Catalog

Catalog

Catalog

Catalog

Correct

Correct

Correct

Correct use

use

use

use and

and

and

and application

application

application

application ........................................................................................... 1

1.

1.

1.

1. Truck

Truck

Truck

Truck Description

Description

Description

Description ......................................................................................................... 2

1.1Application .............................................................................................................. 2

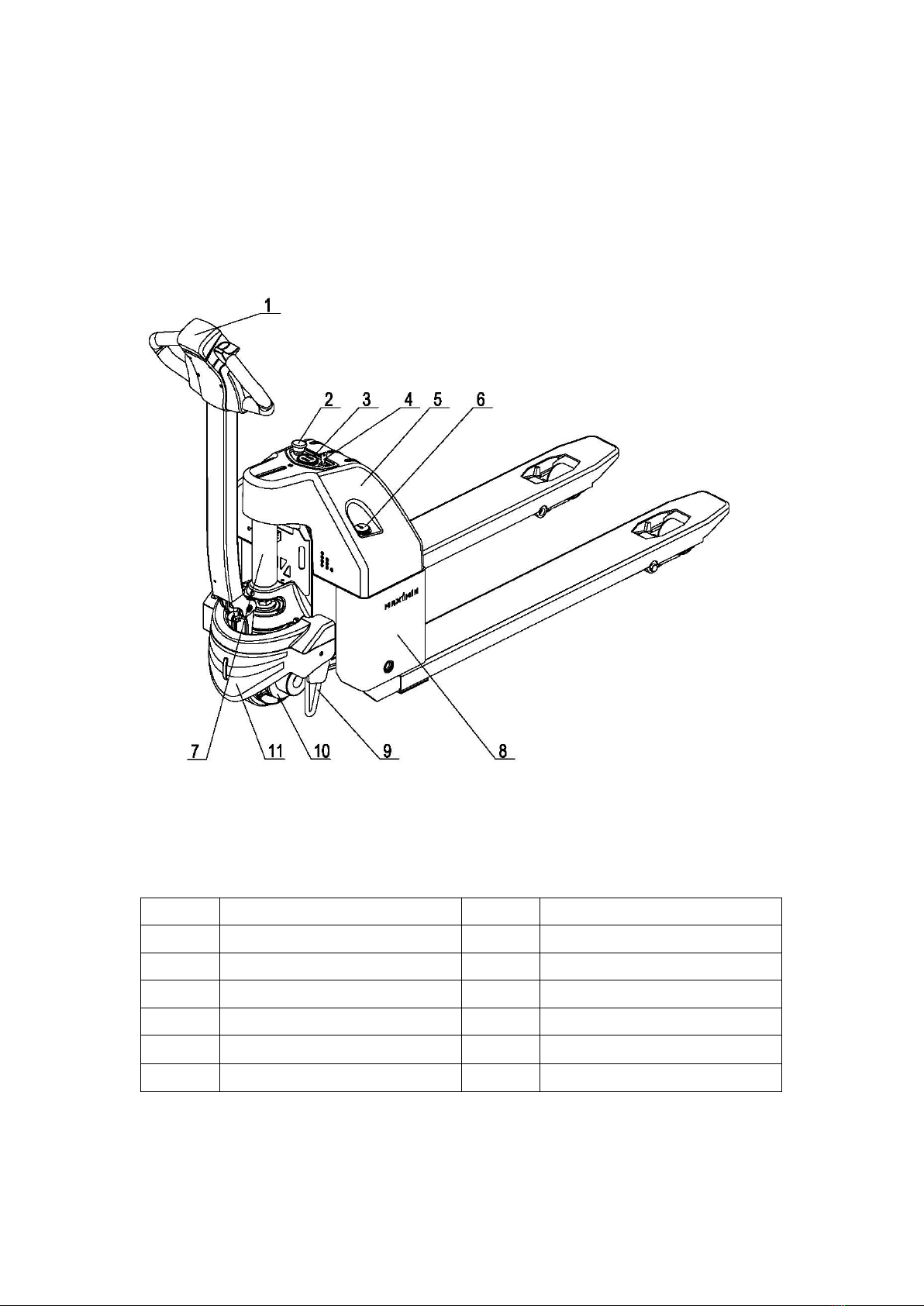

1.2 Assemblies ............................................................................................................. 3

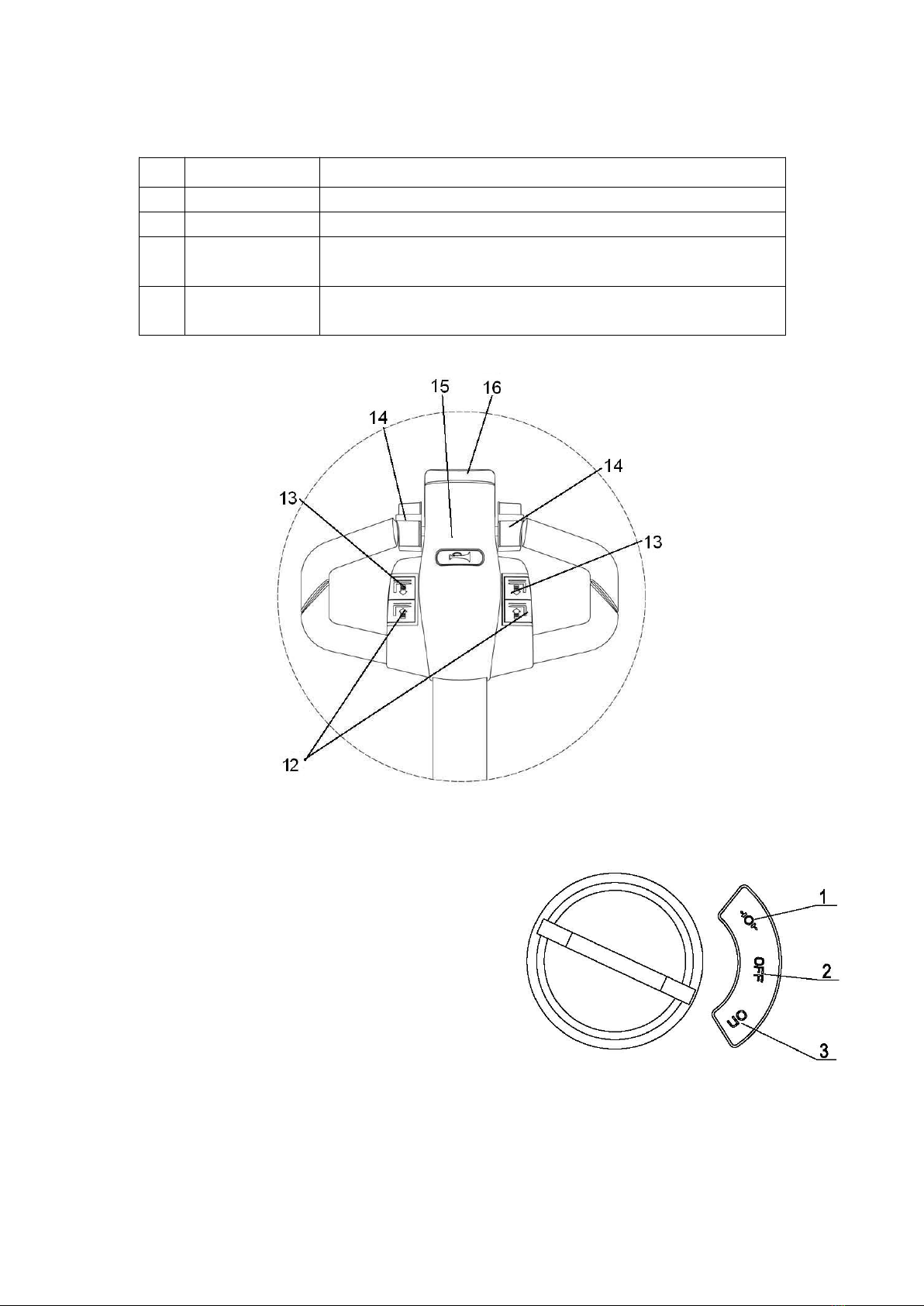

1.2.1Control Handle .................................................................................................... 4

1.2. 2 Key switch ............................................................................................................ 4

1.2.3Battery discharge indicator ................................................................................. 5

1.2.4Emergency brake switch .................................................................................... 5

1.3 Identification points and data plates .................................................................... 6

1.3.1Truck data plate ................................................................................................... 7

1.4.Standard Version Specifications .......................................................................... 8

1.4.1Performance data for standard trucks ............................................................... 8

1.4.2Dimensions .......................................................................................................... 9

2.Transport

2.Transport

2.Transport

2.Transport and

and

and

and Commissioning

Commissioning

Commissioning

Commissioning ................................................................................. 11

2.1Transport 11

2.2Using the Truck for the First Time .......................................................................

11

2.3During brake-in ..................................................................................................... 12

3.Operation

3.Operation

3.Operation

3.Operation ...................................................................................................................... 13

3.1Safety Regulations for the Operation of Forklift Trucks .................................... 13

3.2 Operate and run the truck .................................................................................. 13

3.2.1 Preparing .......................................................................................................... 13

3.2.2 Travel ................................................................................................................ 14

3.3.3Lifting, transporting and depositing loads ....................................................... 16

3.3.4Parking the truck securely ................................................................................ 17

4.Battery

4.Battery

4.Battery

4.Battery Maintenance

Maintenance

Maintenance

Maintenance &

&

&

& Charging

Charging

Charging

Charging ............................................................................. 18

4.1 Safety regulations for handling acid batteries .................................................. 18

4.2 Battery type & dimension ................................................................................... 18

4.3Charging the battery ............................................................................................ 18

4.4Battery removal and installation .......................................................................... 19

4.5Battery maintenance ............................................................................................ 20

4.6 Battery Disposal .................................................................................................. 21