enware IFO SIGN WC P-Trap User manual

I00512_06Jun23

Installation and Maintenance Instructions

IFO SIGN WC P-Trap

RAISED HEIGHT TOILET

The more

stars the more

water efficient

WATER RATING

www.waterrating.gov.au

3.3litres

average flush

4.5 L per full flush / 3 L per half flush

AS1172-1

WM-040187

enware.com.au

2 Call 1300 369 273 www.enware.com.au

contents

Page

Product Description 3

Contents 4

Installation 5

Floor Mounting Method 5

Installation - Accessories 11

Maintenance 12

Cleaning 14

Troubleshooting 14

Spare Parts 15

Warranty 16

www.enware.com.au Call 1300 369 273 3

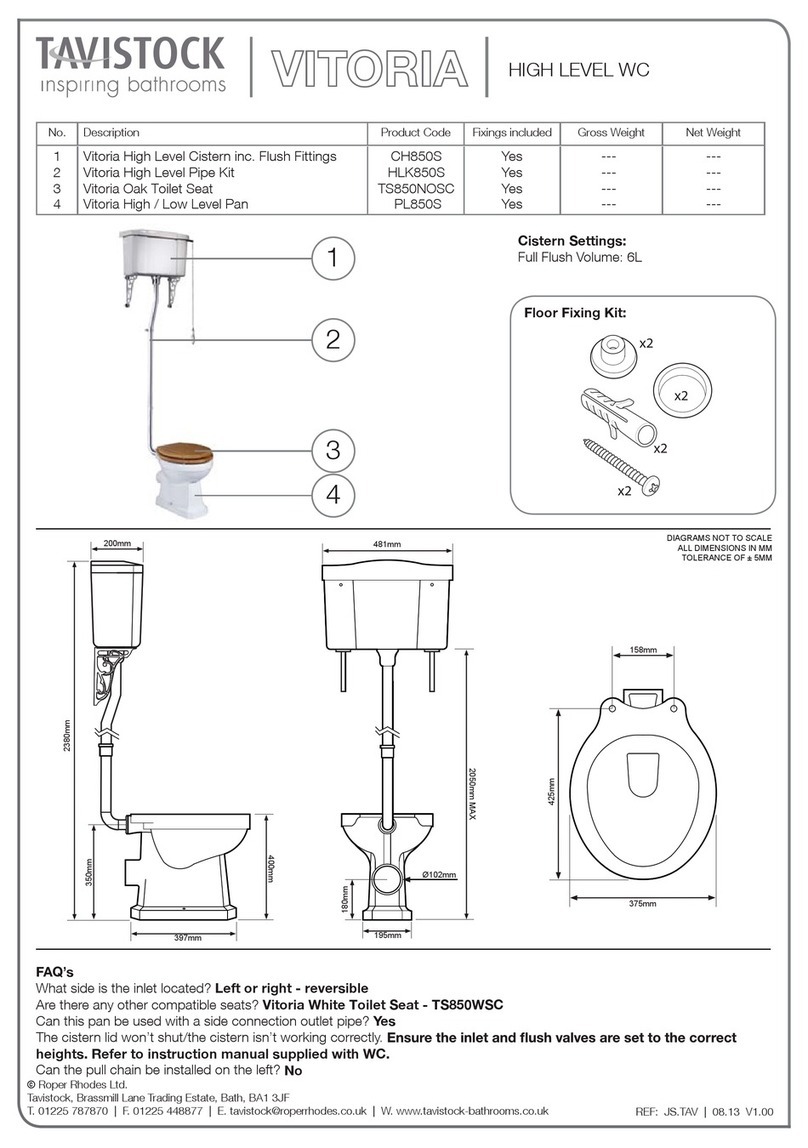

6872 Model (Raised Height P-Trap)

6860 68626861 6872

670

480

to top of seat

460

900

95

360

Bottom

inlet

connec

tion

190

120

FRONT VIEW SIDE VIEW

CARE6872

CARE602

CARE603

6860 68626861 6872

IFO6872

4 Call 1300 369 273 www.enware.com.au

Installation shall be in accordance with the AS/NZS3500 series of Standards, the Plumbing

Code of Australia (PCA), and the manufacturer’s instructions.

Installations not complying with AS/NZS 3500, the PCA or the manufacturer’s instructions

may void the product and performance warranty provisions.

Enware Australia advises:1. Due to ongoing Research and Development, specifications may

change without notice; 2. Component specifications may change on some export models.

All measurements are in millimetres.

contents

90610

11

196763

98303

598308

796766

12

98951

21

96760

22

91370 23

96773 24

96761

14 96759

15

91965 för 6893/6894

34

Water Supply Inlet Pressure Min. 50 kPa - Max. 500 kPa

Inlet Connection 1/2” BSP

Water Inlet Connection Method Bottom Inlet

Outlet Connection DN100 DWV PVC Pan Collar

TECHNICAL INFORMATION

technical data

Toilet Seat (With Lid)

[OPTIONAL]

Toilet Seat (No Lid)

[OPTIONAL]

Raised Flush Button

[OPTIONAL]

IFO98125 Support Arms

[OPTIONAL]

www.enware.com.au Call 1300 369 273 5

Water Inlet Connection

The water connection to the cistern inlet is a 1/2" BSP male,

bottom inlet.

Looking from the front of the pan, it is located on the right hand

side, on the bottom of cistern.

Install a cistern tap in the vicinity.

95

190

Bottom

Inlet

1/2”

BSP

Male

Floor Mounting Method

Determine floor fixing requirements according to the quality and strength of the floor material,

and the site risk assessment.

If there are no support arms, or there is no possibility of using

support arms in future, use:

• Silicone sealant fixing (Tiled or similar hard floor only. No Vinyl);

• Pan Screw fixing; or

• Bracket fixing (Optional - IFO98015 Bracket sold separately.)

If toilet has support arms or may have support arms in future

(raised height toilet models only), use:

• Pan Screw fixing; or

• Bracket fixing (Optional - IFO98015 Bracket sold separately.)

This installaon informaon is a guide only. Appropriate xing method must be determined by

site-specic risk assessment.

installation

6 Call 1300 369 273 www.enware.com.au

Fixing With Silicone Sealant:

Determine if this method of fixing to the floor would be suitable according to the site risk

assessment. This method of fixing is only suitable for tiled or similar hard floor surfaces. It is

not suitable for vinyl floors, or for toilets with support arms.

IMPORTANT - For Toilets with Support Arms:

Due to the extra force applied to the toilet pan by support arms, the toilet pan must be fixed

to the floor using stainless steel Pan Screws or a Floor Fixing Bracket. Fixing the toilet pan

with only silicone sealant is not considered to be an adequate method of fixing.

Ensure the floor surface and bottom surface of pan

are clean and dry - free of dust, moisture and grease.

Apply silicone sealant to the entire bottom contact

surface of pan and around the perimeter, to achieve

good adhesion and to create a strong bonding

between the pan and the floor.

Use white blind cover plugs supplied to plug the

screw holes on the pan.

www.enware.com.au Call 1300 369 273 7

Fixing With Pan Screws:

Determine if using pan screws would be appropriate according

to the quality and strength of the floor material, and the site

risk assessment, taking into account the thickness of floor

surface and mortar bed, the distance to structural concrete

slab, and the impact of the penetration of waterproofing

membrane.

Ensure the pan screws can be fixed onto floor material with

adequate structural integrity and strength. If pan screws

are not long enough or they cannot be fixed onto floor

with adequate strength, use floor mounting bracket with

appropriate fixings. (Floor mounting bracket IFO98015 sold

separately.)

48

105

Base level

of pan

4

Pan Screw

Installing the Pan:

1. Through the pan fixing holes, mark the floor then

pre-drill holes on the floor. The holes should be

drilled at a slight angle and approx. 50mm deep.

Insert suitable screw plugs into the drilled holes.

2. WC pan should be bedded with silicone sealant.

Ensure the floor surface and bottom surface of

pan are clean and dry, free of dust, moisture and

grease.

3. Apply silicone sealant to the entire bottom contact

surface of pan and around the perimeter to

achieve good adhesion and to create a strong

bonding between the pan and the floor.

4. Install pan into position.

5. Fix the pan in place with pan screws. Hand

tighten the screws, but do not over-tighten. (Over-

tightening screws will cause the ceramic to crack.)

6. Attach white screw caps (supplied) onto the heads

of fixing screws.

50

60°-65°

8 Call 1300 369 273 www.enware.com.au

Fixing With Floor Mounting Bracket:

(IFO98015 Floor Mounting Bracket sold separately.)

On Concrete Slab / Floor Before Waterproofing:

1. Position the bracket on the floor so that it is lined up

with pan fixing screw holes. (See diagram below.)

2. Mark fixing bolt hole positions to fix the bracket onto

floor. (Do not drill bolt holes through the bracket yet.)

3. Where marked, install 4 threaded rods onto structural

concrete slab/ floor. Ensure threaded rods are long

enough so that they protrude at least 50mm from the

finished floor.

4. Apply waterproofing as normal.

After The Floor is Finished:

5. Once the floor is finished, mark 4 bolt holes on bracket,

and pre-drill the marked holes.

6. Fix the bracket onto floor using the threaded rods and

matching washers and nuts.

7. Cut off any excess threaded rod.

60

80

1

94

11

0

Bo

l

t

h

o

l

e

positions

to

x

b

r

a

cket

onto oor

W

C pan

xing

h

o

l

e position

s

Bracket Position

www.enware.com.au Call 1300 369 273 9

4x 12Gx50mm

Screws

(Drill pilot holes

on bracket with

3 mm drill)

Installing the Pan:

8. WC pan should be bedded with silicone sealant.

Ensure the floor surface and bottom surface of

pan are clean and dry, free of dust, moisture and

grease

Apply silicone sealant to the entire bottom

contact surface of pan and around the perimeter

to achieve good adhesion and to create a strong

bonding between the pan and the floor.

9. Install pan into position.

10. Through the pan fixing holes, pre-drill the bracket

using a 3mm drill bit.

11. Fix the pan in place using four 12G x 50mm

screws supplied. Hand tighten the screws, but

do not over-tighten. (Over-tightening screws will

cause the ceramic to crack.)

12. Attach white screw caps (supplied) onto the

heads of fixing screws.

10 Call 1300 369 273 www.enware.com.au

Do not use the toilet until the silicone bed has cured.

Water Inlet Connection

Flush the water supply line to ensure the line is clear,

and connect water supply to the inlet connection of

the cistern.

The inlet connection requires sealing with a washer.

For hard pipe connection with compression nuts

or thread sealing, use a loose nut extension fitting

(available separately, Enware part code IFOS-009).

The inlet connection is flexible. Hold the inlet thread

on the hex with a spanner when making the thread

connection.

(Use loose nut

extension tting for

hard pipe connection)

Flush Volume

The flush volume is fixed at 4.5L for full flush and 3L

for half flush. Flush volume is not adjustable for this

product.

www.enware.com.au Call 1300 369 273 11

fresh odour cleaning tablets

This WC is prepared for Fresh WC function,

with a hygienic dosing of a tablet through the

flush button. The tablet is placed inside the

Cover Screw Rod by opening the flush button

and releasing the tablet in the blue Cover Screw

Rod, as illustrated.

The tablet produces a fresh odour and cleaning

effect on the whole bowl and colour.

installation - accessories

Install Toilet Seat and Support Arms (Optional)

Install toilet seat according to toilet seat instructions.

If installing support arms, note that the support arms need to be fixed with the seat at the

same time. Refer to IFO98125 support arms installation instructions for more details.

Raised Flush Button (Optional):

IFO FRESH WC

ONLY

Max. 1

The raised flush button can be

installed in place of the standard

flush button.

To take off the standard flush

button, lift the flush button by

the hinge, then unscrew Cover

Screw Rod using a 15mm Allen

key or a large screw driver.

Similarly, lift the button on the

new flush button, fit the Cover

Screw Rod through and install

back onto cistern.

Press the flush button on the

full flush side, then push down

further gently but firmly until the

button clicks into place.

CLICK

CLICK

Removing standard flush button: Fitting raised flush button:

1

2

12 Call 1300 369 273 www.enware.com.au

access to cistern internal components

1

2

To take off the standard flush button, lift the flush button by the hinge, then unscrew Cover Screw

Rod using a 15mm Allen key or a large screw driver.

Unscrew the two cistern fixing screws using T25 Torx head, then take off the ceramic shroud.

12

4

3

5

maintenance

Access to Inlet & Outlet Valves

STEP 1

Turn off and disconnect water supply.

To access the cistern valves, first take the complete cistern off the pan.

To remove cistern valves, release the inlet hose from the bottom of cistern by pulling down

and out. Then twist the valve assembly clockwise and lift it out of the cistern.

www.enware.com.au Call 1300 369 273 13

4

CLICK

Installing New Valve Kit ( IFOS-105 ) 2022 -

4

CLICK

STEP 2

Take out old valve base adaptor and replace with a new one. Ensure the adaptor is

pushed all the way down, then twist anti-clockwise and lock into position.

STEP 3

Attach blue inlet valve holder

marked "LEFT" onto inlet valve

as shown, making sure it clicks

into place.

Then attach the inlet valve and

holder to outlet valve on the

side marked "LEFT". Slide the

inlet valve holder on and make

sure it clicks into place.

Check that the inlet valve and

holder are aligned correctly.

CLICK

CLICK

CLICK

CLICK

CLICK

CLICK

CLICK

CLICK

CLICK

STEP 4

Fit valve assembly onto valve

base and push down until it

clicks into place.

Hook the inlet tube onto the

guide on valve holder. Feed the

inlet tube over to the back right

hand corner of cistern, then fit

the inlet fitting into the housing

on the bottom of cistern.

Reinstall cistern cover,

connect water supply and test

operation.

14 Call 1300 369 273 www.enware.com.au

cleaning

• WC units have a glazed surface. Glazed surfaces are easy to keep clean and are resistant

against most chemicals.

• Clean bowl regularly.

• Clean external surfaces regularly with a dry, soft cloth. Alternatively clean with hot water

and soap, using soft cloth or a sponge, and wipe dry with a cloth.

• Avoid using cleaning agents on the flush button, instead, use hot water and soap and

wipe dry with a cloth. This is because cleaning agents for porcelain are not intended for

chrome parts/plastics and can risk cracking the flush button if used frequently.

• Cleaning utensils, which contain abrasive agents, such as steelwool and green scouring

pads, must not be used. Strong abrasive materials can scratch the glaze and devoid it of

its original qualities.

• Strong acids such as hydrochloric acid or sulphuric acid, strong alkaline such as caustic

soda, and cleaning powders or pastes must not be used.

• Running WC units should be repaired immediately.

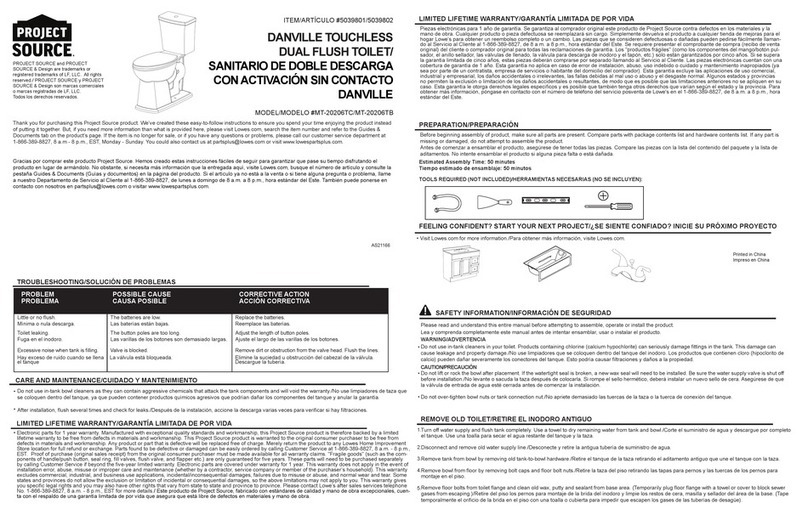

troubleshooting

PROBLEM CAUSE RECTIFICATION

Toilet not flushing away

Drain blockages

Offset pan collars are

used

Do not use offset pan collars

that can impede outlet flow

Water constantly runs into

bowl

Inlet valve failure Replace invet valve

(IFOS-103)

Outlet valve seal washer

is worn or damaged

Replace outlet seal washer

(IFO245V)

Water leaks between

cistern and pan

Spreader has dislodged

from cistern during transit

Take ceramic cistern cover off,

fit spreader back onto cistern,

reinstall cistern onto pan

For further assistance, call Enware on 1300 369 273.

Reinstalling Cistern Cover:

To reinstall the ceramic cistern cover, follow steps 1-5 on page 12 in reverse order.

The screws for the cistern mounting must be tightened alternately to a maximum torque

of 2.5 Nm. The cover screw rod should be tightened to a maximum torque of 1.0 Nm.

www.enware.com.au Call 1300 369 273 15

spare parts

Description

Sales Code

AInlet and outlet valve kit IFOS-105

BOutlet valve assembly IFOS-104

COutlet valve seal - 816.418.00.1 IFO245V

DInlet valve assembly IFOS-103

EInlet valve arm and seal - 243.801.00.1 IFO333V

1Sign Dual Flush Button - Chrome IFO98303

Sign Raised Dual Flush Button - Chrome IFO98308

2Cover Screw Rod IFO96763

3Cistern Cover White - Ceramic Shroud Only IFO90610

4Cistern Mounting Clip and Screw Kit (pair) IFO98949

5Inner Cistern - Tank only with seal IFO98951

6Flush Water Distributor / Spreader IFO91370

7Outlet Valve Assembly - IFO96769 replaced

by IFOS-105 IFOS-105

8Outlet Valve Seal (Cistern Seating Washer) IFO96765

9

Inlet Valve Assembly (Inlet valve body with

locking clip, shuttle piston and rubber seal)

- IFO96766 replaced by IFOS-105

IFOS-105

10 Inlet Pipe Assembly (Inlet tube with spigot

fitting) - IFO96761 replaced by IFOS-105 IFOS-105

11 Valve Frame Assembly - IFO96772 replaced

by IFOS-105 IFOS-105

12 O-ring seal for Valve Frame Assembly /

Cistern IFO96764

14 Replacement Armrest Handle - Grey (each) IFO96350

Replacement Nurse Call Switch IFO80011

15 Toilet Roll Holder for IFO98125 (each) IFO96348

16 White Screw Caps x4 for Pan Screws IFO94751

17 Pan Screws x 4, White Screw Caps x 4,

White Blind Cover Plugs x 4 IFO98381

18 White Blind Cover Plugs x4 IFO94752

19 Floor Mounting Kit IFO98015

20 Ifo S-Trap Pan Back Inspection Opening

Cover Plug -Soft IFO733

21 Fresh Sticks Blue (Pack of 5) IFO94690

22 Ifo Cistern Key with Hex and T25 Torx IFO91960

23 Loosenut Extension 1/2” BSP for inlet con-

nection IFOS-009

1

2

3

4

5

6

21

14

15

16

17

18

20

19

21 22

7

8

11

910

12

2011 - 2022

2022 -

A

B

C

D

E

DI

SCO

NTIN

U

ED

23

C

E

D

B

22

product warranty for Australia Effective May 2023

Enware Pty Ltd (“we” or “us”) warrants that this

product (also referred to as “our goods”) will be free

from all defects in materials and workmanship for 12

months* from the date of purchase. Our liability under

this warranty is limited at our option to the repair or

replacement of the defective product or part, the

cost of repair of the defective product or part or the

supply of an equivalent product or part, in each case

if we are satisfied the loss or damage was due to a

defect in the materials or workmanship of the product

or part. All products must be installed in accordance

with the manufacturer’s instructions, the Plumbing

Code of Australia (PCA), and AS/NZS3500 including

any other applicable regulatory requirements.

exceptions

This warranty does not apply in respect of any

damage or loss due to or arising from:

a) Failure by you or any other person to follow

any instructions for use (including instructions

and directions relating to the handling, storage,

installation, fitting, connection, adjustment or repair of

the product) published or provided by us;

b) Failure by you or any other person responsible for

the fitting, installation or other work on the product to

follow or conform to applicable laws, standards and

codes (including the AS/NZ 3500 set of Standards,

all applicable State and Territory Plumbing Codes,

the Plumbing Code of Australia and directions and

requirements of local and other statutory authorities);

or

c) Any act or circumstance beyond our control

including faulty installation or connection, accident,

abnormal use, acts of God, damage to buildings,

other structures or infrastructure and loss or damage

during product transit or transportation.

making a claim

To make a claim under this warranty you must

notify us in writing within 7 days of any alleged defect

in the product coming to your attention, provide us

with proof of your purchase of the product and have

completed the Online Product Service and Warranty

Form available on website:

www.enware.com.au/product-service-enquiry

All notifications and accompanying forms must be

sent to us marked for the attention of Enware Pty Ltd,

9 Endeavour Road, Caringbah NSW 2229. We can

also be contacted by telephone (1300 369 273) or by

Your costs in making a claim under this warranty,

including all freight, collection and delivery costs, are

to be borne and paid by you. We also reserve the

right at our cost to inspect any alleged defect in the

product wherever it is located or installed or on our

premises.

* Vitreous China Pans - 10 Years warranted against material and

manufacturing defects | Toilet Seats - 1 Year warranted against

material and manufacturing defects | Pressalit Toilet Seats - 10

years warranted against material and manufacturing defects |

Mechanical Flushing Mechanisms - 5 Years warranted against

material and manufacturing defects | Accessories & Spare Parts -

1 Year warranted against material and manufacturing defects | Ifo

Arm Supports - 3 Years (1 Year parts and labour on the complete

assembly; after 1 Year a further 2 year parts only warranty applies

against material and manufacturing defects)

For more on warranty, see www.enware.com.au/warranty

other conditions

Except as provided or referred to in this document,

we accept no other or further liability for any

damages or loss (including indirect, consequential

or economic loss) and whether arising in contract,

tort or otherwise. Any benefits available to you under

this warranty are in addition to any non-excludable

rights or remedies you may have under applicable

legislation, including as a “consumer” under the

Australian Consumer Law. To that extent you need to

be aware that: our goods come with guarantees that

cannot be excluded under the Australian Consumer

Law. You are entitled to a replacement or refund for

a major failure and for compensation for any other

reasonably foreseeable loss or damage. You are also

entitled to have the goods repaired or replaced if the

goods fail to be of acceptable quality and the failure

does not amount to a major failure.

ADDRESS: 9 Endeavour Rd Caringbah NSW 2229 Australia

POSTAL ADDRESS: P.O. Box 2545, Taren Point NSW 2229 Australia

1300 369 273 (AUS) WWW.ENWARE.COM.AU INFO@ENWARE.COM.AU

Table of contents

Other enware Toilet manuals

Popular Toilet manuals by other brands

Project Source

Project Source DANVILLE MT-20206TC manual

Dometic

Dometic 970 SERIES instruction manual

Olympia

Olympia ETHER 69195 Installation and Maintenance

Kohler

Kohler Eir Comfort Height K-77795-0 installation guide

Wolfen

Wolfen 800 CCBTW Series installation manual

Kohler

Kohler K-3901 Homeowner's guide

American Standard

American Standard Right Height Elongated Toilet Triumph Cadet... owner's manual

BEMIS

BEMIS Haven 5000 owner's manual

DURAVIT

DURAVIT Ben 0847370000 Mounting instructions

Simas

Simas VIGNONI VI18 Installation and maintenance instructions

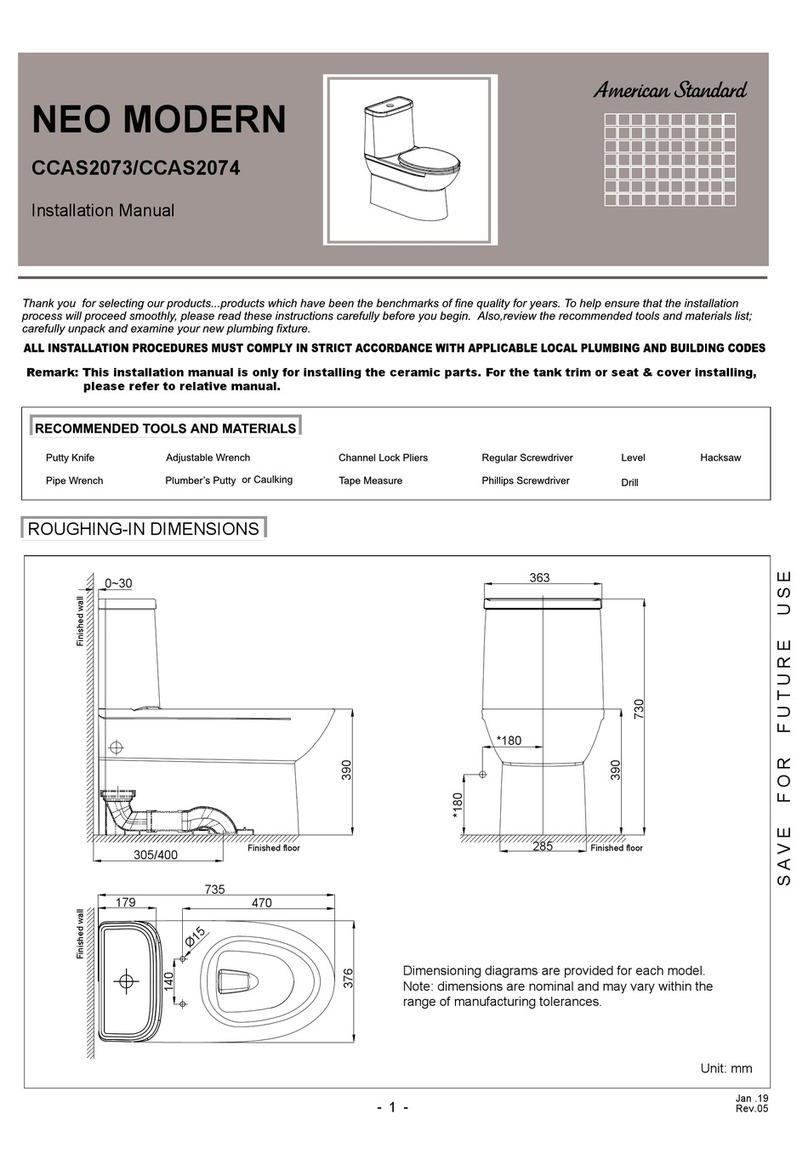

American Standard

American Standard NEO MODERN CCAS2073 installation manual

Toto

Toto CST436 Installation and owner's manual