3

ANDERSON GREENWOOD 4142HF PRESSURE RELIEF VALVE

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

4 SET PRESSURE VERIFICATION

If the pressure setting is to be verified prior to

installation, it is recommended that a test rig

with a suitable accumulator be used having the

following general features:

• Connection to the accumulator tank should

ensure a negligible pressure drop between

the accumulator and the test valve.

• Observed pressure shall be measured in the

accumulator tank.

• The flange on which the valve is mounted

shall be level.

• The valve should be tested using clean air or

nitrogen.

Remove valve from shipping container and

remove all packaging. Check that the pressure

setting, the rated capacity and other details on

the nameplate are correct.

4.1 Set Pressure Verification

For set pressure verification, the test apparatus

needs to limit the maximum flow rate into

the accumulator such that a pressure drop

measured in the accumulator can be observed

when the valve set pressure is reached.

1. Ensure that the test rig is clean and fasten

the valve securely to the test flange.

2. Check nameplate for required set pressure.

3. Increase the inlet pressure slowly until the

pallet assembly can be seen to be gently

lifting and reseating on the seat. The inlet

pressure at this point is the adjusted set

pressure and should coincide with the point

at which no further rise in inlet pressure

is observed. Repeat a further two times to

ensure repeatability.

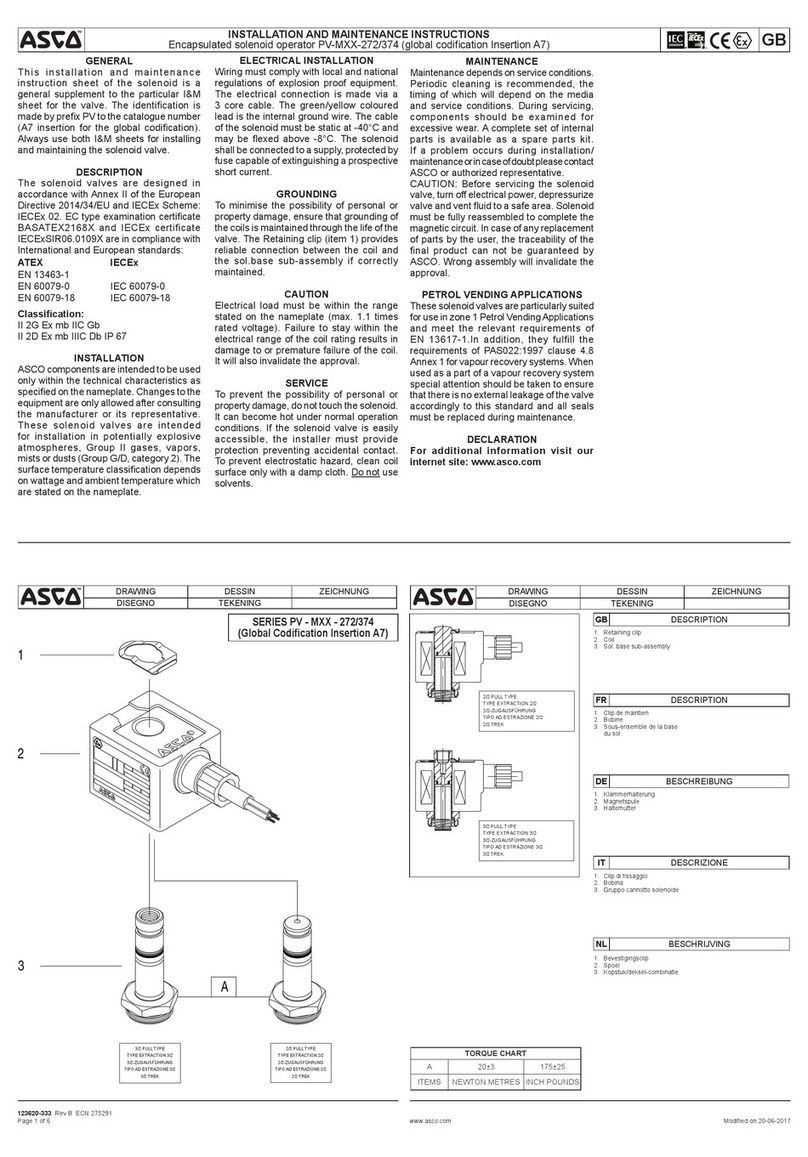

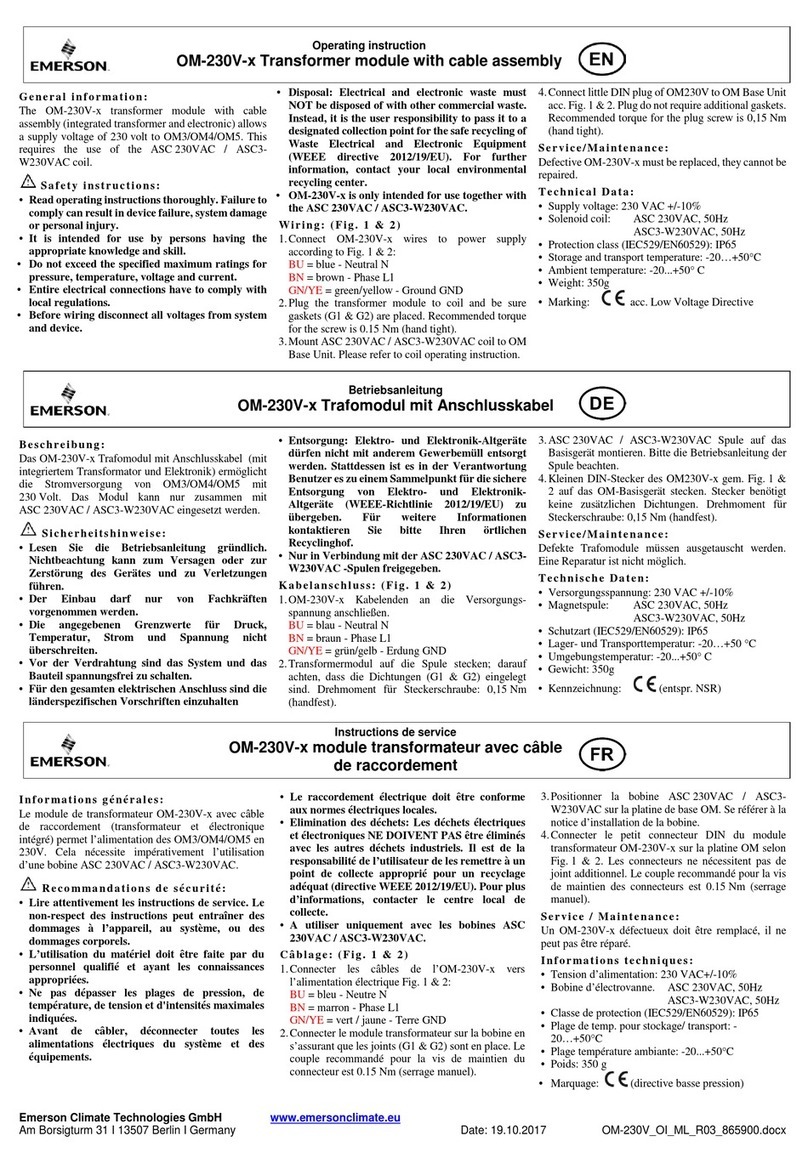

4.2 Set Pressure Adjustment (See Figure 1)

The valve has been factory set to the required

setting, however, if it is necessary to make a

set pressure adjustment this can be done as

follows:

1. Remove hex set screws [7] and washers [5]

then remove cover [2] and O-ring [8].

2. The set pressure can be increased or

reduced by adding or removing lead weights

which can be supplied in various settings.

3. Refit cover [2] ensuring O-ring [8] is correctly

installed and secure using hex set screw [7]

and washers [5].

CAUTION

Whenever the cover is removed and re fitted,

ensure correct engagement of the pallet stem in

the weather hood guide tube.

4. Repeat set pressure verification as per 4.1

and repeat set pressure adjustment if

required.

If it is not possible to verify the set pressure on

a test rig, the required setting can be verified

by measuring the combined weight of the pallet

and installed weights. Refer to Table 4 for

combined weight and equivalent set pressures.

5 INSTALLATION

The mating connection to the tank should be

flat machined horizontal flange and should be

thoroughly cleaned to remove all foreign matter

which could lead to valve leakage if trapped

between the valve seat and the pallet. The bore

diameter of the tank connection nozzle should

be at least equal to the inlet bore of the valve

connection. For correct valve operation, all

discharge piping shall be adequately supported

and there shall be no external loads applied to

the valve body.

Fit an inlet gasket to the mating flange

ensuring it does not obstruct the flow path

and install the valve. Ensure that the main axis

of the valve is perpendicular. Flange bolting

should be tightened uniformly to ensure a good

seal.

For valves of aluminium construction,

appropriate flat face flanges should be used

and a full face gasket fitted.

NOTE:

Storage tank inlet piping configurations should

conform to recognised standards. Different

configurations will develop different inlet pressure

losses when the valve is flowing. This should be

taken into consideration when sizing the valve for

the application.

It is recommended that the external surfaces

of carbon steel valves are painted immediately

after installation.

Any discharge pipework should be adequately

supported to prevent any loads being applied

to the valve body and should have adequate

drainage to prevent accumulation of liquids on

the downstream side.

Discharge pipework must be at least equal in

size to the valve outlet and any built up back

pressure in the discharge line should be limited

to 10% of the valve set pressure.

Discharge lines should be positioned so as

to allow safe disposal of tank contents under

relief conditions.