V

Catalog

Correct use and application .........................................................................................1

1.

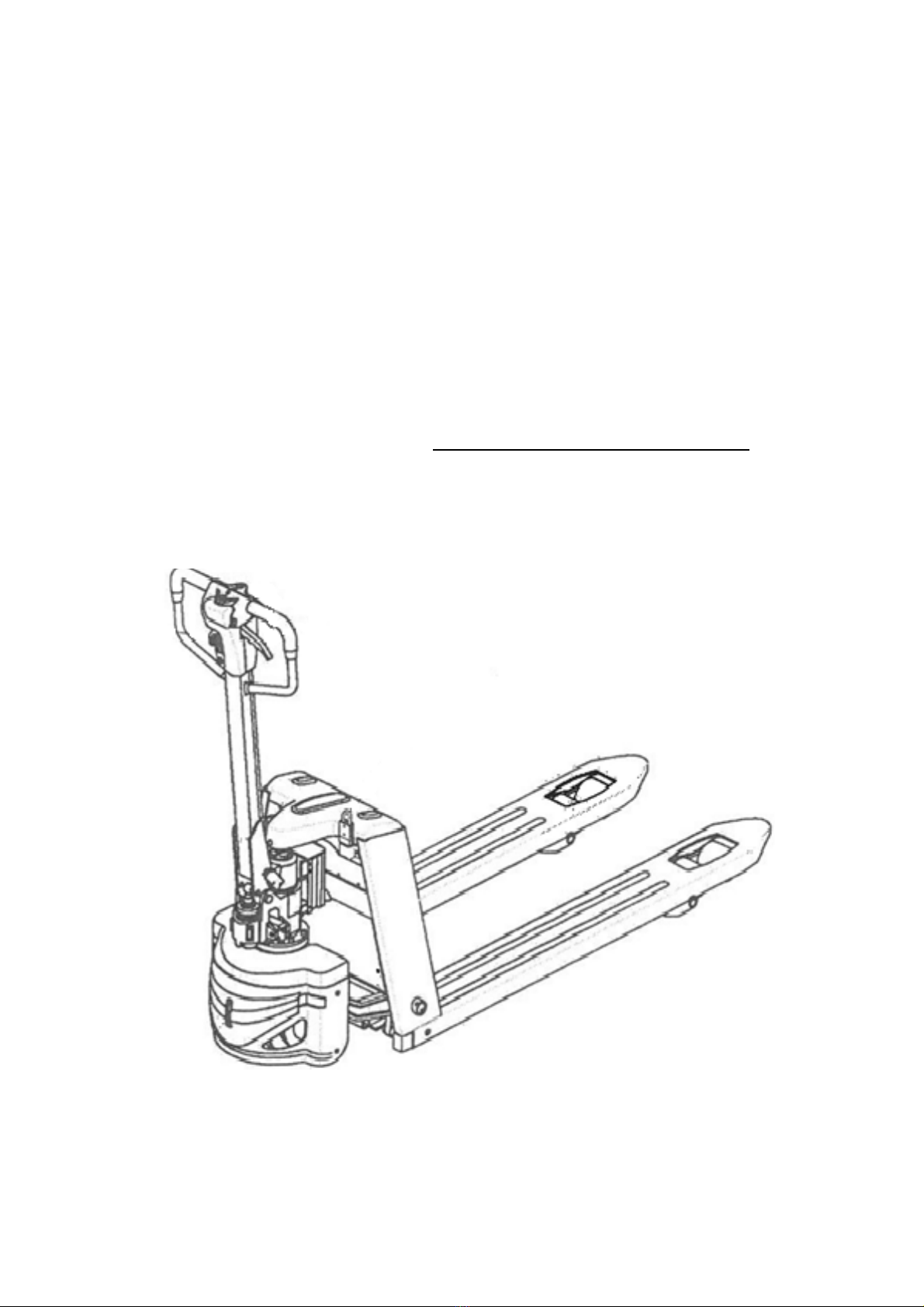

Truck Description .......................................................................................................... 2

1.1 Application .............................................................................. 2

1.2

Assemblies ........................................................................................................... 3

1.2.1

Control Handle ........................................................................................4

1.2.2

Key switch ( Option ).............................................................................. 4

1.2.3

Battery discharge indicator .................................................................... 5

1.3 ldentification points and data plates................................................................ 6

1.3.1

Truck data plate ..................................................................................... 7

1.4 Standard Version Specifications .................................................................... 8

1.4.1

Performance data for standard trucks ................................................... 8

1.4.2

Dimensions ..................................................................................................9

2.

Transport and Commissioning................................................................................ 11

2.1 Using the Truck for the First Time................................................................. 11

2.2 During brake-in.............................................................................................. 11

3.

Operation.................................................................................................................12

3.1

Safety Regulations for the Operation of Pallet Trucks ..................................12

3.2 Operate and run the truck .............................................................................13

3.2.1

Preparing ..............................................................................................13

3.2.2

Travel ,Steering,Braking .......................................................................13

3.2.3

Lifting, transporting and depositing loads..............................................14

3.2.4

Parking the truck securely .....................................................................15

4.

Battery Maintenance & Charging............................................................................16

4.1 Safety regulations for handling acid batteries...............................................16

4.2 Battery type & dimension ............................................................................. 16

4.3

Charging the battery ...................................................................................... 16

4.4 Battery removal and installation ................................................................... 18

4.5

Battery maintenance...................................................................................... 18

4.6 Battery Disposal ........................................................................................... 19

5.

Pallet Truck Maintenance ....................................................................................... 20

5.1

Operational

safety

and

environmental

protection

...........................................

2

.

0

5.2

Maintenance Safety Regulations................................................................... 20

5.3

Servicing and inspection................................................................................ 21

5.3.1

Maintenance Checklist................................................22

5.3.2

Lubrication Schedule..................................................23

5.3.3

Maintenance lnstructions ..................................................................... 24

5.4 Decommissioning the industrial truck...........................................................25