Safety and operating instructions

© Construction Tools PC AB | 9864 0046 01 | 2020-11-13

Original Instructions

7

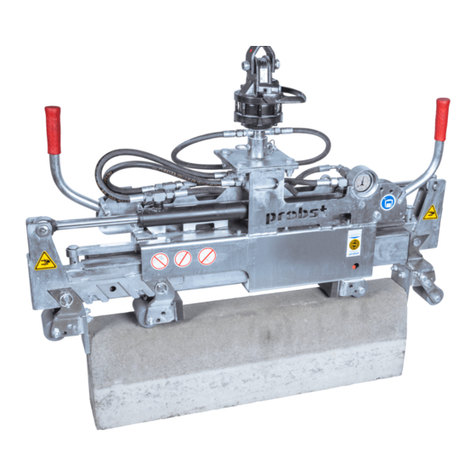

2.5 Operation, precautions

WARNING Operating pressure

If the maximum operating pressure for the hydraulic ma-

chine is exceeded, the accumulator can be over charged

which can result in material damage and personal injury.

uAlways run the hydraulic machine with the correct

operating pressure. See "Technical data".

DANGER Explosion hazard

If a working tool comes into contact with explosives or

explosive gases, an explosion could occur. When work-

ing on certain materials and when using certain materi-

als in machine parts, sparks and ignition can occur. Ex-

plosions will lead to severe injuries or death.

uNever operate the machine in any explosive environ-

ment.

uNever use the machine near flammable materials,

fumes or dust.

uMake sure that there are no undetected sources of

gas or explosives.

WARNING Trapping hazard

There is risk of neck ware, hair, gloves and clothes get-

ting dragged into or caught by a rotating insertion tool or

accessories. This may cause choking, scalping, lacera-

tions or death. To reduce the risk:

uNever grab or touch a rotating drill steel.

uAvoid wearing clothing, neck ware or gloves that may

get caught.

uCover long hair with a hair net.

WARNING Projectiles

Failure of the work piece, of accessories, or even of the

machine itself may generate high velocity projectiles.

During drilling, splinters, or other particles may become

projectiles and cause bodily injury by striking the opera-

tor or other persons. Also, breakage of the work piece,

accessories, or the insertion tool may generate high ve-

locity projectiles that can cause bodily injury. In addition,

objects falling from a height can cause bodily injury. To

reduce risks:

uClose off the working area.

uBefore starting, make sure that no persons are in the

danger area, 5 meters both horizontally and vertically

from the machine.

uImmediately switch off the machine when persons

are present in the danger area.

uNever operate unless the inserted tool is retained in

the machine with a proper tool retainer.

WARNING Slipping, tripping and falling hazards

There is a risk of slipping or tripping or falling, for exam-

ple tripping on the hoses or on other objects. Slipping or

tripping or falling can cause injury. To reduce this risk:

uAlways make sure that no hose or other object is in

your way or in any other person's way.

WARNING Dust and fume hazard

Dusts and/or fumes generated or dispersed when using

the machine may cause serious and permanent respira-

tory disease, illness, or other bodily injury (for example,

silicosis or other irreversible lung disease that can be fa-

tal, cancer, birth defects, and/or skin inflammation).

Some dusts and fumes created by drilling, breaking,

hammering, sawing, grinding and other construction ac-

tivities contain substances known to the State of Califor-

nia and other authorities to cause respiratory disease,

cancer, birth defects, or other reproductive harm. Some

examples of such substances are:

uCrystalline silica, cement, and other masonry products.

uArsenic and chromium from chemically-treated rubber.

uLead from lead-based paints.

Dust and fumes in the air can be invisible to the naked

eye, so do not rely on eye sight to determine if there is

dust or fumes in the air.

To reduce the risk of exposure to dust and fumes, do all

of the following:

uPerform site-specific risk assessment. The risk as-

sessment should include dust and fumes created by

the use of the machine and the potential for disturb-

ing existing dust.

uUse proper engineering controls to minimize the

amount of dust and fumes in the air and to minimize

build-up on equipment, surfaces, clothing, and body

parts. Examples of controls include: exhaust ventila-

tion and dust collection systems, water sprays, and

wet drilling. Control dusts and fumes at the source

where possible. Make sure that controls are properly

installed, maintained and correctly used.

uWear, maintain and correctly use respiratory protec-

tion as instructed by your employer and as required

by occupational health and safety regulations. The

respiratory protection must be effective for the type

of substance at issue (and if applicable, approved by

relevant governmental authority).

uWork in a well ventilated area.

uIf the machine has an exhaust, direct the exhaust so

as to reduce disturbance of dust in a dust filled envi-

ronment.