MAINTENANCE

Periodically dismantle the “D” PILOTAIR® Valve for

inspection and cleaning. Wash all metal parts with

a non-flammable solvent. Wash all seals with soap

and water and examine them for cracks or signs of

wear. Dry all parts with a low-pressure air jet.

Replace worn or defective parts.

Reassemble the valve, using the exploded view

as reference. The valve should be reassembled

using new rubber parts. As the assembly proceeds,

lubricate all rubber parts with Dow Corning 55 M

Grease and all metal-to-metal surfaces with Number

107 Lubriplate.

KIT ASSEMBLY

At times, operators in kit form and assembled valve

portions are stocked separately, and complete “D”

PILOTAIR Valves are assembled as needed. The

operator kits are packages containing the entire

operator’s parts and all the fastenings needed to

assemble the operator to the valve.

The explored illustrations accompanying the

operators’ parts lists in this booklet show how the

parts fit together.

To assemble a complete valve from the kits, remove

the stem from the valve portion. Assemble the

operator portion and connect the stem to it. Cover

the stem with light oil. Remove the tie rod nuts and

always assemble the short threaded ends of the tie

rod first to use the full thread. This will obtain full

thread engagement on both ends when the long

threaded end is assembled last. Insert the stem in

the valve portion. Tighten the bolts evenly together.

OPERATION

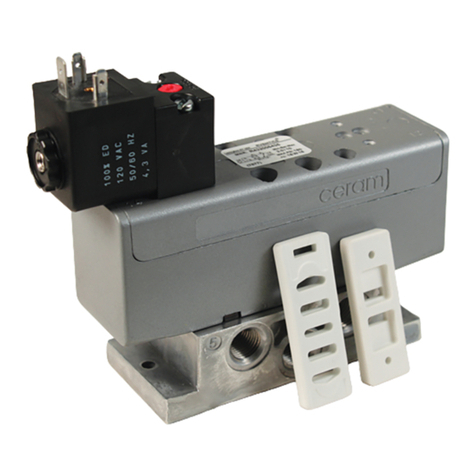

To operate a “D” PILOTAIR Valve a manual,

mechanical, pneumatic, hydraulic or electrical force

is applied to its operator. This force moves the

valve’s stem which, in moving to another position,

opens and/or closes internal passages in the valve.

The accompanying diagrams illustrate how the

valve’s stem opens and closes its passages.

Some stems have two positions –one at each end of

its travel. Some stems have three positions-the

third being midway between the end positions. In

their end positions, three and four-way valves have

one or more passages open. Moving the stem to

other end position closes the passages that

were open and then opens the passages that

were closed. The mid-position results in one

of three conditions-all ports lapped, supply

connected to delivery, or supply connected to

exhaust.

The valve portion of a “D” PILOTAIR Valve in

addition to its stem, has two end sections, a

body segment for each tapped port, seals

between sections and seal retainers. Four tie

rods, which pass through each section, hold

these parts together.

Two-way valves have two-tapped ports-supply

and delivery. Three-way valves with open

exhaust ports also have two ports – supply

and delivery. Their exhaust port is the open-

ing in one of their end sections through which

the stem passes. Three-way valves with

tapped exhaust ports have three ports: supply,

delivery and exhaust. Four-way valves with

open exhaust ports have three tapped ports-

one supply and two delivery ports. Their ex-

haust ports are the openings in the end sec-

tions through which the stem passes. Four-

way valves with tapped exhaust ports have

five tapped ports-one supply, two deliveries

and two exhaust ports.

Passages between sections are the open-

ings in the sides of sections through which the

stem passes. Lands on the stem close these

openings. Grooves on the stem open them.

Stem position determines whether a land or a

groove is in an opening.

The seals in the valve portion prevent the es-

cape of fluid through the joints between sec-

tions and past the lands of the stem. The seal

retainers keep stem drag and unbalanced in-

ternal fluid pressures from forcing the seals

into the path of the stem where they could be

damaged.

Operators are attached to the ends of valve

portions by tapped bolts, which screw onto the

ends of the tie rods. They are connected to

the valve stems by cotter pins or roll pins.

Lever, button and treadle operators can move

a stem in both directions. The others can only

push it. The solenoid operator uses local fluid

pressure to move the valve’s stem. These

operations are made with full return spring,

with

Page 2