1

POWERFUL SOLUTIONS. GLOBAL FORCE.

Instruction Sheet

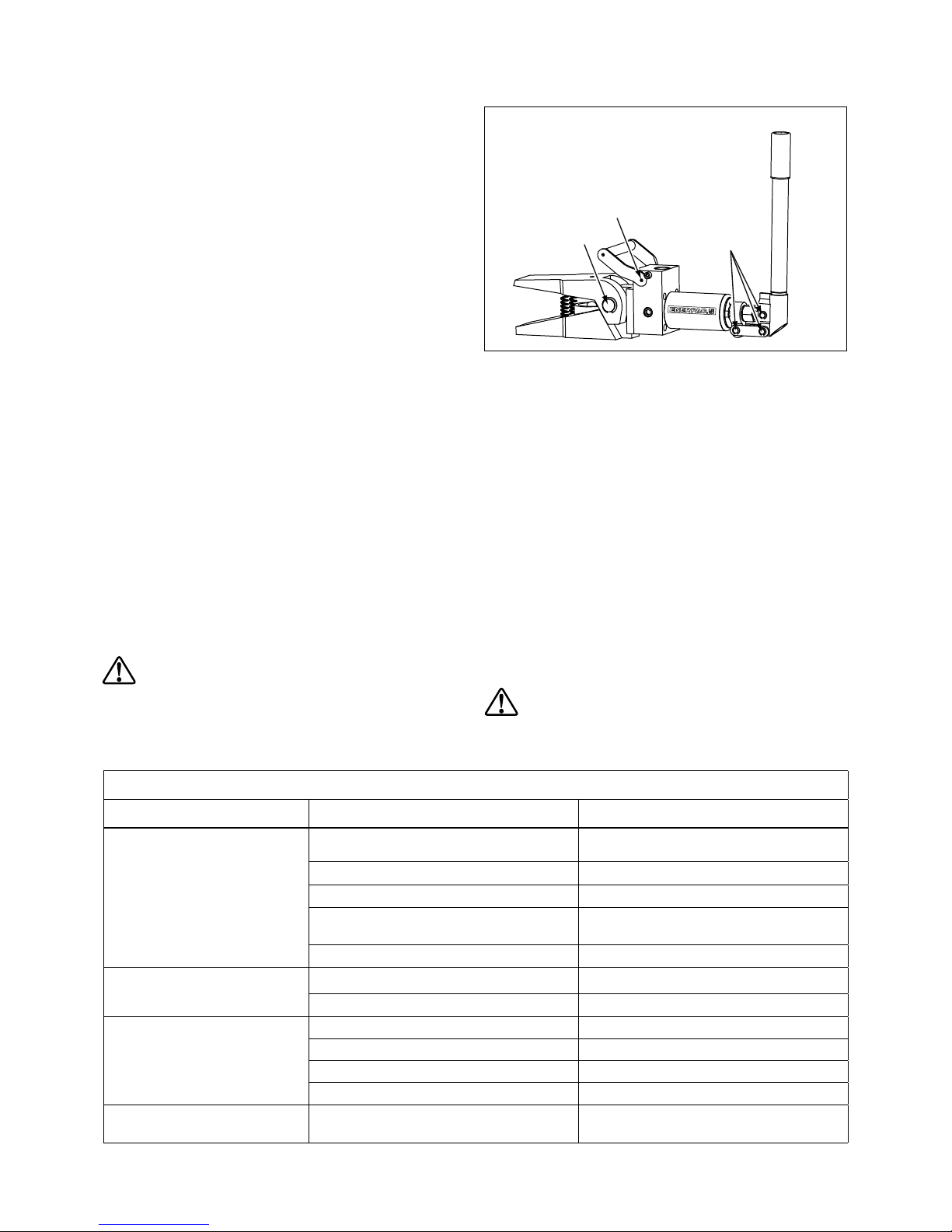

Integrated Spreader

Model WR-13

L2913 Rev. A 06/09

•Never place fingers,

hands, feet or other

body parts between the

spreader's upper and

lower jaws.

•Keep fingers, hands,

feet and other body

parts clear of the area

under the load being

lifted by the spreader.

• After lifting, always support the load with blocking, cribbing

or other suitable supports. Never allow persons to reach or

work under a load supported by the spreader

• Items that are pushed sideways or spread apart can be under

tremendous force. Always support these items with blocking,

cribbing or other suitable supports before allowing persons to

reach or work inside the danger zone.

•Be alert while operating the spreader. If items become

unstable or begin to shift or tip, stop operating the spreader

immediately. Install suitable blocking and/or cribbing as

needed to prevent items from tipping, falling or shifting.

•The spreader pressure relief valve is factory set for 10,000

PSI [700 bar]. Never attempt to disable the pressure relief valve

or change the valve setting. Allow only qualified hydraulic

technicians to check and adjust the pressure relief valve

setting.

•Do not loosen or remove any plugs on the spreader while it

is in use.

• Never perform maintenance, adjustments or repairs while

the spreader is in use.

• Do not attempt to lift vehicles, such as cars and trucks, using

the spreader. The spreader is not intended for lifting vehicles.

•No modification or alteration of this product is allowed. Do

not use the spreader for any purpose other than for which it

is intended.

• Do not loosen release valve screw more than one turn

counter-clockwise from fully closed.

• Keep the spreader away from flames and heat. Excessive

heat will soften packings and seals, resulting in fluid leaks.

For optimum performance do not expose equipment to

temperatures of 150°F [65°C] or higher. Protect the spreader

from weld spatter.

Index:

English. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Français. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Deutsch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Italiano. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Español . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Nederlands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Portuguese . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Finnish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Norwegian . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Swedish. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

中文 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

日本語. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Repair Parts Sheets for this product are available from the

Enerpac web site at www.enerpac.com, or from your nearest

Authorized Enerpac Service Center or Enerpac Sales office.

1.0 IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage. Shipping

damage is not covered by warranty. If shipping damage is found,

notify carrier at once. The carrier is responsible for all repair and

replacement costs resulting from damage in shipment.

SAFETY FIRST

2.0 GENERAL SAFETY INFORMATION

Read all instructions, warnings and cautions

carefully. Follow all safety precautions to avoid

personal injury or property damage during system

operation. Enerpac cannot be responsible for damage or injury

resulting from unsafe product use, lack of maintenance or

incorrect product and/or system operation. Contact Enerpac

when in doubt as to the safety precautions and operations. If

you have never been trained on high-pressure hydraulic safety,

consult your distribution or service center for a free Enerpac

Hydraulic safety course.

Failure to observe the hazard statements contained in this

document could result in equipment damage, personal injury

or death.

A CAUTION is used to indicate correct operating or

maintenance procedures and practices to prevent damage to,

or destruction of equipment or other property.

A WARNING indicates a potential danger that requires correct

procedures or practices to avoid personal injury.

A DANGER is only used when your action or lack of action

may cause serious injury or even death.

2.1 Integrated Spreader Safety Precautions

DANGER: Failure to observe the following precautions

could result in serious personal injury or death!

• Wear proper personal protective gear when operating the

spreader. Use of safety footwear, thick gloves, overalls and

safety glasses is mandatory. These items are in addition to any

other safety equipment required at your site.

•Do not exceed the spreader's rated load. The spreader has a

maximum capacity of 3000 lbs [13.4 kN]. Never attempt to lift,

push or separate objects that will result in larger loads.

•Keep fingers, hands, feet and other body parts clear of the

spreader upper and lower jaws during spreader operation.

WARNING: • Crush Hazard

•Pinch Point Hazard

WARNING: • Crush Hazard

•Pinch Point Hazard