Emerson Fisher CML-750 User manual

Other Emerson Controllers manuals

Emerson

Emerson Copeland XC643 User guide

Emerson

Emerson DIXELL XD70T Wiring diagram

Emerson

Emerson Autochangeover Controllers AC8 User manual

Emerson

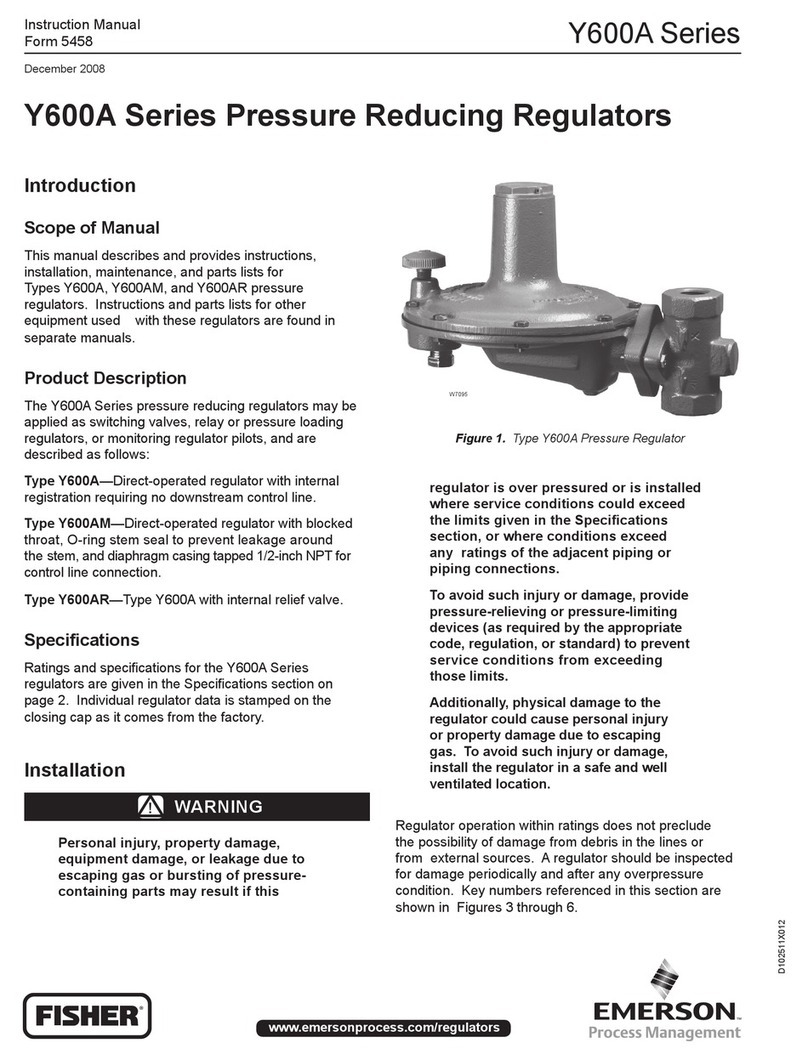

Emerson Fisher Y600A Series User manual

Emerson

Emerson BETTIS E796 2000 M2CP User manual

Emerson

Emerson Dixell XR64CX Wiring diagram

Emerson

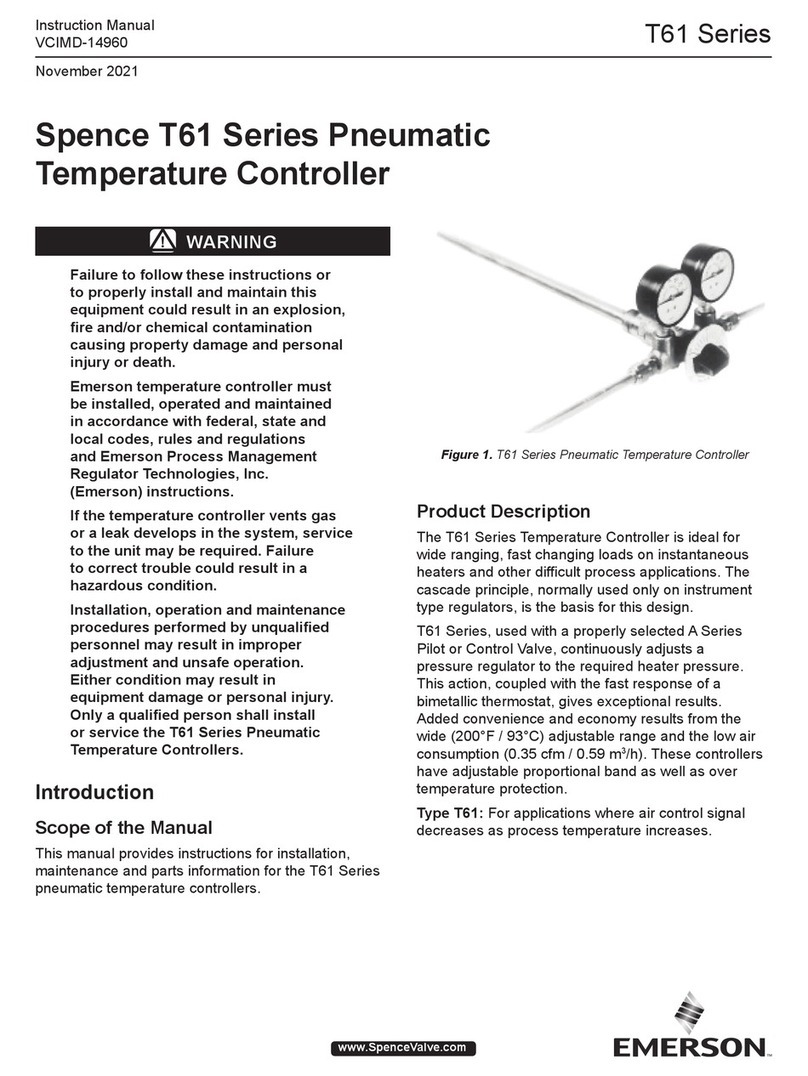

Emerson Spence T61 Series User manual

Emerson

Emerson uerdant VX Series User manual

Emerson

Emerson Fisher 92S User manual

Emerson

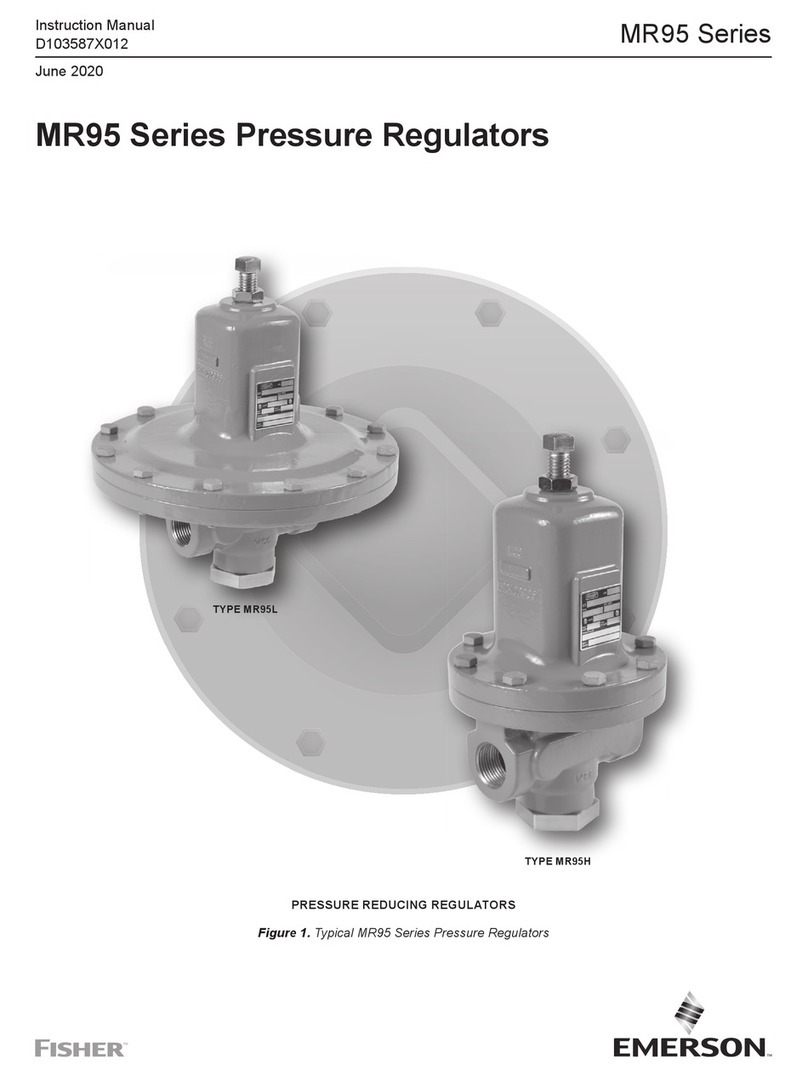

Emerson Fisher MR95 Series User manual

Emerson

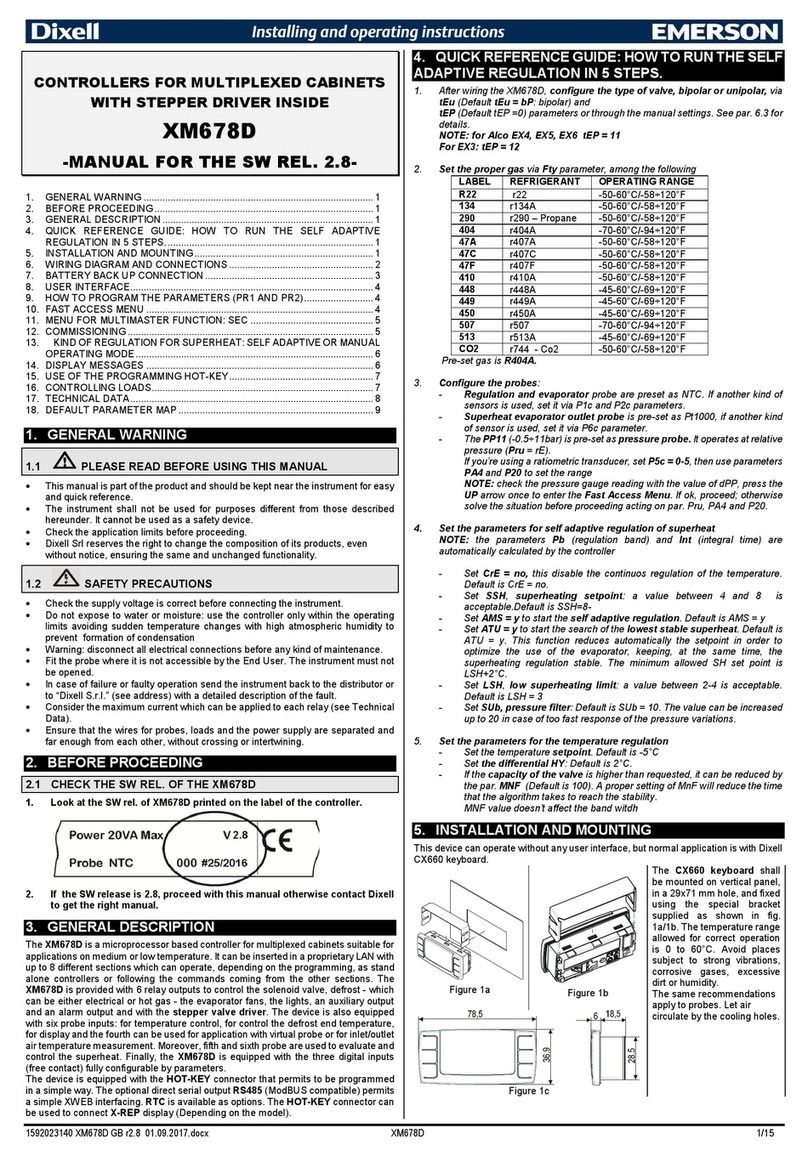

Emerson XM678D User manual

Emerson

Emerson RTS FQ User manual

Emerson

Emerson Fisher FIELDVUE DVC2000 User manual

Emerson

Emerson ECD-002 User manual

Emerson

Emerson MultiFlex ESR User manual

Emerson

Emerson Bettis SCE300 User manual

Emerson

Emerson Bettis XTE3000 User manual

Emerson

Emerson Dixell XR03CH Wiring diagram

Emerson

Emerson dixell WING XW260L Wiring diagram

Emerson

Emerson TESCOM WegaMed Compact Series User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions