© 2020 Emerson. All rights reserved.Emerson.com

Before installation, these instructions must be read carefully and understood.

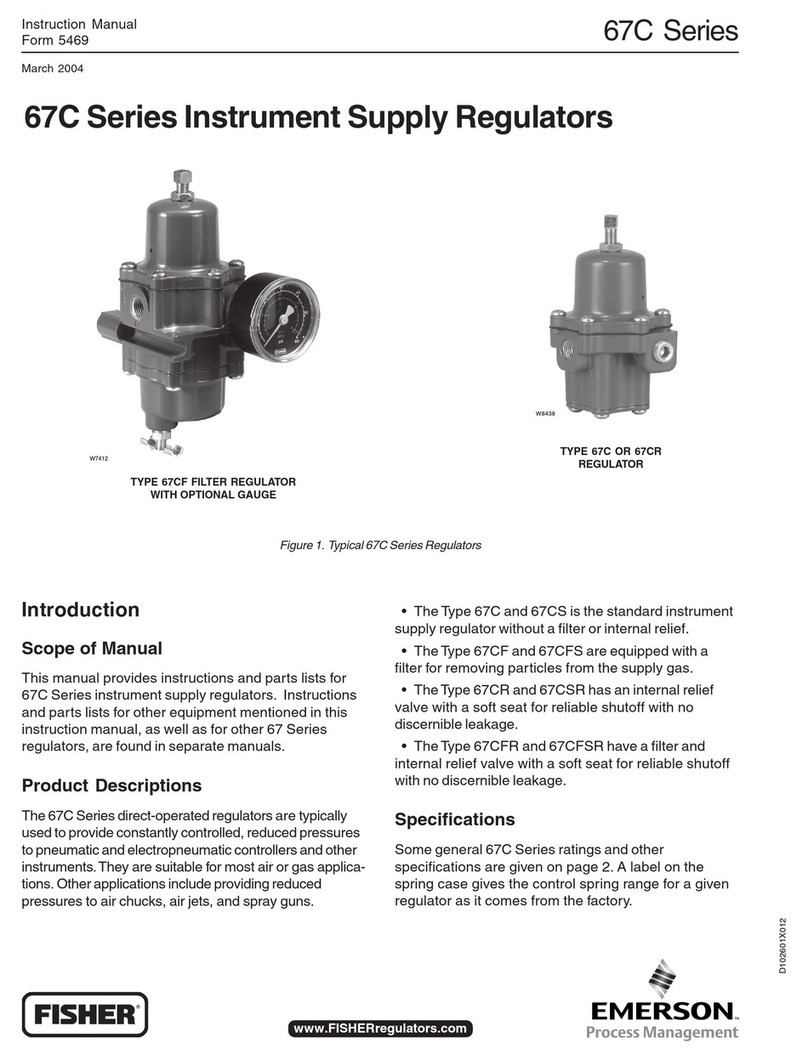

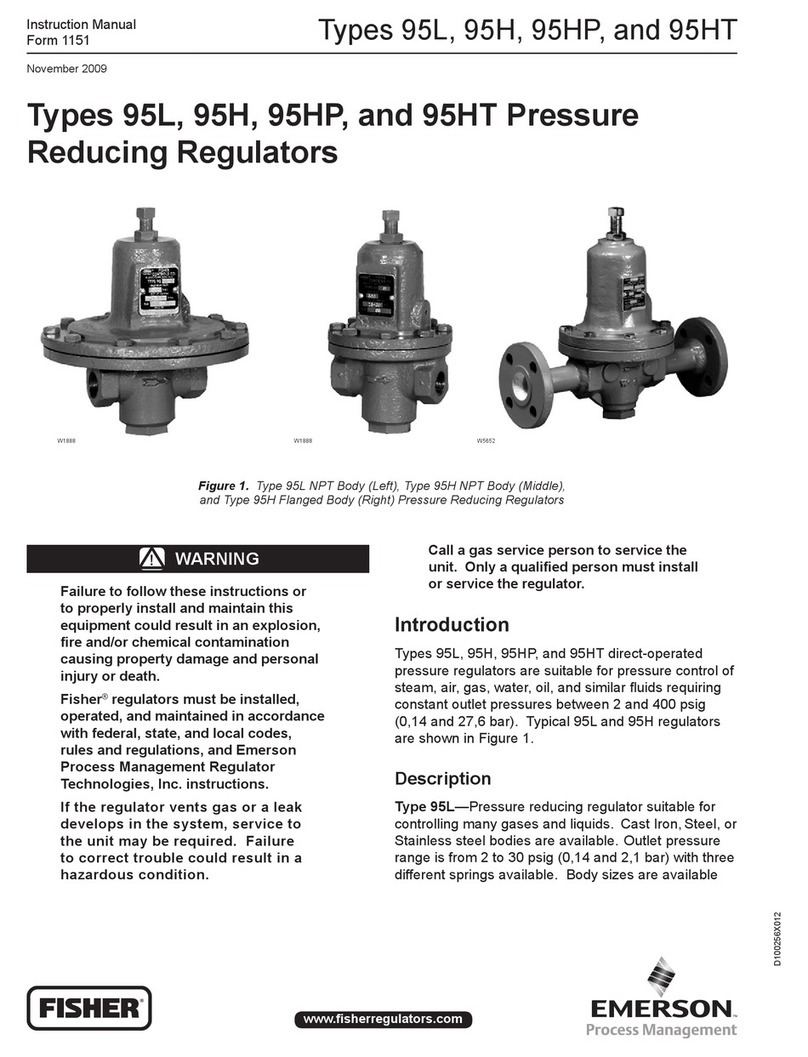

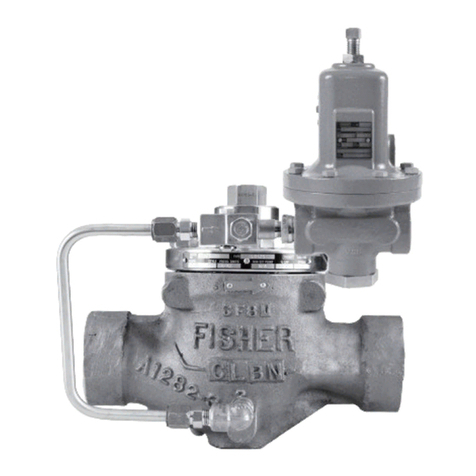

CASH VALVE™ A-360 AND A-361 PRESSURE REGULATORS

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

DESCRIPTION

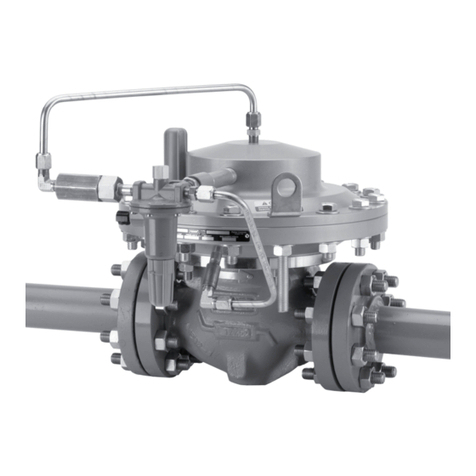

Types A-360 and A-361 pressure reducing and

regulating valves automatically reduce a high

inlet pressure to a lower delivery pressure and

maintain that lower pressure within reasonably

close limits, even during high flow rates.

Type A-360 is 2-way; Type A-361 is 4-way with

gauge taps on sides of body.

SPECIFICATION DATA

Service: Air, water, oil, gases

(except steam) and other

non-corrosive liquids

Sizes: ¼" (6.35 mm),

⅜" (9.53 mm), and

½" (12.7 mm)

Connections: Threaded female inlet

and outlet, A-361 has side

gauge connections

Body: Brass - A-360

Bronze - A-361

Max.

Temperature: 180°F (82°C)

Max.

Inlet Pressure: 400 psi (27.57 bar)

Outlet Pressure

Range: 0-250 psi (0-17.23 bar)

INSTALLATION INSTRUCTIONS

Types A-360 and A-361 regulators can

be installed in any position. For ease of

maintenance and repair however, it is

suggested that the valve be installed in a

horizontal line with the spring chamber upright.

For convenient operation and maintenance,

manual shut-off valves should be installed

upstream and downstream from the valve.

Before installing the valve, the piping should be

thoroughly flushed out to remove any foreign

material. Install the valve with the inlet pipe in

proper relationship to the flow arrow stamped

on the valve body.

OPERATING INSTRUCTIONS

Adjusting the Delivery Pressure

The regulator's delivery pressure setting is

adjusted by turning the adjusting screw (1) at

the top of the spring chamber after loosening

the adjusting screw lock nut (2). To increase

the delivery pressure, turn the adjusting

screw clockwise (into the spring chamber).

To decrease the delivery pressure, turn the

adjusting screw counter-clockwise (out of the

spring chamber). Tighten the adjusting screw

lock nut after the adjustment has been made.

NOTE:

When adjusting the delivery pressure, draw

flow and shutoff downstream to check

pressure set.

VCIOM-14994-EN 22/01

WARNING

Failure to follow these instructions or to properly

install and maintain this equipment could result in

an explosion, fire and/or chemical contamination

causing property damage and personal injury or

death.

Cash Valve regulators must be installed, operated

and maintained in accordance with federal,

state and local codes, rules and regulations

and Emerson Process Management Regulator

Technologies, Inc. (Emerson) instructions.

If the regulator vents gas or a leak develops in

the system, service to the unit may be required.

Failure to correct trouble could result in a

hazardous condition.

Installation, operation and maintenance

procedures performed by unqualified personnel

may result in improper adjustment and unsafe

operation. Either condition may result in

equipment damage or personal injury. Only a

qualified person shall install or service the types

A-360 or A-361 regulators.

CALIFORNIA PROPOSITION 65 WARNING

This product can expose you to chemicals

including lead, which is known to the State of

California to cause cancer, birth defects, or other

reproductive harm. For more information,

go to www.P65Warnings.ca.gov

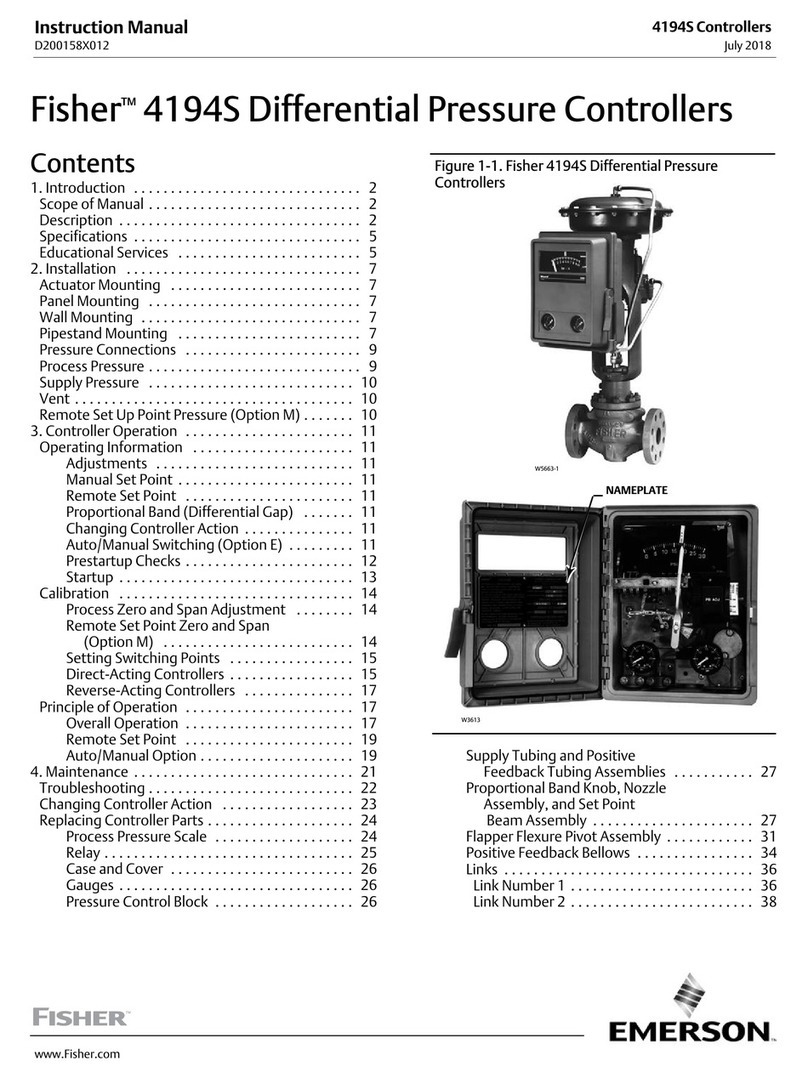

INTRODUCTION

Scope of the Manual

This manual provides instructions for the

installation, adjustment, and maintenance for

the types A-360 and A-361 pressure regulators.