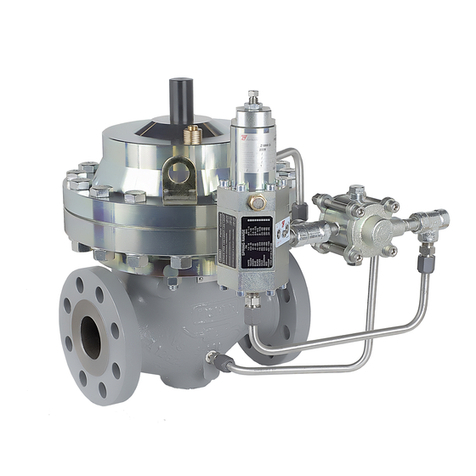

Types 749B and R130

4

handwheel into the old reserve side regulator until

it cannot be turned any further. This side is now

the new “Supply” side. Screw the cap and the

chain assembly into the old supply side until it cannot

be turned any further. This side is now the new

“Reserve” side.

When the “Supply” handwheel is installed in the new

side, the red ag in the indicator should disappear or

the pointer in the gauge should move out of the red.

CAUTION

There will still be pressure in the empty

container equal to the “Reserve” side

manifold setting.

If the containers are cylinders, close the cylinder valve

of the empty cylinder to prevent air from entering

the cylinder and disconnect the cylinder. Clean the

new cylinder’s valve outlet. After the new cylinder

is in place, slowly open the cylinder valve. The new

cylinder now becomes the reserve cylinder. If only one

cylinder, the new supply cylinder, is left connected, the

open line (pigtail or hose) must be capped to prevent

leakage or contamination.

Installation

!

WARNING

Personal injury or system damage may

result if these regulators are installed

without appropriate overpressure

protection. Maximum emergency outlet

pressure for the Type 67C regulators

used on the Type R130 is 50 psig /

3.4 bar over the outlet pressure setting,

or 100 psig / 6.9 bar, whichever is greater.

Maximum emergency outlet pressure for

the 64 regulators used on the

Type 749B is 220 psig / 15.2 bar.

Maximum emergency outlet pressure

for the Type HSRL nal stage regulator

is 3 psig / 0.21 bar above setpoint.

Outlet pressures greater than these

above set point may cause damage to

regulator parts, leaks in the regulator,

or personal injury due to bursting of

pressure-containing parts or explosion of

accumulated gas.

If the regulator is exposed to an

overpressure condition, it must be

inspected for any damage that may

have occurred.

Large volumes of gas may discharge

through the regulator vent during

internal relief valve operation which

can result in re or explosion from

accumulated gas.

All vents should be kept open to permit

the free ow of air into and out of the

regulator. Protect openings against the

entrance of rain, snow, ice formation,

paint, mud, insects, or any other foreign

material that could plug the vent.

LP-Gas may discharge to the

atmosphere through the vent. An

obstructed vent which limits air or

gas ow can cause abnormally high

pressure that could result in personal or

property damage.

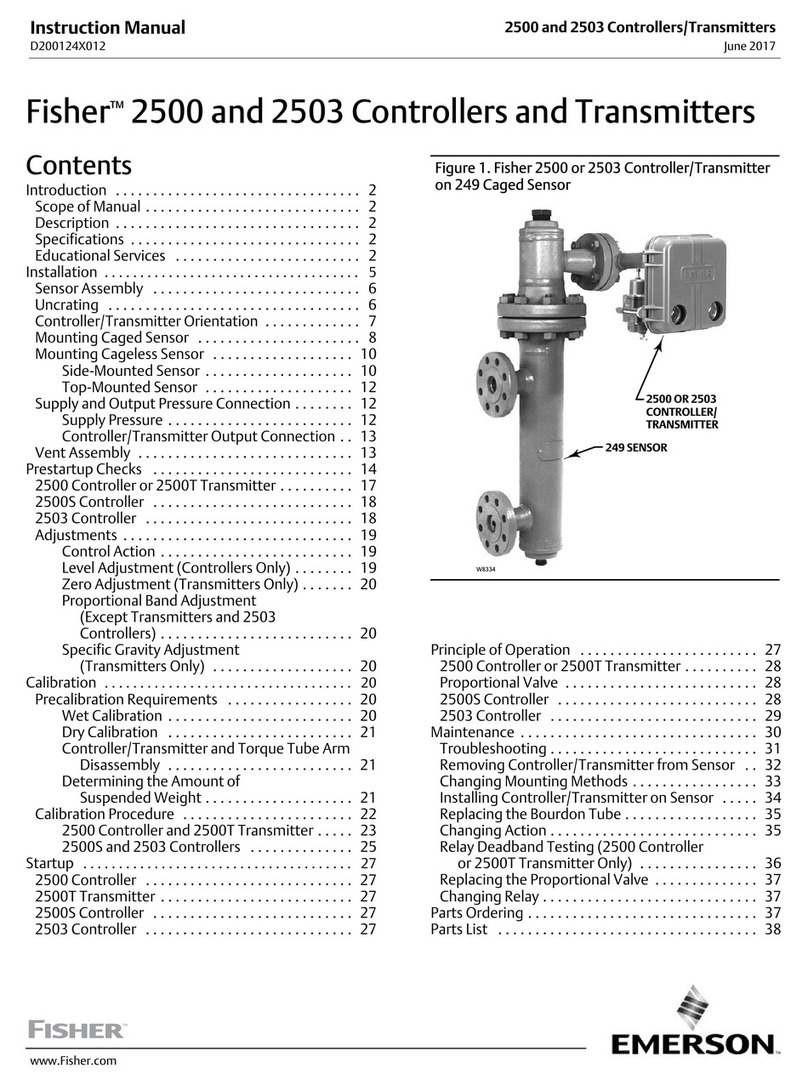

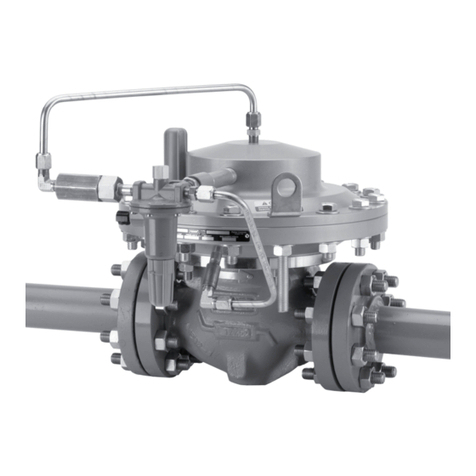

Make sure gas ow through the regulator is in the

correct direction. There are two 1/4-inch NPT

(Type R130) or two 1/2-inch NPT (Type 749B) inlet

connections and the “Outlet” connection is clearly

marked on the regulator. The installation should

be adequately protected from vehicular trafc and

damage from other external sources.

Install the regulator high enough above ground level

- at least 18 inches / 457 mm - so that rain splatter

cannot freeze in the vents. Whether a protective hood

is used or not, do not install the regulator in a location

where there can be excessive water accumulation or

ice formation, such as directly beneath a downspout,

gutter, or roof line of a building.

A regulator installed outdoors without a protective

hood must have its vent pointed vertically down, see

Figure 2, to allow condensate to drain. This minimizes

the possibility of freezing and of water or other foreign

material entering the vent and interfering with proper

operation. Some installations, such as in areas with

heavy snow fall, require a hood or enclosure to protect

the regulator. Before installing the regulator, check for

damage which might have occurred in shipment. Also

check for and remove any dirt or foreign matter which

may have accumulated in the regulator body or the

pipeline. The outlets of the container valves should be

cleaned to remove dirt or water. One method of doing