资料版本 V1.4 归档日期 2009-07-14 BOM 编码 31011979

IRM-S02TH Intelligent Temperature

and Humidity Sensor User Manual

1 Overview

IRM-S02TH intelligent temperature and humidity sensor (sensor for short) is

used to measure and display environment temperature and humidity. It

supports MODBUS protocol through RJ45 port in RS-485 mode to configure

and collect data. It is applicable for indoor sites which need temperature and

humidity control such as communication rooms and IT data centers.

1.1 Product Introduction

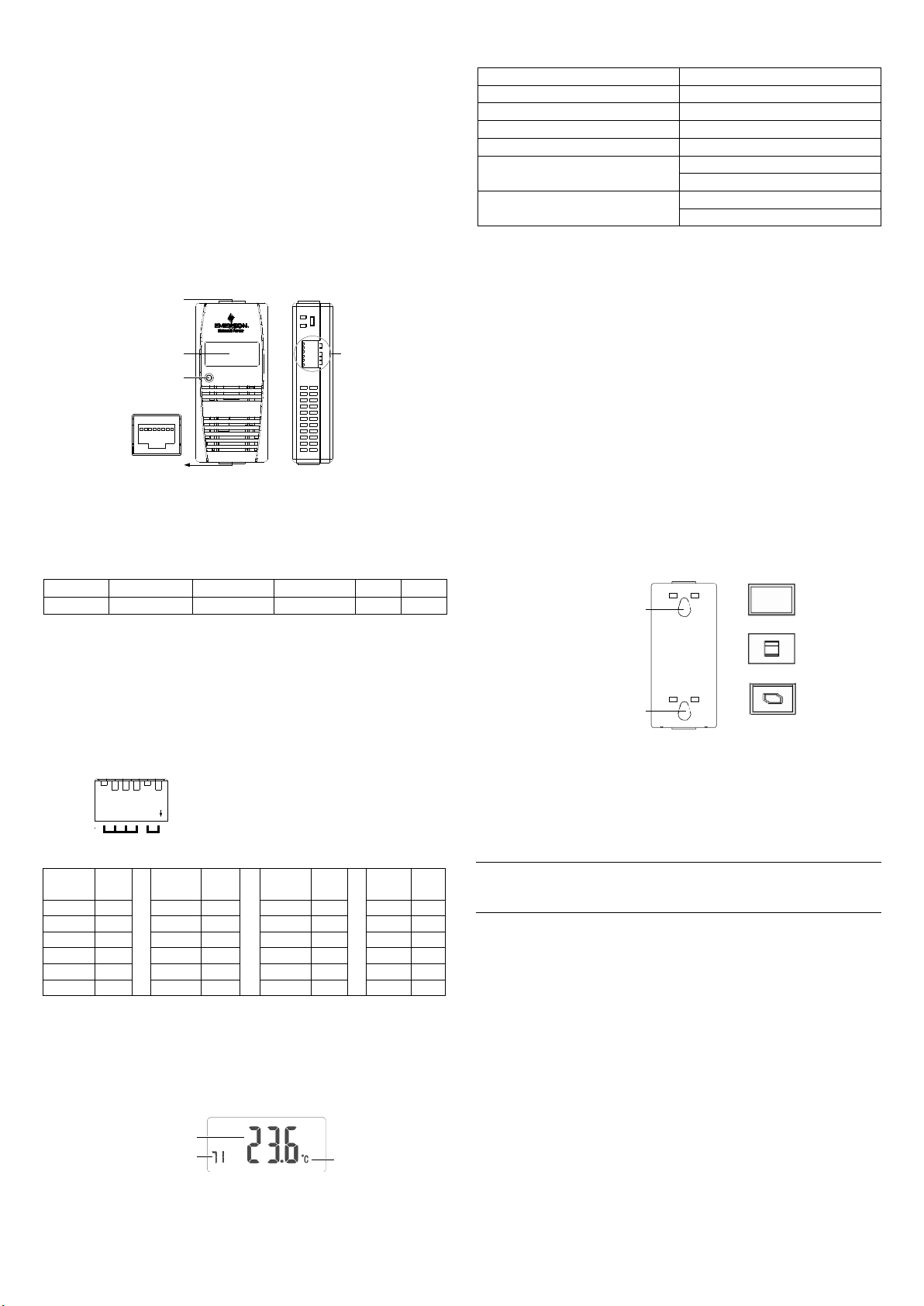

1.1.1 Appearance

The sensor’s appearance is shown as the following figure.

ALARM

Temp&Hum Sensor

IRM-S02TH

DIP switch

RJ45 port

LCD display panel

Alarm indicator

Front view Right view

12345678

RJ45 port

Size (height × width × depth): 97mm × 44mm × 22mm Weight: about 100g

1.1.2 RJ45 Port

Two RJ45 ports are used in the electric connection of the sensor for power

supply, communication and equipment connection in series. The definition of

RJ45 ports is shown in the following table.

1.1.3 DIP Switch

The DIP switch is used to set sensor address to communicate with upper

equipment through MODBUS protocol. The sensor address is composed of

group number and serial number within the group. The DIP1 ~ DIP4 are used

to set the group number and the DIP5 ~ DIP6 are used to set the serial

number within the group. For example, the sensor address of 71 is set as

shown in the following figure, among which 0111 means group number 7 and

01 means serial number 1 within the group.

Group Num

1 2 3 4 5 6

DIP ON

0 1 1 1 0 1

Note: 1. DIP switch in the ON position means 1,

or it means 0;

2. The sensor address cannot be set as 00,

which is the broadcast address.

The settings of DIP1 ~ DIP6 are listed in the following table.

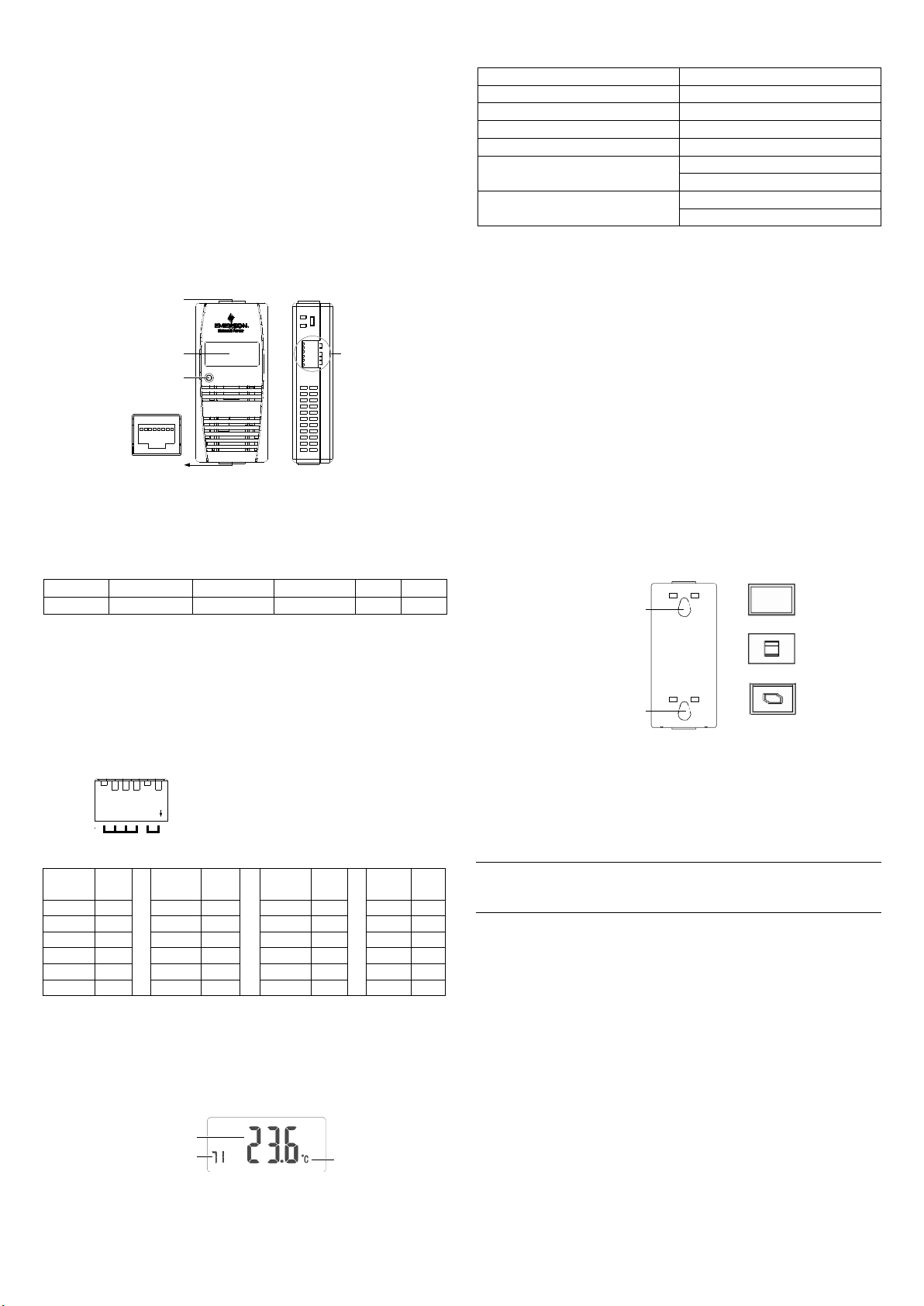

1.1.4 LCD Display Panel

The LCD display panel can display sensor address, temperature and humidity

data in real time. Temperature and humidity are displayed by turns every 2

seconds. For example, when the sensor address is 71, and the temperature

data is 23.6°C, the LCD display panel indicates the data as shown in the

following figure.

Temperature data

Sensor address Data unit

1.1.5 Alarm Indicator

When the temperature data is outside the the configured data range or the

sensor fails, the alarm indicator flashes; when the temperature data is in the

range of the configured data, the alarm indicator extinguishes.

1.2 Technical Specification

Measurable temperature range

Measurable humidity range

Temperature measuring precision

±2°C (other temperature range)

Humidity measuring precision

±20%RH (other humidity range)

2 Installation

2.1 Environment Requirement

1. Operating environment should be free of conductive dust and

metal-corrosive & insulation-breaking gases.

2. Avoid using the sensor in watery or foggy places.

3. Keep a clearance of more than 20mm around the sensor’s airway to

ensure ventilation inside and outside of the sensor.

4. Operating temperature: -10°C ~ +50°C; storage temperature: -30°C ~

+70°C; humidity: 5% ~ 95% RH (non-condensing).

2.2 Unpacking Inspection

Unpack the sensor and visually inspect the sensor’s appearance. If any

damage is found, please contact the carrier immediately.

Check against the consignment list to make sure the sensor and accessories

are complete and correct.

2.3 Mechanical Installation

Three modes are available for the sensor’s mechanical installation. The

installation accessories and modes are shown in the following figure.

Back installation hole Magnet pothook

L pothook

T pothook

Sensor

Back installation hole

Mode one: Insert the magnet pothook into the sensor’s back installation hole,

and the sensor can absorb on iron surface.

Mode two: Insert the L pothook into the sensor’s back installation hole, and

hang the pothook in the square hole of rack’s column with care.

Mode three: Insert the T pothook into the sensor’s back installation hole,

insert the bulge of the T pothook into the installation slot of the rack’s basic

frame, and rotate the sensor 90 degree clockwise with care.

Note

The sensor can not only be installed through the three kinds of accessories above, but

also can hang on fixed screws directly through the installation hole.

2.4 Cable Connection

Insert one end of the standard straight network cable into the sensor’s RJ45

port, and insert the other end into the sensor appropriative port of upper

equipment or sensor in series.

3 Maintenance

1. To clean the sensor, you should cut off the power and use a piece of soft

cloth to wipe it.

2. Do not disassemble the sensor, or the inside subtle parts may be damaged.

Emerson Network Power Co., Ltd.

Address: No.1 Kefa Rd., Science & Industry Park, Nanshan District 518057,

Shenzhen China

Homepage: www.emersonnetworkpower.com.cn

E-mail: support@emersonnetwork.com.cn

Copyright © 2009 by Emerson Network Power Co., Ltd.

All rights reserved. The contents in this document are subject to change

without notice.

Version V1.4 Revision date July 14, 2009 BOM 31011979