SINGLE ELEMENT CARTRIDGE FILTER

TABLE OF

CONTENT

PAGE

P1 CONTENT

2

.... 1. OVERVIEW

1.1 PRODUCT INFORMATION

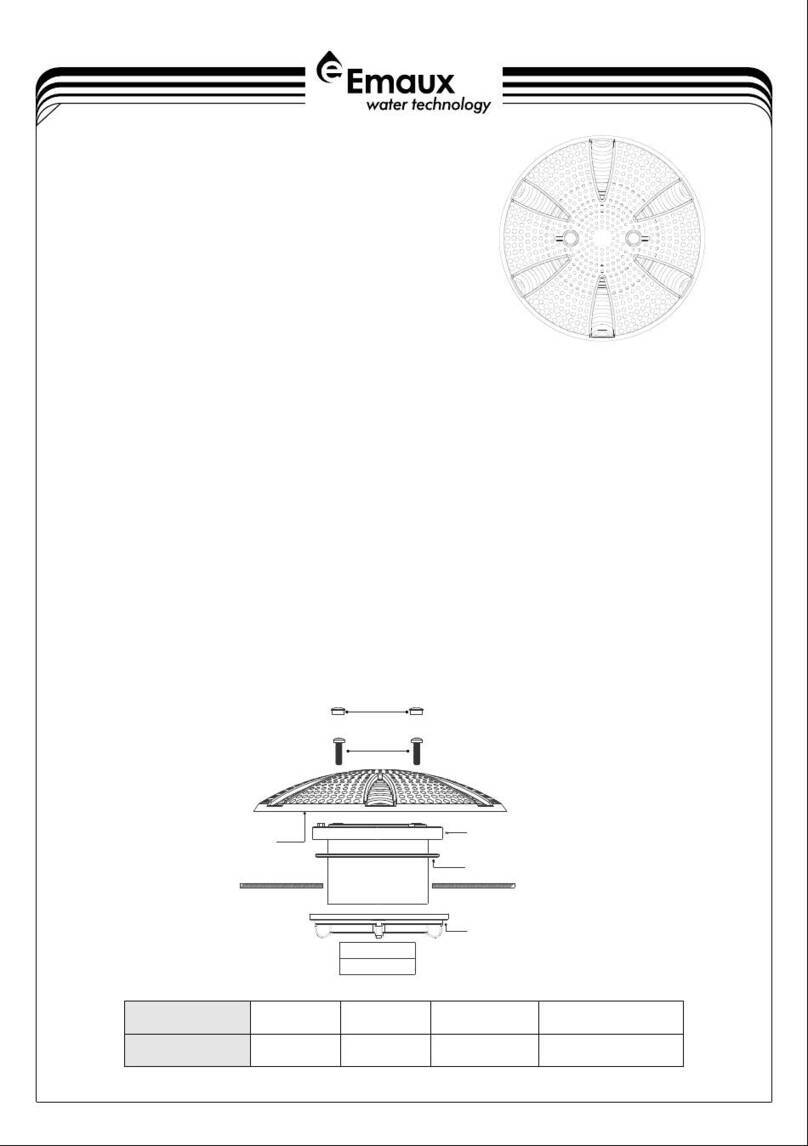

1.2 DIMENSIONS

2. INSTALLATION

3.1 BEFORE STARTING THE PUMP

3.2 STARTING PUMP

4.1 FILTER DISAEEMBLY INTRUCTIONS

10

....

IMPORTANT SAFETY INSTRUCTIONS P2

4

....

7

....

IMPORTANT SAFETY INSTRUCTIONS

THESE OPERATING INSTRUCTIONS CONTAIN IMPORTANT INFORMATION ON THE

SAFE, PROPER AND ECONOMICAL OPERATION OF THIS SWIMMING POOL

APPLIANCE. STRICT OBSERVATION OF THE OPERATING INSTRUCTIONS WILL HELP

TO AVOID DANGERS, REDUCE REPAIR COSTS, SHUTDOWN TIMES AND INCREASE

THE RELIABILITY AND WORKING LIFE OF THE PRODUCT.

Failure to follow the instructions in this manual may result in serious adverse health effects, or even serious or

fatal injury. Failure to follow the instructions in this manual will in all cases invalidate all guarantees and liability

on the part of the manufacturer.

Consumer Information and Safety

This Cartridge Filters are designed and manufactured to provide years of safe and reliable operation. Operated

and maintained according to the information in this manual and the installation codes referred to in later

sections.

THIS FILTER OPERATES UNDER HIGH PRESSUR

When any part of the circulating system, (e.g., closure, pump, filter,

valve(s), etc.), is serviced, air can enter the system and become

pressurized. Pressurized air can cause the top closure to separate

which can result in severe injury, death, or property damage. To avoid

this potential hazard, follow these instructions:

1. If you are not familiar with your pool filtering system :

Do NOT attempt to adjust or service without consulting your dealer, or a qualified pool technician.

Read the entire Installation & Operation Manual before attempting to use, service or adjust the pool

filtering system.

2. Before repositioning valve(s) and before beginning the assembly, disassembly, or any other service of the

circulating system:

(1) Turn the pump OFF and shut OFF any automatic controls to ensure the system is NOT inadvertently started

during the servicing;

open the manual air release valve;

Wait until all pressure is relieved.

3. Whenever installing the filter closure follow the filter closure warnings exactly.

4. Once service on the circulating system is complete follow initial start-up instructions exactly.

5. Maintain circulation system properly. Replace worn or damaged parts immediately, (e.g., closure, pressure

gauge, valve(s), O-rings, etc.).

6. Be sure that the filter is properly mounted and positioned according to instructions provided.

(1)

(2)

(2)

(3)

This filter must be installed by a licensed or certified electrician or a qualified pool

serviceman in accordance with the Local Code and all applicable local codes and

ordinances.

Improper installation could result in death or serious injury to pool users, installers, or

others and may also cause damage to property.

Always disconnect power to the pool circulating system at the circuit breaker before servicing the filter. Ensure

that the disconnected circuit is locked out or properly tagged so that it cannot be switched on while you are

working on the filter. Failure to do so could result in serious injury or death to serviceman, pool users or others

due to electric shock.

Installation and Operation Manual

3. STARTING THE PUMP AND FILTER SYSTEM

3.3 OPERATION

4. MAINTAINING YOUR FILTER

4.2 REMOVING CARTRIDGES

4.3 CLEANING CARTRIDGES

4.4 FILTER REASSEMBLY INTRUCTION

4.4.1 RE-INSTALLLING CARTRIDGES

4.4.2 CLEAN SEAL RING AND SEAL SURFACE

4.4.3 BODY AND LOCKING RING RE_ASSEMBLY

4.4.4 VACCUUMONG POOL

4.5 REMOVING THE MANUAL AIR RELEASE VALVE

4.5.1 RE-INSTALLATION OF THE MANUAL AIR RELEASED VALVE

5. WINTERIZING FILTER

7. SPARE PART LIST

6. TROUBLE SHOOTING

6.1 WATER CHEMISTRY

8. TEMS OF THE WARRANTY PRODUCT

5

....

10

....

11

....

12

....