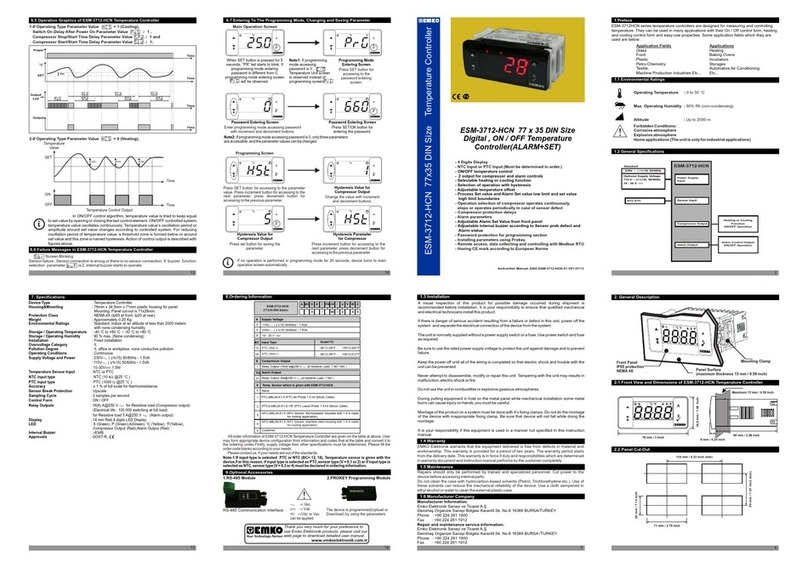

Cooling

Heating

Sensor Offset Parameter ( Default = 0 ) MODBUS ADDRESS:40007

from -20 to 20 °C for NTC(-50°C, 100°C) or PTC(-50°C, 150°C) or J Type TC (0°C,800°C)

or J Type TC (0°C,1000°C) or PT-100(-50°C, 400°C)or PT-1000 (-50°C, 150°C) or

PT-100 (-20°C, 100°C),

from -36 to 36 °F for NTC(-58°F, 212°F) or PTC(-58°F, 302°F) or J Type TC (32°F,1472°F) or

or K Type TC (32°F,1830°F) or PT-100(-58°F, 752°F) or PT-1000(-58°F, 752°F) or

PT-100(-4°F, 212°F),

from -10.0 to 10.0°C for NTC(-50.0°C,100.0°C) or PTC(-50.0°C,150.0°C) or

PT-100 (-19.9°C,99.9°C),

from -18.0 to 18.0°F for NTC(-58.0°F,212.0°F) or PTC(-58.0°F,302.0°F) or

PT-100 (-4.0°F,212.0°F),

Compressor Start Delay at Power On Parameter ( Default = 0)

MODBUSADDRESS:40009

When power is first applied to the device, compressor is on when this time delay is expired.

It can be adjusted from 0 to 20 minutes.

Compressor Stop-Start Delay Parameter ( Default = 0) MODBUS ADRES:40010

When compressor is inactive, this time delay must be expired for activation of the

compressor. It can be adjusted from 0 to 20 minutes

Compressor Start-Start Delay Parameter ( Default = 0) MODBUS ADRES:40011

This time delay must be expired between two activation of the compressor. It can be

adjusted from 0 to 20 minutes.

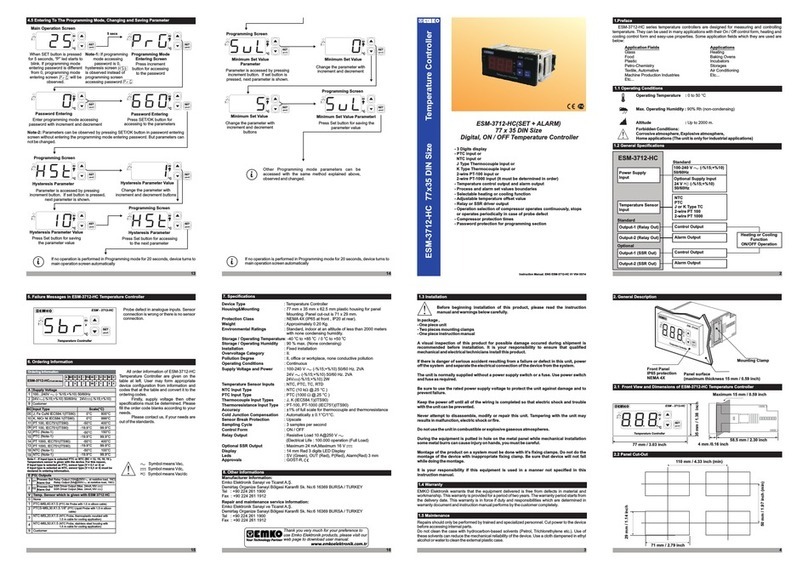

Operating Type Parameter ( Default = 0) MODBUSADDRESS:40008

If parameter value is ‘0’device skips to parameter

9

Minimum Temperature Set Value Parameter (Default = Minimum Value of Device

Scale ) MODBUS ADDRESS:40005

Temperature set value can not be lower than this value.

This parameter value can be adjusted from minimum value of device scale to maximum

temperature set value parameter

Maximum Temperature Set Value Parameter (Default = Maximum Value of Device

Scale ) MODBUSADDRESS:40006

Temperature set value can not be bigger than this value.

This parameter value can be adjusted from minimum temperature set value parameter

to maximum value of the device scale

Sensor Defect Parameter ( Default = 0 ) MODBUS ADRES:40012

Compressor is active during this time period in case of probe defect (Default = 0)

MODBUSADRES:40013

If probe defect parameter is 2, then this parameter is observed. It can be adjusted

from 0 to 99 minutes.

Compressor is OFF in case of sensor defect.

Compressor is ON in case of sensor defect.

Compressor operates periodically according to and Time periods in

case of sensor defect.

Compressor is inactive during this time period in case of probe defect

( Default = 0 )MODBUS ADRES:40014

If probe defect parameter is 2, then this parameter is observed. It can be adjusted

from 0 to 99 minutes.

Buzzer Function Selection Parameter ( Default = 0 ) MODBUSADDRESS:40015

Buzzer is inactive.

Buzzer is active during sensor failures.

ENGLISH