10

3DISON PRO User Manual V.1

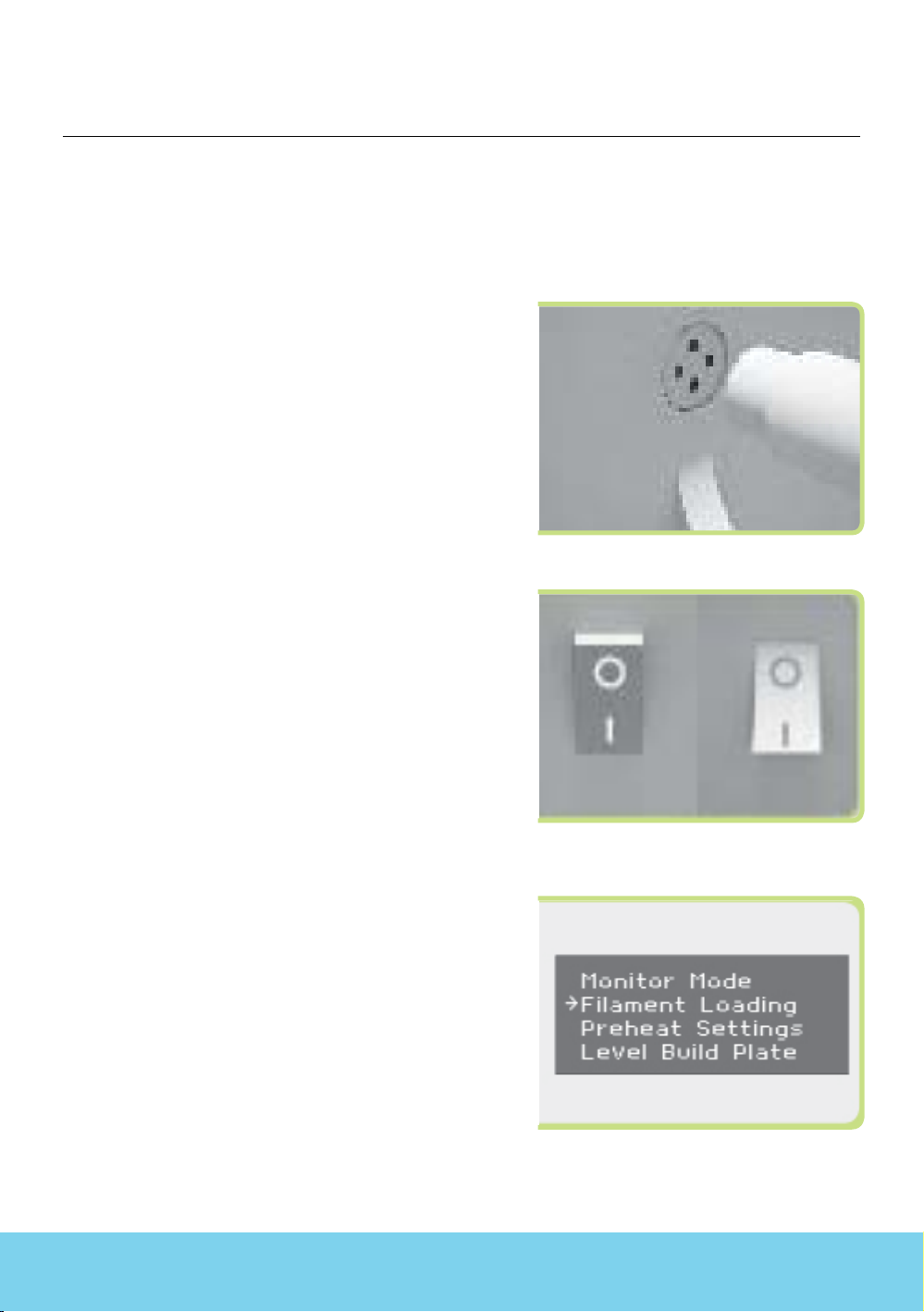

Display Menu Introduction

1. Create from SD : To load a le from SD Card

2. Preheat : To preheat the hot-end(nozzle)

- Extruder : by setting On/O you can start preheating of the extruder

- Platform : by setting On/O you can start preheating of the print bed

3. Utilities : It will lead to 12 dierent options for hardware. You do not want to change the

settings without any specic explanation because they are only for developers or after-

sales service

- Monitor mode : it shows current temperature of the extruder and printing status

- Filament loading : to put the lament into the extruder or pull it out of the extruder

- Preheat settings : to set up temperature and the printing bed

- Level Build Plate : to manually level the printing bed

- Pre-leveling : to level the printing bed before starting Auto-leveling

- Home Axes : To default the position of X, Y, Z axis

- Bot Statistics : Shows the operation time spent printing.

- Life Time: Total operation time of 3DISON PRO

- Last Print: Last build time

- Filament: Total amount of filament used (in meter)

- Fil. Trip: Amount of filament used for the last build (in meter)

- Filament Odometer : Not only this shows the lament information, but also you can de

fault the trip value here.

- Life: Total amount of filament used (in meter, unable to reset)

- Trip: Amount of filament used for the last build (in meter)

- General Settings : To congure sound, LED color or etc

- Ditto Printing Off

- Override GCTemp OFF

- Pause with heat OFF

- Sound ON/OFF

- Heat LEDs ON/OFF

- LED Color :to change LED colors.

- Accelerate : To accelerate the extruder speed

- Extruders : To choose SINGLE or DOUBLE depending on 3DISON PRO

- Extruder Hold ON/OFF

- HBP Installed NO

- Tool Offset Sys NEW

- Check SD Reads YES

- P-Stop Control OFF

- Prole

- Home Osets

- Jog Mode : To control manually the location of the extruder and the build platform

* Press the 3D button to go back to the main menu

- Disable Steppers : To stop the motor.

- Enable Steppers : To start the motor.

- Blink LEDs : To make LED lamp ickering

- Calibrate Nozzles

- Restore Settings :To initialize 3DSION PRO

- Eeprom

- Version Information : It shows the rmware version.

C.UnpackingandSettingup∃DISONPRO