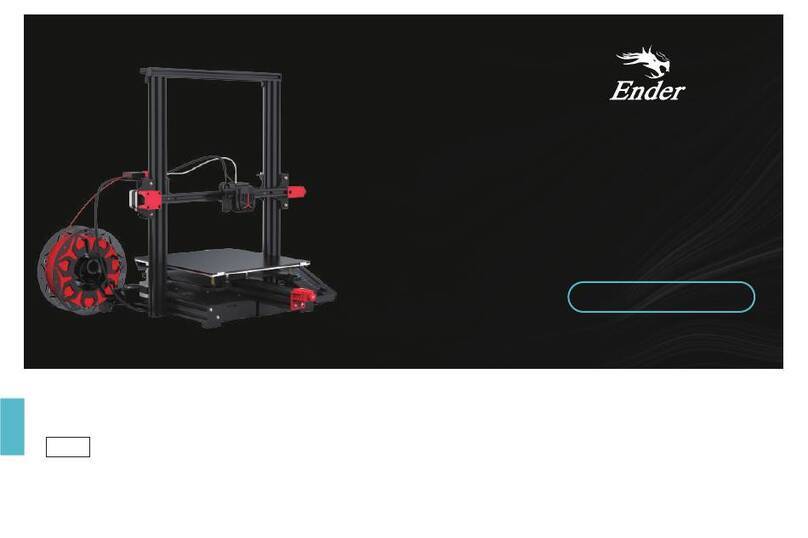

Ender 3 V2 Neo User manual

3D Printer User Manual

V1.0

Create reality,achieve dreams

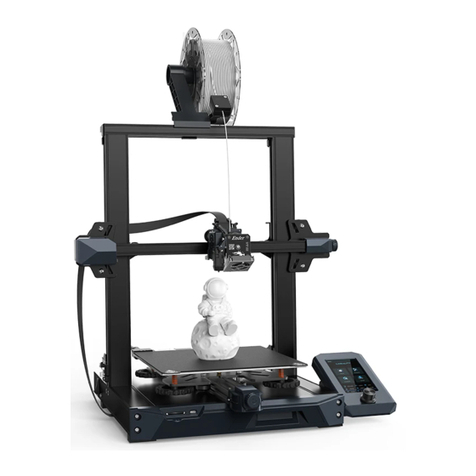

Ender-3 V2 Neo

Ender-3 V2 Neo

To Our Dear Users

Thank you for choosing Creality. For your convenience, please read through this User Manual before you start and follow

the instructions provided carefully.

Creality is always ready to provide you with high-quality services. If you encounter any issues or have any questions when

using our products, please use the contact information at the end of this manual to contact us. To further improve your

user experience, you can find more about our devices via the following methods:

User manual: You can find instructions and videos in the memory card provided with the printer.

You can also visit our official website (https://www.creality.com) to find information regarding software, hardware,

contact information, device instructions, device warranty information, and more.

Firmware Upgrade

Please visit our official website https://www.creality.com/download. Click Homepage → Support → Download.

Download the required firmware and install it.

Instructions for Use

1

2

3

4

5

6

7

8

9

10

12

11

Do not use this printer by methods or operations that are not described in this manual, otherwise it may result in accidental injury or property damage.

Do not place this printer in a vibrating or any other unstable environment, as the printing quality will be compromised when the printer shakes.

Do not place this printer near flammable materials, explosive materials or high heat sources. Please place this printer in a ventilated, cool and low-dust environment.

Please use the power cord provided with the printer and do not use the power cord of other products. The power plug must be plugged into a three-hole socket with a ground wire.

Do not touch the nozzle or hotbed while the printer is in operation, otherwise you may get burned.

Do not wear gloves or accessories while operating the printer, otherwise the moving parts may cause accidental injury including cuts and lacerations.

After the printing process is complete, please use tools to clean up the filament on the nozzle while the nozzle is still hot. Do not touch the nozzle with your hands when cleaning,

otherwise your hands may get burned.

Please regularly clean the printer body with a dry cloth while the power is off, and wipe off dust, sticky printing materials, and foreign objects on the guide rails.

Children under the age of 10 must not use this printer without adult supervision in order to avoid accidental injury.

This printer has a safety protection mechanism. Please do not manually move the nozzle or printing platform quickly while the printer is on, otherwise the printer will automatically

power off for protection.

Users should abide by the laws and regulations of the corresponding country and region where the equipment is located (place of use), abide by professional ethics, and pay

attention to safety obligations. The use of our products or equipment for any illegal purpose is strictly prohibited. Our company is not responsible for the relevant legal responsibilities

of any violators.

Please use the filament recommended by the manufacturer, otherwise the nozzle may be clogged or the printer may be damaged.

Table of Contents

About the Printer 01-01

Device Specifications 02-02

List of Accessories 03-03

04-07

Installing the 3D Printer

08-12

Using the 3D Printer

13-13

First Printing

14-14

Circuit Wiring

·········································································

·······································································

·········································································

·····································································

········································································

············································································

············································································

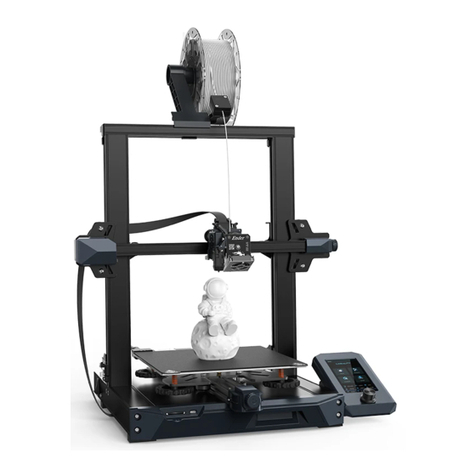

1. About the Printer

01

1XE-axis component

2X-axis limit switch

3Printing platform

4Y-axis tensioner

5Tool box

6Nozzle kit

7Material rack and material barrel

8 Z-axis passive block

9 X-axis tensioner

10 Display screen

11 Rotary switch

12 Voltage regulation gear

13 Y-axis limit switch

14 Y-axis motor

15 Indication knob

17 X-axis motor

16 E-axis motor

18 Coupler

19 Z-axis motor

20 Power switch and socket

13

12

15

16

17

18

19

20

14

11

10

9

8

6

1

2

3

4

5

7

2. Device Specifications

02

Product model Ender-3 V2 Neo

1

0.1mm-0.4mm

Standard 0.4mm

±0.1mm

Creality Slicer/Creality Print/Cura/Repetier-Host/Simplify3D

100-120V~, 200-240V~, 50/60Hz

≤100°C

Slice height

Nozzle diameter

Precision

Filament

Supported file format

Print Method

FDM

Molding tech

Number of nozzles

Supported slice software

Input voltage

Rated power

Hotbed temperature

≤250°C

Yes

Nozzle temperature

Power loss recovery

中文/ English/ Español/ Deutsche/ Français/ Pусский/ Português/ Italiano/ Türk

Switch languages

Yes

Auto leveling

Windows XP/Vista/7/10/MAC/Linux

Operating system

Printing speed

220*220*250mm

Modeling dimensions

General Specifications

PLA/PETG/ABS

STL/OBJ/AMF

≤ 120 mm/s, generally 50 mm/s

350W

USB/storage card

03

3. List of Parts

Base Frame Package Display Screen Component

14

Material Rack and

Barrel Assembly

3

Gantry Frame

2

List of Accessory Kit Item

Cutting Plier

5Wire Clip (Blue)

6

Filament (20mm)

12

Wrench and Screwdriver

7

Power Cable

8Nozzle Cleaner

9Storage Card & Card Reader

10

Nozzle

11

Indication Knob

14 Quick Release Claw

15

M5x45 Hexagon Socket

Head Spring Washer

Combination Screw × 5

13

Black tie × 5

16

Note: The components above are for reference only. The actual product may vary.

4. Installing the 3D Printer

04

4.1 Gantry Frame Installation

A. Place the gantry frame in the slot of the base frame, and pre-lock it with two M5x45 hexagon socket head spring washer combination screws from the bottom to the top.

B. Place the gantry frame in the slot of the base frame, and pre-lock it with two M5x45 hexagon socket head spring washer combination screws from the bottom to the top.

C. Rotate the bottom component by 180° to ensure that the profiles on both sides are level. Use two M5x45 hexagon socket head spring washer combination screws to align

the holes on the left side to pre-lock the holes first, and then tighten to fix them.

D. Rotate the bottom component by 180°, and tighten the screw on the right side.

To tighten the screw, put the short side of the wrench into the screw and secure it.

Bottom View

113 13

2

05

4.2 Installing display screen

A. Place the display screen assembly on the side of the right profile, snap it

into the profile in parallel and tighten the screws;

B. Connect the display screen wiring.

4

4.3 Installing material rack

A. Fix the material rack and barrel assembly to the profile,

as shown in the diagram below.

3

4. Installing the 3D Printer

06

4.4 Cable Connection

X, E, Z-axis motor port

6pin (4 wires) 3pin (2 wires)

X-axis limit switch

A. Put the indication knob directly onto the motor shaft;

B1. Follow the yellow label on the 6pin (4 wires) port to connect the X-axis stepper motor;

B2. Follow the yellow label on the 6pin (4 wires) port to connect the E-axis stepper motor;

B3. Follow the yellow label on the 6pin (4 wires) port to connect the Z-axis stepper motor;

C. Follow the yellow label on the 3pin (2 wires) port to connect the X axis limit switch;

D. Plug in the power cord and toggle the switch to turn on the power.

Caution

●

Before powering on, be sure to select the correct

voltage mode according to the local grid voltage

to avoid burning out the power supply;

●

If the local power grid voltage is within 200-240V,

please dial the power supply of the machine to 230V

(it is 230V by default).

●

If the local power grid voltage is within 100-120V,

please dial the power supply of the machine to 115V;

115V

230V

B2

B1 C

D

B3

A

14

4. Installing the 3D Printer

07

4.5 Adjusting pulley tightness

A. Check the pulley looseness before switching on the machine.

X/Y/Z axis pulley adjustment: Gently turn the pulley to check whether it is idling or jammed. If this phenomenon occurs, use an open-end wrench to adjust the

tightness of the hexagonal eccentric isolation column to make it rotate smoothly.

115V

230V

Hexagonal eccentric

isolation column

4. Installing the 3D Printer

5. Auto Leveling

08

Power up the appliance and select “Leveling"

Default: After the printer has first automatically returned to the home position for auto-calibration, and after 16 points of data calibration, the printer will return

to the home position again and the levelling process is complete.

Go to “Prepare → Z-offset", adjust the Z-axis compensation value so that the height of the nozzle to the printing platform is about the thickness of a piece of

A4 paper (0.08-0.1mm); then, click the knob and the Z-axis compensation value is thus successfully determined.

0.08-0.1MM

5.1

5.2

0.00

Leveling

Leveling

6. Auxiliary levelling

09

6.2 Go to “Prepare → Auto home" to return to the starting position.

6.1 Go to “Control → Reset configuration" to reset the printer parameters.

0.00

Leveling

Leveling

10

Go to “Prepare → Z-offset", adjust the Z-axis compensation value so that the height of the nozzle to the platform is almost the thickness of A4 paper

(0.08-0.1mm); then, click the knob, and the central point leveling is done.

6.4

6.3 Go to “Prepare → Move → Move Z" and reset.

6. Auxiliary levelling

0.00

0.00

Leveling

Leveling

Go to “Prepare → Disable stepper" to switch off all motor enables.

6.5

11

The nozzle is too far away from the platform, so the

filaments can not adhere to the platform.

The nozzle is too close to the platform, leading to

insuficient filament extrusion, even scraping the platform.

Filaments are extruded evenly, just sticking on the platform.

Adjust the knob at the bottom of the hotbed and move the nozzle to the four corners of the printing platform, respectively, so that the height of the nozzle to the

printing platform is approximately the thickness of A4 paper (0.08-0.1mm). Make sure that the four corners are properly leveled.

6.6

6. Auxiliary levelling

0.00

Leveling

7. Load resin

12

7.1 When you wait for the temperature to rise, hang the filament over the filament rack.

7.2 Press the extrusion clamp and insert the filaments along the extruder hole up to the nozzle. When the temperaturehits the target value, a flow of filaments can be seen at the nozzle,

meaning that the filaments have been loaded.

For smoother printing, the end of

the filament should be cut as

shown above.

Replacement of filaments:

1. When the printer is not under work:

A. Heat the nozzle to above 185°C first, wait for the filaments inside the nozzle to soften,

then press the extrusion handle and pull out the filaments quickly to prevent them from

getting stuck at the heat break;

B. Replace the new filaments onto the material rack and repeat the loading procedure in 7.

2. When the printer is working:

A. Suspend printing first and, once the printer has stopped, press the extrusion handle to pull

the filaments out quickly and prevent them from getting stuck at the heat break;

B. Replace the new filaments onto the material rack, press the extrusion handle, insert the

filaments through the extruder feed hole into the nozzle, then push the filaments hard to

squeeze out the residual filaments from the nozzle, and clean it up for printing.

8. First Printing

13

8.1 Download from www.creality.com, or

find the Creality software on your

memory card and install it.

Creality Slicer

8.2 Go to Preferences → Basic → Select

Language → Finish to complete the settings.

8.3 Select the model of the printer

(Ender-3 V2 Neo).

8.4 Enter Parameters → Close.

8.5 Launch the

Creality Slicing

Software.

8.6 Load the file.

8.7 Select the file.

Creality Slicer

Load

8.9 Insert the memory card → Press the screen

knob → Select from the menu → Select the

used for printing.

8.8

Generate the G-code file → Save it to

the memory card.

The file name must only contain Latin letters and digits.

Chinese characters or special symbols must not be used.

Note: For details on using the software, please refer to the

slicing software user manual in the storage card.

Neo

9. Circuit Wiring

14

X-axis motor port Y-axis motor port Z-axis motor port Extrusion motor port TF card slot

Controllable

fan port

Fuse

Power input

jack

NO fan port Hotbed

cable port

Nozzle

cable

port

Filament

detection

port

X-axis

limit

switch

por

Y-axis

limit

switch

port

Z-axis

limit

switch

port

Nozzle thermistor interface

Hotbed thermistor interface

Micro USB interface

Display port

CR-touch port

Since each model is different, the actual product may be different from the picture. Please refer to the actual product.

The final interpretation right belongs to Shenzhen Creality 3D Technology Co., Ltd.

18F, JinXiuHongDuBuilding, Meilong Blvd., LonghuaDist., Shenzhen,

China 518131

Official Website: www.creality.com

Tel: +86 755-8523 4565

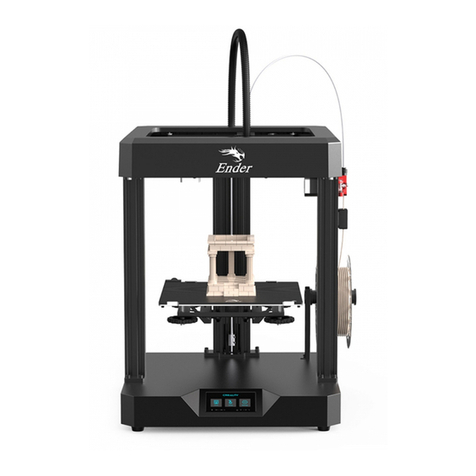

Table of contents

Other Ender 3D Printer manuals

Ender

Ender Ender-3 Max Neo User manual

Ender

Ender 3 Neo User manual

Ender

Ender 3 Series User manual

Ender

Ender Ender-3 Assembly instructions

Ender

Ender 3 S1 User manual

Ender

Ender 2 Pro User manual

Ender

Ender 3 Series Assembly instructions

Ender

Ender Ender-3 E User manual

Ender

Ender Ender-3 Pro User manual

Ender

Ender 3 S1 Installation guide