List of FiguresMaintenance and Troubleshooting Manual

00809-0100-3818 April 2022

List of Figures v

List of Figures

Figure 1-2 Maintenance log collection parameters........................................................................ 3

Figure 1-3 Trend log collection ...................................................................................................... 4

Figure 1-4 Archive log collection parameters................................................................................. 5

Figure 2-1 Meter Monitor status alarms......................................................................................... 7

Figure 2-2 Meter Monitor (Detailed) view...................................................................................... 7

Figure 2-3 Monitor page Check status and Status Summary .......................................................... 8

Figure 2-4 Monitor page Check status and Status Summary .......................................................... 9

Figure 2-5 Meter Monitor (Summary) view ................................................................................. 19

Figure 2-6 Meter Monitor (Detailed) view ................................................................................... 20

Figure 2-7 Excel® 2000 Tools Menu ............................................................................................ 31

Figure 2-8 Excel® Trusted Access Setting .................................................................................... 32

Figure 2-9 Excel® 2007 Tools Menu ............................................................................................ 32

Figure 2-10 Excel® 2007 Developer tab - Macro Security .............................................................. 33

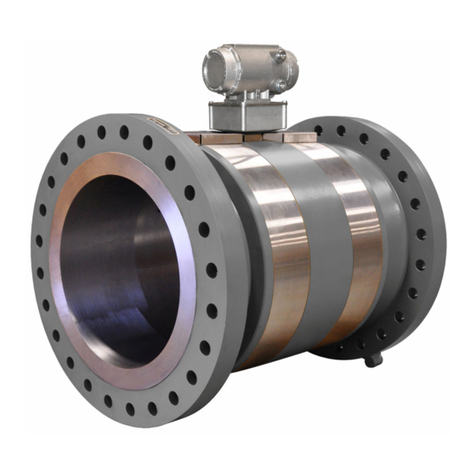

Figure 3-2 3818 LNG Meter top assembly ................................................................................... 38

Figure 3-3 Top shroud disassembly ............................................................................................ 40

Figure 3-4 Shroud worm screw assembly .................................................................................... 41

Figure 3-5 Clamped shroud worm screw parts ............................................................................ 42

Figure 3-6 Band shroud hem bend joint....................................................................................... 43

Figure 3-7 LT-07 transducer assembly ......................................................................................... 44

Figure 3-8 3818 meter with thermal wrap ................................................................................... 46

Figure 3-9 Transducer assembly removal..................................................................................... 47

Figure 3-10 LT-07 Transducer assembly removed from transducer housing .................................. 47

Figure 3-11 Re-wetting the LT-07 transducer face ......................................................................... 48

Figure 3-12 Re-installing the thermal wrap.................................................................................... 49

Figure 3-13 LT-07 Transducer assembly ........................................................................................ 51

Figure 3-14 LT-07 Transducer assembly removed from transducer housing .................................. 52

Figure 3-15 LT-07 transducer and transducer cable wiring............................................................. 53

Figure 3-16 3818 LNG Liquid Ultrasonic Flow Meter electronics .................................................... 56

Figure 3-17 CPU replacement ...................................................................................................... 57

Figure 3-18 Fuse holder cap .......................................................................................................... 59

Figure 3-19 Backplane board replacement .................................................................................... 61

Figure 3-20 I.S. Barrier board replacement ................................................................................... 63

Figure 3-21 Power Supply Board replacement .............................................................................. 65