Emotron AB 01-5016-01r0 3

Contents

Safety Instructions ......................................... 1

Contents.......................................................... 3

1. Introduction..................................................... 5

1.1 Delivery and unpacking ............................................ 5

1.2 Using of the instruction manual............................... 5

1.3 Standards .................................................................. 5

1.3.1 Recommendations with respect to EMC ................. 5

1.4 Dismantling and scrapping....................................... 6

1.4.1 Disposal of old electrical and electronic

equipment ................................................................. 6

2. General description ........................................ 7

2.1 Emotron EMX -D is available with different

gearboxes .................................................................. 7

2.2 Accessories................................................................ 7

2.3 Built-in functions ....................................................... 8

2.3.1 Automatic purging ..................................................... 8

2.3.2 Rotation monitor ....................................................... 8

2.3.3 Display of exact rotation speed................................ 8

2.3.4 Alarm relay................................................................. 8

2.3.5 Priority switch ............................................................ 8

2.3.6 Analogue output ........................................................ 8

2.3.7 Absolute humidity...................................................... 8

2.3.8 Protection of control unit and motor........................ 8

3. Installation ...................................................... 9

3.1 Basic installation....................................................... 9

3.2 Mounting the rotation monitor ................................. 9

3.3 Choice of pulley diameter......................................... 9

3.4 Cable connections................................................... 10

3.4.1 Mains cables ........................................................... 10

3.4.2 Motor cables............................................................ 10

3.4.3 EMC recommendations .......................................... 11

4. Control Connections.................................... 13

4.1 Control board........................................................... 13

4.2 Terminal connections ............................................. 14

4.3 Inputs configuration

with the switches..................................................... 14

4.4 Connection example ............................................... 15

4.4.1 Cables ...................................................................... 16

4.4.2 Types of control signals .......................................... 16

4.4.3 Screening................................................................. 16

4.4.4 Current signals ((0)4-20 mA).................................. 17

4.4.5 Twisted cables......................................................... 17

4.4.6 Manual control using 10 kpotentiometer ......... 17

4.4.7 Switching off ............................................................ 17

5. Getting Started ............................................ 19

5.1 Connect the mains and motor cables.................... 19

5.2 Remote control........................................................ 19

5.2.1 Connect control cables and set direction

of rotation ................................................................ 19

5.2.2 Switch on the mains ............................................... 19

5.2.3 Run the drive system .............................................. 19

5.3 Using the function keys .......................................... 20

6. Operation via the Control Panel.................. 21

6.1 General .................................................................... 21

6.2 The control panel .................................................... 21

6.2.1 The display............................................................... 21

6.2.2 LED indicators ......................................................... 22

6.2.3 Function keys .......................................................... 22

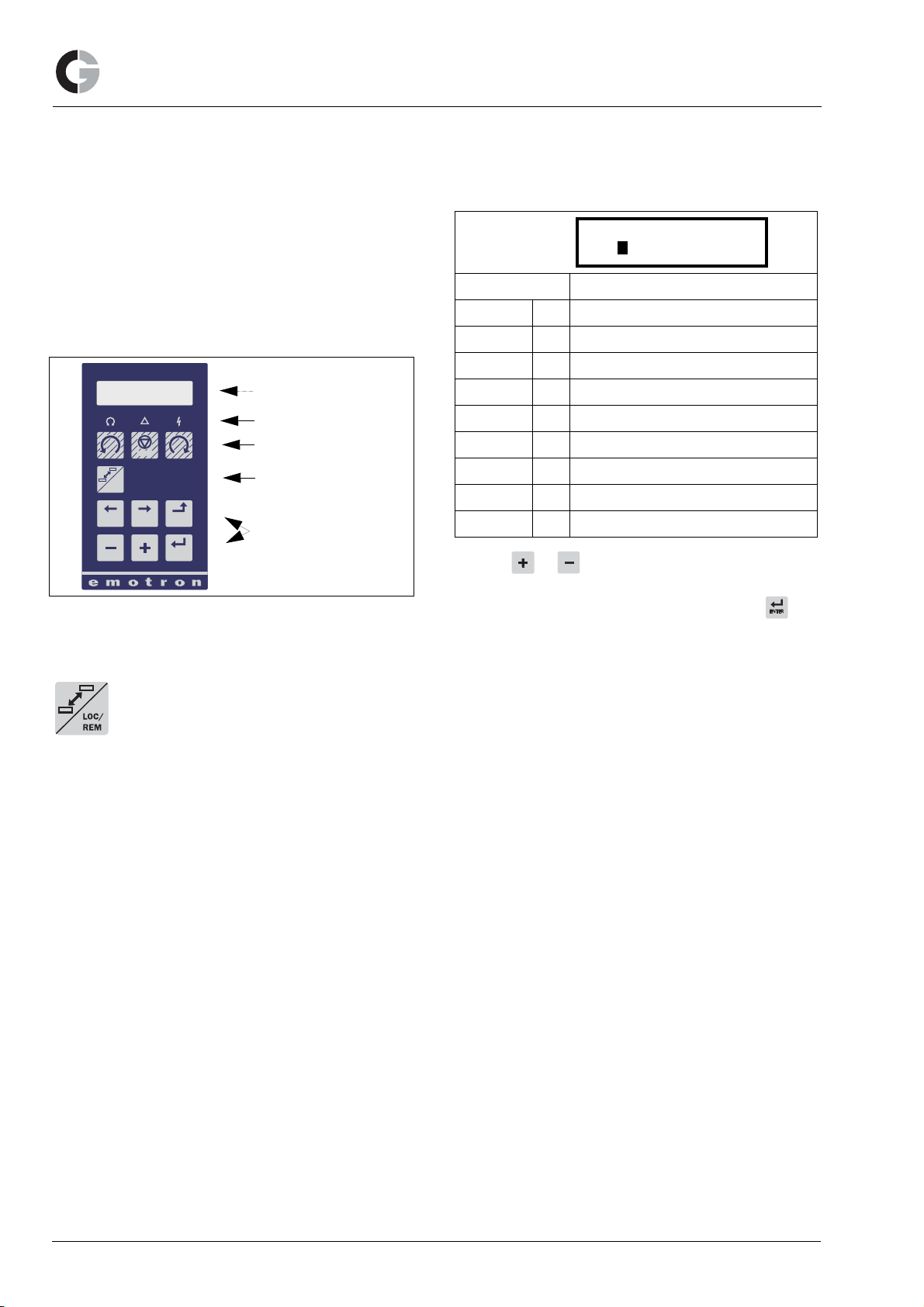

6.3 The menu structure ................................................ 22

6.3.1 The main menu ....................................................... 23

6.4 Programming during operation .............................. 23

6.5 Editing values in a menu ........................................ 23

6.6 Programming example............................................ 24

7. Functional Description ................................ 27

7.1 Normal View [100] .................................................. 27

7.2 EMX-D Options[O00] ............................................... 27

7.2.1 EMX-D Pars[010]..................................................... 27

7.3 Main Setup [200].................................................... 29

7.3.1 Operation [210]....................................................... 29

7.4 View reference [300] .............................................. 29

7.4.1 View Reference speed [310].................................. 29

7.5 View Operation/Status [700] ................................. 29

7.5.1 Operation [710]....................................................... 29

7.5.2 Status [720] ............................................................ 30

7.5.3 Stored values [730] ................................................ 32

7.6 View Trip Log [800] ................................................. 32

7.6.1 Trip Message log [810]........................................... 32

7.6.2 Reset Trip Log [8A0] ............................................... 33

8. Troubleshooting, Diagnoses and Mainte-

nance 35

8.1 Trips, warnings and limits....................................... 35

8.2 Trip conditions, causes and remedial action ........ 35

8.2.1 Technically qualified personnel.............................. 36

8.2.2 Opening the variable speed drive .......................... 36

8.2.3 Precautions to take with a connected motor ........ 36

8.2.4 Auto reset Trip ......................................................... 36

8.3 Maintenance ........................................................... 38

9. Technical Data ............................................. 39

9.1 Dimensions.............................................................. 40

9.2 Control signals......................................................... 41

10. Menu List ...................................................... 43

Index ............................................................. 45