2

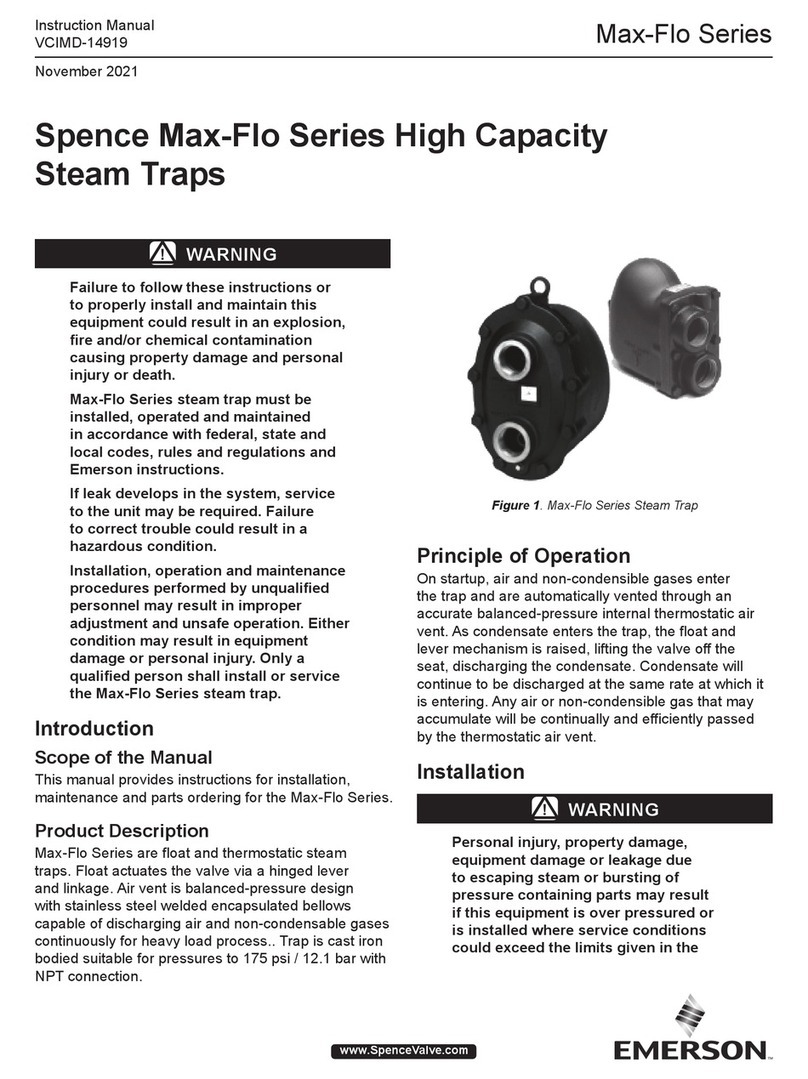

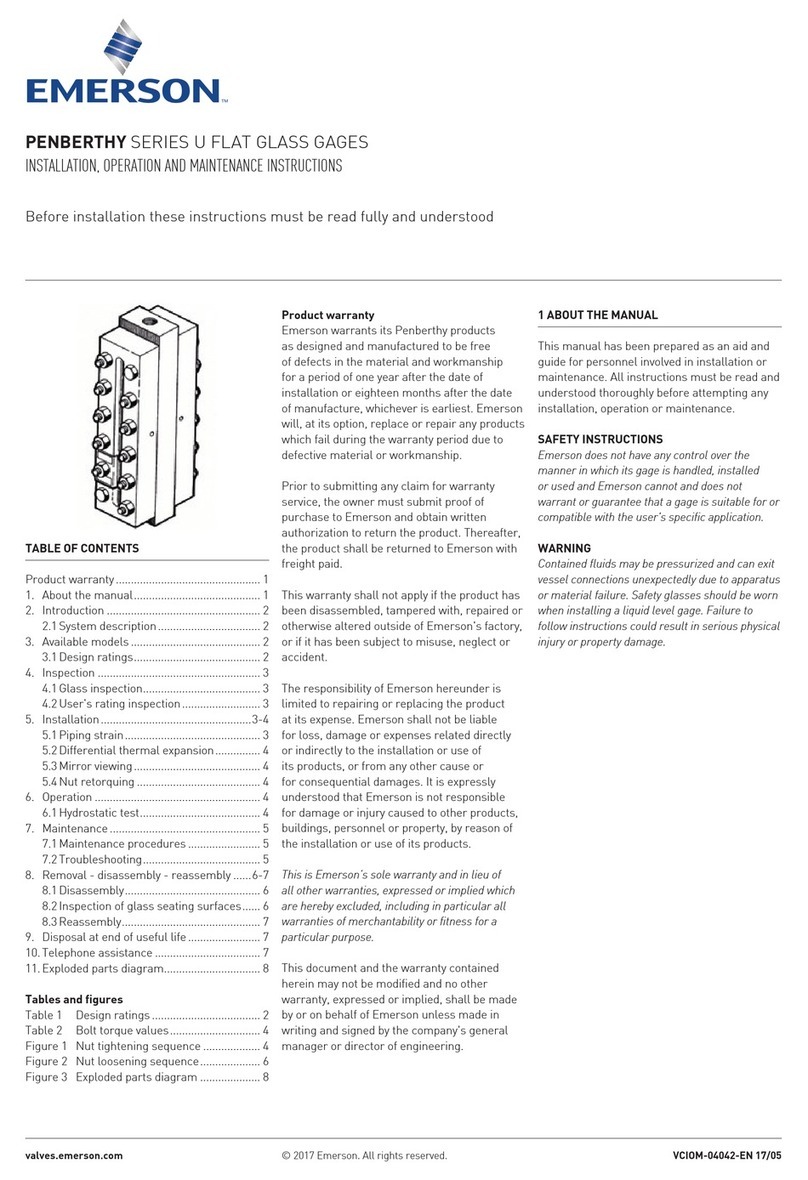

YARWAY CT150 SERIES THERMOSTATIC STEAM TRAPSTRAPS

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

PRINCIPLE OF OPERATION

Thermal actuator is filled at its free length with

a liquid having a lower boiling point than water.

On start-up, valve is normally open to discharge

air, non-condensibles and condensate.

When steam enters trap, thermal actuator

fill vaporizes to a pressure higher than line

pressure. This forces valve into seat orifice to

prevent any further flow.

As condensate collects, it takes heat from

thermal actuator, lowering internal pressure.

Line pressure will then compress thermal

actuator to open valve and discharge

condensate. Valve opening automatically

adjusts to load conditions from minimum on

very light loads to full lift at maximum load.

• Best Air Handling Capacity — Fast start up

and operation.

• Fast Response — Quickly adjusts to

condensate load or temperature changes.

• One Size Suits Most Services — Universal

ferruled end connection fits both ½ and ¾ in.

(12.7 and 19.1 mm) piping.

WARNING

Personal injury or system damage may result if

this steam trap is installed, without appropiate

overpressure protection, where service conditions

could exceed the limits given in the Specifications

section and/or steam trap nameplate.

Additionally, physical damage to the steam trap

may result in personal injury or property damage

due to escaping of accumulated gas. To avoid

such injury and damage, install the steam trap in

a safe location.

All pressure equipment should be installed in

a non-seismic areal should not be exposed to

fire; and should be protected from thunderbolt

(lightning) striles.

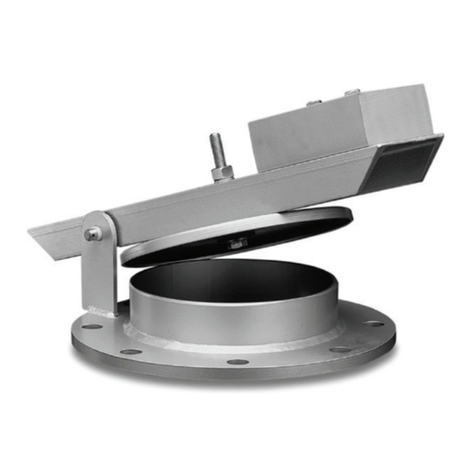

INSTALLATION

1. Before installing trap, blow all dirt and scale

from apparatus and piping.

2. Install trap with arrow on body in flow line

as close as possible to apparatus with

strainer and valve upstream of trap.

3. Pitch all drain lines toward trap.

NOTE

Approved practice is to install separate traps on

each piece of apparatus to be drained. Steam

supplied to inlets of several units may be of uniform

pressure, but invariably there is a differential at the

outlets. Although this differential may be small, unit

discharging highest pressure will control the action of

trap, while other units become air-bound and water

logged. Piping upstream and downstream of trap

should be at least equal to or one size larger than

trap connection.

4. Record the location of the trap for

maintenance accessibility.

MAINTENANCE

The CT150 Series Thermostatic Steam Traps

are sealed units making it maintenance free. It

is composed of corrosion resistant stainless

steel components with welded construction to

prevent damage to actuator. No bolts, gaskets

or adjustments are necessary.