entegris 4000 Series User manual

P/N 01-1027289 | REV. A 04/17

NT Pressure Transducer

Models 4100, 4210

User Guide

NT PRESSURE TRANSDUCER MODELS 4100, 4210

1Entegris, Inc. | User Guide

Table of Contents

Safety Alert Symbol ........................ 2

Introduction ..................................... 2

Installation ........................................ 3

Mechanical Installation ................ 3

Electrical Installation .................... 4

Power Supply

Requirements ................................. 4

Warnings ......................................... 5

Unit Operation ................................. 6

Operating Environment ............... 6

Process Connections ................... 6

Pressure Transducer

Cover Assembly ............................. 6

Pressure and Temperature

Requirements ................................. 6

Pressure Limits ............................... 7

Pressure Reference

Accuracy ......................................... 7

Linear Output Signal .................... 8

Troubleshooting .............................. 9

Reference ....................................... 10

Physical Specifications ............... 10

Electrical Specifications ............. 10

Performance

Specifications ............................... 10

Certifications .................................. 11

CE Compliance ........................... 11

Class I, Division 2

Hazardous Environments ......... 11

Ordering Information .................. 12

Model 4100 Single-port ............ 12

Model 4210 Flow-through ......... 13

Installation Drawings ................... 14

Model 4100 Single-port ............ 14

Model 4210 Flow-through ......... 15

Control Drawing ......................... 17

Appendix ......................................... 18

For More Information .................. 22

Terms and Conditions of Sale .... 22

Product Warranties ....................... 22

NT PRESSURE TRANSDUCER MODELS 4100, 4210

2User Guide | Entegris, Inc.

Introduction

This manual is for use with the

following standard NT Pressure

Transducer 4000 Series Models

4100 and 4210. These instruments

have been designed for use in high

purity applications in the semicon-

ductor industry.

These products feature no moving

parts and no filled cavities, which

reduces the possibility of a contami-

nated process. The wetted parts of

these nonmetallic transducers are

constructed with PTFE, PFA or other

similar high purity inert materials.

WARNING! Attempting to install

or operate standard NT 4000

Series Pressure Transducers

without reviewing the instruc-

tions contained in this manual

could result in personal injury or

equipment damage.

Polypropylene electrical

connector option

Signal conditioning circuit

Electronic pressure senso

r

Process connection

PTFE body

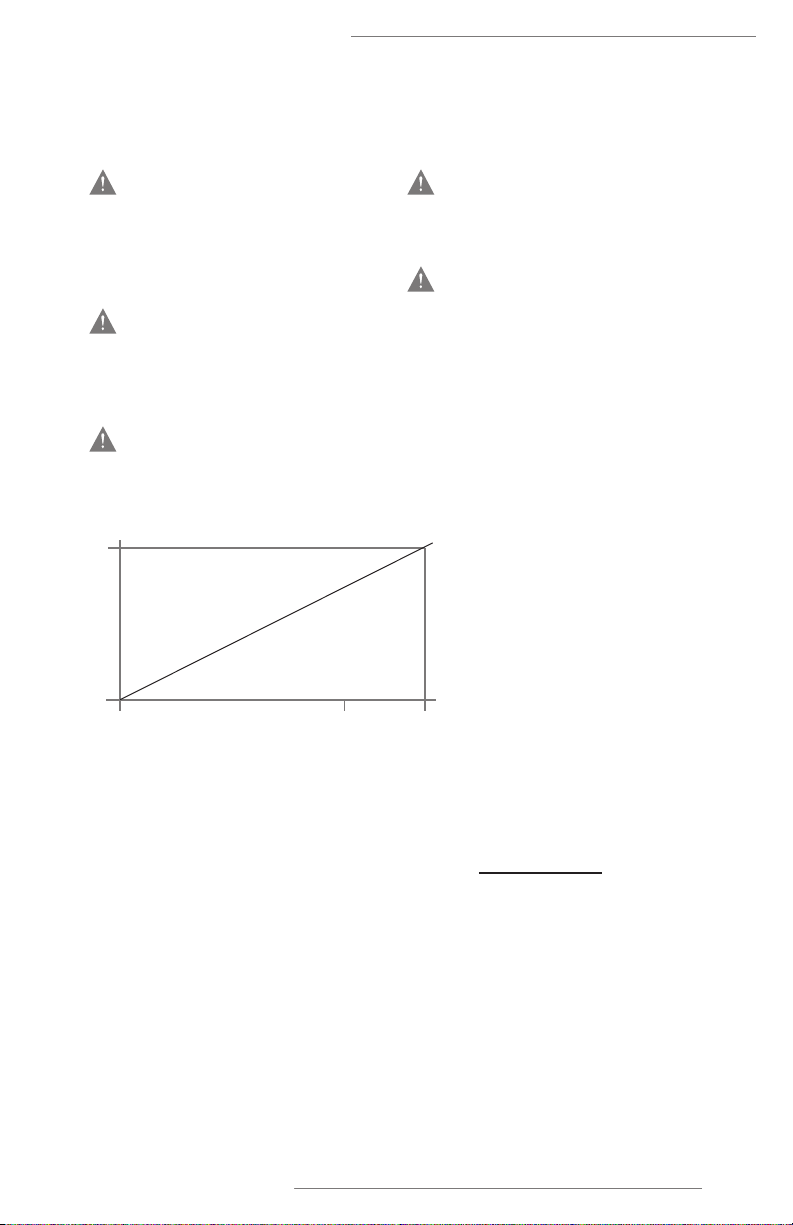

Cut-away Example:

NT Single-port

Pressure Transducer

Cut-away Example:

NT Flow-through

Pressure Transducer

Process

connection

Polypropylene

electrical

connector option

Signal condition-

ing circuit

Electronic

pressure sensor

PTFE body

Safety Alert Symbol

Indicates a hazardous situation which, if not avoided,

could result in serious injury or death.

WARNING!

NT PRESSURE TRANSDUCER MODELS 4100, 4210

3Entegris, Inc. | User Guide

Installation

WARNING! The pressure trans-

ducer has been factory sealed.

Do not attempt to remove the

cover of the pressure transducer.

Any attempt at removal of the

pressure transducer cover

will void the warranty and

damage the unit.

WARNING! Do not tighten the

nuts that protect the process

connections during shipment.

Do not tighten the nuts unless the

proper tubing has been installed.

Tightening these nuts may result in

damage to the pressure transducer

process connections.

MECHANICAL INSTALLATION

—

NOTE: For detailed tube flaring

instructions, see “Flaretek tube

fitting flare and assembly procedure”

at www.entegrisfluidhandling.com

(follow the Fittings>Tube Fittings>

Flaretek Tube Fittings links).

When installing flared tubing to

the pressure transducer, the flared

tube is pushed over the transducer’s

fitting until the fitting reaches the

smaller tube diameter. The amount

of torque required to tighten the

coupling nut is dependent upon

the size of the fitting.

Fitting size 1⁄4"3⁄8"1⁄2"3⁄4" 1"

Torque (in•lbs) 5 8 11 14 30

Care should be taken when instal-

ling flared tubing onto the pressure

transducer. Do not use excessive

torque or subject the transducer

to high heat during installation.

The transducer should be firmly

mounted to a solid surface to

ensure stability. Verify that the

pressure transducer and the signal

cable are free from mechanical

stress or excessive bending from

the surrounding equipment.

NT PRESSURE TRANSDUCER MODELS 4100, 4210

4User Guide | Entegris, Inc.

ELECTRICAL INSTALLATION

—

The pressure transducer provides

an analog (0–5 VDC, 0–10 VDC or

4–20 mA) electrical output propor-

tional to the pressure measured.

NOTE: The white wire is not required

for the 4–20 mA output configuration,

please refer to the wiring diagrams below.

POWER SUPPLY REQUIREMENTS

—

The pressure transducer requires

a 12–30 volt DC power supply with

less than 2% ripple at 100 or 120 Hz.

The required power supply voltage

varies with the load resistance (RLoad),

please refer to the formulas on page

5. The power supply must provide

clean power and must be used only

to power similar measurement-type

devices. The power supply must not

be used to power inductive loads,

such as motors, relays or solenoids.

These devices may produce

transients that may aect the

pressure transducer measurements

when the inductive device is powered

up or powered down.

NOTE: Be sure to ground the shield of

the cable to local ground.

+24 VDC

Pressure transducer

4–20 mA output version

Pressure transducer

0–5 VDC, 0–10 VDC output version

4–20 mA pressure signal

Voltage pressure signal

RED

WHITE

GND

BLACK

RED

WHITE

BLACK

No connection

Display

or PLC

Display

or PLC

Electrical connector information

WIRE 4–20 MA OUTPUT VERSION VOLTAGE OUTPUT VERSION

Red VDC+ 24 VDC (12–30 VDC) 24 VDC (12–30 VDC)

Black VDC– Ground Ground

White Not used 0–5 VDC signal or 0–10 VDC signal

NT PRESSURE TRANSDUCER MODELS 4100, 4210

5Entegris, Inc. | User Guide

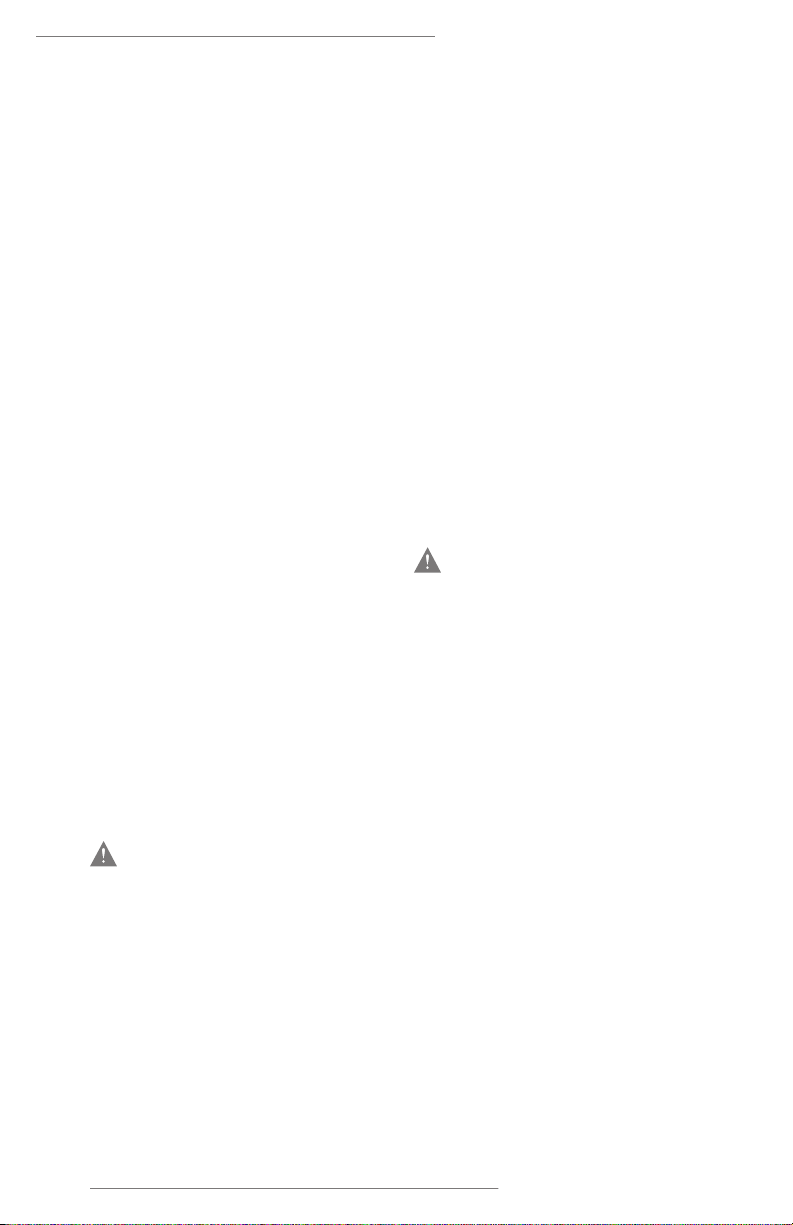

Load Resistance: Current Output

(4–20 mA Configuration)

If a load resistor, RLoad, is used

in series with the current output,

the value of RLoad is dependent on

the supply voltage and the meter

resistance and is calculated from

the following formula:

Load Resistance: Voltage Output

(0–5, 0–10 VDC)

The output impedance is 1 kOhm.

The input impedance should

be ≥1 megohm for ±0.1% load

impedance error.

850

12 24 29

Power supply

voltage

(VPS)

Operating

region

RLoad (Ohms)

0

Figure 1. Power required for a 4–20 mA loop.

R

Load = – Rmeter

RLoad

Rmeter

where:

= maximum load

resistance (ohms)

= power supply

voltage (volts)

= meter resistance (ohms)

(theoretically = 0)

VPS

V

PS

– 12 V

20 mA

WARNINGS

—

WARNING! For use in Class I

Division 2 Hazardous Environ-

ments, models with disconnecting

cable options must be wired in

accordance with the control

drawing 01-1033562 on page 17.

WARNING! Do not remove or

replace while circuit is live unless

the area is known to be free

of ignitible concentrations of

flammable substances.

WARNING! Do not replace comp-

onents unless power has been dis-

connected or the area is known to

be free of ignitible concentrations.

WARNING! Explosion hazard.

Do not connect while the circuit is

live or unless the area is known to

be free of ignitible concentrations.

WARNING! Substitution of com-

ponents may impair suitability for

Division 2.

NT PRESSURE TRANSDUCER MODELS 4100, 4210

6User Guide | Entegris, Inc.

Unit Operation

OPERATING ENVIRONMENT

—

The pressure transducer is to

be mounted in a well vented and

controlled environment. Refer to

the Reference section on page 10

for additional specifications.

PROCESS CONNECTION

—

To avoid possible pressure leaks,

make sure all process connections

have been performed in accordance

with the Mechanical Installation

guidelines on page 3.

PRESSURE TRANSDUCER COVER

ASSEMBLY

—

NT Pressure Transducer covers are

factory sealed and should not be

tampered with or opened. Opening

the cover shall void the product

warranty.

WARNING! Any attempt to remove

or tamper with the transducer

cover will void the warranty

and damage the unit.

PRESSURE AND TEMPERATURE

REQUIREMENTS

—

The minimum pressure required

is atmospheric pressure. The pres-

sure transducer may be damaged

if subjected to vacuum pressure

(pressure that is less than atmo-

spheric pressure).

The pressure transducer is rated for

use with fluids at process tempera-

tures between 10–65°C (50–149°F)

under normal operating conditions.

WARNING! NT Pressure Transduc-

ers, Models 4100 and 4210 may be

damaged if the sensor is subjected

to any level of vacuum pressure

(pressure less than atmospheric

pressure).

NT PRESSURE TRANSDUCER MODELS 4100, 4210

7Entegris, Inc. | User Guide

PRESSURE LIMITS

—

TRANSDUCER

RANGE

MAXIMUM OVER PRESSURE

LIMIT @ 23°C (73°F)

MAXIMUM OVER PRESSURE

LIMIT @ 65°C (149°F)

0 – 30 psig 690 kPa (100 psig) 690 kPa (100 psig)

0 – 60 psig 1034 kPa (150 psig) 690 kPa 100 psig

0 –100 psig 1034 kPa (150 psig) 690 kPa 100 psig

0 –150 psig 1310 kPa (190 psig) N/A

Maximum over pressure can be limited by the fitting. Consult the fitting specification for

maximum over pressure limits.

WARNING! The pressure limits

for standard NT Pressure Trans-

ducers (4000 Series) decrease

significantly for temperatures

above 65°C (149°F). Exceeding

these limits may result in personal

injury or equipment damage.

PRESSURE REFERENCE ACCURACY

—

The accuracy of the pressure

transducer output is ±1% of full

scale. This accuracy includes the

eects of linearity, hysteresis and

repeatability, measured at room

temperature. Accuracy specifica-

tions for non-standard product

configurations might vary.

NT PRESSURE TRANSDUCER MODELS 4100, 4210

8User Guide | Entegris, Inc.

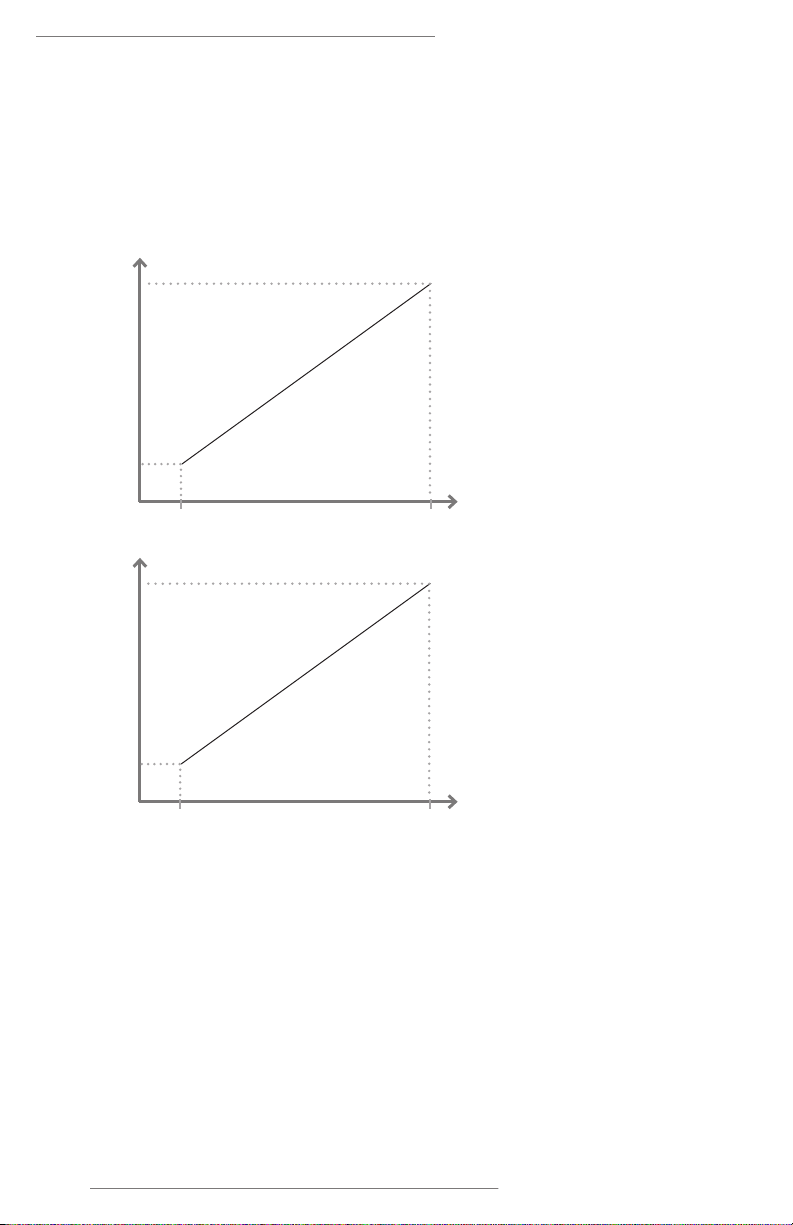

LINEAR OUTPUT SIGNAL

—

The output signal of the pressure

transducer is a linear function

proportional to the applied pressure.

Full scale

4 mA

0 psig Pressure

Measurement

Full scale0 psig Pressure

Measurement

Current Output (mA)Voltage Output (V)

20 mA

10 V

or 5 V

0V

NT PRESSURE TRANSDUCER MODELS 4100, 4210

9Entegris, Inc. | User Guide

Troubleshooting

Troubleshooting the NT Pressure

Transducers (4000 Series) may

be accomplished by measuring

the output signal of the pressure

transducer with a battery powered

current/voltage meter. The meter

may be placed in series with the

pressure transducer to measure the

current output or it may be used to

directly measure the voltage output.

Using the battery powered current/

volt meter is an eective method to

determine whether the device or the

on-site data acquisition system is not

functioning properly.

NT PRESSURE TRANSDUCER MODELS 4100, 4210

10 User Guide | Entegris, Inc.

Reference

The following lists the specifications

for the NT Pressure Transducer

product line. Please consult the

factory for product specifications

manufactured for nonstandard

applications.

NOTE: Specifications are subject to

change without notice.

Physical Specifications:

Materials Wetted parts Body PTFE

Sensor interface CTFE or PFA

O-ring Kalrez®

Nonwetted

parts

Polypropylene, polyethylene, Viton®, PVDF

(in addition to materials listed above)

Connection type Flaretek tube fitting, Super 300 Type Pillar®tube fitting, NPT

(PrimeLock®available upon request.)

Electrical Specifications:

Input voltage 24 VDC (12–30 VDC)

Input current 20 mA maximum

Pressure signal output ranges 4–20 mA, 0–5 VDC, 0–10 VDC

Electrical connection 6', 12', 30' FEP-jacketed pigtail or polypropylene

3-pin connector

Electrical enclosure IP54

Performance Specifications

Reference accuracy ±1% of full scale (includes linearity, hysteresis and

repeatability) at 23°C (73°F)

Process temperature 10–65°C (50–149°F)

NT PRESSURE TRANSDUCER MODELS 4100, 4210

11Entegris, Inc. | User Guide

Certifications

CE COMPLIANCE

Entegris products have been tested

to various test standards required

by the EMC 2104/30/EU directive.

The results of this testing are on

file at Entegris and are available

upon request.

Please contact the factory for

the latest information. The most

current specifications may be

found on Entegris’ Web site at:

http://www.entegrisfluidhandling.

com/Product.aspx?G=1613

CLASS I DIVISION 2

HAZARDOUS ENVIRONMENTS

Entegris has tested our standard

products to the UL 61010-1,

ANSI/ISA 12.12.01 standards for

use in Class I, Division 2 Group A–D,

T6 10°C ≤Ta ≤65°C hazardous

environments. The results of this

testing are on file at Entegris and

are available upon request.

All specifications are subject to

change. Please contact the factory

for the latest information.

NT PRESSURE TRANSDUCER MODELS 4100, 4210

12 User Guide | Entegris, Inc.

Ordering Information

Refer to the following for the desired configuration.

Model 4100 Single-port Pressure Transducer: part number

4100 - - - - - -

Pressure range

030G = 207 kPa (30 psig)

060G = 414 kPa (60 psig)

100G = 690 kPa (100 psig)

150G = 1034 kPa (150 psig)

(Flaretek and Pillar

port connections

only)

Inlet/outlet port connection

F02 =

1⁄4" Flaretek tube fitting

F03 =

3⁄8" Flaretek tube fitting

F04 =

1⁄2" Flaretek tube fitting

W02 = 1⁄4" Super 300 Type Pillar tube fitting

W03 =

3⁄8" Super 300 Type Pillar tube fitting

W04 =

1⁄2" Super 300 Type Pillar tube fitting

N02 =

1⁄4" FNPT

N04 =

1⁄2" FNPT

M02 = 1⁄4" MNPT

Electrical connector types

B06 = FEP-jacketed 6'pigtail electrical cable

B12 = FEP-jacketed 12'pigtail electrical cable

B30 = FEP-jacketed 30'pigtail electrical cable

D00 = Polypropylene connector (cable not included)

D06 = Polypropylene connector and 6'PVC cable

D12 = Polypropylene connector and 12'PVC cable

D30 = Polypropylene connector and 30'PVC cable

Primary/secondary seal

U3 = Kalrez 6375 UP / Viton

S3 = Kalrez 6375 UP / Kalrez 6375 UP

Sensor interface

P1 = CTFE sensor interface (default)

P2 = PFA sensor interface

Electrical outputs

A = 4–20 mA (12–30 VDC input)

B = 0–10 VDC (12–30 VDC input)

C = 0–5 VDC (12–30 VDC input)

Example: 4100-100G-F02-D06-A-P1-U3

• 4100 — Model

• 100G — Pressure range

• F02 — Inlet/outlet port connection

• D06 — Electrical connector type

• A — Electrical outputs

• P1 — Sensor interface

• U3 — Primary/secondary seal

NT PRESSURE TRANSDUCER MODELS 4100, 4210

13Entegris, Inc. | User Guide

Model 4200 Single-port Pressure Transducer: part number

4200- - - - - -

*For detailed pressure limit information on Flaretek tube fitting connections, refer to the

Maximum Pressure Capabilities chart in the Flaretek fittings product section on Entegris’

website at http://www.entegrisfluidhandling.com.

Pressure range

030G = 207 kPa (30 psig)

060G = 414 kPa (60 psig)

100G = 690 kPa (100 psig)

Inlet/outlet port connection

F02 =

1⁄4" Flaretek tube fitting

F03 =

3⁄8" Flaretek tube fitting

F04 =

1⁄2" Flaretek tube fitting

F06 =

3⁄4" Flaretek* tube fitting

F08 = 1" Flaretek* tube fitting

W02 = 1⁄4" Super 300 Type Pillar tube fitting

W03 =

3⁄8" Super 300 Type Pillar tube fitting

W04 =

1⁄2" Super 300 Type Pillar tube fitting

W06 = 3⁄4" Super 300 Type Pillar tube fitting

W08 = 1" Super 300 Type Pillar tube fitting

Electrical connector types

B06 = FEP-jacketed 6'pigtail electrical cable

B12 = FEP-jacketed 12'pigtail electrical cable

B30 = FEP-jacketed 30'pigtail electrical cable

D00 = Polypropylene connector (cable not included)

D06 = Polypropylene connector and 6'PVC cable

D12 = Polypropylene connector and 12'PVC cable

D30 = Polypropylene connector and 30'PVC cable

Primary/secondary seal

U3 = Kalrez 6375 UP / Viton

S3 = Kalrez 6375 UP / Kalrez 6375 UP

Sensor interface

P1 = CTFE sensor interface (default)

P2 = PFA sensor interface

Electrical outputs

A = 4–20 mA (12–30 VDC input)

B = 0–10 VDC (12–30 VDC input)

C = 0–5 VDC (12–30 VDC input)

Example: 4210-100G-F02-D06-A-P1-U3

• 4100 — Model

• 100G — Pressure range

• F02 — Inlet/outlet port connection

• D06 — Electrical connector type

• A — Electrical outputs

• P1 — Sensor interface

• U3 — Primary/secondary seal

NT PRESSURE TRANSDUCER MODELS 4100, 4210

14 User Guide | Entegris, Inc.

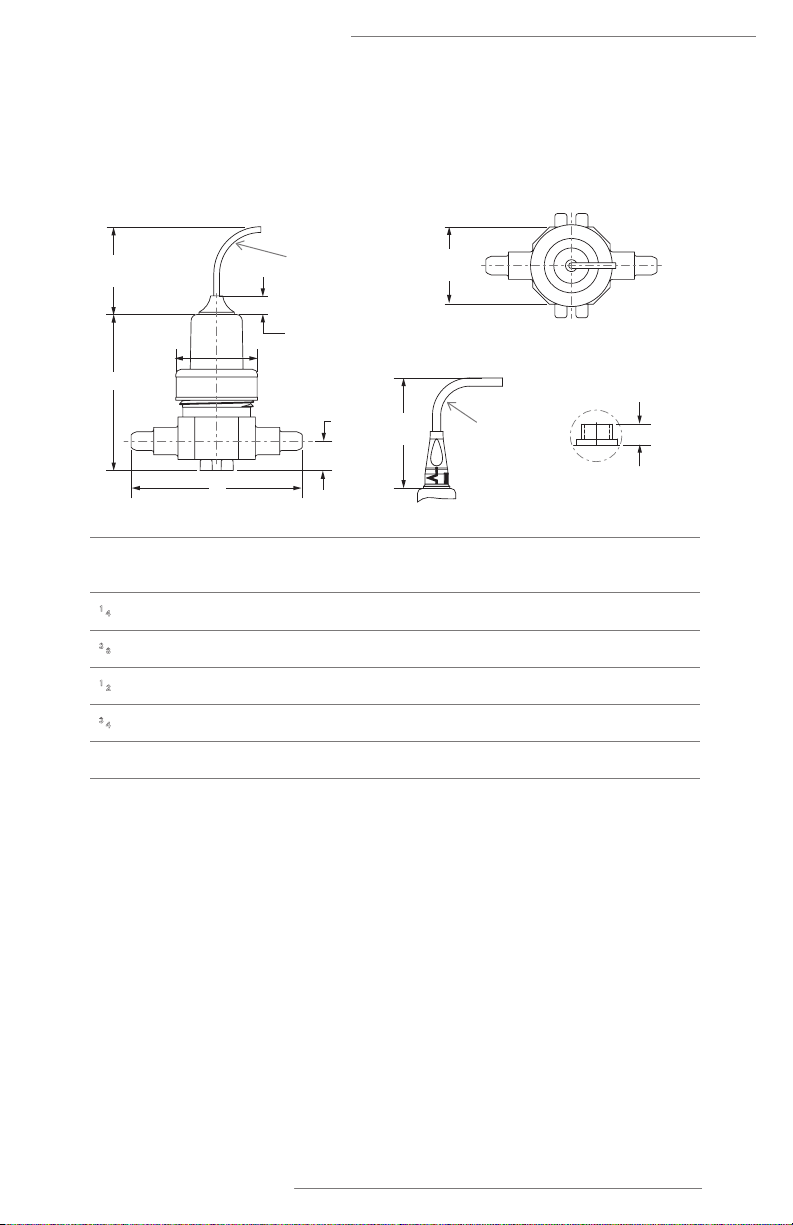

Installation Drawings

4100 Single-port Pressure Transducer

Inlet/outlet

port connection

A

B

1⁄4" Flaretek tube fitting 76.2 mm

(3.00")

25.2 mm

(0.99")

3⁄8" Flaretek tube fitting 76.2 mm

(3.00")

26.9 mm

(1.06")

1⁄2" Flaretek tube fitting 76.2 mm

(3.00")

29.0 mm

(1.14")

1⁄4" FNPT 82.3 mm

(3.24")

–

1⁄2" FNPT 88.9 mm

(3.50")

–

1⁄4" MNPT 76.2 mm

(3.00")

15.0 mm

(0.59")

1⁄4" Super 300 Type Pillar

tube fitting

76.2 mm

(3.00")

11.0 mm

(0.43")

3⁄8" Super 300 Type Pillar

tube fitting

76.2 mm

(3.00")

15.0 mm

(0.59")

1⁄2" Super 300 Type Pillar

tube fitting

76.2 mm

(3.00")

17.5 mm

(0.69")

Side View Side View Side View

Flaretek®Connection

10.7 mm (0.42”)

A

B

3 conductor

FEP-jacketed pigtail

connection (BXX)

(Cable length up

to 30 feet)

25.4 mm

(1.00”)

Ø47.8 mm

(1.88”)

Ø47.8 mm

(1.88”)

Super 300 Type Pillar®

Connection

10.7 mm

(0.42”)

NPT Connection

Ø47.8 mm

(1.88”)

25.4 mm

(1.00”)

25.4 mm

(1.00”)

A

B

A

B

Receptacle with connector removed

8.4 mm

(0.33”)

3 conductor

connector/cable

(DXX) (Cable length

up to 30 feet)

76.2 mm

(3.00”)

NT PRESSURE TRANSDUCER MODELS 4100, 4210

15Entegris, Inc. | User Guide

4210 Flow-through Pressure Transducer

Inlet/outlet

port connection

A

B

C

1⁄4" Flaretek tube fitting 89.7 mm (3.53") 94.7 mm (3.73") 18.5 mm (0.73")

3⁄8" Flaretek tube fitting 89.7 mm (3.53") 98.3 mm (3.87") 17.0 mm (0.67")

1⁄2" Flaretek tube fitting 96.0 mm (3.78") 102.4 mm (4.03") 21.6 mm (0.85")

3⁄4" Flaretek tube fitting 104.1 mm (4.10") 108.5 mm (4.27") 25.4 mm (1.00")

1" Flaretek tube fitting 112.5 mm (4.43") 120.7 mm (4.75") 30.5 mm (1.20")

Note: No NPT option on Model 4210.

Side View Top View

Flaretek Connection

10.7 mm

(0.42”)

A

BReceptacle with

connector removed

8.4 mm

(0.33”)

3 conductor pigtail

connection (BXX)

(Cable length

up to 30 feet)

3 conductor

connector/

cable (DXX)

(Cable length

up to 30 feet)

25.4 mm

(1.00”)

76.2 mm

(3.00”)

C

Ø47 mm

(1.85”)

44.5 mm

(1.75”)

NT PRESSURE TRANSDUCER MODELS 4100, 4210

16 User Guide | Entegris, Inc.

4210 Flow-through Pressure Transducer

Inlet/outlet

port connection

A

B

C

1⁄4" Super 300 Type Pillar

tube fitting

89.7 mm (3.53") 66.5 mm (2.62") 18.5 mm (0.73")

3⁄8" Super 300 Type Pillar

tube fitting

89.7 mm (3.53") 74.5mm (2.93") 17.0 mm (0.67")

1⁄2" Super 300 Type Pillar

tube fitting

96.0 mm (3.78") 79.5 mm (3.13") 21.6 mm (0.85")

3⁄4" Super 300 Type Pillar

tube fitting

104.4 mm (4.11") 88.4mm (3.48") 25.7 mm (1.01")

1" Super 300 Type Pillar

tube fitting

111.8 mm (4.40") 98.6mm (3.88") 29.7 mm (1.17")

Side View Top View

Super 300 Type Pillar Connection

10.7 mm

(0.42”)

A

B

8.4 mm

(0.33”)

25.4 mm

(1.00”)

76.2 mm

(3.00”)

C

44.5 mm

(1.75”)

Ø47 mm

(1.85”)

3 conductor

connector/

cable (DXX)

(Cable length

up to 30 feet)

Receptacle with

connector removed

3 conductor

FEP-jacketed pigtail

connection (BXX)

(Cable length up

to 30 feet)

NT PRESSURE TRANSDUCER MODELS 4100, 4210

17Entegris, Inc. | User Guide

Control Drawing 01-1033562

Nonincendive Field Wiring Required for Disconnecting Cable Options

A

03/22/2016

1

01-1033562

Control Drawing - Model 4100/4210

ENT

ENG MNGR:

MODIFIED BY:

ELEC ENG:

BAK

Entegris

B

1

REV:SIZE:CODE:

DRAWN: DATED:

DATED:

DATED:

DATED:

COMPANY:

TITLE:

DRAWING NO:

SHEET: OFSCALE:

REVISION RECORD

APPROVED:ECO NO:

A

B

D

DATE:

12345 6

D

C

A

B

C

LTR

Pressure

Hazardous (Classified) Location

Class I Division 2 Groups A, B, C, D

Unclassified Location

Associated

Field Wiring

Apparatus

Nonincendive

Ground (-)

Power (+)

Cable Option Conductor Color

Signals Vmax (VDC) Imax (mA) Ci (nF) Li (mH)

Red & Black Power & Ground

30 150 0.025

Table 1 - Entity Parameters for Models 4100, 4210 with 4-20mA Output (See Note 1)

Nonincendive Field Wiring Relationship

Associated Nonincendive

Field Wiring ApparatusApparatus (Model 4100/4210)

Vmax

Imax

Ci + C cable(60pf/ft)

Li + L cable(0.2uH/ft)

>=

>=

<=

<=

Voc

Isc

Ca

La

Table 3 - Nonincendive Field Wiring Apparatus vs. Associated Nonincendive Field Wiring Apparatus Requirements

A BAK 03/22/ 16

Notes:

4100-XXXX-XXX-A00-A-XX-XX

Associated

Field Wiring

Apparatus

Nonincendive

Ground (-)

Power (+)

Pressure Output

Table 2 - Entity Parameters for Models 4100, 4210 with Voltage Output (See Note 2)

Signals Vmax (VDC) Imax (mA) Ci (nF) Li (mH)

Red & Black 30 150 0.00.48

Brown & Blue

A00, DXX Cable Options PXX, TXX Cable Options

Cable Option Conductor Color

Transducer

4-20mA Output

Pressure

Transducer

Voltage Output

2. For use in Class I Division 2 Groups A, B, C, D, the following pressure

transducer models must be used with an approved associated

nonincendive field wiring apparatus that meets the requirements in

table 3 with the entity parameters in table 2.

4100-XXXX-XXX-DXX-A-XX-XX

4210-XXXX-XXX-A00-A-XX-XX

4210-XXXX-XXX-DXX-A-XX-XX

4100-XXXX-XXX-A00-B-XX-XX

4100-XXXX-XXX-DXX-B-XX-XX

4210-XXXX-XXX-A00-B-XX-XX

4210-XXXX-XXX-DXX-B-XX-XX

4100-XXXX-XXX-A00-C-XX-XX

4100-XXXX-XXX-DXX-C-XX-XX

4210-XXXX-XXX-A00-C-XX-XX

4210-XXXX-XXX-DXX-C-XX-XX

4100-XXXX-XXX-XXX-B-XX-XX-PXX

4210-XXXX-XXX-XXX-B-XX-XX-TXX

4210-XXXX-XXX-XXX-C-XX-XX-TXX

A00, DXX Cable Options

Nonincendive Field Wiring

1. For use in Class I Division 2 Groups A, B, C, D, the following pressure

transducer models must be used with an approved associated

nonincendive field wiring apparatus that meets the requirements in

table 3 with the entity parameters in table 1.

Power & Ground

Model 4100 or 4210

Model 4100 or 4210

165941

Pi (W)

2.25

Pi (W)

2.25

Pi >= Po

Nonincendive Field Wiring Required for Disconnecting Cable Options

NT PRESSURE TRANSDUCER MODELS 4100, 4210

18 User Guide | Entegris, Inc.

Appendix

Table 1. Entity parameters for Models NT4100, NT4200 with

4–20 mA output (see note 1.)

Cable option

conductor color

A00, DXX cable option Red and black

Signals Power and ground

Vmax 30 VDC

Imax 150 mA

Pi 2.25 W

Ci 25 nF

Li 0.0 mH

Table 2. Entity parameters for Models NT4100, NT4200 with

voltage output (see note 2.)

Cable option

conductor color

A00, DXX cable option Red and black

Signals Power and ground

Vmax 30 VDC

Imax 150 mA

Pi 2.25 W

Ci 0.48 nF

Li 0.0 mH

Table 3. Nonincendive field wiring apparatus vs. associated nonincendive

field wiring apparatus requirements

NONINCENDIVE FIELD WIRING

APPARATUS (MODEL NT4100 /4200

RELATIONSHIP

ASSOCIATED NONINCENDIVE

FIELD WIRING APPARATUS

Vmax ≥Voc

Imax ≥Isc

Pi ≥Po

Ci + C cable (60 pf/ft) ≤Ca

Li + L cable (0.2 uH/ft) ≤La

NT PRESSURE TRANSDUCER MODELS 4100, 4210

19Entegris, Inc. | User Guide

NOTES:

1. For use in Class I Division 2 Groups A, B, C, D, the following pressure trans-

ducer models must be used with an approved associated nonincendive field

wiring apparatus that meets the requirements in Table 3 with the entity

parameters in Table 1.

4100-XXXX-XXX-A00-A-XX-XX

4100-XXXX-XXX-DXX-A-XX-XX

4210-XXXX-XXX-A00-A-XX-XX

4210-XXXX-XXX-DXX-A-XX-XX

2. For use in Class I Division 2 Groups A, B, C, D, the following pressure

transducer models must be used with an approved associated nonincendive

field wiring apparatus that meets the requirements in Table 3 with the entity

parameters in Table 2.

4100-XXXX-XXX-A00-B-XX-XX

4100-XXXX-XXX-DXX-B-XX-XX

4100-XXXX-XXX-XXX-B-XX-XX-PXX

4100-XXXX-XXX-A00-C-XX-XX

4100-XXXX-XXX-DXX-C-XX-XX

4210-XXXX-XXX-A00-B-XX-XX

4210-XXXX-XXX-DXX-B-XX-XX

4210-XXXX-XXX-XXX-B-XX-XX-TXX

4210-XXXX-XXX-A00-C-XX-XX

4210-XXXX-XXX-DXX-C-XX-XX

4210-XXXX-XXX-XXX-C-XX-XX-TXX

This manual suits for next models

2

Table of contents

Other entegris Transducer manuals

Popular Transducer manuals by other brands

Mianyang Weibo Electronic

Mianyang Weibo Electronic WBV342U05-S user manual

LEI Extras

LEI Extras TH-FLWBL Transducer installation instructions

Camille Bauer

Camille Bauer SIRAX BT5400 Device handbook

Siedle

Siedle Novotechnik TP1 CANopen user manual

Kongsberg

Kongsberg Simrad CP200-5C installation manual

NK TECHNOLOGIES

NK TECHNOLOGIES AT 2 Series instructions