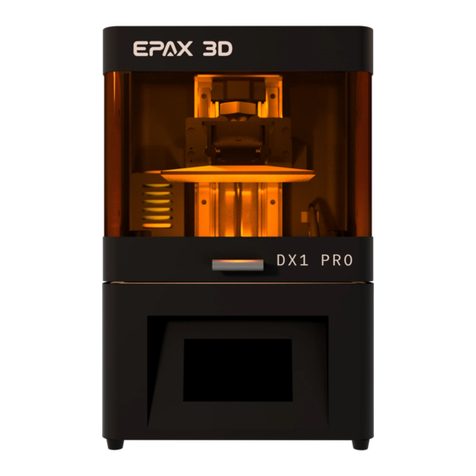

EPAX X1 User manual

Warning: After get the printer ready and then power it on, please do an “Auto Home” as the first thing so

that the printer knows where the ground zero is. The printer does not save its last z position before last

power off. So “Auto Home” is necessary as soon as you get the printer ready to power on. Doing so will

keep manual up/down boundary in check. This is important when you try to test many menu options. It

is not needed if you just go straight to print.

It is strongly recommended to watch videos before operating the printer.

For instructions and videos, please visit www.epax3d.com

1. Technical Specification

Printing

Operation

3.5-inch Color TFT Screen

Slicing Software

ChiTu

Connectivity

USB memory

Specifications

Technique

LCD Shadow Masking

Light source

UV-LED (wave-length 405nm)

XY Resolution

0.047mm (2560*1440)

Z axis Accuracy

0.00125mm

Suggested Layer Thickness

0.01 ~ 0.2mm

Suggested Print Speed

20mm/h

Rated power

50W

Physical Dimensions

Dimension

230mm (L) *230mm (W) *400mm (H)

Build volume

115mm (L) *65mm (W) *155mm (H)

Materials

405nm UV-resin

Net weight

7.9KG

Gross weight

10KG

1

2. Touchscreen Menu Structure

MENU

TOOLS SYSTEM PRINT

Please “Auto Home” as the first operation after powered on printer.

2

The menu has more options than what this printer uses. Network menu is not supported by this printer.

3

3. Slicing Software Installation

Slicing software is located in the included USB drive. The file names start with ChiTuBox……. You can install

one of them according to what kind of PC you use. For Windows 64, it is “ChiTuBox64Install_130.exe”. For

Macbook, it is “ChiTuBox_V1.3.0.dmg”. Follow the installation guide as any software installation. For latest

slicer download, you can visit below site:

https://www.chitubox.com/download.html

4. Slicer Settings

Open the ChiTubox application, on the right side click “Settings”. Then click “Import” and inport the

“ChiTuBox_EPAX_X1.cfg” file from the included USB drive. This will load all the settings for EPAX X1

printer, including Machine volume size, resolution, Print layer height, bottom layers, bottom exposure time and

regular exposure time. They are critical for a first successful print.

For updated instruction and recommended support settings etc. you may visit:

https://epax3d.com/pages/slicer-settings-chitubox

For live help, please visit our Facebook group. We are there actively. Many customers are also very active there

helping each other.

https://www.facebook.com/groups/epax3d

5. Slicer Operations

There are many operations in the ChiTuBox slicer. If you can’t figure out how some options work, always look at

the Facebook group or ask there. Below are some basic but very important setting recommendation.

1. Parameters

Layer height: It is suggested to set it to 0.05mm (range: 0.01 ~ 0.2mm). The thicker the layer thickness, the longer

the exposure time per layer needed. Normal exposure time: Setting range: 6s〜15s. The exposure time is set

4

according to the thickness of each layer and the details complexity of the model.

Bottom Exposure Time: Setting range: 35s-50s, the longer the bottom exposure time, the easier for the bottom

layer of the model to stick onto the build platform.

Bottom layers: setting range: 4〜5

2. Support

The menu is the top right most icon besides settings icon. The types of support can be configured are Light,

Medium and Heavy and Raft. Each choice has a corresponding parameter setting.

Light: Contact area between the support and model is small, easy to remove the support;

Heavy: Support contact with the model area is large, solid.

It is recommended to try the “Medium” first, and use the default settings.

Raft: Add the raft will make the bottom stick better to the build platform (but using more materials], the parameters

can be changed according to you own unique model needs.

3. Slicing and Save the files

When you have the file sliced, You can save it in the USB drive. The .cbddlp file is then saved to the USB drive

and ready for printing.

5

6. First Printing

1. Install the build platform

Install the build platform into the Z axis platform bracket, turn the fasten knob in clockwise rotation to fasten the

platform. Then if just powered on, do an “Auto Home” first. Then raise platform to the middle of z axis so that

you can add resin easily.

Note that our printer was pre calibrated. You do not need to relevel the platform!

2. Load resin

Slowly pour the resin into the resin vat until the resin level reached about 1/3 height of the resin vat.

WARNING: Always wear gloves and goggle and don’t touch resin by skin.

6

3. Choose File to be printed

Insert the USB flash drive into the machine's USB socket. As shown in the figure, select a test model (such as

lamp-shade.cbddlp file) and start printing. During the printing process, you must close the top cover to avoid

lights. The machine must be placed on flat and stable table. It is recommended to print the included test

file as the first file printed with your new printer. The file was already sliced and ready to print.

During printing, if you find the resin is not enough to finish the model you can click "Pause", wait for the

build plate to rise up automatically, then add extra resin to the resin vat slowly (maximum 1/3 height of the

resin vat). Click "Print” again, the build platform will go down again and the printing will resume. You can

also pause as many times as you want so that you can check and make sure all things going well,

especially for a new model.

If you slice your own model, you must know what exposure time for your resin and layer height. Here are

settings for our general purpose and PLA based resins:

Resin model: eSUN bio-based or general purpose hard resin for LCD

Layer thickness(mm) 0.02-0.1

Bottom Exposure Time: 30-50s when layer thickness is 0.05mm, recommend set to 40s.

Normal Exposure Time: 6-10s when layer thickness is 0.05mm, recommend set to 8s.

PS;Exposure time is proportional to layer thickness. The numbers above are for layer thickness 0.05mm.

if layer thickness is 0.1mm, the normal exposure time will be 12-20s. If layer thickness is 0.02 then the

normal exposure time is 2-4s.

For the first print, or a new model, it is a good idea to pause the printing after printed a while, such as

30 minutes. You can pause and check whether the first layers stick to build platform. You can then

resume printing if all look good. If the print does not stick to build platform, then you need to modify

your design by adding more support, changing orientation or adjust first several layers’ exposure time.

Typically first several layers require at least 35 seconds each.

7

7. Post Printing Treatment

When printing done, wait till no more residual resin drop from on the platform. Twist the black knob

counterclockwise and take off the build platform. Remove the print by shoveling and clean it by soaking it into

IPA at least three minutes if IPA is 95%. If IPA is 91%, then soak 5 minutes. Swirling a bit while soaking for

better cleaning of resin. You can purchase IPA from any drug stores like CVS etc. After model cleaned, take it

out and put it in a cool, dry and well-ventilated area. After a few hours, the print will become fully dry and

solid.

8

8. Warnings

1. When you find printing failed or solid residue in the resin vat, you must filter the resin in

order to protect the 2K curing LCD screen. You must clean the resin in the resin vat by

filtering out the resin solid residue. If there are solid residue in the resin vat, when build

plate dip into the vat, the force may crush residues, damage the film and even the 2k curing

screen.

2. If there are residue resin in the resin vat or build plate outer surface, please clean with tissue to

avoid drop into the machine.

3. Always wear gloves, respirator mask and protective goggle. Print in a well-ventilated

area. It is best to have vent fan drawing air around printer to outside.

It is strongly recommended to watch videos before operating the printer.

For printer instructions, videos, firmware parameters and new developments, please visit

www.epax3d.com

You can also search “EPAX X1” on youtube.

Customer Support Email: [email protected]

Warranty: 1 year US warranty for the printer, except the LCD masking screen, film and resin.

3 months US warranty for LCD masking screen

For printer replacement parts, supplies and various resins, visit www.epax3d.com

Join us on our Facebook group for active discussions and knowledge sharing:

https://www.facebook.com/groups/epax3d/

9

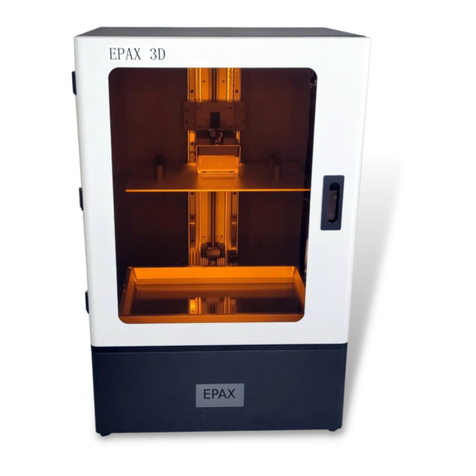

Other manuals for X1

1

Table of contents

Other EPAX 3D Printer manuals