1592001520 XC10CX - XC30CX GB rel1.0 08.08.2012 XC30XC 2/4

5.4 EXTERNAL THEMOSTAT (14-17)

Function: the thermostat input, if present, enables the regulation only when active.

Contacts: 14-17 free voltage.

Parameters:

di1

Thermostat digital input presence (14-17)

n= the regulation is performed independently from the status of digital input 14-17.

Y =the regulation is performed only when the digital input 14-17 is enabled.

i1P

Thermostat digital input polarity 14-17

oP = the digital input is activated by opening the contacts 14-17.

CL =the digital input is activated by closing the contacts 14-17.

5.5 HP SAFETY PRESSURE SWITCH (15-17)

Function: the HP safety input, if present, switches off the compressor when active.

Contacts: 15-17 free voltage

Parameters:

di2

HP safety digital input presence 15-17

n= the regulation is performed independently from the status of digital input 15-17.

Y =the regulation is performed only when the digital input 15-17 is disabled.

i1P

HP safety digital input polarity 15-17

oP = the digital input is activated by opening the contacts 15-17.

CL =the digital input is activated by closing the contacts 15-17.

HPn

HP safety digital input activation before compressor lock

0= always automatic restart

1 to 15 = when the number of activation of the digital input in an hour reaches HPn times,

the regulation is locked and a manual restart is required.

HPF Minimum time of compressor off when the HP digital input is activated (0 to 15 min).

5.5.1 Functioning

NOTE: the HP safety digital input is checked only when the compressor is running

If the HP safety digital input is activated, the following actions will be performed

a. The compressor will be shut down.

b. The display will show the “HP” message alternated with suction probe

c. The HP alarm counter will be increased.

5.5.2 Automatic restart

If the HP digital input is switched off, the compressor will be able to restart only when the HPF and AC

timers are expired.

If the HP digital input is activated HPn times in an hour, a manual restart will be required. In this

situation:

a. The compressor will be shut down.

b. The display will show the “HPL” message alternated with suction probe.

c. The HP alarm counter will be increased.

5.5.3 Manual restart

a. Switch the controller off and on - or -

b. With rSC=rSt, keep the RESTART key pressed more than 5 sec - or -

c. Enter programming mode and set rSt=Y.

5.6 BUMP START FUNCTION

Purpose: the bump start function is useful to get the refrigerant out of the compressor, without losing

all of the oil, in the event of a flooded start and when pump-down and crank-case heaters are not

applicable or inadequate.

Parameters:

bMP

Bump start enabling

n= bump start disabled.

Y= bump start enabled.

on Compressor on time: 1 to 15 sec.

oFF Compressor off time: 1 to 15 sec.

nub Number of cycle during bump start: 1 to 15.

bEn Compressor stop time for next bump start: 1.0 to 23h50min, res. 10 min.

5.6.1 Functioning

At power on, after a power down or when the compressor remains off for the bEn time, it is activated

for on seconds and switched off for oFF seconds nub times.

5.7 COMPRESSOR SHUT DOWN WITH HIGH DLT TEMPERATURE ALARM

Purpose: with P3C=dLt, it’s possible to connect a PTC 990ohm probe to the 16-17 terminals for

monitoring the discharge line temperature. When the temperature reaches the set threshold, the

compressor will be shut down.

Parameters

doF DLT alarm temperature to stop compressor: don to 200°C; don to 392°F.

don DLT temperature for compressor restart: -30.0°C to doF; -22°F to doF.

ALd Stop compressor delay: 0 to 255 sec.

nPS

Number of activation of DLT alarm in a hour to lock compressor

0= always automatic restart.

1 to 15 = when the DLT alarm happens nPS times in an hour, the regulation is locked and

a manual restart is required.

dLF Minimum time of compressor off with dLt temperature alarm: 0 to 15 min.

5.7.1 Functioning

When the temperature detected by the DLT probe is higher than doF value, the following actions will

be performed:

a. The compressor will be shut down.

b. The display will show the “dLt” message alternated with suction probe.

c. The dLt alarm counter will be increased.

5.7.2 Automatic restart

When the temperature detected by the dLT probe is lower than the don value, the compressor will be

able to restart only when both dLF and AC timers will expire.

If the temperature detected by the dLT probe reaches the doF value nPS times in an hour, a manual

restart will be required.

In this situation:

a. The compressor will be shut down.

b. The display will show the “dLL” message alternated with suction probe.

c. The dLL alarm counter will be increased.

5.7.3 Manual restart

a. Switch controller off and on -or -

b. With rSC=rSt, keep the RESTART key pressed more than 5 sec -or -

c. Enter programming mode and set rSt=Y.

NOTE: In any case the compressor can restart only if the dLt temperature is less than don

value.

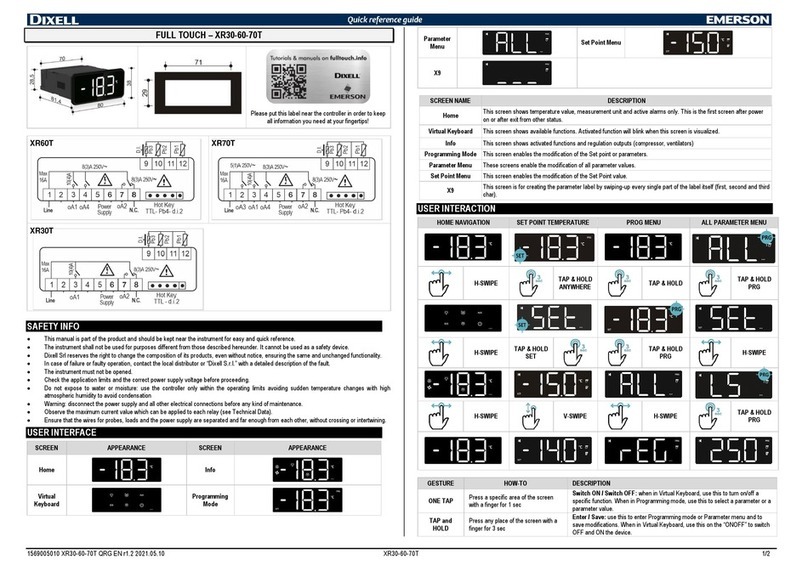

6. MAIN INTERFACE

6.1 HOW TO SEE THE SETPOINT

1. Push and immediately release the SET key: the display will show the Cin

message.

2. Push the SET key to see the value.

3. Push and immediately release the SET key: the display will show the

Cou message.

4.

Push the SET key to see the value.

6.2 HOW TO MODIFY THE SETPOINT

1. Keep push the SET key since the display will show the Cin message.

2. Push the SET key to see the value.

3. Use UP or DOWN to change its value

4. Push and immediately release the SET key: the display will show the

Cou message.

5. Push the SET key to see the value.

6. Use UP or DOWN to change its value

6.3 HOW TO CHANGE A PARAMETER VALUE

To change a parameter value, operate as follows:

1. Enter the Programming mode by keeping SET+DOWN keys pressed 3 sec (the “PSI” or “bar”LED

starts blinking).

2. Select the required parameter. Press SET key to display its actual value.

3. Use UP or DOWN to change its value.

4. Press SET to store the new value and move to the following parameter.

To exit: Press SET+UP or wait for 15 sec without pressing a key.

NOTE: the set value is stored even when the procedure is exited by waiting the time-out to expire.

6.4 THE HIDDEN MENU

The hidden menu includes all the parameters of the instrument.

6.4.1 HOW TO ENTER THE HIDDEN MENU

1. Enter the Programming mode by pressing the SET+DOWN buttons for 3 sec (the °C or °F LED will

start blinking).

2. Released the buttons and then push again the SET+DOWN buttons for more than 7 sec. The Pr2

label will be displayed immediately followed from the HY parameter.

Now it is possible to browse the hidden menu.

3. Select the required parameter.

4. Press the SET button to display its value.

5. Use UP or DOWN to change its value.

6. Press SET to store the new value and move to the following parameter.

To exit: Press SET+DOWN or wait 15 sec without pressing a key.

NOTE1: if no parameter is present in Pr1 menu, after 3 sec the “noP” message will be displayed.

Keep the buttons pushed till the Pr2 message will be displayed.

NOTE2: the set value is stored even when the procedure is exited by waiting for the time-out to expire

6.4.2 HOW TO MOVE A PARAMETER FROM THE HIDDEN MENU TO THE

FIRST LEVEL AND VICEVERSA

Each parameter present in the hidden menu (Pr2) can be moved into the user level (Pr1) by pressing

SET+DOWN buttons. If a parameter is part of the user level, when showed in the hidden menu the

decimal point will be lit.

6.5 HOW TO LOCK THE KEYBOARD

1.

Keep both UP and DOWN buttons pressed for more than 3 sec.

2.

The “PoF” message will be displayed and the keyboard will be locked. At this point it will be

possible only to see the set point or the MAX o Min temperature stored

3.

If a button is pressed more than 3 sec the “PoF” message will be displayed.

6.6 TO UNLOCK THE KEYBOARD

Keep pressed together for more than 3 sec the UP and DOWN keys till the “Pon” message will be

displayed.

7. ALARM MENU

The controller records in the Alarm menu the total number of activation of the following alarms.

-HP safety pressure switch activation ( up to 999) - HP menu

-High dLt temperature alarm ( up to 999) - dLt menu

-Total number of manual restarts (HPL and dLL) up to 255 - LOC menu.