2

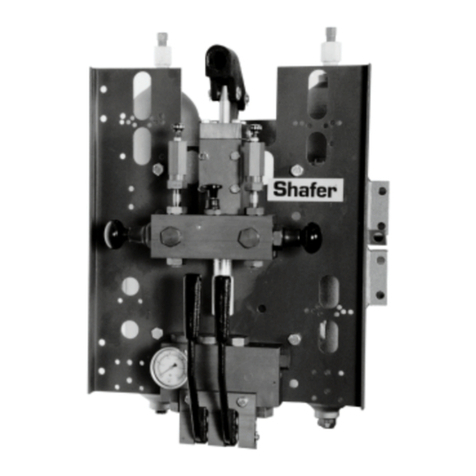

ANDERSON GREENWOOD TYPE 727 DUAL PILOT MANIFOLD

INSTALLATION AND MAINTENANCE INSTRUCTIONS

1 GENERAL DESCRIPTION

Operation

The Type 727 pilot operated safety valve uses

the principle of loading the larger area of a

differential area piston with line pressure to

hold the piston closed up to set pressure.

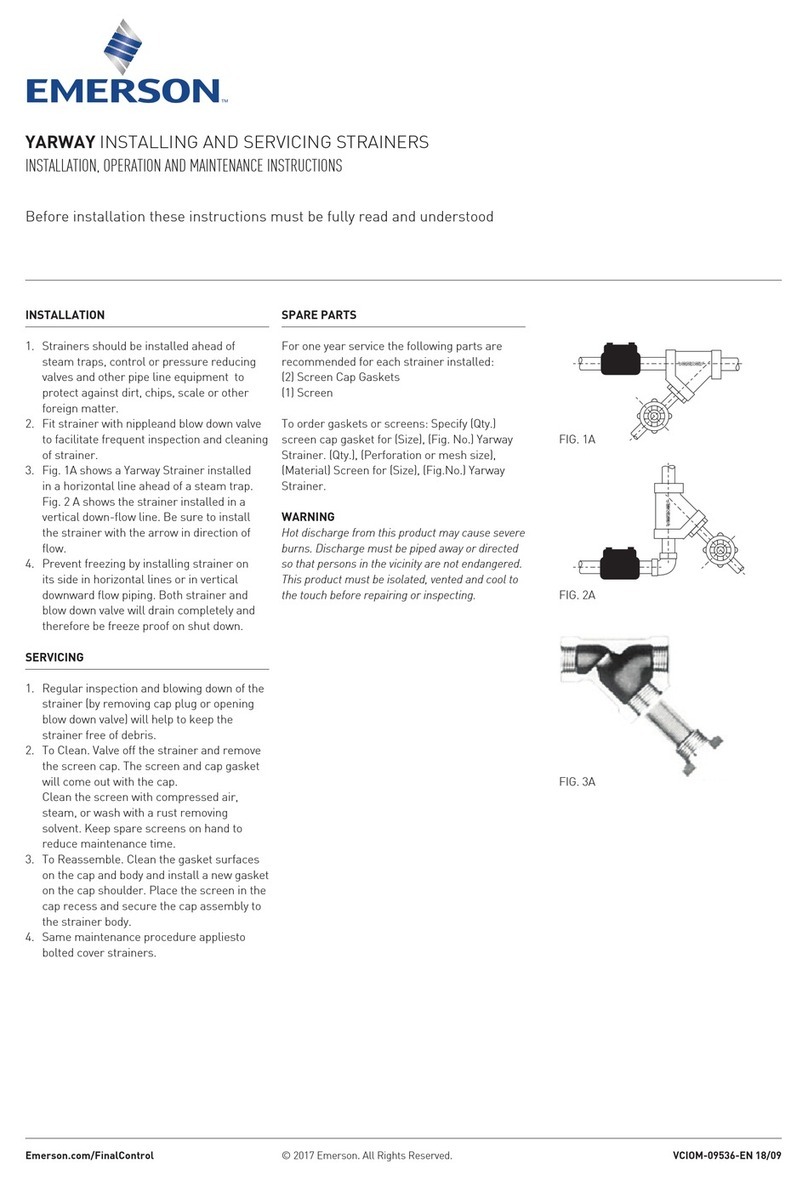

Service configurations (see Figure 1)

The 727 assembly is shipped in one of two main

valve configurations depending on whether it

is to be applied to steam or air/gas service.

Thepilot assembly is identical for both services.

1. Steam service configuration

Valves for steam service are identified

externally by the presence of tubing

connecting the unloader valve in the

manifold assembly to the main valve

outlet. When the pilot actuates, it vents the

small volume of steam in the dome of the

unloader causing the unloader to open.

The unloader is connected directly to the

main valve dome chamber and allows the

pressure in the dome chamber to vent

intothe outlet of the main valve.

2. Air/gas service configuration

Valves for air/gas service are identified

externally by the lack of tubing from the

manifold to the main valve outlet. The

unloader piston has been removed and a

cap is installed in the unloader cavity in

the manifold. The pilot vents main valve

dome pressure directly to the atmosphere.

An NPT plug is installed in the unloader

discharge port in the main valve outlet.

Internally, the main valve piston radial hole

used for steam service either is eliminated

or plugged permanently for air/gas service.

Installed in the top groove of the air/gas

piston is a special piston ring with a low

leakage end joint design. Installed in

the pressure sense port in the cap is a

pressurespike snubber.

WARNING

The protection and safety of equipment, property

and personnel depends on the proper operation

of the safety valves described in this manual. All

Emerson Flow Control safety valves should be

kept in proper working condition in accordance

with the manufacturer’s written instructions.

Periodic testing and maintenance by the user of

this equipment is essential for reliable and safe

valveoperation.

All installation, maintenance, adjustment, repair

and testing performed on safety valves should

be done by qualified technicians having the

necessary skills and training adequate to perform

such work. All applicable codes and standards,

governing regulations and authorities should be

adhered to when performing safety valve repair.

No repair, assembly, adjustment or testing

performed by other than Emerson Flow Control

or its authorized assemblers and representatives

shall be covered by the warranty extended by

Emerson Flow Control to its customers. The

user should use only original, factory supplied

OEM parts in any maintenance or repair activity

involving this product.

This maintenance manual is provided as a general

guide for the repair and maintenance of the

safety valves described herein. It is not possible

to describe all configurations or variations

with such equipment. The user is advised to

contact Emerson Flow Control or its authorized

assemblers and representatives for assistance

in situations that are not covered adequately or

described in this manual.

Before removing a safety valve for maintenance,

ensure that the system pressure has been fully

depressurized. If an isolation block valve is used,

ensure that any trapped fluid between the block

valve and the safety valve is vented safely.

Before disassembling the safety valve ensure

that the valve has been decontaminated from

any harmful gasses or fluids and that it is at a

safe temperature range for handling. Fluids can

be trapped in the dome space of pilot operated

safetyvalves.

Before installation, the Installation and

Operational Safety Instructions should be read

fully and understood. These Instructions may

be requested from the factory or are available

atvalves.emerson.com.

Onrising system pressure, the pilot actuates at

set pressure, venting pressure from the main

valve dome chamber. When the main valve

dome pressure is reduced to 40% of system

pressure, the main valve disk lifts off the nozzle

seat, thereby venting system pressure through

the outlet.

When system pressure drops by 5 to 7% of set,

the pilot closes, allowing system pressure to

recharge the main valve dome causing the disk

to reseat on the nozzle.

When operating below set pressure, the inlet

and main valve dome pressures are equal so

that the seating force on the main valve seat is

equal to the system pressure times the seating

area. Since the seat load increases with system

pressure, the main valve maintains premium

seat tightness up to set pressure.