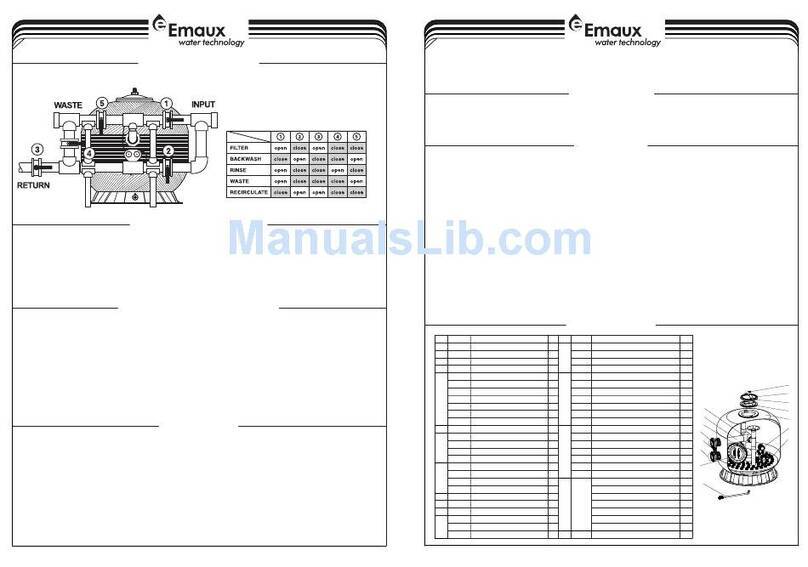

THESE OPERATING INSTRUCTIONS CONTAIN IMPORTANT INFORMATION ON THE

SAFE, PROPER AND ECONOMICAL OPERATION OF THIS SWIMMING POOL

APPLIANCE. STRICT OBSERVATION OF THE OPERATING INSTRUCTIONS WILL HELP

TO AVOID DANGERS, REDUCE REPAIR COSTS, SHUTDOWN TIMES AND INCREASE

THE RELIABILITY AND WORKING LIFE OF THE PRODUCT.

Failure to follow the instructions in this manual may result in serious adverse health effects, or even serious or

fatal injury. Failure to follow the instructions in this manual will in all cases invalidate all guarantees and liability

on the part of the manufacturer.

Consumer Information and Safety

This Cartridge Filters are designed and manufactured to provide years of safe and reliable operation. Operated

and maintained according to the information in this manual and the installation codes referred to in later

sections.

THIS FILTER OPERATES UNDER HIGH PRESSURE

When any part of the circulating system, (e.g., closure, pump, filter,

valve(s), etc.), is serviced, air can enter the system and become

pressurized. Pressurized air can cause the top closure to separate

which can result in severe injury, death, or property damage. To avoid

this potential hazard, follow these instructions:

1. If you are not familiar with your pool filtering system :

Do NOT attempt to adjust or service without consulting your dealer, or a qualified pool technician.

Read the entire Installation & Operation Manual before attempting to use, service or adjust the pool

filtering system.

2. Before repositioning valve(s) and before beginning the assembly, disassembly, or any other service of the

circulating system:

(1) Turn the pump OFF and shut OFF any automatic controls to ensure the system is NOT inadvertently started

during the servicing;

open the manual air release valve;

Wait until all pressure is relieved.

3. Whenever installing the filter closure follow the filter closure warnings exactly.

4. Once service on the circulating system is complete follow initial start-up instructions exactly.

5. Maintain circulation system properly. Replace worn or damaged parts immediately, (e.g., closure, pressure

gauge, valve(s), O-rings, etc.).

6. Be sure that the filter is properly mounted and positioned according to instructions provided.

(1)

(2)

(2)

(3)

This filter must be installed by a licensed or certified electrician or a qualified pool

serviceman in accordance with the Local Code and all applicable local codes and

ordinances.

Improper installation could result in death or serious injury to pool users, installers, or

others and may also cause damage to property.

Always disconnect power to the pool circulating system at the circuit breaker before servicing the filter. Ensure

that the disconnected circuit is locked out or properly tagged so that it cannot be switched on while you are

working on the filter. Failure to do so could result in serious injury or death to serviceman, pool users or others

due to electric shock.

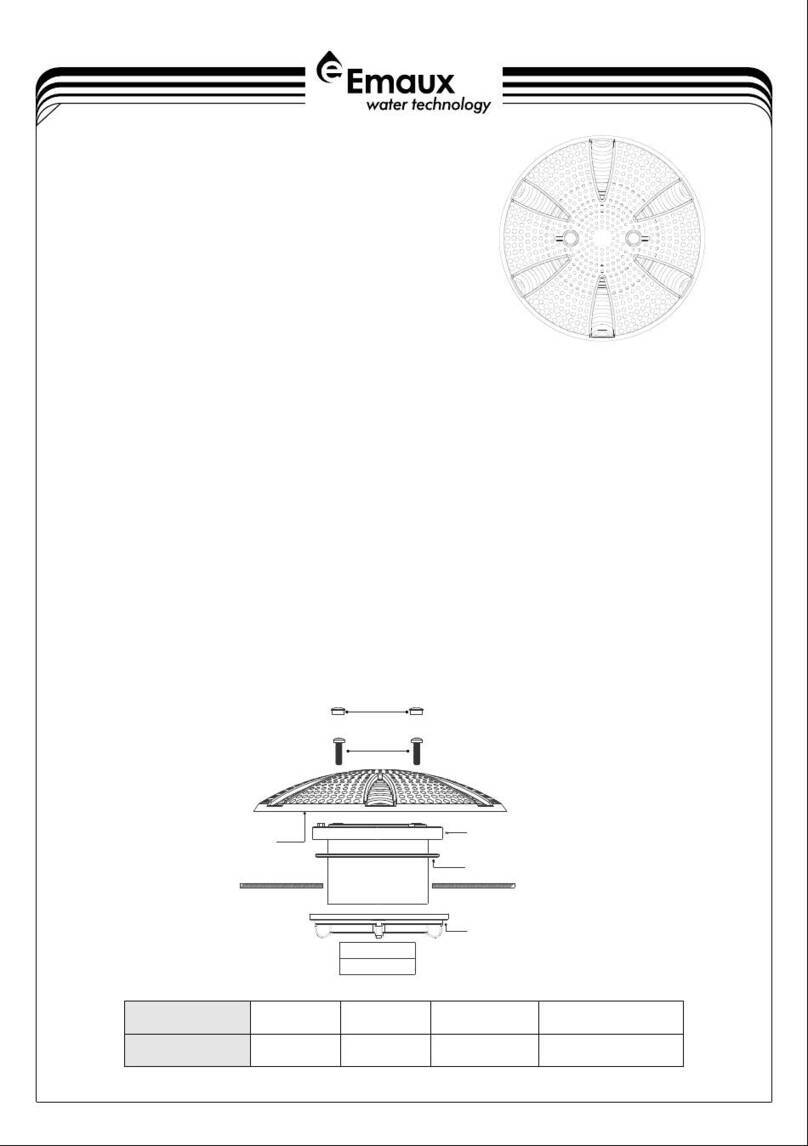

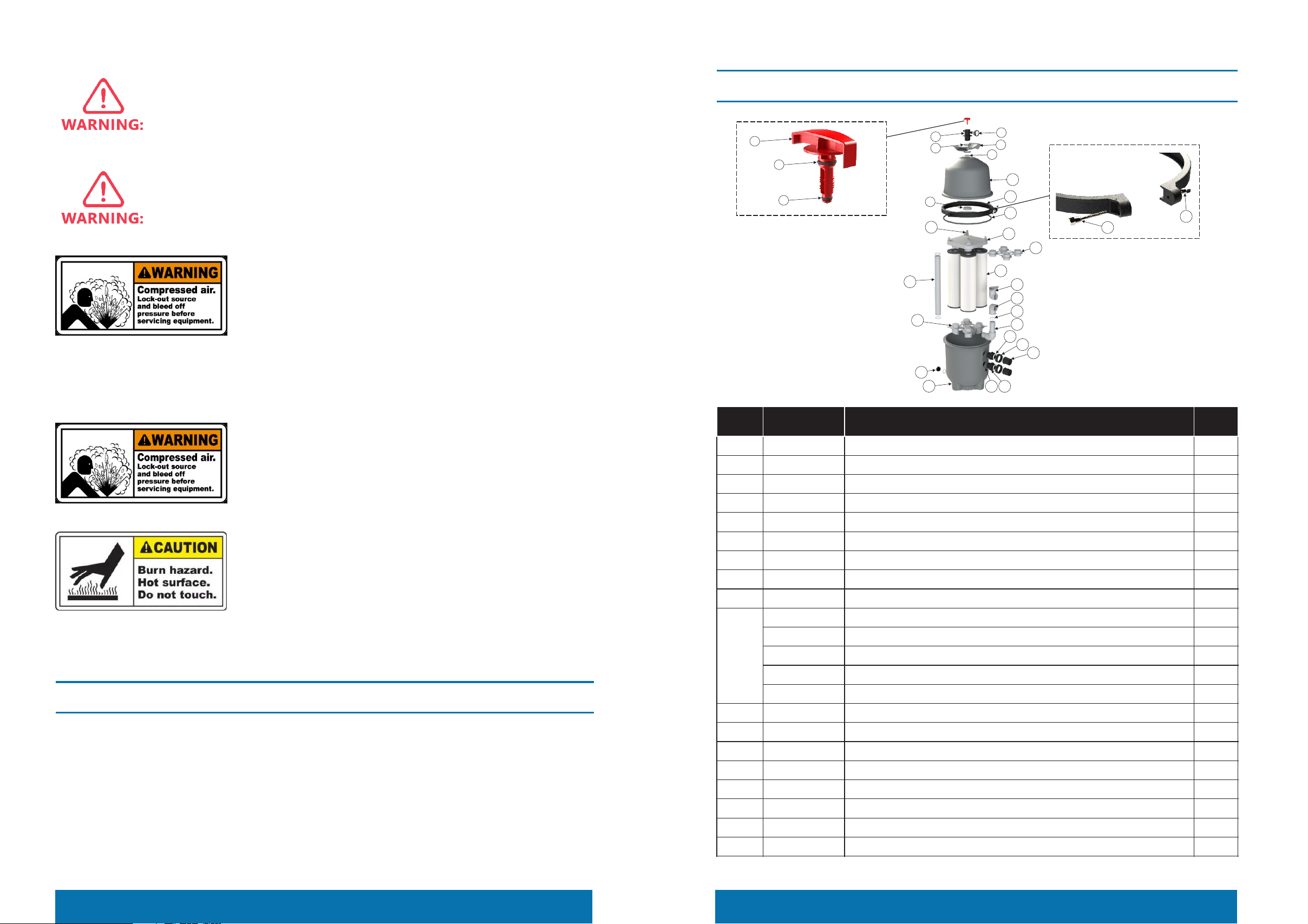

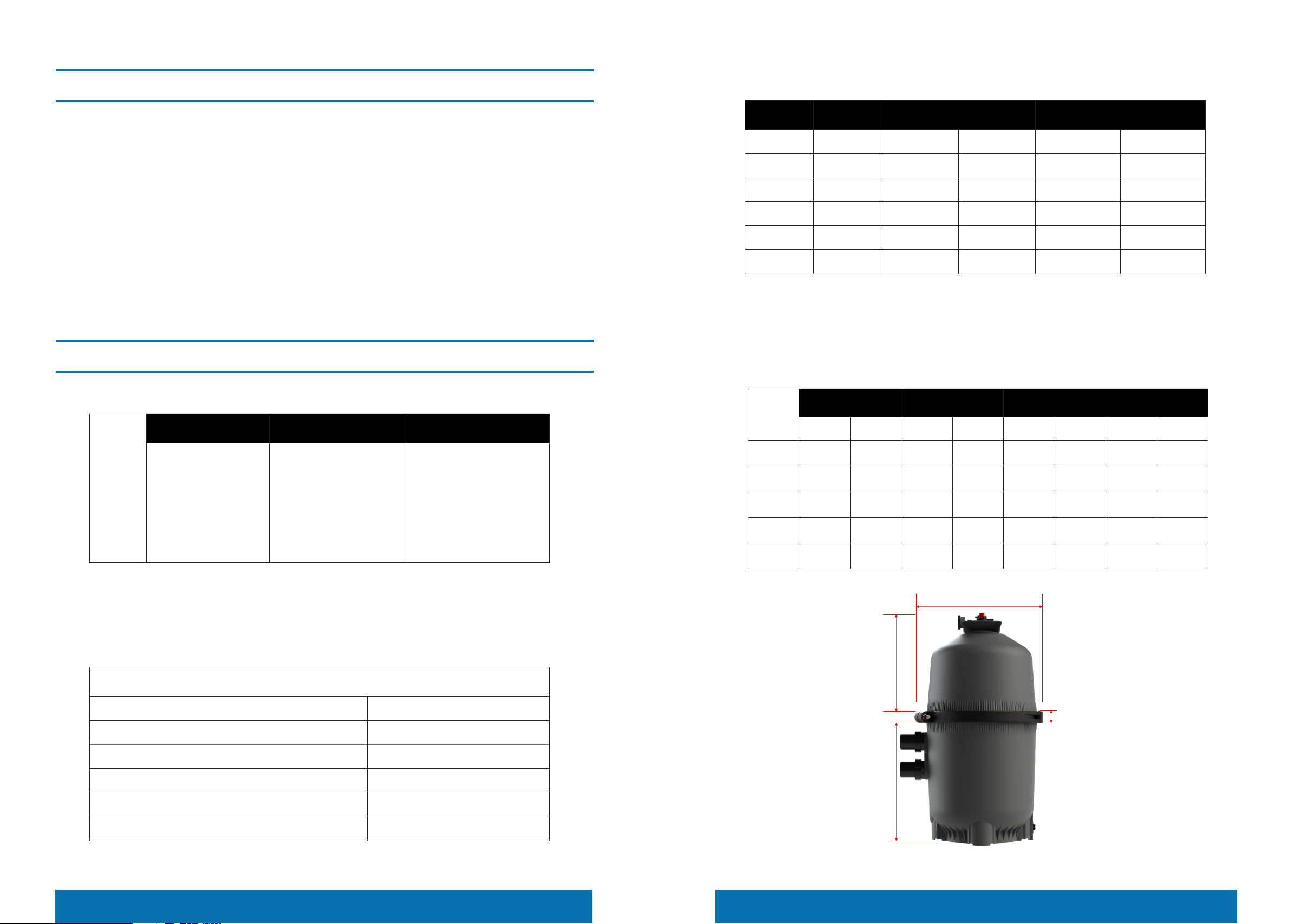

QTYQTYKey No. Part No. Description

19

20

21

22

23

24

25

26

27

28

29

30

31

111040081

550128231

E140403

111040080

112000083

112030022

E140404

111000043

550228177

E160553

107048527

107048528

107048529

107048530

107048531

914100007

914100008

914100009

914100010

914100011

550028176

O-ring d63.8×5

Outlet adaptor

Elbow assemble

O-ring d56.2×2.5

Screw 3/8in

Nut 3/8in

Ring clamp assemble

Rubber washer D526×d502x14

Bottom Body

End cap with O-ring

PVC Pipe 452mm for ICF230

PVC Pipe 508mm for ICF330

PVC Pipe 658mm for ICF430

PVC Pipe 845mm for ICF530

PVC Pipe 986mm for ICF680

Element ICF230

Element ICF330

Element ICF430

Element ICF530

Element ICF680

Element adaptor for ICF680 Only

2

1

1

4

1

1

1

1

1

1

1

1

1

1

1

4

4

4

4

8

1

As original purchaser of this equipment have purchased from Emaux Water Technology Co Ltd, through Authorized

International Distributor or Dealer, warrants its products free from defects in materials and workmanship under

normal use during warranty period. The warranty period begins on the day of purchase and extends only to the

original purchaser. It is not transferable to anyone who subsequently purchases the product from you. It excludes

all expendable parts.

During the warranty period, Emaux authorized reseller will repair or replace defective parts with new parts or, at the

option of Emaux, serviceable used parts that are equivalent or superior to new parts in performance.

8. TERMS OF THE WARRANTY

P13 TERMS OF THE WARRANTY PRODUCT