B

A

1-4

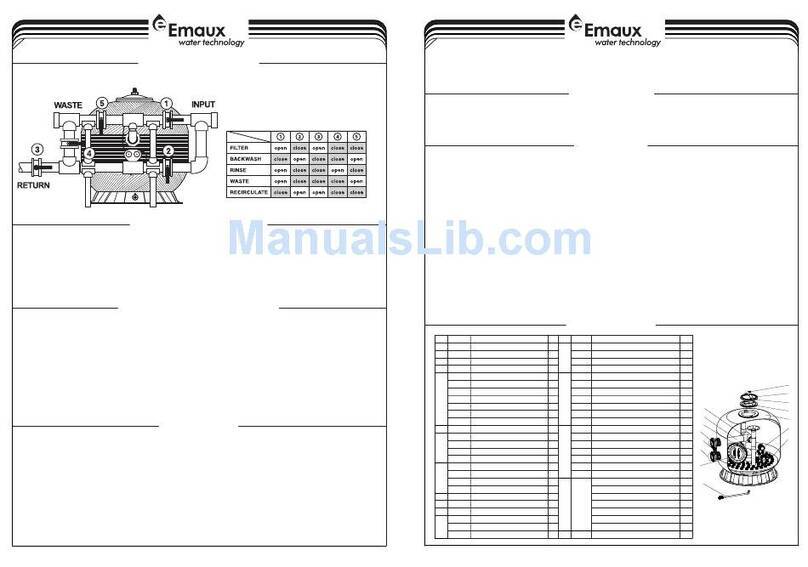

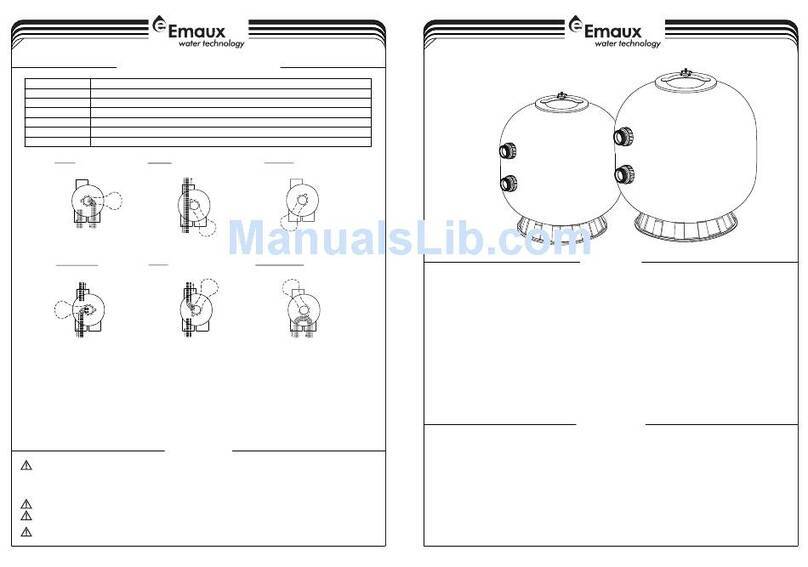

FUNCTION

INSTALLATION

Models: TMG500 / TMG650 / TMG650(B) / TMG750 / TMG900

WARNING

4-4

By-passes filter for circulating water to pool

Used after backwash to flush dirt from valve

Cleaning Filter by reversing the flow

By-passes filter, used for vacuuming to waste or lowering water level

CLOSED Shuts off all flow to filter or pool

RECIRCULATE

WASTE

RINSE

BACKWASH

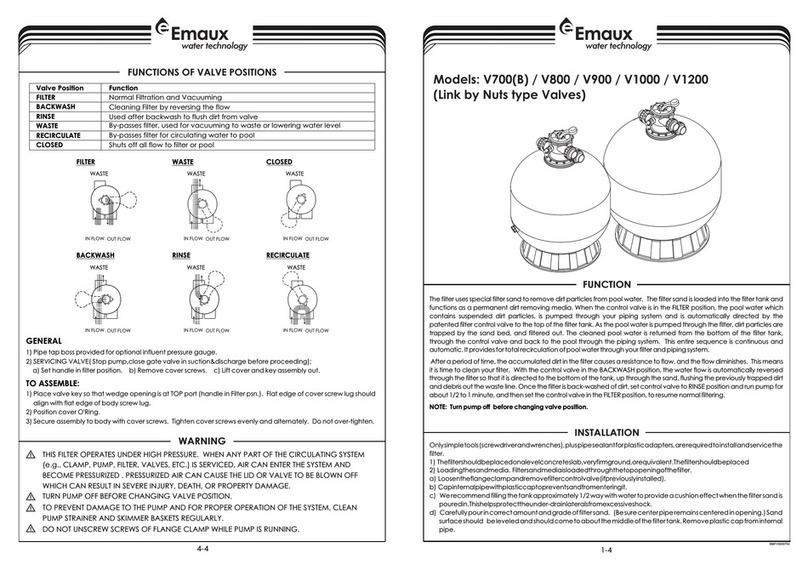

FILTER

Valve Position Normal Filtration and Vacuuming

Function

FUNCTIONS OF VALVE POSITIONS

WASTE

FILTER

IN FLOW OUT FLOW

WASTE

WASTE

IN FLOW OUT FLOW

CLOSED

WASTE

IN FLOW OUT FLOW

BACKWASH

WASTE

IN FLOW OUT FLOW

RINSE

WASTE

IN FLOW OUT FLOW

RECIRCULATE

WASTE

IN FLOW OUT FLOW

Thefilterusesspecialfiltersandtoremovedirtparticlesfrompoolwater. Thefiltersand

is loaded into thefilter tank and functions as a permanent dirt removing media. When

thecontrol valveis intheFILTERposition,the pool waterwhich containssuspendeddirt

particles, is pumped through your piping system and is automatically directed by the

patented filter control valve to the top of the filter tank. As the pool water is pumped

through the filter, dirt particles are trapped by the sand bed, and filtered out. The

cleaned pool water is returned from the bottom of the filter tank, through the control

valve and back to the pool through the piping system. This entire sequence is

continuousandautomatic.Itprovidesfortotalrecirculationofpoolwaterthroughyour

filterandpipingsystem.

Aftera periodoftime,theaccumulateddirtinthefiltercausesa resistancetoflow,andtheflowdiminishes. Thismeansitis

timetocleanyourfilter. WiththecontrolvalveintheBACKWASHposition,thewaterflowisautomaticallyreversedthrough

the filter so that it is directed to the bottom of the tank, up through the sand, flushing the previously trapped dirt and debris

outthewasteline.Oncethefilterisback-washedofdirt,setcontrolvalvetoRINSEpositionandrunpumpforabout1/2to1

minute,andthensetthecontrolvalveintheFILTERposition,toresumenormalfiltering.

NOTE: Turnpumpoff beforechangingvalveposition.

Onlysimpletools(screwdriverandwrenches),pluspipesealantforplasticadapters,arerequiredtoinstallandservicethefilter.

1) Thefiltershouldbeplacedonalevelconcreteslab,veryfirmground,orequivalent.Thefiltershouldbeplaced

2) Loadingthesandmedia. Filtersandmediaisloadedthroughthetopopeningofthefilter.

a) Loosentheflangeclampandremovefiltercontrolvalve(ifpreviouslyinstalled).

b) Capinternalpipewithplasticcaptopreventsandfromenteringit.

c) Werecommendfillingthetankapproximately1/2waywithwatertoprovideacushioneffectwhenthefiltersandispoured

in.Thishelpsprotecttheunder-drainlateralsfromexcessiveshock.

d) Carefullypourincorrectamountandgradeoffiltersand. (Besurecenterpiperemainscenteredinopening.)Sand

surfaceshould beleveledandshouldcometoaboutthemiddleofthefiltertank.Removeplasticcapfrominternalpipe.

3)Assemblefiltercontrolvalveintothefiltertank.

a) Insert filter control valve (with O'ring in place) into the tank neck, taking care that the center pipe slips into the

hole in the bottom of the valve.

b) Place two plastic clamps around valve flange and tank flange and tighten just enough so that the valve may

be rotated on tank for final positioning.

c) Carefully screw pressure gauge (with O'ring in place) into tapped hole in valve body. Do not over-tighten.

d) Connect pump to control valve opening marked PUMP. After connections are made, tighten valve flange

clamps with screwdriver, tapping around clamp with screwdriver handle to help seat valve flange clamp.

4) Make return to pool pipe connection to control valve opening marked RETURN and complete other necessary

plumbing connections, suction lines to pump, waste, etc.

5) Make electrical connections to pump per pump instructions.

6) To prevent water leakage, make sure all pipe connections are tight.

THIS FILTER OPERATES UNDER HIGH PRESSURE. WHEN ANY PART OF THE CIRCULATING SYSTEM (e.g., CLAMP, PUMP,

FILTER, VALVES, ETC.) IS SERVICED, AIR CAN ENTER THE SYSTEM AND BECOME PRESSURIZED . PRESSURIZED AIR CAN

CAUSE THE LID OR VALVE TO BE BLOWN OFF WHICH CAN RESULT IN SEVERE INJURY, DEATH, OR PROPERTY

DAMAGE.

TURN PUMP OFF BEFORE CHANGING VALVE POSITION.

TO PREVENT DAMAGE TO THE PUMP AND FOR PROPER OPERATION OF THE SYSTEM, CLEAN PUMP STRAINER AND

SKIMMER BASKETS REGULARLY.

DO NOT UNSCREW SCREWS OF FLANGE CLAMP WHILE PUMP IS RUNNING.

UNDER LOW TEMPERATURE SHUT OFF CONDITION, IT IS STRONGLY RECOMMEND TO TURN TO WINTERISE POSITION

AND DISCHARGE ALL THE WATER INSIDE FILTER THROUGH THE BOTTOM DRAIN.

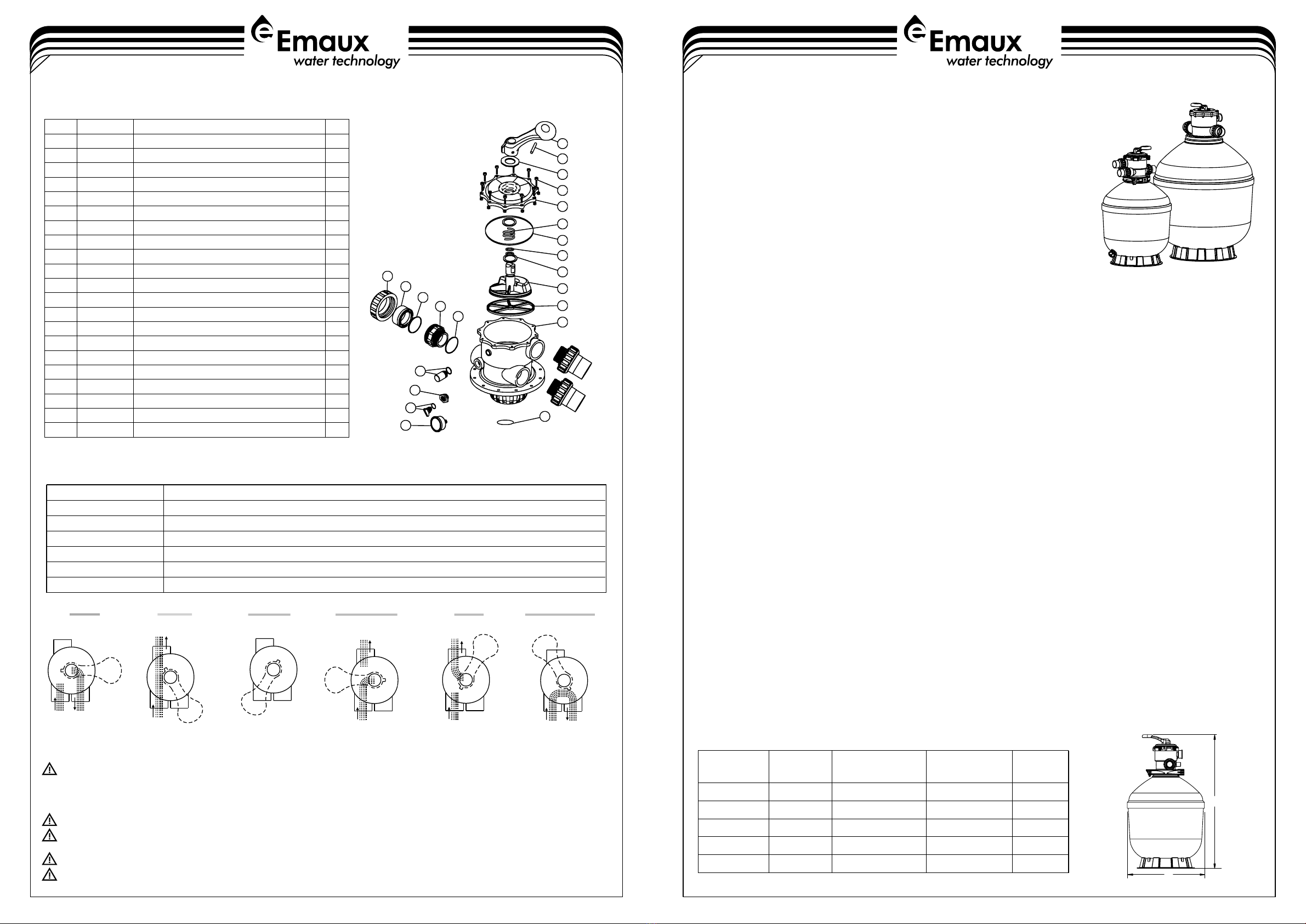

TMG SERIES GEL-COAT FILTER USER MANUAL

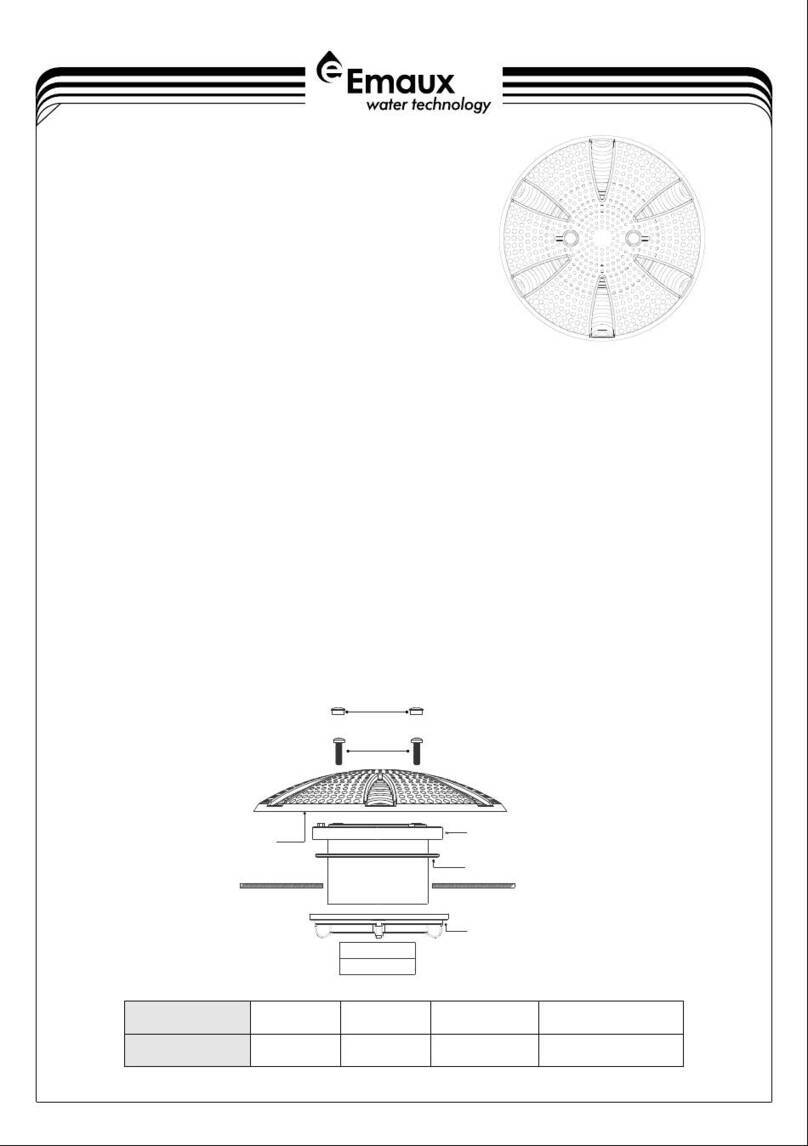

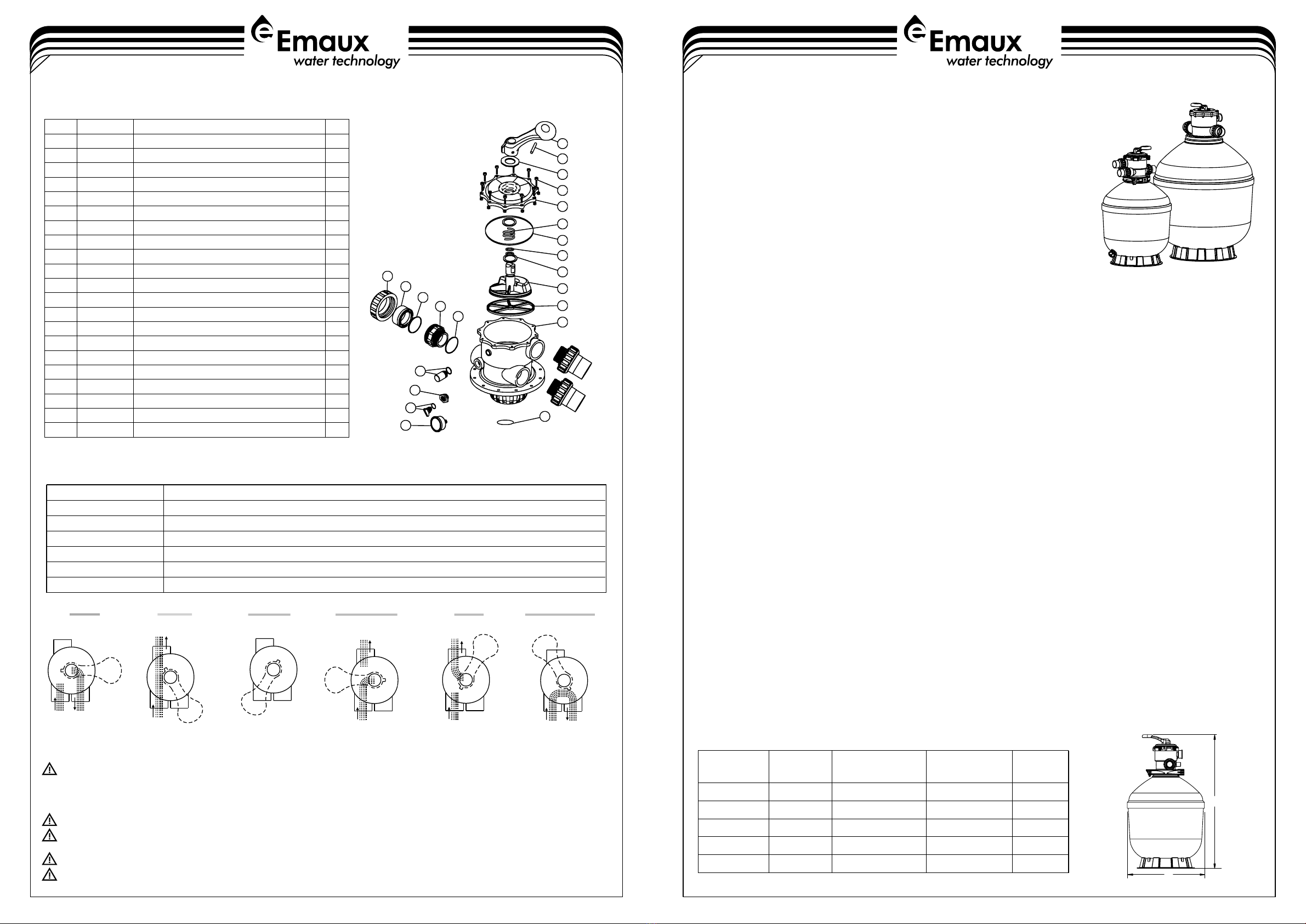

REPLACEMENT PARTS OF 2.0" MULTIPORT VALVE (TMG750 / TMG900)

DIMENSIONS

EMFI19031320

TMG500

Model

998

886

Height(A)

mm

1034

1159

1294

500

650

Diameter(B)

mm

650

750

900

Sand

kg

158

88

158

260

422

Inch

Valve Port Size

1.5"

1.5"

2.0"

2.0"

2.0"

TMG650

TMG650(B)

TMG750

TMG900

2.0" Top Mount Valve Standard Lid (Black)

O-Ring for 2.0" Top Mount Valve Lid

2.0" Body with Diffuser (Black)

Drain Plug Fitting with O-ring

Oil Pressure Gauge with O-ring

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

14

16

17

18

19

20

21