Commissioning

Operating keys and their function

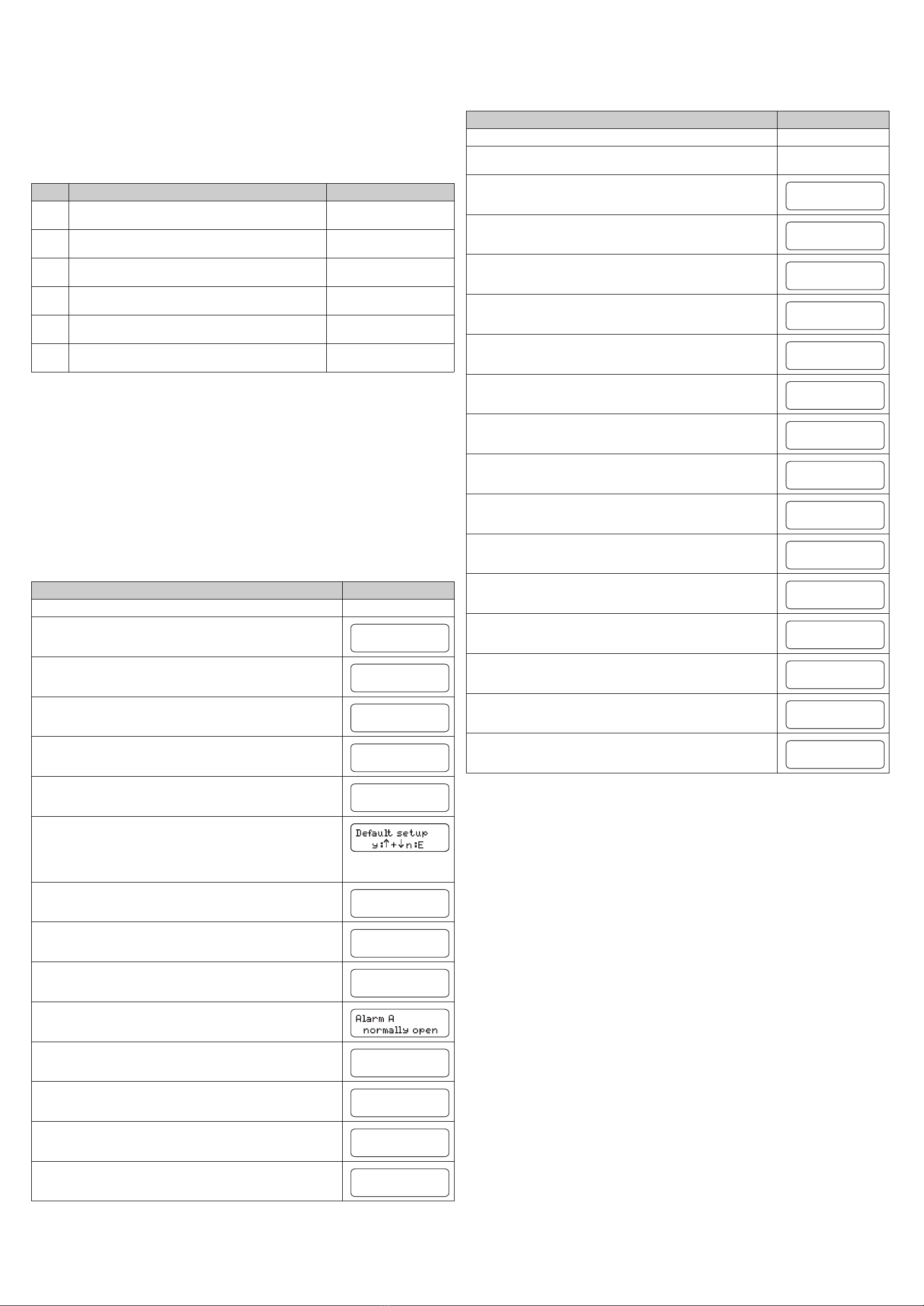

The operating keys and the integrated indicator LEDs have the following functions:

First commissioning

!Note!

• Before switching the system on for the first time, familiarise yourself with the

operation of the transmitter. For this, see in particular chapters "Safety instructions"

and "Operation".

• The sensor should be left in the medium for approx. 1 hour, so that the sensor can

adapt to the medium temperature.

• The transmitter has already been pre-configured at the factory and starts measuring

automatically when switched on. Due to the different waste water composition, the

media can vary greatly. Therefore, we recommend using an application-specific

calibration for commissioning.

Key Key function Indicator LED function

H– “Auto measuring” option

– back to the main menu from all sub-menus

Alarm value 1 exceeded

K– backwards in the sub-menu

(horizontal, see Appendix,)

Alarm value 2 exceeded

V– backwards in the main menu (vertical)

–increasevalue

Measuring range exceeded

W– forwards in the main menu (vertical)

– reduce value

Measuring range undershot

F– select option

– adopt value, forwards in the sub-menu (horizontal)

Retrieve error message

J– selection in the sub-menu Unassigned

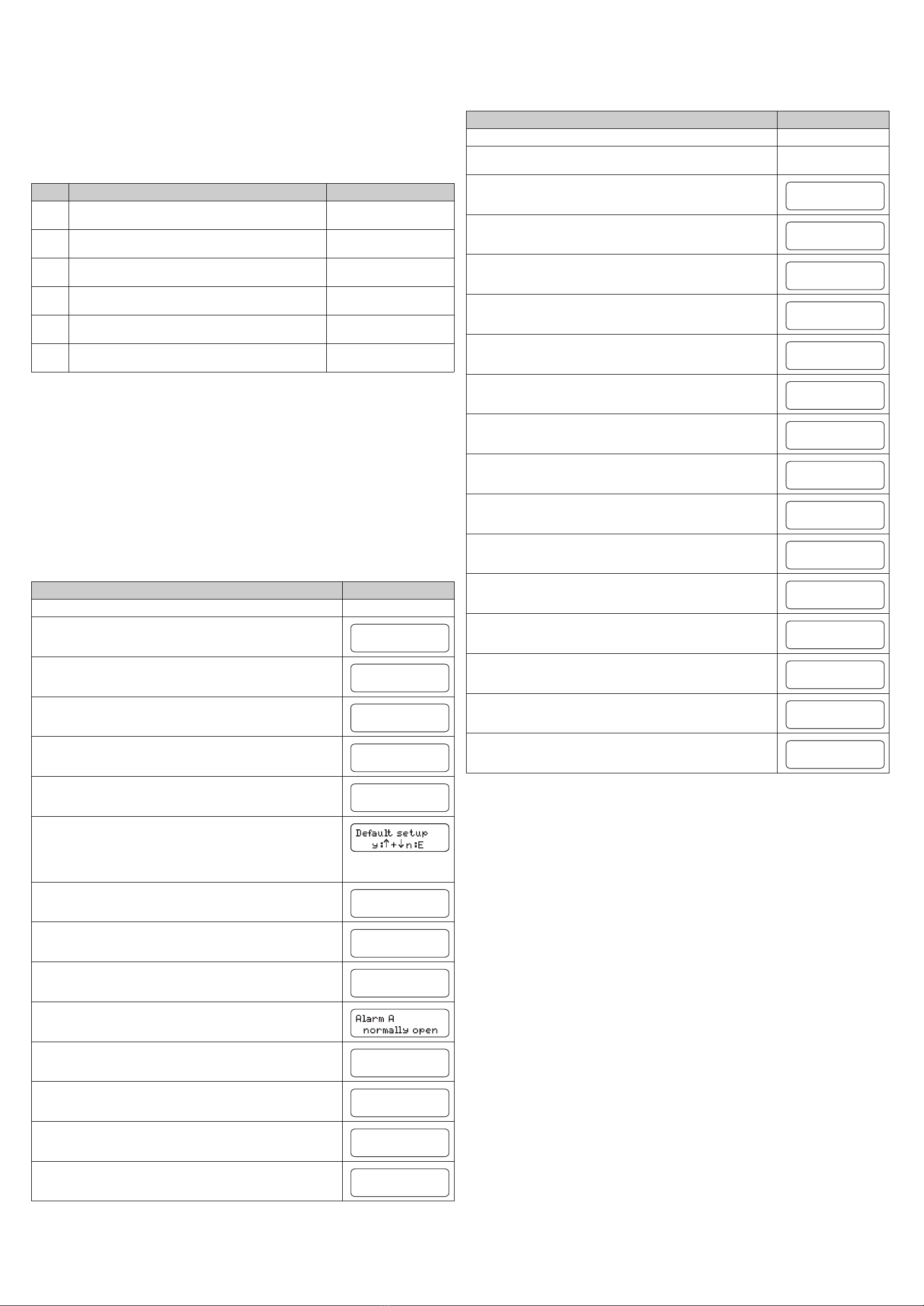

Action Display

Switch the transmitter on.

Press H.

Press five times Wand once F.

Press the Wkey to set the "99" code and confirm with F.

Use the Wor Vkeys to select your sensor and confirm with F.

Use the Wor Vkeys to select the desired unit of measure and confirm with F.

Hold down the Wand Vkeys simultaneously to activate the default setup for the

selected sensor type.

!Note!

The default setup is compulsory for initial start-up, in order to use the correct default

calibration.

Confirm the "Correction factor 0%" function with F.

Use the Wor Vkeys to select the number of measured values for forming the mean

value and confirm with F.

Use the Wor Vkeys to select the the current output and confirm with F.

Use the Wor Vkeys to select the configuration for alarm value A and confirm with

F.

Repeat the previous step for alarm value B.

Select the configuration for the diagnostic alarms similar to the alarm value setting.

Use the V, Wand Fkeys to set the current date and time. Confirm with F.

Press H. The system is ready for measurement now.

MEASUREMENT

CONFIGURATION

Code No.

99

NOx BS 0-30

Type of sensor

mg/l-N

Unit of measure

0%

Correct. factor

10

n mean value

4-20 mA

Analog output

Alarm B

normally open

Diagnostic alarm

normally open

10.02.02. 11:38

act. Date/Time

MEASUREMENT

One-point calibration

Three-point calibration

A one-point calibration is not useful for the activated sludge sensor. Therefore, carry

out a three-point calibration:

1. Take three samples at three times of different nitrate concentration and note down

the displayed frequency at the time of sampling.

!Note!

The concentrations must differ by 1 mg/l at minimum.

2. Determine the nitrate content of the samples in the laboratory.

3. Enter the value pairs of determined concentrations and noted frequencies (in order

of increasing resp. decreasing concentrations):

a. Proceed as with the one-point calibration (see above).

However, enter "3" instead of "1" for the number of measuring points in the

CALIBRATION POINTS menu .

b. Enter the first concentration in the NITRATE INPUT menu.

c. Enter the frequency value corresponding to the first concentration in the

FREQUENCY menu.

d. Repeat steps b and c for the remaining concentrations. After entering the last

frequency, return to the measuring mode.

The calibration is then finished.

Action Display

Leave the sensor to rest in the medium for approx. 1 hour.

Take a sample in the direct vicinity of the sensor and determine the nitrate content in the

laboratory.

Press H.

Press three times Fto display the sensor frequency associated with the measured value.

Note the sensor frequency value.

Press H.

Press twice Wand confirm with F.

Press the Wkey to set the "99" code and confirm with F.

Use the Wkey to set the number of measuring points to "1". Confirm with F.

Press H.

Press three times Wand confirm with F.

Press the Wkey to set the "99" code and confirm with F.

Use Wor Vto set the 1st measured value to the laboratory value. Confirm with F.

Press H.

Press four times Wand confirm with F.

Press the Wkey to set the "99" code and confirm with F.

Press three times Fto set the previously noted sensor frequency value.

Press H. The one-point calibration is now completed.

MEASUREMENT

Frequency

4836 Hz

MEASUREMENT

CALIBRATION PTS

Code No.

99

1

No. of points

MEASUREMENT

NITRATE INPUT

Code No.

99

1. Value

5.00 mg/l-N

MEASUREMENT

FREQUENCY

Code No.

99

Frequency

4836 Hz

MEASUREMENT