Installation

!

WARNING

Only qualied personnel should install

or service a regulator. Regulators should

be installed, operated and maintained

in accordance with international and

applicable codes and regulations and

Emerson instructions.

If the regulator vents uid or a leak develops

in the system, it indicates that service

is required. Failure to take the regulator

out of service immediately may create a

hazardous condition.

Personal injury, equipment damage, or

leakage due to escaping uid or bursting of

pressure containing parts may result if this

regulator is overpressured or is installed

where service conditions could exceed the

limits given in the Specications section, or

where conditions exceed any ratings of the

adjacent piping or piping connections.

To avoid such injury or damage, provide

pressure-relieving or pressure-limiting

devices (as required by the appropriate code,

regulation, or standard) to prevent service

conditions from exceeding limits.

Additionally, physical damage to the

regulator could result in personal injury and

property damage due to escaping uid. To

avoid such injury and damage, install the

regulator in a safe location.

Clean out all pipelines before installation of the regulator and

check to be sure the regulator has not been damaged or has

collected foreign material during shipping. For NPT bodies,

apply pipe compound to the external pipe threads. For flanged

bodies, use suitable line gaskets and approved piping and

bolting practices. Install the regulator in any position desired,

unless otherwise specified, but be sure flow through the body

is in the direction indicated by the arrow on the body.

Note

It is important that the regulator be installed

so that the vent hole in the spring case

is unobstructed at all times. For outdoor

installations, the regulator should be located

away from vehicular trafc and positioned

so that water, ice and other foreign materials

cannot enter the spring case through the

vent. Avoid placing the regulator beneath

eaves or downspouts and be sure it is above

the probable snow level.

Downstream Control Line Installation

!

WARNING

Failure to install a downstream control line

could result in a hazardous condition. Install

downstream control line(s) to the slam-shut

device when construction uses external

pressure registration. The regulator and

slam-shut device will not control pressure

or shutoff if a downstream control line is not

installed on those constructions where external

pressure registration is required.

CSB600 Series regulators with an “ET” or “EN” in the type

number use external pressure registration. To communicate

the downstream pressure to the regulator, connect a

downstream control line tubing to the 3/4 NPT control line

tapping in the lower diaphragm casing and connect the other

end of the tubing downstream of the regulator outlet with a

minimum distance of 6 times the outlet pipe diameter.

For all types with external control lines, use tubing with an

inner diameter of 16 mm / 0.63 in. or larger.

Downstream Control Line Installation with

Slam-Shut Device

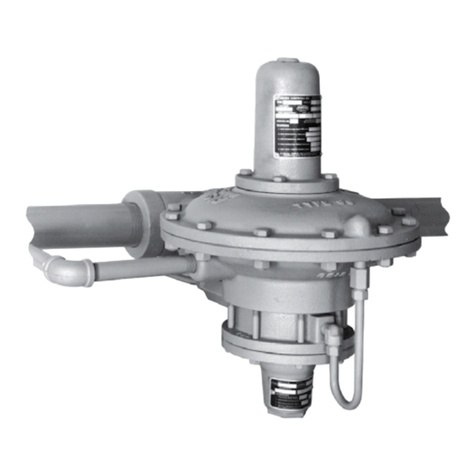

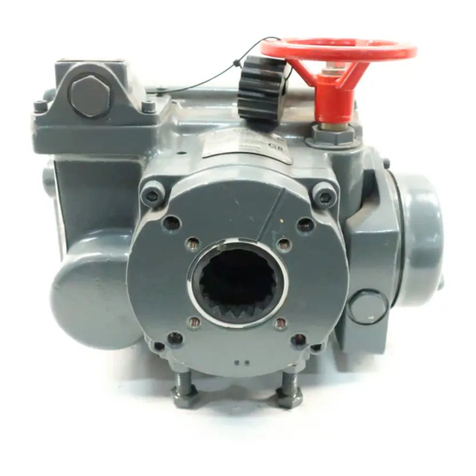

Refer to Figure 1. When installing the Types CSB604ET,

CSB604EN, CSB604FET, CSB604FEN CSB624ET,

CSB624EN, CSB624FEN, CSB654ET and CSB654EN

regulators, connect downstream control line tubing to the

lower casing of the regulator and run the tubing downstream

of the regulator outlet with a minimum distance of 6 times

the outlet pipe diameter. Connect a second, separate

downstream control line tubing to the lower casing of

the slam shut and run the tubing downstream of the

regulator outlet a minimum distance of 6 times the outlet

pipe diameter.

For all types with external control lines, use tubing with an

inner diameter of 16 mm / 0.63 in. or larger for the primary

regulator and 6.4 mm / 0.25 in. or larger for the slam shut.

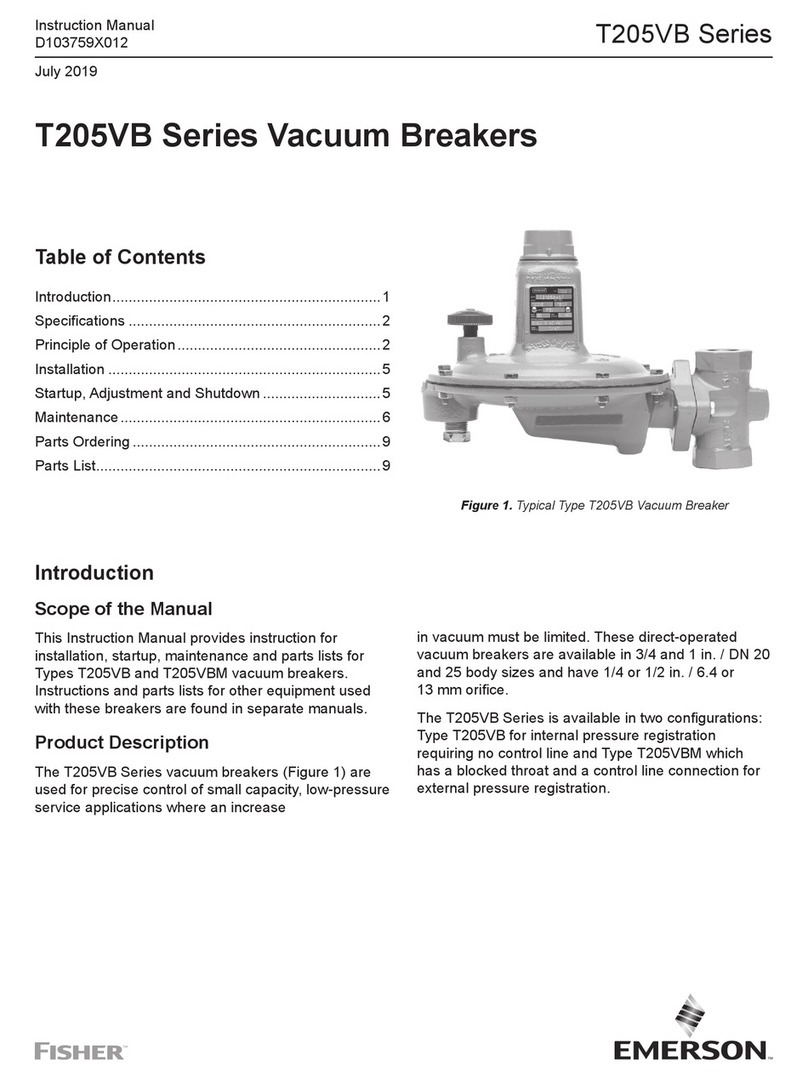

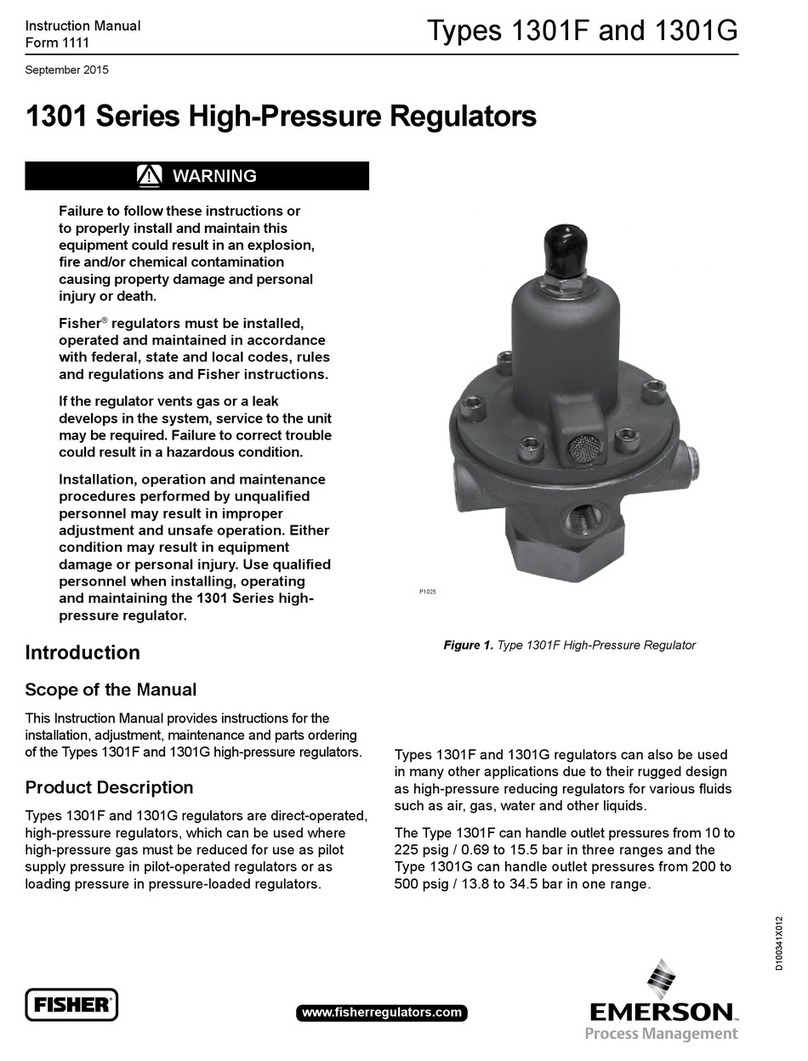

Installation with External Overpressure Protection

If the regulator is used in conjunction with a Type 289H

relief valve, it should be installed as shown in Figure 3.

The outside end of the vent line should be protected

with a rainproof assembly. The Type 289H is typically

set 25 mbar / 10 in. w.c. higher than the outlet pressure

setting of the regulator, up to 75 mbar / 30 in. w.c. outlet

pressure. For pressure greater than this, set the Type 289H

0.05 bar / 0.75 psi higher than the outlet pressure setting

of the regulator. Refer to the 289 Series Instruction Manual

(D100280X012) for complete information.

CSB600 Series

6