Table of Contents

3

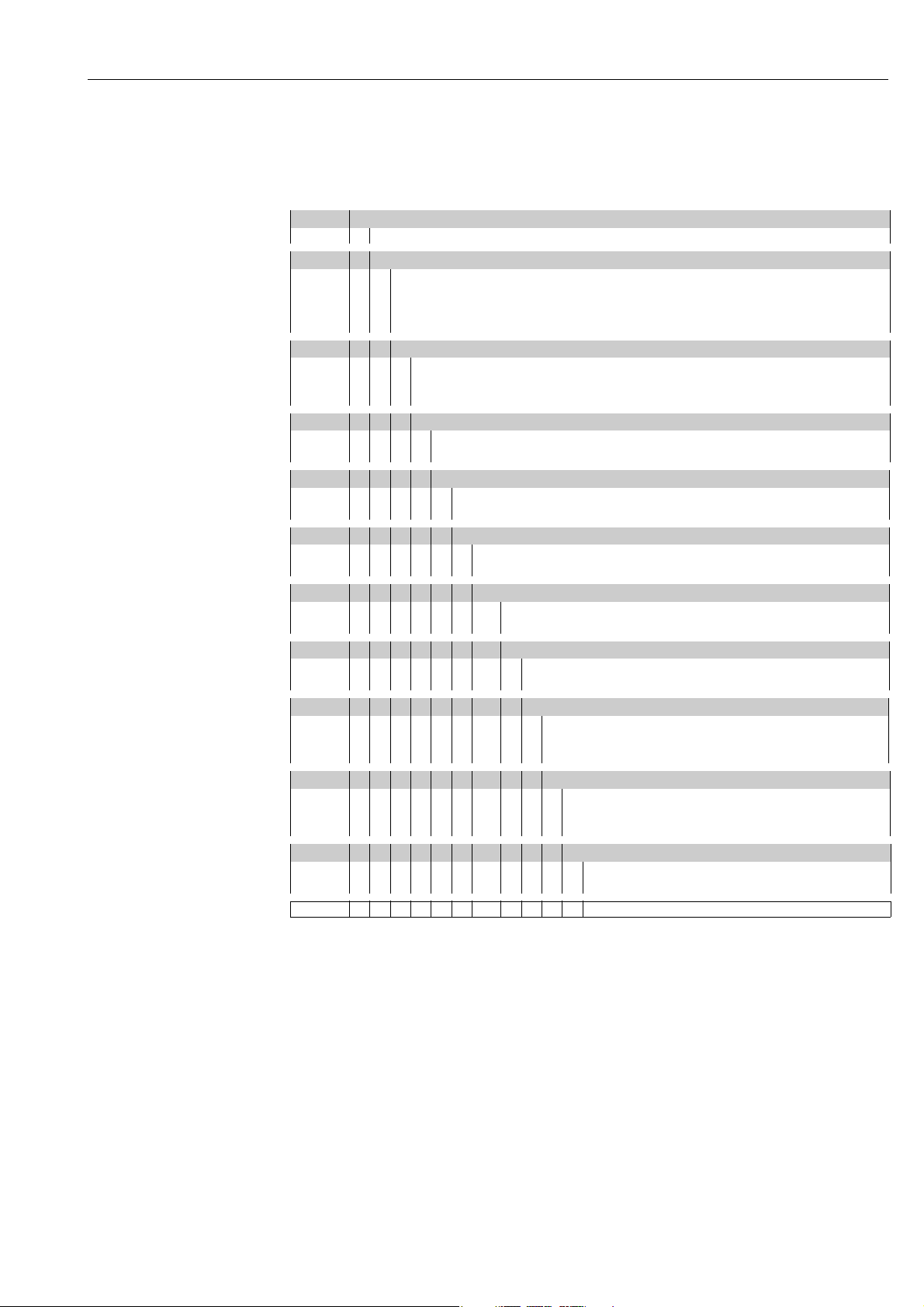

Table of Contents

1 Safety Instructions . . . . . . . . . . . . . . . . 4

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Installation, commissioning, operation . . . . . . . . . . . 4

1.3 Notes on safety conventions and symbols . . . . . . . . . 5

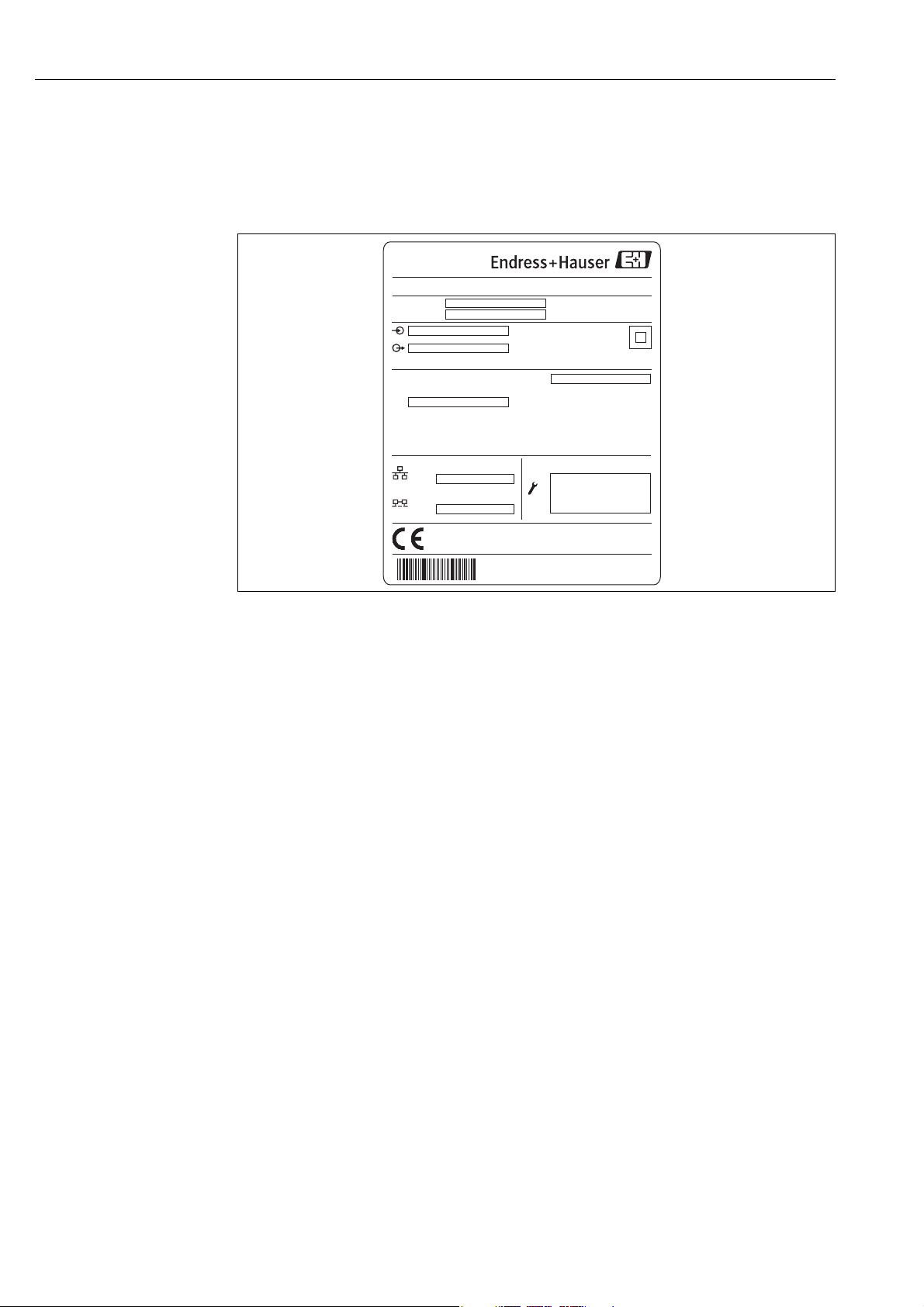

2 Identification . . . . . . . . . . . . . . . . . . . . 6

2.1 Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Product Structure . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Supplied documentation . . . . . . . . . . . . . . . . . . . . 10

2.4 Certificates and approvals . . . . . . . . . . . . . . . . . . . 10

2.5 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . 10

3 Installation . . . . . . . . . . . . . . . . . . . . . 11

3.1 Incoming acceptance, transport, storage . . . . . . . . . 11

3.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 Installation check . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Wiring examples . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Terminal assignment for Tank Scanner NXA820 . . 15

4.3 Terminal assignment for

Data Concentrator NXA821 . . . . . . . . . . . . . . . . . 19

4.4 Terminal assignment for Host Link NXA822 . . . . . 21

5 Operation station settings. . . . . . . . . . 25

5.1 Deactivate proxy server usage . . . . . . . . . . . . . . . . 25

5.2 Java Runtime Environment (JRE) . . . . . . . . . . . . . . 26

6 The Tankvision operating concept . . . 27

6.1 Logging into the Tankvision system . . . . . . . . . . . . 27

6.2 The Tankvision User Interface . . . . . . . . . . . . . . . . 28

6.3 Exit the Tankvision system . . . . . . . . . . . . . . . . . . 31

7 Tankvision configuration . . . . . . . . . . 32

7.1 Network configuration . . . . . . . . . . . . . . . . . . . . . 32

7.2 Subscription Store definition . . . . . . . . . . . . . . . . . 36

7.3 Configuration of an isolated Tank Scanner NXA820 37

7.4 Configuration of a group of Tank Scanners NXA820

including a Data Concentrator NXA821 . . . . . . . . . 38

7.5 Configuration of the Host Link (NXA822) . . . . . . . 38

8 Trouble shooting . . . . . . . . . . . . . . . . 39

8.1 Test network connection . . . . . . . . . . . . . . . . . . . . 39