Enerpac JH Premium User manual

Other Enerpac Jack manuals

Enerpac

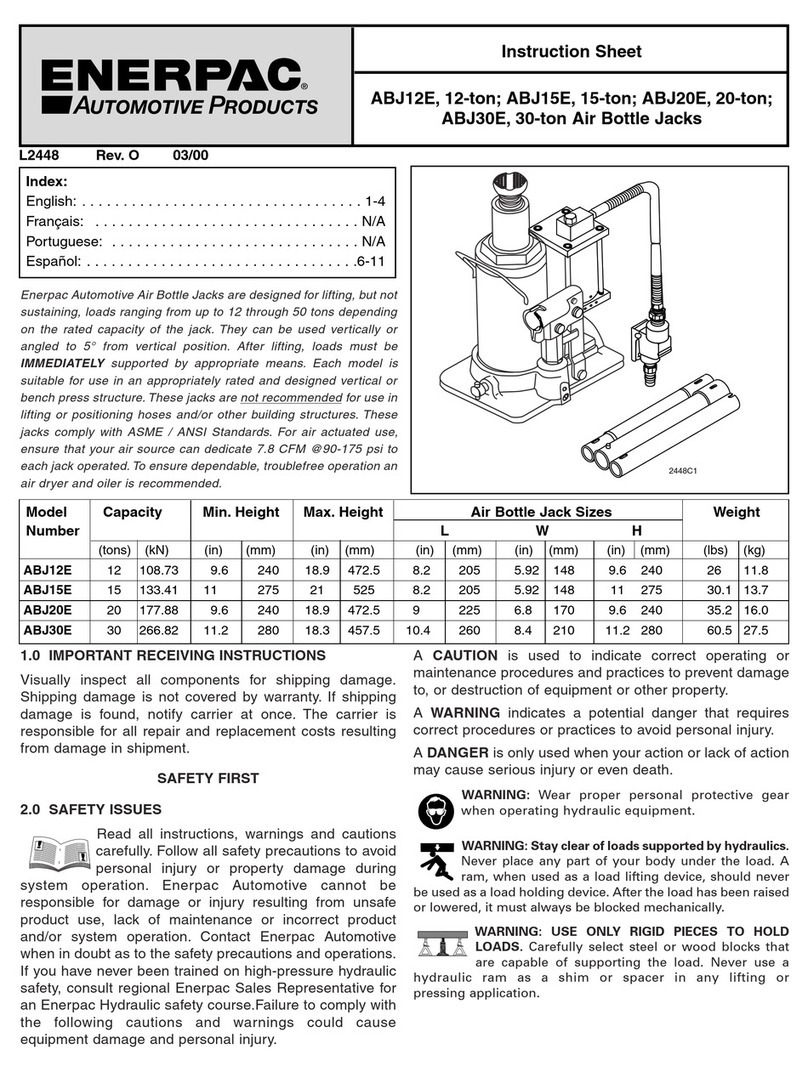

Enerpac ABJ12E User manual

Enerpac

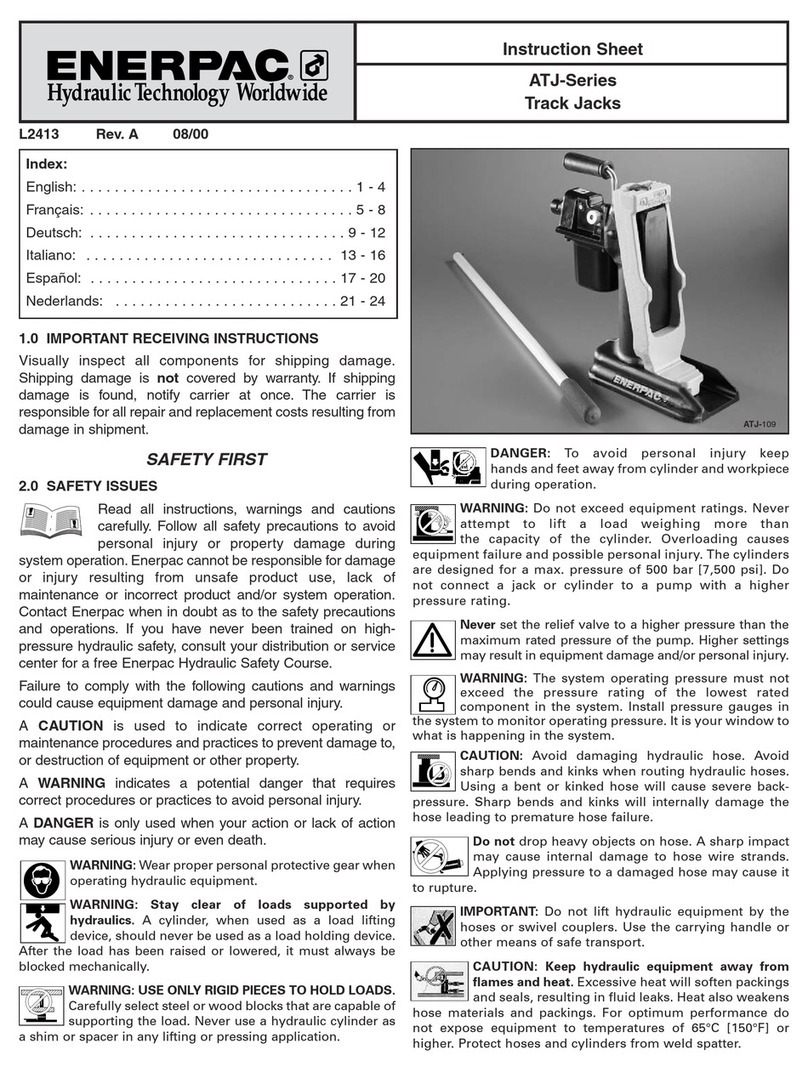

Enerpac ATJ Series User manual

Enerpac

Enerpac JH Premium User manual

Enerpac

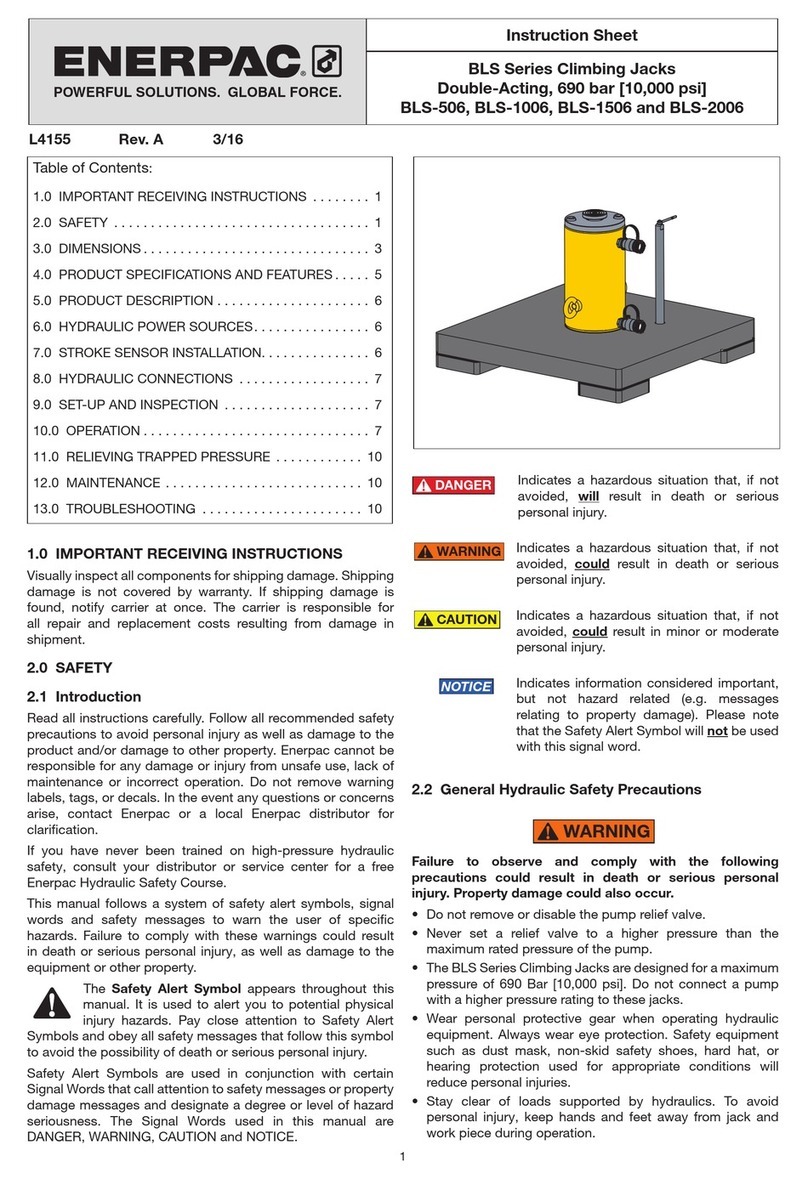

Enerpac BLS Series User manual

Enerpac

Enerpac Saf-T-Lite JHA Series User manual

Enerpac

Enerpac JH Premium Series User manual

Enerpac

Enerpac A5 User manual

Enerpac

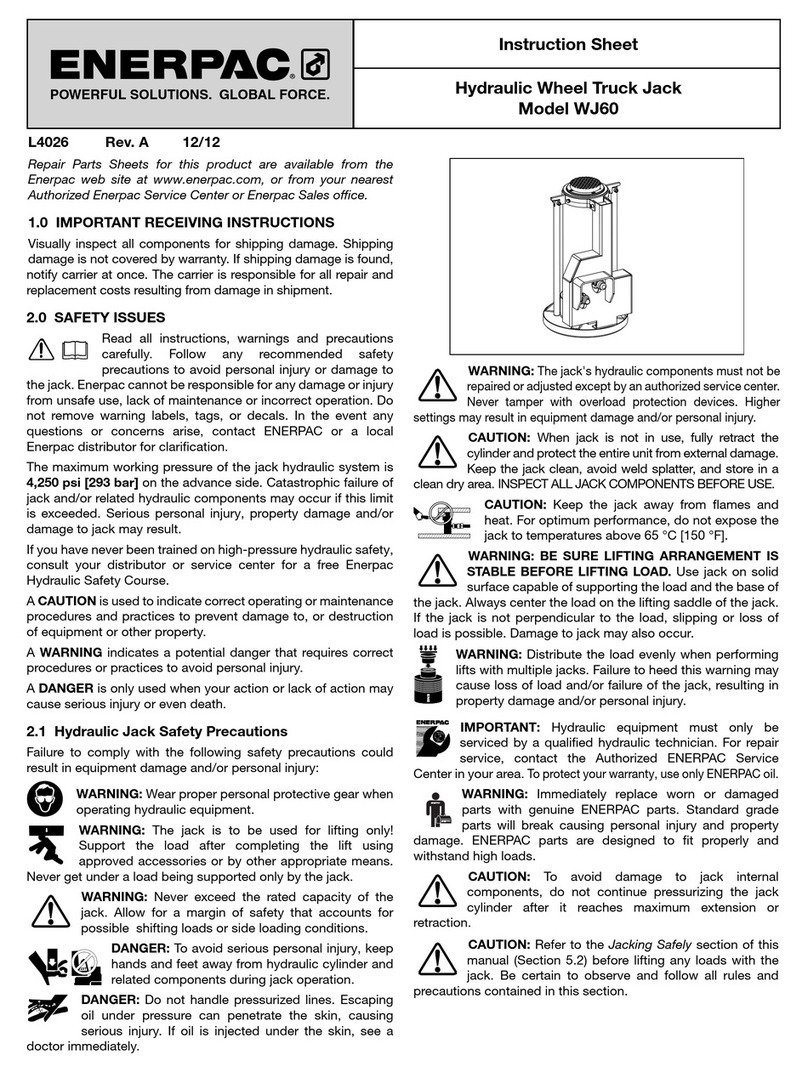

Enerpac WJ60 User manual

Enerpac

Enerpac SOH-10-6 User manual

Enerpac

Enerpac GBJ Series User manual

Enerpac

Enerpac GBJ Series User manual

Enerpac

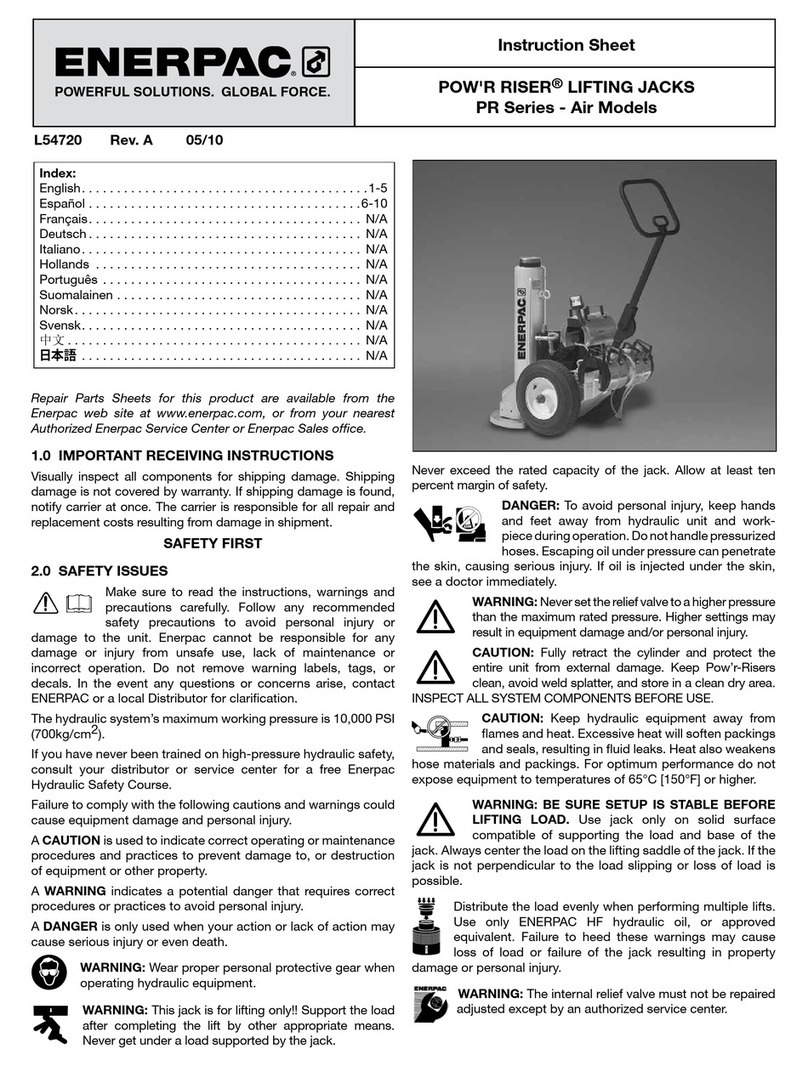

Enerpac Pow'r-Riser PR Series User manual

Enerpac

Enerpac SCJ-50 User manual

Enerpac

Enerpac PT Series User manual

Enerpac

Enerpac SOH-10-6 User manual

Enerpac

Enerpac Saf-T-Lite JHA User manual

Enerpac

Enerpac Pow'r Claw TJ105LS User manual

Enerpac

Enerpac POW'R RISER PR Series User manual

Enerpac

Enerpac TBJ2E User manual

Enerpac

Enerpac Pow'r-Riser PR Series User manual

Popular Jack manuals by other brands

Omega Lift Equipment

Omega Lift Equipment 18122C Operating instructions & parts manual

Pittsburgh

Pittsburgh 58816 Owner's manual & safety instructions

Unimec

Unimec TP Assembly instructions

Sonic

Sonic 4800703 instructions

BGS technic

BGS technic 70039 instruction manual

TradeQuip

TradeQuip 1128T owner's manual

VEVOR

VEVOR TJD-12000SP-F quick start guide

ULTIMATE SPEED

ULTIMATE SPEED URW 2 A1 HYDRAULIC TROLLEY JACK operating instructions

Stels

Stels 51131 user manual

Valex

Valex 1650520 Translation of the original instructions

Clarke

Clarke CTJ2500QLG Operating & maintenance instructions

Pfaff

Pfaff Merkur M0 Operating instruction