enz 10.125TR Series User manual

10.028

10.060ATR

10.060BTR

10.060CTR

10.125TR-xxx

10.061A

10.061B

10.150RL

10.150RS

10.200R

10.300R

10.200RS

10.400R

10.400RS

10.800R

Operating Manual

English

June 20 | Version 1.4

Wire Rope

and Chain Scrapers

Operating Manual

Page 2of 72 ©2020 enz® technik ag June 2020 Version 1.4

1Table of Contents

Preface .............................................................................................. 4

Purpose of the document ................................................................... 4

2Safety ........................................................................................... 5

2.1 Noncompliance with the safety information and its consequences. ........ 5

2.2 Target group .............................................................................................. 5

2.3 User requirements..................................................................................... 5

2.4 Explanation of general safety instructions ................................................ 6

2.5 Information provided in these operating instructions .............................. 6

2.6 Intended use .............................................................................................. 6

2.7 Safety warnings for modifications ............................................................. 7

2.8 Protective equipment for working in manholes, excavations, and channels

8

2.9 General safety instructions...................................................................... 10

3Legal........................................................................................... 12

3.1 Copyright ................................................................................................. 12

3.2 Exclusion of liability ................................................................................. 12

3.3 Warranty conditions ................................................................................ 12

4Wire rope and chain scrapers ...................................................... 13

4.1 Introduction............................................................................................. 13

4.2 Application............................................................................................... 13

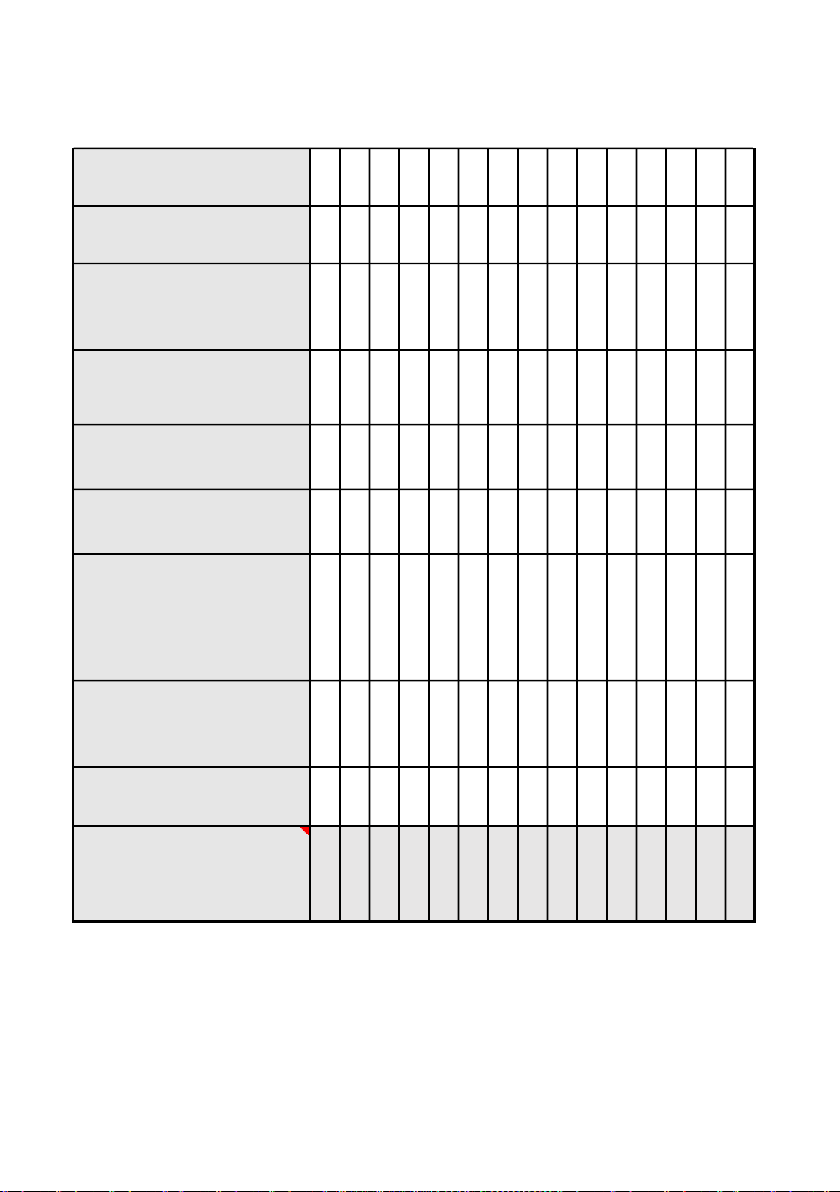

4.3 Technical data & overview table ............................................................. 14

5Installation.................................................................................. 16

5.1 Assembling the tools ............................................................................... 16

5.2 Preparatory work..................................................................................... 16

5.3 Setting up the work area ......................................................................... 16

5.4 Adjusting the wire rope and chain scraper to the channel diameter ...... 17

Operating Manual

June 2020 Version 1.4 ©2020 enz® technik ag Page 3of 72

6Operation ................................................................................... 19

6.1 How to operate the tools ........................................................................ 19

6.2 Cleaning easily damaged pipes................................................................ 19

6.3 Cleaning pipes with minor damage ......................................................... 20

6.4 After use .................................................................................................. 20

6.5 Completing the work process .................................................................. 20

6.6 Troubleshooting....................................................................................... 21

7Maintenance............................................................................... 22

7.1 Maintenance after each use .................................................................... 22

7.2Nozzle inserts........................................................................................... 22

7.3 Replacing parts ........................................................................................ 23

7.4 Disposal, environmental protection ........................................................ 23

8Our chain scrapers....................................................................... 24

8.1 Chain scraper 10.028 ............................................................................... 24

8.2 Chain scraper 10.060 A / B / CTR ............................................................. 26

8.3 Chain scraper 10.061 A / B ...................................................................... 30

8.4Chain scraper 10.125TR-xxx..................................................................... 33

8.5 Chain scraper 10.150RL ........................................................................... 39

8.7 Chain scraper 10.200R / 300R / 200RS .................................................... 44

8.8 Chain scraper 10.400R ............................................................................. 58

8.9 Chain scraper 10.800R ............................................................................. 67

8.10 Adjusting the chains for 10.400RS ........................................................... 68

9Index .......................................................................................... 69

9.1 Drawings .................................................................................................. 69

9.2 Figures ..................................................................................................... 70

Version

Revision:

Date

Initials

1.0

Created

January 2019

bho

1.2

Rope brush

April 2019

rri

1.3

Pictures & tables updated

Mai 2019

bho

1.4

Art. No updated

Operating Manual

Page 4of 72 ©2020 enz® technik ag June 2020 Version 1.4

Preface

Dear valued customer,

Thank you for the confidence and trust you've placed in us by purchasing one of our

products.

We always appreciate suggestions and new design ideas. Your feedback will help us

improve the design of our product and the associated documentation.

If you have any questions or suggestions, please contact our Customer Service Depart-

ment.

enz® technik ag Phone +41 41 676 77 66

Schwerzbachstrasse 10 Fax +41 41 676 77 67

www.enz.com

Person responsible for documentation:

Fabian Krasniqi (Tech. Support / QM Manager)

We reserve the right to modify and further enhance our products without prior no-

tice as a result of technological advances. Misprints reserved.

Purpose of the document

The purpose of this manual is to instruct you on how to use our product correctly,

effectively, safely, and for its intended purpose. The user will be informed about risks,

reasonably foreseeable misuse, and residual risks.

Important!

Read carefully before use.

Keep for later reference.

Please read this operating manual thoroughly before using the cleaning tool. Make

sure that all employees who work with the product know how to use it correctly.

The operating manual must be available to all operating personnel at all times. It must

be kept in an easily accessible place.

If the manual is misplaced or destroyed, a new copy can be requested from your near-

est dealer or from the manufacturer directly.

Operating Manual Safety

June 2020 Version 1.4 ©2020 enz® technik ag Page 5of 72

2Safety

2.1 Noncompliance with the safety information and its conse-

quences.

Disregarding these safety instructions may lead to accidents and severe personal inju-

ries, material damage, and damage to the environment.

The manufacturer cannot be held responsible for any damages resulting from noncom-

pliance with these instructions.

2.2 Target group

This manual is intended for all persons who will be involved in the assembly, start-up,

and operation of the pipe cleaning tool.

2.3 User requirements

Personnel intending to assemble, start up and

operate the tool must...

•Be familiar with the field of channel maintenance work and possess the appro-

priate technical knowledge.

•Be trained and instructed appropriately in the use of the product.

Have read and understood the operating manual, in particular the section on

“Safety.”

If your personnel do not possess the necessary knowledge, they must be trained and

instructed on it. If necessary, the pipe cleaning tool manufacturer can provide this in-

struction and training.

Only the maintenance and service activities described in this manual may be per-

formed by users who have met the above-listed requirements. Any additional mainte-

nance and service work may be performed only by qualified specialist personnel from

the manufacturer.

Please refer to the section on "MAINTENANCE".

Safety Operating Manual

Page 6of 72 ©2020 enz® technik ag June 2020 Version 1.4

2.4 Explanation of general safety instructions

The general safety instructions in this section provide information about potential re-

sidual risks, which are inherent to the product and may occur unexpectedly, despite

the proper usage of the product.

In order to prevent personal injuries, material damage, and damage to the environ-

ment, all personnel working with this product must comply with these safety instruc-

tions. It is mandatory for said personnel to read and to understand the information

provided in this section.

2.5 Information provided in these operating instructions

DANGER

Noncompliance may lead to serious injury or loss of life.

WARNING

Noncompliance may lead to serious injury or loss of life and/or

cause a long-term disability.

CAUTION

Noncompliance may lead to injury and considerable material dam-

age, financial loss or damage to the environment.

Information on the technically correct and efficient use of the prod-

uct.

2.6 Intended use

The product is designed to clean the insides of pipes (sewer pipes). The following

points must be followed to ensure proper use of the product.

The cleaning tool may be used only in pipes or pipe-like sewers (referred to

in this document generally as “channels”). The profile to be cleaned must be

free of leaks and surrounded by material.

Operating Manual Safety

June 2020 Version 1.4 ©2020 enz® technik ag Page 7of 72

The tool may be used on the following types of pipes:

oPE pipes

oSteel pipes

oConcrete pipes

For use in pipes made of other material, please consult the manufacturer.

The product may be operated only in pipes with correctly installed and de-

fect-free connections.

Cleaning areas (manholes, pipe branches etc.) need to be sufficiently secured

during the operation, including during construction and cleaning work.

During the cleaning operation, no personnel are allowed inside the pipes or

at either end of the pipes.

The maximum pressure indicated on the nozzle may not be exceeded.

Wastewater may not be drained into watercourses (creeks, rivers etc.).

The product must be inspected to ensure it is in proper working order before

every start-up.

Defects must be rectified before start-up.

Use the tool only as intended. (Use only the correct wrench for nuts).

Secure the hose lines in such a way that they cannot become damaged during

operation.

Only the accessories provided and approved by enz® technik ag may be used.

2.7 Safety warnings for modifications

No other changes or modifications to the pipe cleaning tool may be performed. Only

parts authorized by the manufacturer may be used. The manufacturer is not liable

for damage resulting from unauthorized changes to the product.

Safety Operating Manual

Page 8of 72 ©2020 enz® technik ag June 2020 Version 1.4

2.8 Protective equipment for working in manholes, excavations, and

channels

The employer must provide suitable personal protective equipment and ensure that

it is worn by the employees during work.

In the following section, the protective equipment prescribed by Schweizerische Un-

fallversicherung SUVA (the Swiss Accident Insurance Organization) will be described.

For more information on this, refer to the brochure:

Safe entry and working in manholes, excavations, and channels

(in German, French & Italian)

Order number: 44062.d Suva

Schweizerische Unfallversicherungsanstalt

Arbeitssicherheit

Postfach, 6002 Lucerne, Switzerland

For information:

Phone +41 41 419 51 11

For orders:

www.suva.ch/waswo

Fax +41 41 419 59 17

Phone +41 41 419 58 51

Respirators

Self-contained respiratory equipment for spending time in danger-

ous atmospheres and for use during rescue operations.

Respirators

Self-rescue respiratory equipment (devices with compressed air

tanks or regeneration devices) for working in sewers and for first aid

for injured persons.

Rescue harness

Rescue harness or protective clothing with a loop sewn into the

neck. During rescue, the rescue rope will be attached to the neck

loop. Injured persons will be lifted out using a rescue lifting device

with a self-actuating load brake.

Suitable working clothing

Leak-proof clothing protects the skin from becoming soiled and from

possible infections. Visually conspicuous work clothing makes the

employee more visible to traffic.

Operating Manual Safety

June 2020 Version 1.4 ©2020 enz® technik ag Page 9of 72

Appropriate footwear

Safety footwear should, in particular, have good grip and be slip-re-

sistant and leak-proof (e.g. rubber boots).

Gloves

Appropriate gloves will protect you from hand injuries and contact

with materials that could impair your health and from untreated wa-

ter.

Hardhat

The hardhat will protect your head from falling objects and from

bumping into fixed components and objects.

Hearing protection

If there is noise that could damage your hearing, you can wear, e.g.

earmuffs with built-in headphones and microphone.

Eye protection

Your eyes should be protected against grit, sprayed dangerous sub-

stances, etc.

Lighting independent of the power grid

For example, you should carry a waterproof flashlight or wear a

flashlight attached to your hardhat.

Safety Operating Manual

Page 10 of 72 ©2020 enz® technik ag June 2020 Version 1.4

2.9 General safety instructions

Danger! | High-pressure water jets

Defects in or unintended use of the product could cause hazards due

to pressurized water spray. Never remain in the channel during op-

eration. Ensure that the product is in perfect condition before oper-

ation. Highly concentrated water jets can cause serious injury and

could even sever limbs. Noncompliance with these safety instruc-

tions could be fatal or could lead to serious injury.

Danger! | Toxic vapors

There can be toxic vapors in channels. Wear the prescribed protec-

tive equipment such as gas masks, gas warning devices and rescue

harnesses. Inhaling toxic vapors or air that is contaminated with par-

ticles could be fatal or lead to serious injuries if the particles enter

the lungs.

Warning! | Falling objects

Around open manholes, objects can fall down into the manhole and

onto the people below. Never remain directly beneath the manhole

opening when guiding the products in. Secure the manhole entrance

against parts that could fall. Do not throw any tools or objects down

into the manhole. Do not enter any manhole where there is a dan-

ger of falling. Personnel could become trapped. Noncompliance with

these safety instructions can be fatal or could lead to serious injury.

Warning! | Chemical burns

There may be unidentified, corrosive, or otherwise harmful sub-

stances in channels. Put on appropriate protective clothing. Use the

protective equipment prescribed. Otherwise, you could suffer from

chemical burns to your skin and eyes or become infected with path-

ogens.

Operating Manual Safety

June 2020 Version 1.4 ©2020 enz® technik ag Page 11 of 72

Warning! | Falls from height

Open manholes are to be expected in the area where you will be

working with the product. You must warn people about open man-

holes. Pay attention to where you are walking. Falling from height

can be fatal or could lead to serious injury.

Warning! | Hand injuries

If the product is tampered with, there is a risk of hand injury due to

getting caught or abrasion. Wear gloves during work. Pay attention

to where you grip the product. Always have two people carry heavy

equipment. Consequences can include crushing injuries, abrasions

or even the loss of a limb.

Caution! | Sharp objects

If the product is tampered with, there is a risk of hand injuries due

to sharp edges. Wear gloves during work. Pay attention to where

you grip the product. Consequences can include cutting injuries to

your hands or other parts of your body.

Caution! | Trip hazards

Lines and other objects are to be expected on the ground in the area

around where the product is being used. Pay attention to where you

are walking. Keep the area of use tidy. Tripping and falling could

cause serious injuries.

Legal Operating Manual

Page 12 of 72 ©2020 enz® technik ag June 2020 Version 1.4

3Legal

3.1 Copyright

This manual shall not be duplicated partially or in its entirety without the prior written

permission of enz®technik ag. It shall not be photocopied, reproduced, translated, or

converted into an electronic or machine-readable format.

©2020 enz® technik ag, 6074 Giswil, Switzerland.

All rights reserved

3.2 Exclusion of liability

The manufacturer is not liable for damage that:

•Is caused as a result of unauthorized changes to the product.

•Is caused by not following the safety instructions.

3.3 Warranty conditions

In accordance with our sales and delivery conditions, we offer a warranty. However,

the warranty is voided if:

•The product is used under conditions that are not permitted by us.

•Replacement and accessory parts that are not original replacement and acces-

sory parts from enz® technik ag are used.

•If there is damage due to:

oImproper use

oNot following the operating manual

oUnsuitable operating equipment

oIncorrect or improper routing of the hose or pipelines

oUnauthorized changes or modifications to or conversions of the product.

Operating Manual Wire rope and chain scrapers

June 2020 Version 1.4 ©2020 enz® technik ag Page 13 of 72

4Wire rope and chain scrapers

4.1 Introduction

enz® chain scrapers are universally usable tools.

The same tool can be adapted and used for a wide range of pipe diameters. Different

deposits such as limescale, cement slurry, roots, etc. can be removed efficiently.

Tools with Art No. 10.XXXR can be operated with recycled water.

In addition, enz® chain scrapers can be modified in various ways. Simple handling

and maintenance are also traits that go hand-in-hand with enz® chain scrapers.

4.2 Application

•Used to prepare for restoration work, such as relining, grouting, or applying coat-

ings

•Complete root removal

•Removal of incrustations and deposits

•Removal of concrete residues in newly-laid channel pipelines (for acceptance in-

spection)

Wire rope and chain scrapers Operating Manual

Page 14 of 72 ©2020 enz® technik ag June 2020 Version 1.4

4.3 Technical data & overview table

Max. working

pressure

[psi]

5000

5000

5000

3600

3600

3600

3600

2900

2900

2900

2900

2900

2900

2900

2900

Max. working

pressure

[bar]

350

350

350

250

250

250

250

200

200

200

200

200

200

200

200

Minimum flow

rate at 100 bar

[l/min]

20

30/50

30/50

30/50

50/150

60

60

100

100

200

200

200

300

300

400

Weight [kg]

0.32

0.95

0.95

1.05

2.5

1.4

1.4

13.1

13.1

35

35

35

47

47

185

3xM4

2xM6

2xM6

2xM6

2xM6

3xM6

3xM6

3xM8

3xM8

3xM10

3xM10

3xM10

3xM10

3xM10

3xM10

3xM4

4xM6

4xM6

4xM6

4xM8

3xM6

3xM6

3xM10

3xM10

3xM10

3xM10

3xM10

3xM10

3xM10

6xM10

Ø x length [mm]

40/28x81

40x112

40x112

40x134

60x144

60x134

60x134

135/235x500

135/235x500

185/385x560

185/385x560

185/385x560

385/785x625

385/785x625

560/775x1640

Application

range Ø

[mm]

40-100

60-200

60-200

60-200

100-300

80-150

80-150

150-250

200-400

200-400

200-400

200-400

400-800

400-800

800-1200

Connecting

thread

BSPP

1/4"

3/8"

1/2"

3/4"

1"

1/2"

3/4"

1"

1"

1"

1"

1"

1"

1"

1 1/4"

10.028

10.060ATR

10.060BTR

10.060CTR

10.125TR-

10.061A

10.061B

10.150RL

10.150RS

10.200R

10.300R

10.200RS

10.400R

10.400RS

10.800R

Rotating nozzle inserts

Thrust jet inserts

Article number

Table 1 Technical data

Operating Manual Wire rope and chain scrapers

June 2020 Version 1.4 ©2020 enz® technik ag Page 15 of 72

St.

opt.

opt.

opt.

opt.

-

-

-

-

-

-

-

-

-

-

Ø extensions

-

-

-

-

-

-

-

-

-

opt.

opt.

opt.

-

-

-

Pulling

equipment

-

-

-

-

-

-

-

-

-

opt.

opt.

opt.

opt.

opt.

opt.

Diamond crow n

drill bit

-

-

-

-

-

-

-

opt.

opt.

opt.

opt.

opt.

opt.

opt.

-

Cutter head

St.

opt.

opt.

opt.

opt.

-

-

-

-

-

-

-

-

-

-

Wire brushes

-

-

-

-

opt.

-

-

-

-

opt.

opt.

opt.

opt.

opt.

-

Wire rope loops

-

-

-

-

-

-

-

-

-

opt.

opt.

opt.

opt.

opt.

-

Cutter

-

St.

St.

St.

St.

St.

St.

St.

St.

St.

St.

St.

St.

St.

St.

Link chain

St.

opt.

opt.

opt.

opt.

St.

St.

opt.

St.

opt.

opt.

St.

opt.

St.

opt.

Pin bolt chain

opt.

St.

St.

St.

St.

-

-

St.

opt.

St.

St.

opt.

St.

opt.

St.

Change skids

No

Yes

Yes

Yes

Yes

No

No

No

No

No

No

No

No

No

No

Set skids

No

No

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Drive type Turbojet

No

Yes

Yes

Yes

Yes

No

No

No

No

No

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

opt.

st.

40-100

60-200

60-200

60-200

100-300

80-150

80-150

150-250

200-400

200-400

200-400

200-400

400-800

400-800

800-1200

1/4"

3/8"

1/2"

3/4"

1"

1/2"

3/4"

1"

1"

1"

1"

1"

1"

1"

1 1/4"

10.028

10.060ATR

10.060BTR

10.060CTR

10.125TR-

10.061A

10.061B

10.150RL

10.150RS

10.200R

10.300R

10.200RS

10.400R

10.400RS

10.800R

Storage set

Accessories & options

standard, included in standard scope of delivery

option, can be ordered

Set skids

Connecting thread

Article number

Adjust chain or wire rope

length

Application range Ø

[mm]

Table 2 Overview of necessary adjustments & options

Installation Operating Manual

Page 16 of 72 ©2020 enz® technik ag June 2020 Version 1.4

5Installation

5.1 Assembling the tools

All tools are supplied ready to be used. Once the tools have been unpacked, please

check the content for completeness.

5.2 Preparatory work

It makes sense to clarify some points before use. Knowledge of the following points is

helpful during preparations and when adjusting the wire rope and chain scraper:

•Layout of the pipes

•Inner pipe diameter of the channel where work will be performed

•Pipe material of the channel where work will be performed

•Type of foreign material in the pipe

•Planned flushing direction →We recommend that you work against the direction

of flow.

•Any type of gradient in the channel where work will be performed

•Access points to the channel

5.3 Setting up the work area

Prior to working with a wire rope or chain scraper, the following procedures must be

followed:

Set up barriers and safety equipment (warning triangle, block off the area, etc.)

The work area must be blocked off and secured so that there is no risk of falling

or other traffic-related dangers.

The necessary information on the wastewater flowing through the manhole must

be obtained (chemicals, gas, vapors, etc.)

Measuring instruments such as explosive gas meters, oxygen meters, gas warning

devices, etc. must be readily available.

You must ensure that the appropriate nozzle sizes for cleaning the pipes are avail-

able. The application range of each nozzle is listed in the "Technical data" section

on Page 14.

Operating Manual Installation

June 2020 Version 1.4 ©2020 enz® technik ag Page 17 of 72

The layout of the pipes (manhole drawings) must be known before starting the

work so that the nozzle can be prevented from emerging at a pipe end. Support

personnel must be on hand to monitor possible emerging points.

Have the liability waiver signed by the customer to protect against any claims for

damages.

If the tools are heavy, then a tripod winch is required to lower the wire rope or

chain scraper into the manhole. It should not be lowered into manhole by the

hose.

5.4 Adjusting the wire rope and chain scraper to the channel diam-

eter

A wire rope or chain scraper must always be adjusted to the inner diameter of the

pipe where work will be performed.

Chain lengths are selected to ensure that the ends are always scraping against the

pipe wall. The only exception is if the work is to be performed in an ovoid profile. Re-

fer to Drawing 1 for the 10.200R example. This prevents the tool from rotating too

fast during operation and causing unnecessary damage to the tool and the channel.

The skids can be adjusted on some articles in the wire rope and chain scraper series;

in others, the skids and the chains are replaced based on the channel pipe diameter.

Figure 1 Blocked off & signed work area

Installation Operating Manual

Page 18 of 72 ©2020 enz® technik ag June 2020 Version 1.4

When adjusting the skid and cage settings, always use the largest possible setting for

the inner channel diameter being worked on.

To correctly install your wire rope or chain scraper, please refer to the pages specifi-

cally about your product in Section 8. You will find tool-specific information on the

chains, ropes and skids to be used and how to adjust them there.

CAUTION

Always use the correct chain or rope length. The chains or

ropes must drag along the pipe wall, and they must not strike

the wall! Otherwise, the pipe wall or the product could be-

come damaged.

Drawing 1 Chain length greater than pipe Ø

Pin bolt chain with end piece for Ø250

Operating Manual Operation

June 2020 Version 1.4 ©2020 enz® technik ag Page 19 of 72

6Operation

6.1 How to operate the tools

1. Flush all loose debris from the pipe prior to working with a standard nozzle. Loose

debris can interfere with the work. If need be, you must use a pointed nozzle or

a Bulldog, with their specialized center spray features, to clear the pipe of roots.

2. The chain scraper is screwed onto the hose unrolled from the vehicle. The thread

size depends on the size of the tool and can be found in the section “1.1 Technical

data” on Page 14.

3. Push the wire rope or chain scraper at least half of its length into the pipe to be

cleaned. If possible, you should work against the direction of flow.

4. Increase the pressure on the wire rope or chain scraper up to 100–120 bar (while

paying attention to any loss of pressure in the hose).

5. Keep an eye on the forward motion while unrolling the hose and pay attention to

the noise from the work. If you notice any irregularities, refer to Troubleshooting

in Section 6.6 on Page 21.

6. Also allow water to run when retracting the wire rope and chain scraper so that

the nozzles do not become clogged.

7. Close the manhole cover once work is completed.

Normally, the nozzle will turn in a counter-clockwise direction when in use. Mean-

while, the connecting thread will turn in a clockwise direction. This prevents the nozzle

from detaching itself from the connecting thread during operation.

6.2 Cleaning easily damaged pipes

Work on pipes that are made of one of the following materials should be performed

with the utmost care due to their low mechanical strength properties:

Plastic (PE, PVC, and more…)

Clayware

Glass fiber-reinforced plastic (GFK)

Continue to run the water at low pressure when retracting the

tool. This prevents wastewater from entering the interior of

the nozzle, which can lead to failure.

Operation Operating Manual

Page 20 of 72 ©2020 enz® technik ag June 2020 Version 1.4

6.3 Cleaning pipes with minor damage

Slightly damaged pipes usually exhibit cracks in the pipe wall. If detected, always con-

tact the customer or the appropriate authorities.

When working inside a slightly damaged pipe, extreme caution must be used. Use of

the tool is always at your own risk! enz® technik ag waives all liability!

6.4 After use

After you have completed work, you must still do the following:

1. Rinse the tool with fresh water.

2. Spray OIL SPRAY BIO (Item no. C191) on the entire tool. Then manually turn the

rotor several times.

3. Then check the tool for traces of wear and replace any defective parts if needed.

6.5 Completing the work process

If possible, use a special camera to inspect the cleaned pipes. Look out in particular for

any damage and ensure that no liquids can escape into the environment.

All manholes must be closed after the cleaning has been completed.

CAUTION

If the pressure is too high, the cleaning jet can damage or

cause a break in the pipe wall. This could result in interrup-

tions to the work or material damage.

DANGER

When cracks are washed out, pipe fragments can break off

and the material surrounding the pipe may be flushed out.

When in doubt, you should not use the product. Using it in

these circumstances can result in collapsed channels and ac-

companying injuries or death.

This manual suits for next models

14

Table of contents