Emerson Rosemount 485 Annubar User manual

Other Emerson Measuring Instrument manuals

Emerson

Emerson Rosemount CT5100 User manual

Emerson

Emerson AL200 User manual

Emerson

Emerson Machinery Health Expert CSI 2600 User manual

Emerson

Emerson Rosemount 8750W User manual

Emerson

Emerson Rosemount Clarity II T1056 User manual

Emerson

Emerson Rosemount 2051 Wireless Series User manual

Emerson

Emerson mobrey MSP-USTD1 User manual

Emerson

Emerson Daniel 3814 User manual

Emerson

Emerson X-STREAM Series User manual

Emerson

Emerson Rosemount 1057 User manual

Emerson

Emerson Rosemount CT4400 User manual

Emerson

Emerson Rosemount Analytical 385+ User manual

Emerson

Emerson Rosemount 753R User manual

Emerson

Emerson Rosemount CT5100 User manual

Emerson

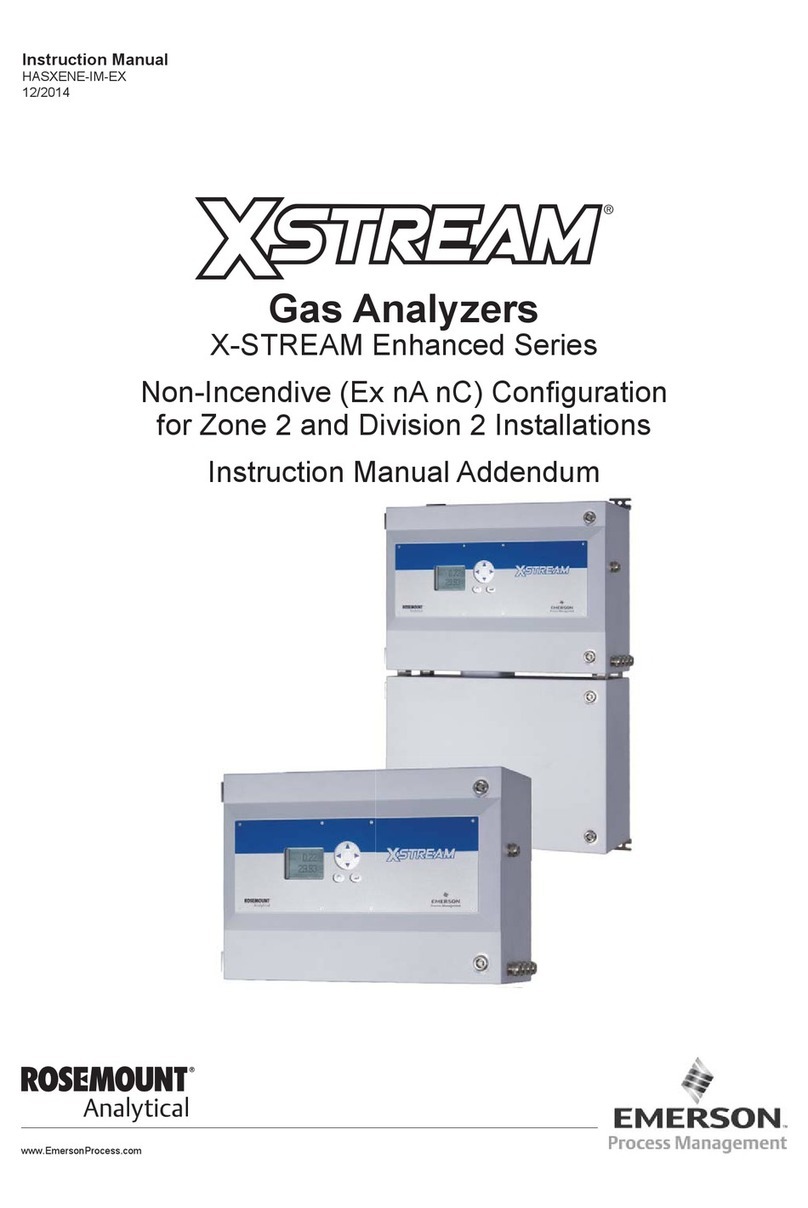

Emerson Rosemount Analytical X-STREAM Enhanced... How to use

Emerson

Emerson Daniel PT User manual

Emerson

Emerson Rosemount MCL-220 User manual

Emerson

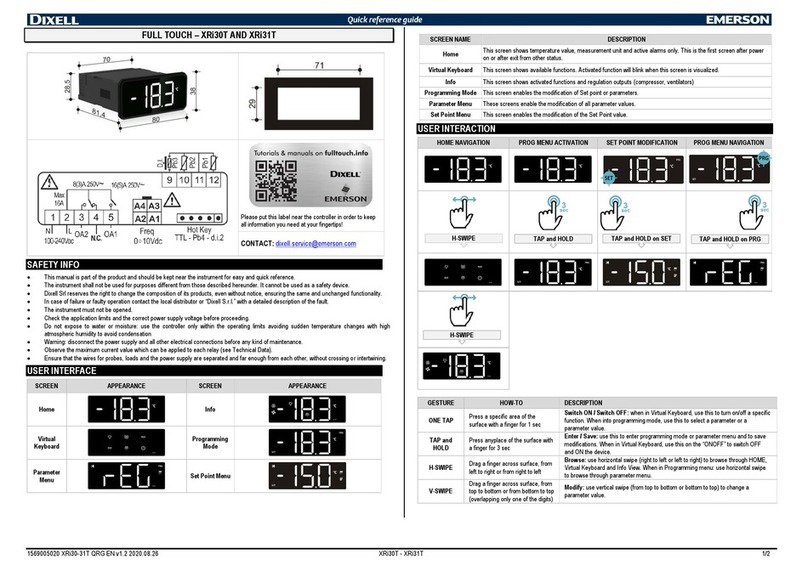

Emerson Dixell XRi30T User manual

Emerson

Emerson Appleton AEPGI User manual

Emerson

Emerson Rosemount CT5100 Ex User manual