4

Enardo ES-850 and Enardo ES-950 Series

Outside North America Only

Smart Wireless Monitoring Option

▲ WARNING

The surface resistivity of the antenna

assembly when the optional transmitter

is installed is greater than 1 GΩ. To avoid

electrostatic charge build up, it must not be

rubbed or cleaned with solvents or dry cloth.

The Smart Wireless Monitoring Option is available

with PVRV Models Enardo ES-850 (Pipe-away) and

Enardo ES-950 (Vent-to-atmosphere). This option allows the

remote sensing and “OPEN/CLOSED” value transmission

of the open or closed status of the pressure vent, the

vacuum vent or both. Use Option Code WP for pressure vent

monitoring, Option Code WV for vacuum vent monitoring

or WPV for the monitoring of both at the end of the model

string. Knowing whether a PVRV is open or closed can

enable immediate response to prevent problems related to

safety, emissions and quality of the tank contents.

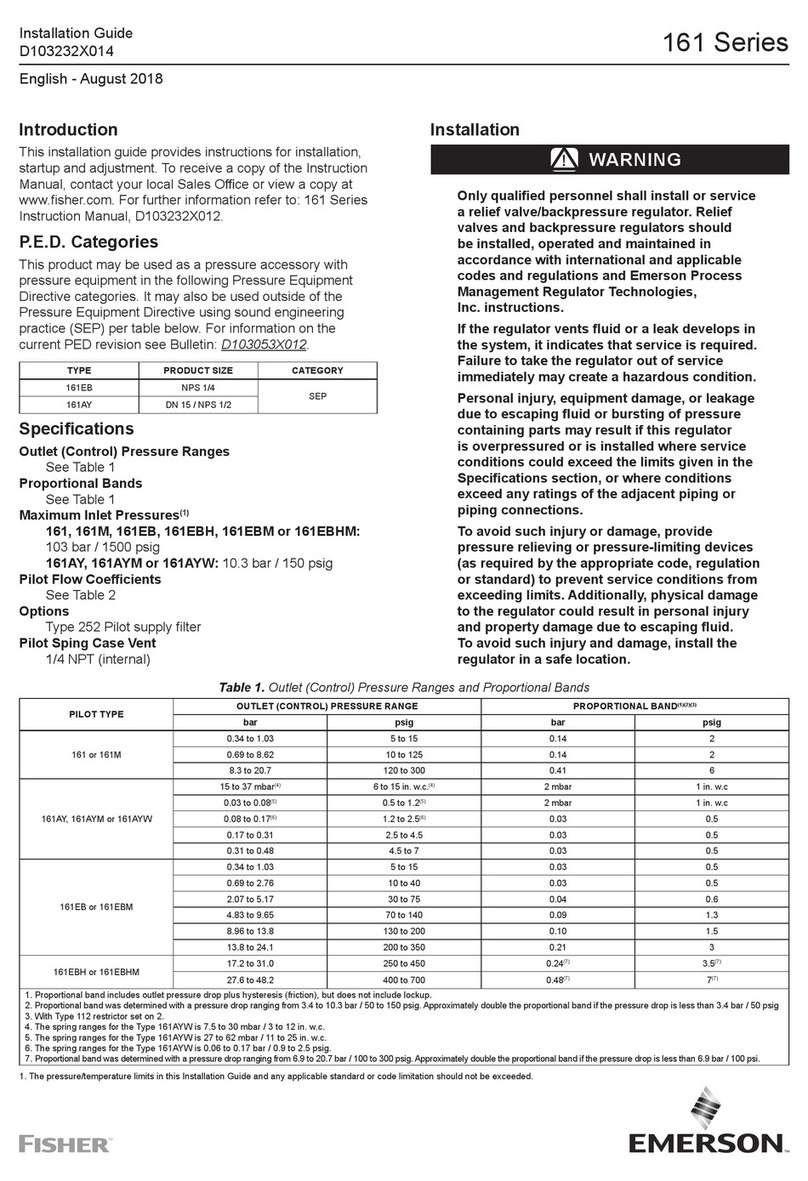

INLET CONNECTION OUTLET CONNECTION WEIGHT

(ALUMINUM)

WEIGHT

(STAINLESS STEEL OR

CARBON STEEL)

WEIGHT OF CALIBRATION WEIGHTS REQUIRED TO

ACHIEVE DESIRED RELIEF SETTING(2)(3)

Weight per oz/sq. in. Weight per in. w. c.

In. mm In. mm Lb kg Lb kg Lb kg Lb kg

2 50 3 80 29 13 80 36 0.9 0.3 0.5 0.2

3 80 3 80 31 14 85 39 0.9 0.3 0.5 0.2

3 80 4 100 33 15 90 41 0.9 0.3 0.5 0.2

4 100 6 150 57 26 144 65 2.3 1.0 1.3 0.6

6 150 6 150 62 28 155 70 2.3 1.0 1.3 0.6

6 150 8 200 70 32 178 81 2.3 1.0 1.3 0.6

8 200 10 250 161 73 485 220 7.8 3.5 4.5 2.0

10 250 10 250 166 75 503 228 7.8 3.5 4.5 2.0

10 250 12 300 172 78 525 238 7.8 3.5 4.5 2.0

12 300 12 300 175 79 532 241 7.8 3.5 4.5 2.0

12 300 14 350 208 94 622 282 7.8 3.5 4.5 2.0

1. Unit weights indicate Net Weight of valve in pounds and kilograms at standard set pressure (0.5 oz/sq. in. pressure – 0.5 oz/sq. in. vacuum). It does not include shipping crate or box.

2. Multiply the relief setting by the value shown to determine the weight of the calibration weights used to achieve the desired relief setting.

3. Values shown for calibration weights are for reference purposes only. They are not intended to be used for determination of valve relief setting.

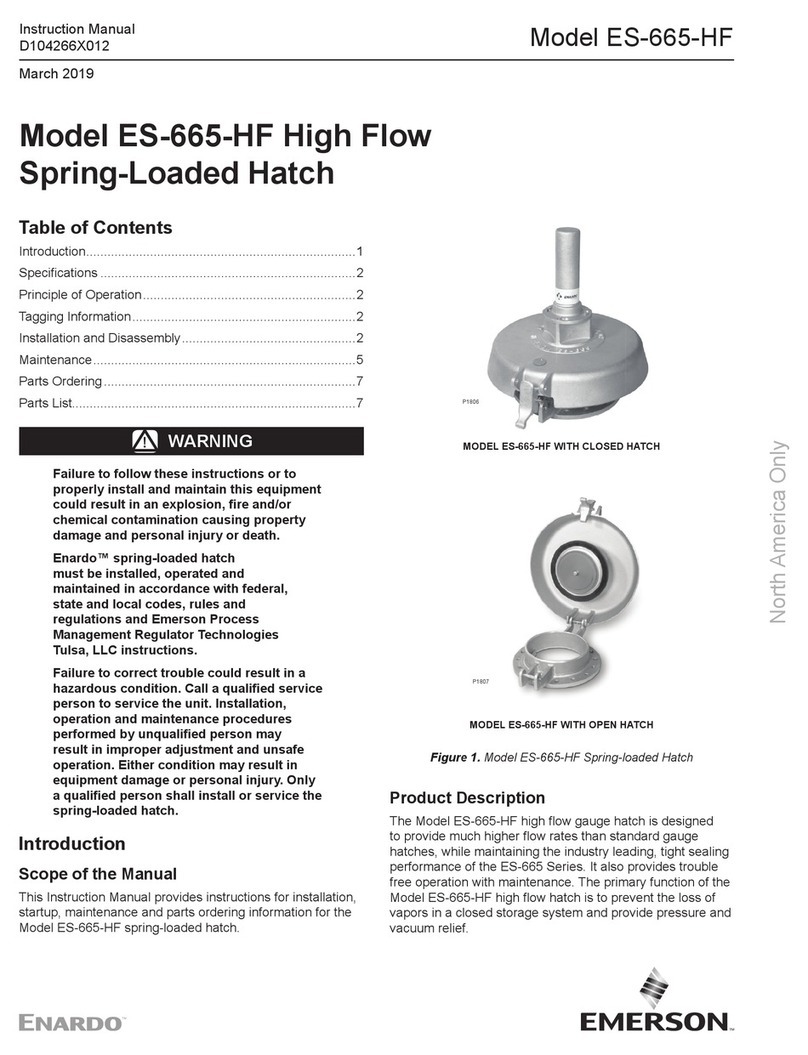

INLET CONNECTION WEIGHT

(ALUMINUM)

WEIGHT

(STAINLESS STEEL OR

CARBON STEEL)

WEIGHT OF CALIBRATION WEIGHTS REQUIRED TO ACHIEVE

DESIRED RELIEF SETTING(2)(3)

Weight per oz/sq. in. Weight per in. w. c.

In. mm Lb kg Lb kg Lb kg Lb kg

2 50 21 10 54 24 0.9 0.3 0.5 0.2

3 80 23 10 58 26 0.9 0.3 0.5 0.2

4 100 41 19 110 50 2.3 1.0 1.3 0.6

6 150 45 20 123 56 2.3 1.0 1.3 0.6

8 200 123 56 362 164 7.8 3.5 4.5 2.0

10 250 129 59 383 174 7.8 3.5 4.5 2.0

12 300 144 65 405 184 7.8 3.5 4.5 2.0

1. Unit weights indicate Net Weight of valve in pounds and kilograms at standard set pressure (0.5 oz/sq. in. pressure – 0.5 oz/sq. in. vacuum). It does not include shipping crate or box.

2. Multiply the relief setting by the value shown to determine the weight of the calibration weights used to achieve the desired relief setting.

3. Values shown for calibration weights are for reference purposes only. They are not intended to be used for determination of valve relief setting.

Table 1. Model Enardo ES-850 Weights(1)

Table 2. Model Enardo ES-950 Weights(1)

The following are a few specic examples of how this added

visibility can help prevent problems:

Example #1 – Redundant PVRVs

Redundant PVRVs are commonly used for added safety. If

the primary PVRV fails closed or partially-closed, then the

backup PVRV automatically takes over. This is achieved by

establishing a pressure set point that is slightly higher for

the backup device. In this way, if the primary PVRV fails, the

tank remains protected. But redundancy is lost and should

be addressed as soon as possible. But how will you know

if this has occurred? Monitoring the open/closed position

of the backup PVRV can provide quick identication of this

issue, for either the pressure or vacuum side. Under normal

conditions, the backup PVRV remains closed. If the backup

PVRV is open, this points to either the primary PVRV not

functioning as expected or a separate pressure control

problem in the tank system that is causing both PVRVs to

be open. Ideally, the wireless monitoring of both primary and

backup devices is preferred in order to gain the most insight.

Further troubleshooting can then be performed and the

problem can be detected and addressed.