!

9

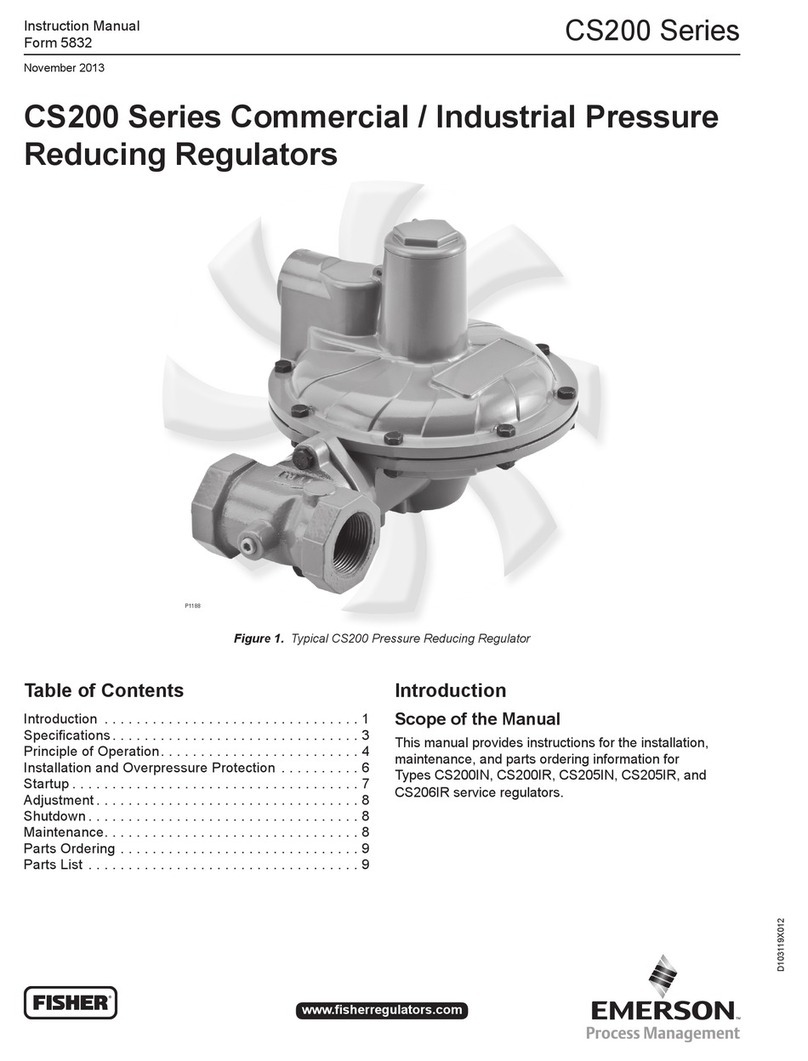

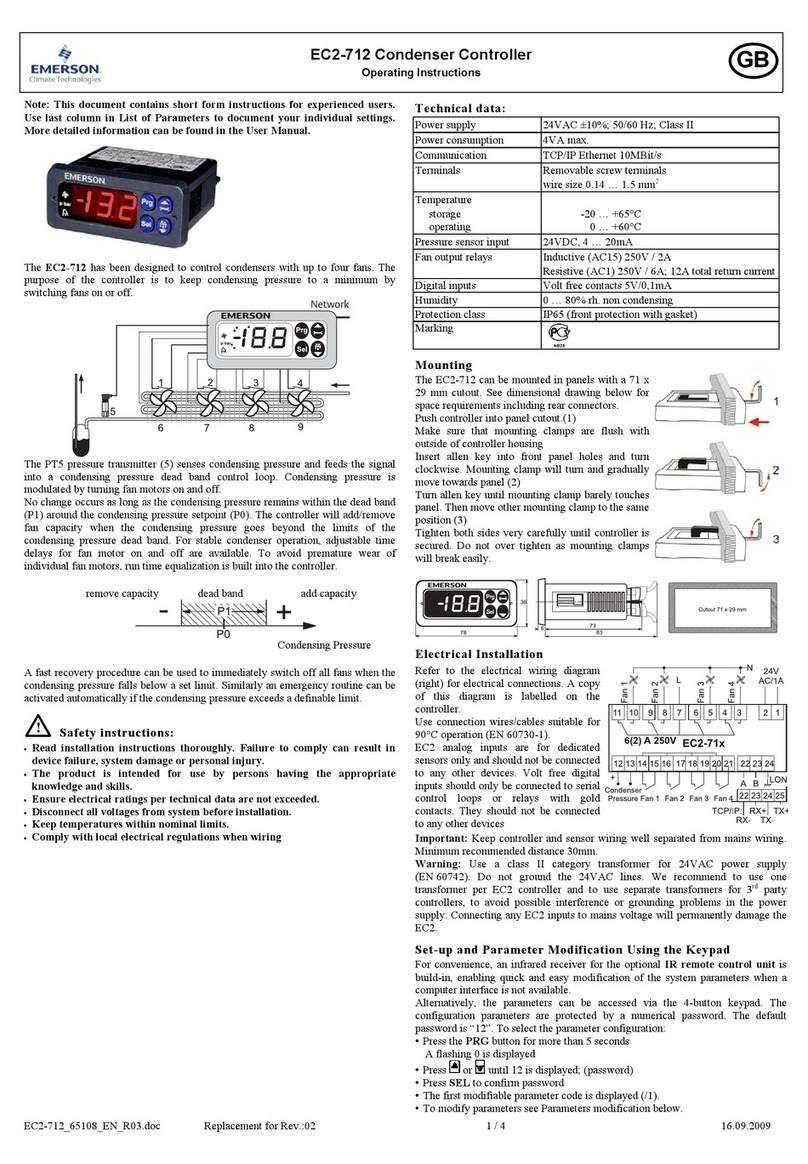

MR95 Series

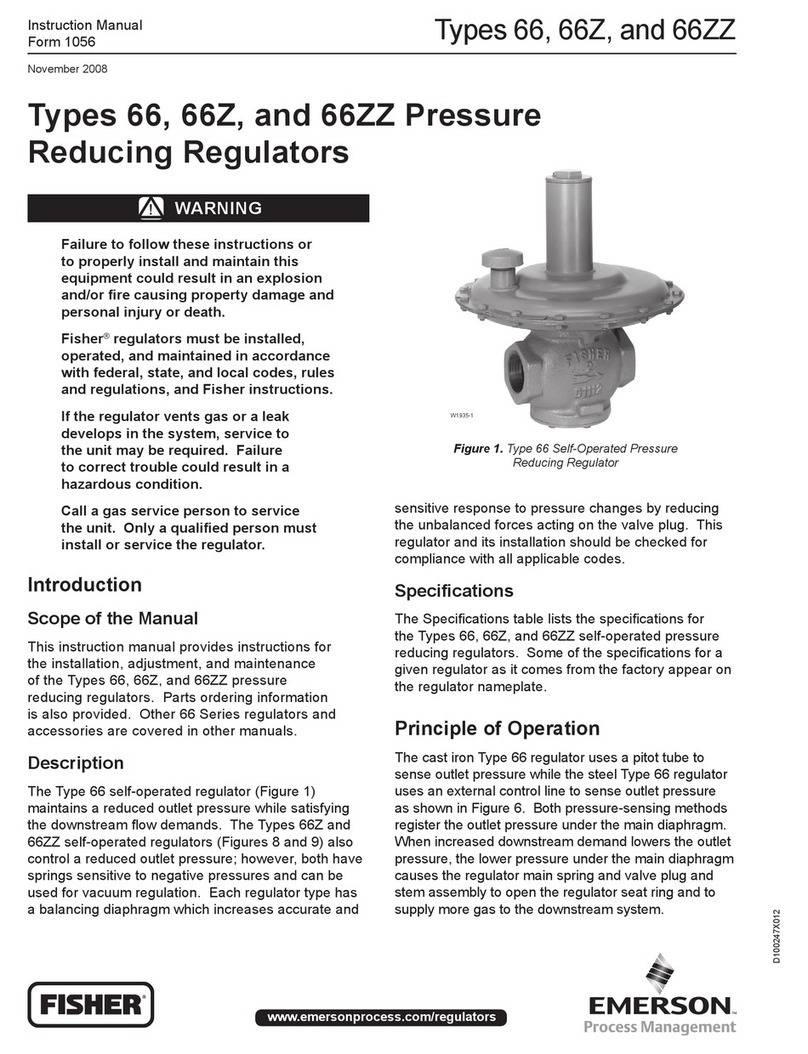

Failure to follow these instructions or

to properly install and maintain this

equipment could result in an explosion,

re and/or chemical contamination

causing property damage and personal

injury or death.

Fisher™ regulators must be installed,

operated and maintained in accordance

with federal, state and local codes, rules

and regulations and Emerson Process

Management Regulator Technologies,

Inc. (Emerson) instructions.

If the regulator vents gas or a leak

develops in the system, service to

the unit may be required. Failure

to correct trouble could result in a

hazardous condition.

Installation, operation and maintenance

procedures performed by unqualied

personnel may result in improper

adjustment and unsafe operation. Either

condition may result in equipment

damage or personal injury. Only a

qualied person shall install or service

the MR95 Series regulator.

Introduction

Scope of the Manual

Product Description

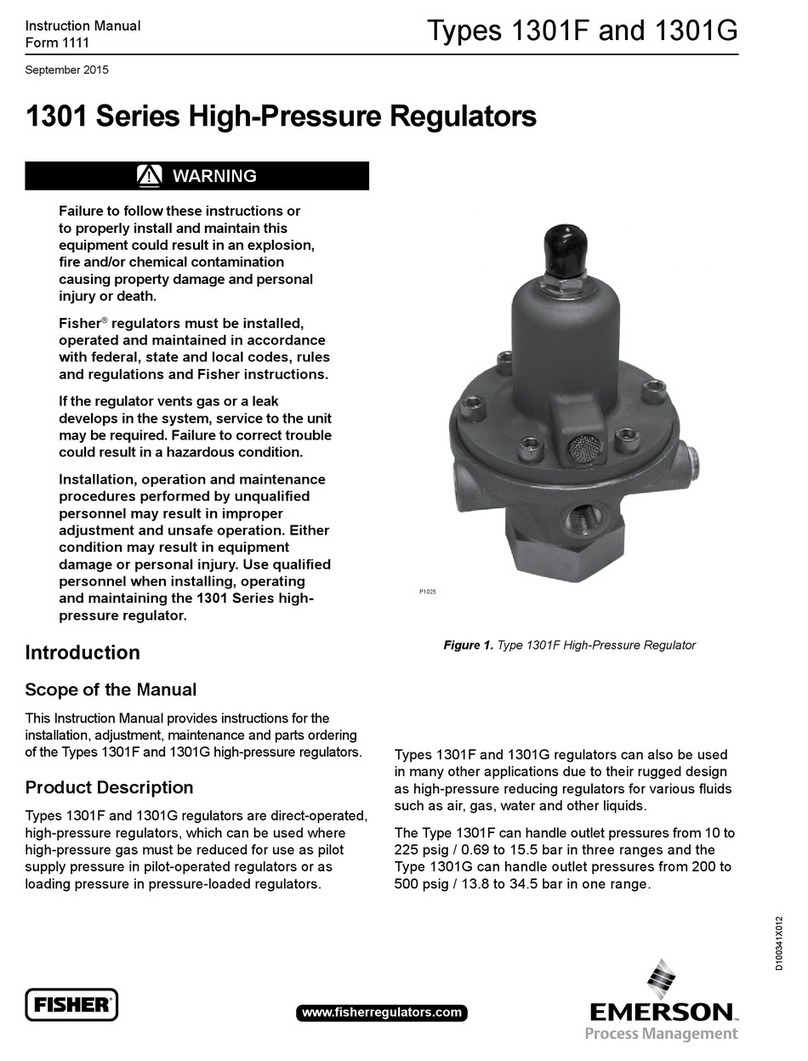

Pressure Reducing Regulators

.

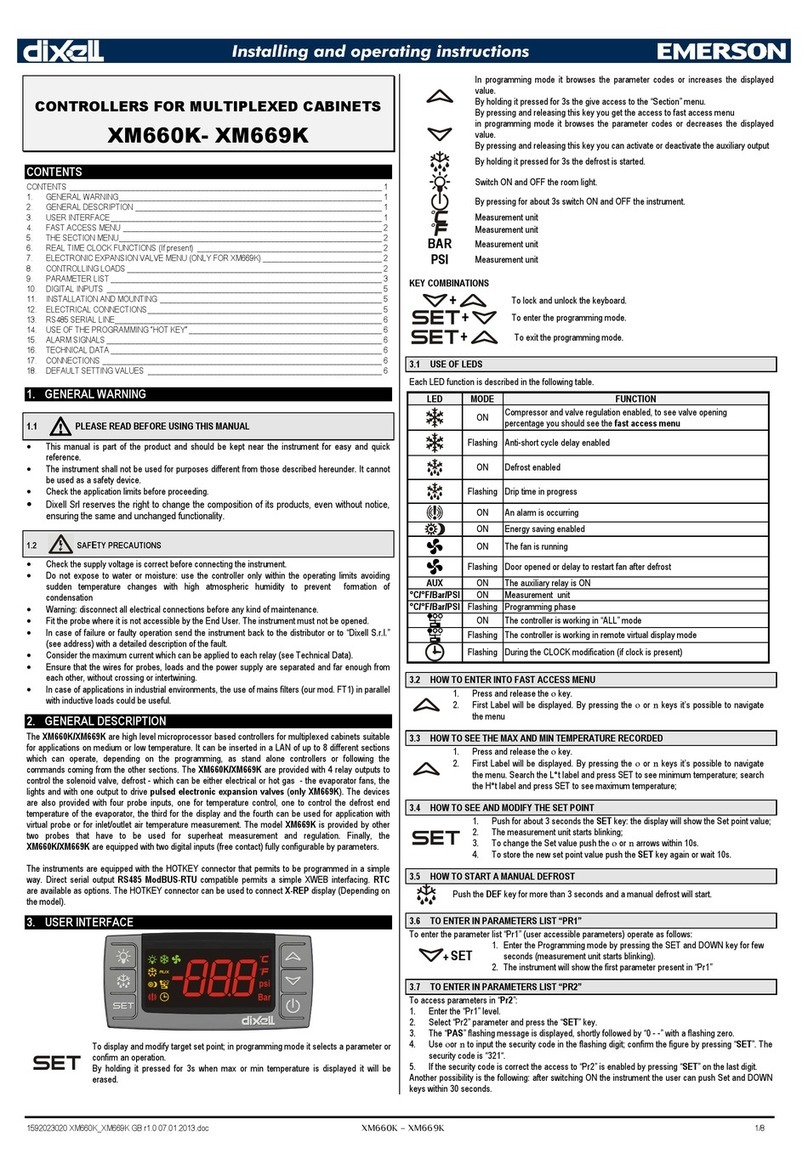

Dierential Pressure Regulators

Principle of Operation

For Types MR95H, MR95L,

MR95HP and MR95HT

Pressure Reducing Regulators

For Types MR95LD, MR95HD and

MR95HDP Dierential Pressure Regulators

WARNING