SAFETY PRECAUTIONS

Read and understand this instruction manual

before installing, operating or performing

maintenance on a 121FSV pressure and vacuum

relief valve. Follow all precautions and warnings

noted herein when installing, operating or

performing maintenance on this equipment.

Safety precaution definitions

CAUTION

Damage to equipment may result if this

precaution is disregarded.

WARNING

Direct injury to personnel or damage to

equipment that can cause injury to personnel may

result if this precaution is not followed.

NOTE

This manual is issued for guidance only and does not

affect our standard terms and conditions and our

product limited warranty, all of which are available

upon request.

Read Anderson Greenwood Marvac general instructions before continuing

ANDERSON GREENWOOD MARVAC FIGURE 121FSV PRESSURE AND VACUUM RELIEF VALVES

INSTALLATION AND MAINTENANCE INSTRUCTIONS

Emerson.com/FinalControl © 2017 Emerson. All rights reserved. VCIOM-04095-EN 18/01

1 INSTALLATION

121FSV pressure and vacuum relief valves

must be mated with the appropriate flange.

1. These valves must be gasketed and bolted

to a flat machined horizontal flange. Bolts

must be tightened uniformly to ensure a

good seal.

2. The exhaust pipework which is to be

gasketed and bolted to the horizontal flange

must not be supported by the valve, i.e.

these valves are not designed to carry any

external loads.

3. This valve does not contain any internal

packing. Therefore, internal checks should

not be necessary.

4. It is recommended that carbon steel valves

be given a coat of paint immediately after

installation is complete. Apply paint to

external surfaces only.

2 MAINTENANCE (DURING ATMOSPHERIC

VENTING PERIOD)

WARNING

The relief valve must be isolated from tank

pressure before servicing. All gas must be

blocked and pressure vented safely.

Wear appropriate gloves and/or breathing

apparatus if hazardous vapors are present.

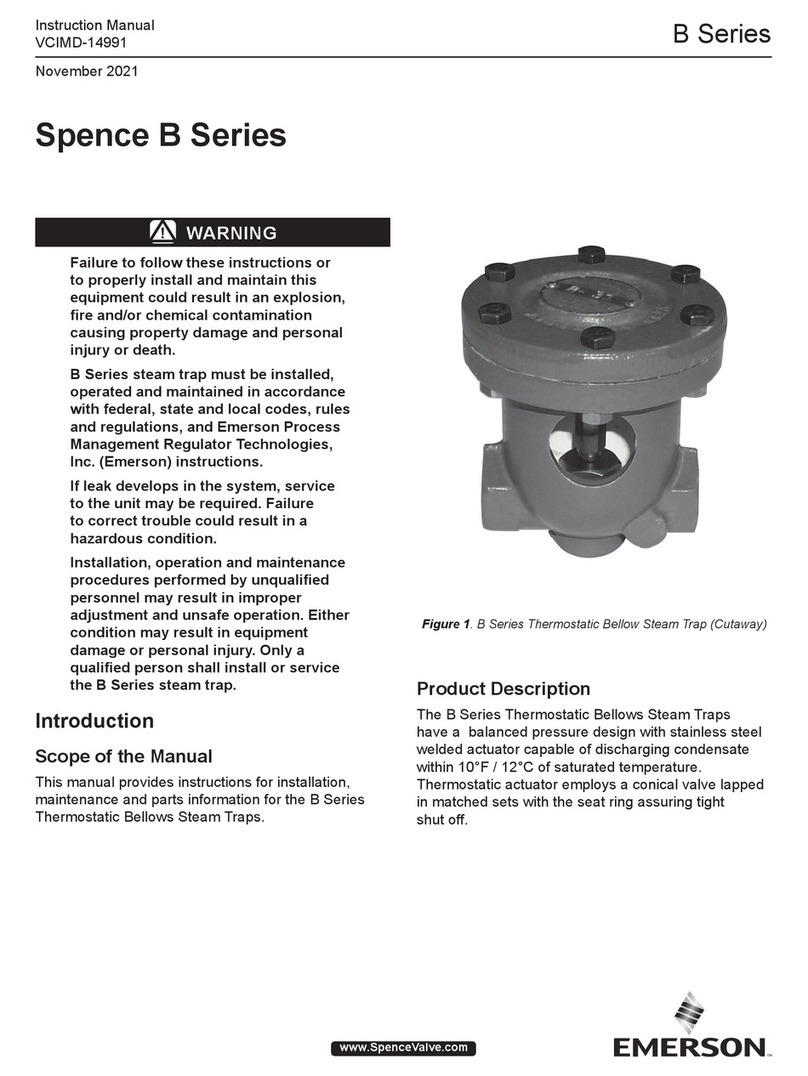

Pressure relief (refer to Figure 1)

1. Remove pressure cover (item 15), inspect

O-ring for damage and replace if necessary.

2. Remove pallet assembly to inspect pallet

seating for wear and replace if necessary.

3. To replace damaged/worn items from pallet

assembly (see recommended spares):

a. remove nut from pallet stem, remove

support disc, diaphragm & backing disc

b. clean pallet surface and threads

c. replace with new parts

d. reassemble in reverse order

4. Inspect valve seats (item 3) for wear and

regrind or replace where necessary.

5. Clean seating surface thoroughly with

suitable solvent.

6. Generally clean inside of valve, remove all

foreign matter and repaint exterior where

possible to prevent corrosion.

7. Replace pressure pallet on pressure seat

(with lead disc if fitted).

8. Replace pressure cover & replace sealing

washers if necessary, secure with screws.