Equalizer ROCK STAR User manual

VCD1464

VAF1471

VAL1472

VPF1452

VPL1453

VMR1450

VML1451

VTR1448

VTL1449

TRR652

TRO653

2611 Oakmont Drive • Round Rock • Texas • 78665

Toll Free USA & Canada: 800.334.1334

International: 512.388.7715 • Fax: 512.388.4188

Email: sales@equalizer.com

www.equalizer.com

www.equalizer.com

© 2012 Equalizer Industries, Inc.

Revision 11/10/17

Additional Accessories

ROCK STAR™

Windshield Repair System

Part# RSR800

User Guide

VCB1454VPO1455 AVL209

DL1093 BNG418

BNL820

MS492VPT1489

RB497

VUV1447

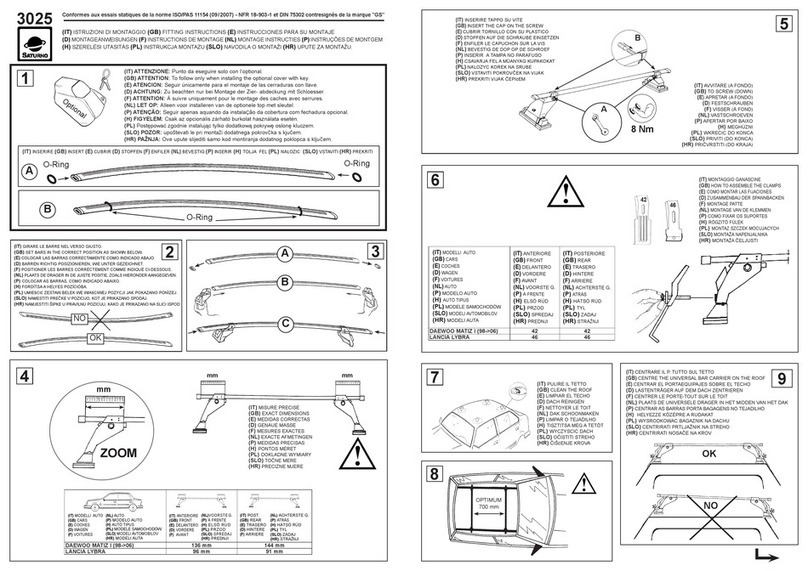

110

2.5 mm thick

10 mm outer diameter

4 mm inside diameter

2 mm thick

12 mm outer diameter

8 mm inside diameter

2 mm thick

13 mm outer diameter

10 mm inside diameter

3.5 mm thick

13 mm outer diameter

6 mm inside diameter

VOR1468

11. Clean the area that you have worked on with a good glass cleaner and a paper

towel.

Cleaning & Maintenance -

1. Clean the resin off of (and out of) your injector, o-rings and bridge with our

cleaning solution. *Keeping these items clean and free of build up assures no

contamination on you next repair, proper functioning of the tools, and will

increase the longevity of the tools. Failure to properly clean and maintain

these items could result in voiding your warranty!

VBA1443

9 2

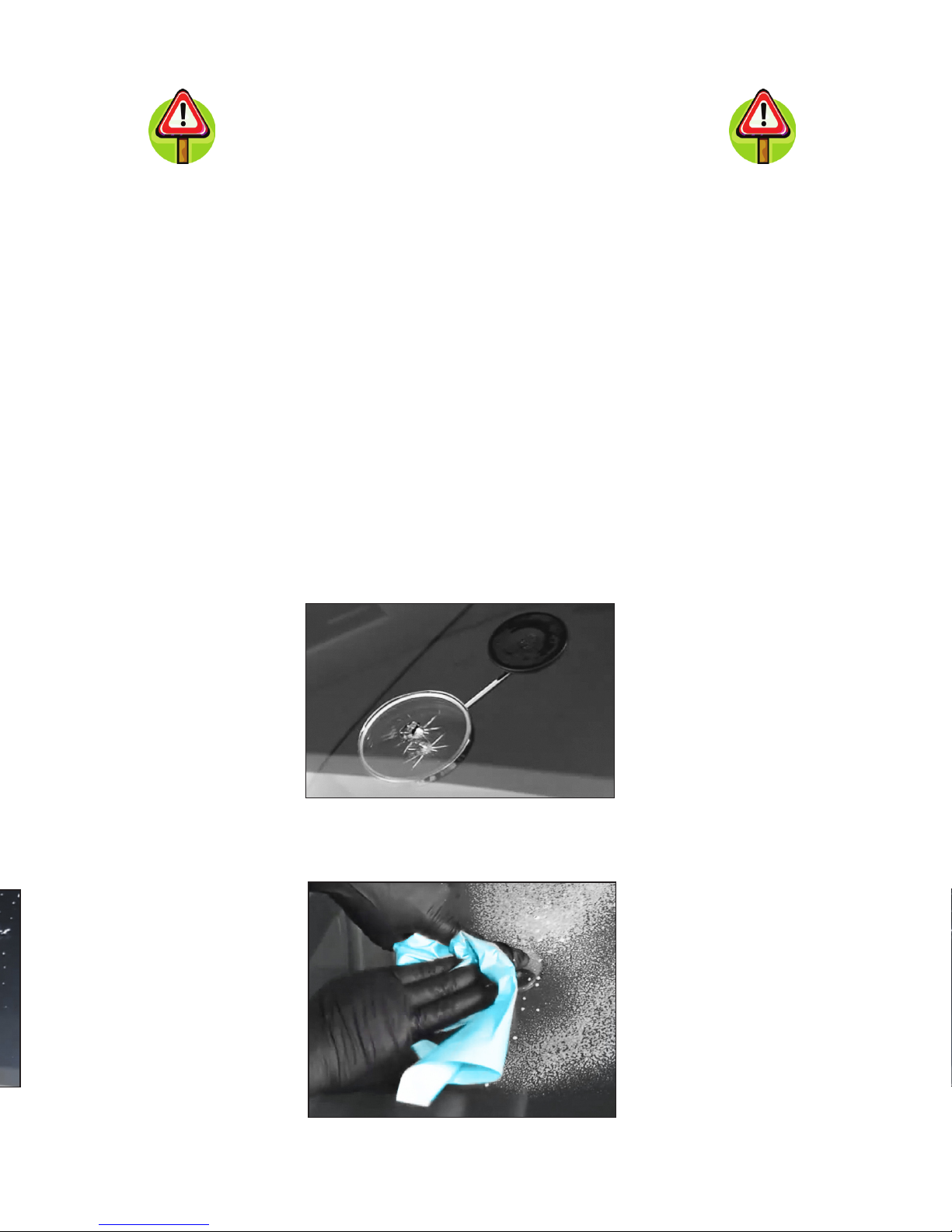

Inspection And Assessment -

1. Examine the damaged area from the inside and outside of the vehicle. Look for

hidden cracks, moisture, contamination or previous repair attempts.

2. Determine if the damage is within the scope of your technical experience to

repair.

3. Assess to make sure that the windshield is at the appropriate temperature.

Ideal temperature is between 65°F to 85°F plus or minus 5°F.

Preparing the Rock Chip -

1. Place the mirror on the inside of the windshield, under the damaged area.

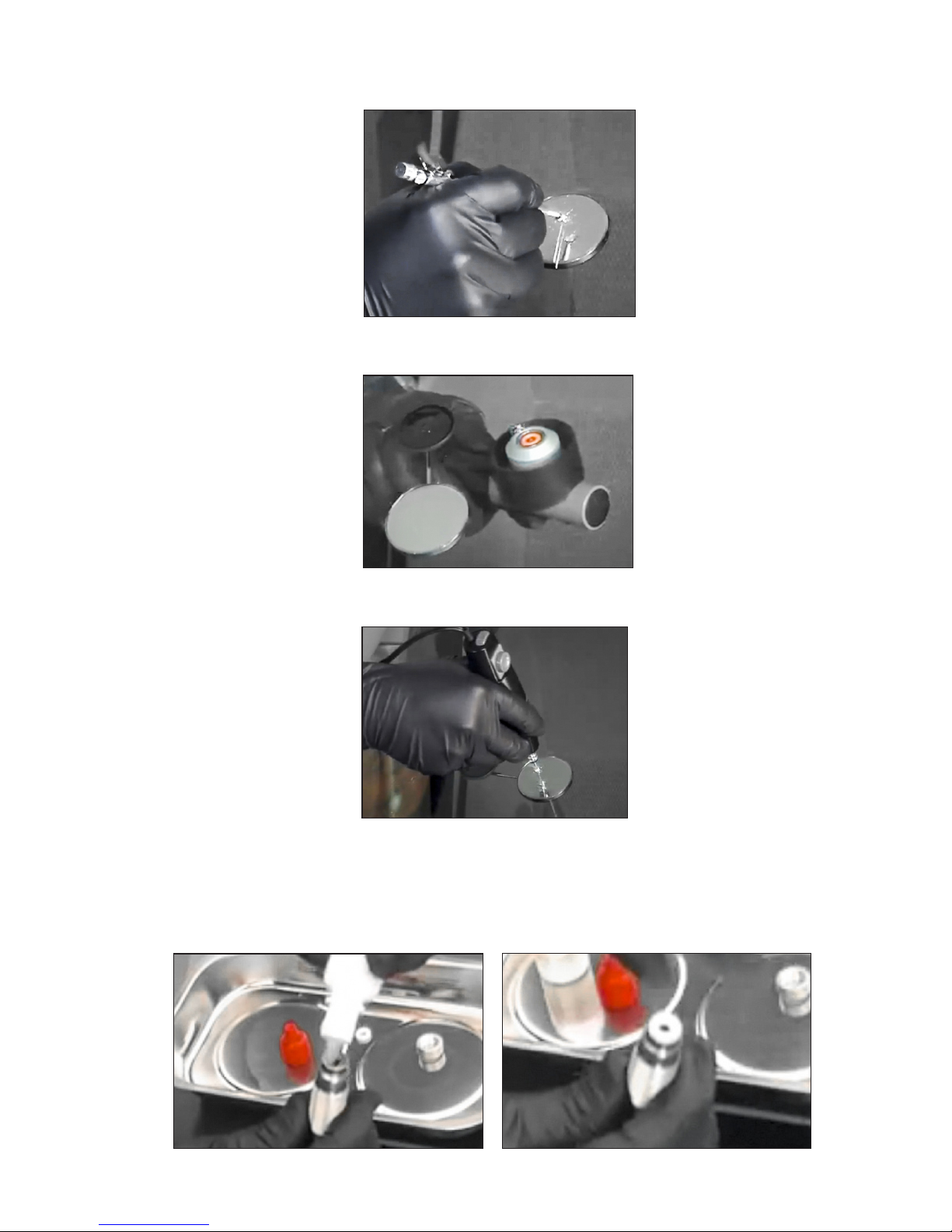

2. Clean around the damaged area. Be sure to place a nitrile glove-covered finger

over the rock chip in order to keep from contaminating the break.

Always wear safety glasses and nitrile gloves

when repairing a windshield!

7. Cure the break for approximately three minutes using either an ultra violet lamp

or the use of natural sun light. *Always make sure to let the break cure to the

required allotted time. Do Not rush this process. e outer part of the break

might be cured but the actual pit may not be. It is very important that it be cured

all the way through.

8. Remove the mylar square cure sheet.

9. With the use of a new razor blade, scrape the cured resin in a back and forth, up

and down motion until the resin is even and level with windshield.

10. Apply a small amount of pit polish and vigorously buff with a soft cloth or paper

towel until the pit resin is shiny.

3 8

3. Using the probe, remove broken glass debris from the chip.

4. If moisture is present in the break, dry out by using the windshield chip

moisture evaporator.

5. If the rock chip area is not open, consider drilling the chip. At a slow setting start

to drill into the glass but be careful not to drill into the PVB (Poly Vinyl Butyral)

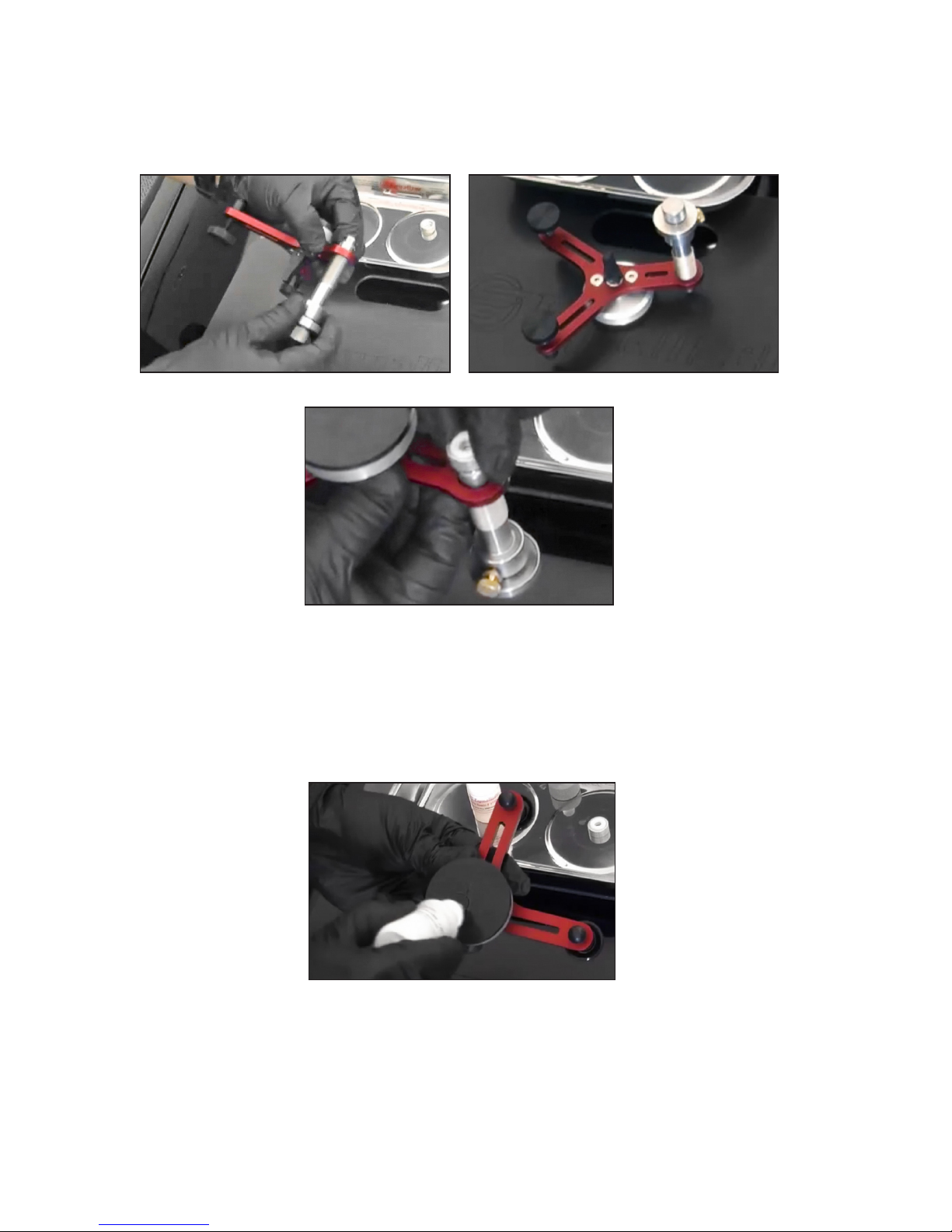

Preparing the Bridge and Injector Assembly -

1. Place the injector tip o-ring on the end of the injector assembly. To do so, use a

small drop of resin to wet the injector assembly tip and then put the o-ring in

place.

Curing Procedure -

1. When the repair is to your satisfaction, release the pressure by loosening the

injector pressure rod.

2. Release the lever on the vacuum cup.

3. Remove the bridge and injector assembly.

4. Wipe away any residual resin.

5. Apply a drop of pit filler resin.

6. Place a mylar square cure sheet onto the pit filler resin. Be sure to gently place the

cure sheet in a downward laying motion and let gravity do the rest.

7 4

2. Screw the injector assembly into the bridge. If the rock chip area is larger than

the o-ring on the injector assembly tip, then add the large pit adaptor onto the

unit.

3. Place a light film of vacuum cup lubricant onto the vacuum cup of the bridge and

on the two bridge adjusting screws. Once the bridge and injector assembly is set

up on the glass this will help to move the unit if the o-ring placement needs to be

adjusted.

6. Now push the injector in until it hits the bottom of the barrel.

7. Tighten the injector pressure rod.

8. Pull the injector up until the end of the groove makes contact with the retaining

screw. Fully tighten the retaining screw. You are now in the vacuum phase.

9. Hold vacuum for one minute.

10. Next, release the vacuum by loosening the injector pressure rod.

11. en re-tighten the injector pressure rod to secure the seal.

12. Next, loosen the retaining screw and push the injector in a downward motion

until the point when you feel resistance. en tighten the retaining screw. You are

now in the pressure phase.

13. Hold pressure for two minutes.

Note: For stubborn breaks, you might have to repeat the vacuum to pressure cycle

until the break is fully filled. Applying a little pressure on your break with your probe

will flex the break and help move resin into the tight areas.

5 6

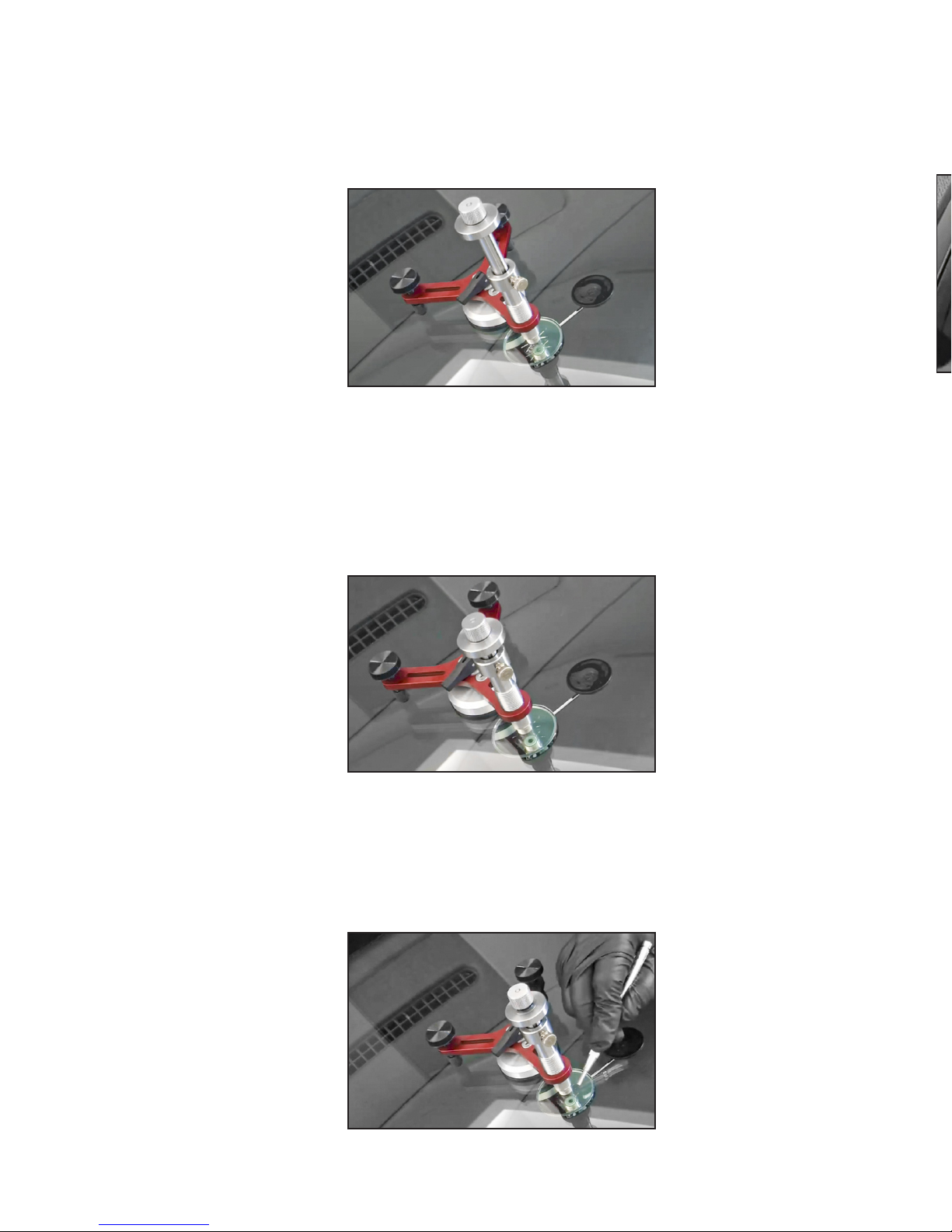

Injection Procedure -

1. Loosen the injector pressure rod.

2. Remove the injector from the barrel.

3. Place between 3 to 5 drops of resin into the injector barrel. *Always make sure to

use the right resin for the job. If the temperature of the work area is warm or the

job is at high altitude; always use a thicker resin. If the temperature of the work

area is cool or at sea level use a thinner resin.

4. Wet the two o-rings on the injector tip using resin.

5. Place the injector back into the injector barrel making sure that the groove on the

injector lines up with the retaining screw. Adjust the retaining screw so that the

threaded end of the screw slips into the groove and is just tight enough for the

injector to move freely up and down but not be removed from the barrel (the end

of the groove on the injector will catch the retaining screw and stop).

4. Make sure that the injector assembly and bridge adjusting screws are backed out

enough so that they do not make contact with the glass until the vacuum cup is

fully engaged on the glass. Note: If the injector assembly and bridge adjusting

screws are not backed far enough out, this could result in applying pressure and

causing further damage to the break.

Setting Up the Bridge and Injector Assembly -

1. Place the bridge and injector assembly onto the glass so that the injector tip

o-ring is over the rock chip.

2. Secure the bridge by flipping the vacuum cup lever.

3. Screw the injector assembly down until the o-ring makes contact with the surface

of the glass.

4. Screw the bridge adjusting screws down equally until the o-ring has a flat look to

its appearance. is will ensure that the o-ring is snug enough to create an air-

tight seal.

Note: Always make sure not to over-tighten the injector assembly or the bridge

adjusting screws. is could cause further damage to the break.

5 6

Injection Procedure -

1. Loosen the injector pressure rod.

2. Remove the injector from the barrel.

3. Place between 3 to 5 drops of resin into the injector barrel. *Always make sure to

use the right resin for the job. If the temperature of the work area is warm or the

job is at high altitude; always use a thicker resin. If the temperature of the work

area is cool or at sea level use a thinner resin.

4. Wet the two o-rings on the injector tip using resin.

5. Place the injector back into the injector barrel making sure that the groove on the

injector lines up with the retaining screw. Adjust the retaining screw so that the

threaded end of the screw slips into the groove and is just tight enough for the

injector to move freely up and down but not be removed from the barrel (the end

of the groove on the injector will catch the retaining screw and stop).

4. Make sure that the injector assembly and bridge adjusting screws are backed out

enough so that they do not make contact with the glass until the vacuum cup is

fully engaged on the glass. Note: If the injector assembly and bridge adjusting

screws are not backed far enough out, this could result in applying pressure and

causing further damage to the break.

Setting Up the Bridge and Injector Assembly -

1. Place the bridge and injector assembly onto the glass so that the injector tip

o-ring is over the rock chip.

2. Secure the bridge by flipping the vacuum cup lever.

3. Screw the injector assembly down until the o-ring makes contact with the surface

of the glass.

4. Screw the bridge adjusting screws down equally until the o-ring has a flat look to

its appearance. is will ensure that the o-ring is snug enough to create an air-

tight seal.

Note: Always make sure not to over-tighten the injector assembly or the bridge

adjusting screws. is could cause further damage to the break.

7 4

2. Screw the injector assembly into the bridge. If the rock chip area is larger than

the o-ring on the injector assembly tip, then add the large pit adaptor onto the

unit.

3. Place a light film of vacuum cup lubricant onto the vacuum cup of the bridge and

on the two bridge adjusting screws. Once the bridge and injector assembly is set

up on the glass this will help to move the unit if the o-ring placement needs to be

adjusted.

6. Now push the injector in until it hits the bottom of the barrel.

7. Tighten the injector pressure rod.

8. Pull the injector up until the end of the groove makes contact with the retaining

screw. Fully tighten the retaining screw. You are now in the vacuum phase.

9. Hold vacuum for one minute.

10. Next, release the vacuum by loosening the injector pressure rod.

11. en re-tighten the injector pressure rod to secure the seal.

12. Next, loosen the retaining screw and push the injector in a downward motion

until the point when you feel resistance. en tighten the retaining screw. You are

now in the pressure phase.

13. Hold pressure for two minutes.

Note: For stubborn breaks, you might have to repeat the vacuum to pressure cycle

until the break is fully filled. Applying a little pressure on your break with your probe

will flex the break and help move resin into the tight areas.

3 8

3. Using the probe, remove broken glass debris from the chip.

4. If moisture is present in the break, dry out by using the windshield chip

moisture evaporator.

5. If the rock chip area is not open, consider drilling the chip. At a slow setting start

to drill into the glass but be careful not to drill into the PVB (Poly Vinyl Butyral)

Preparing the Bridge and Injector Assembly -

1. Place the injector tip o-ring on the end of the injector assembly. To do so, use a

small drop of resin to wet the injector assembly tip and then put the o-ring in

place.

Curing Procedure -

1. When the repair is to your satisfaction, release the pressure by loosening the

injector pressure rod.

2. Release the lever on the vacuum cup.

3. Remove the bridge and injector assembly.

4. Wipe away any residual resin.

5. Apply a drop of pit filler resin.

6. Place a mylar square cure sheet onto the pit filler resin. Be sure to gently place the

cure sheet in a downward laying motion and let gravity do the rest.

9 2

Inspection And Assessment -

1. Examine the damaged area from the inside and outside of the vehicle. Look for

hidden cracks, moisture, contamination or previous repair attempts.

2. Determine if the damage is within the scope of your technical experience to

repair.

3. Assess to make sure that the windshield is at the appropriate temperature.

Ideal temperature is between 65°F to 85°F plus or minus 5°F.

Preparing the Rock Chip -

1. Place the mirror on the inside of the windshield, under the damaged area.

2. Clean around the damaged area. Be sure to place a nitrile glove-covered finger

over the rock chip in order to keep from contaminating the break.

Always wear safety glasses and nitrile gloves

when repairing a windshield!

7. Cure the break for approximately three minutes using either an ultra violet lamp

or the use of natural sun light. *Always make sure to let the break cure to the

required allotted time. Do Not rush this process. e outer part of the break

might be cured but the actual pit may not be. It is very important that it be cured

all the way through.

8. Remove the mylar square cure sheet.

9. With the use of a new razor blade, scrape the cured resin in a back and forth, up

and down motion until the resin is even and level with windshield.

10. Apply a small amount of pit polish and vigorously buff with a soft cloth or paper

towel until the pit resin is shiny.

110

2.5 mm thick

10 mm outer diameter

4 mm inside diameter

2 mm thick

12 mm outer diameter

8 mm inside diameter

2 mm thick

13 mm outer diameter

10 mm inside diameter

3.5 mm thick

13 mm outer diameter

6 mm inside diameter

VOR1468

11. Clean the area that you have worked on with a good glass cleaner and a paper

towel.

Cleaning & Maintenance -

1. Clean the resin off of (and out of) your injector, o-rings and bridge with our

cleaning solution. *Keeping these items clean and free of build up assures no

contamination on you next repair, proper functioning of the tools, and will

increase the longevity of the tools. Failure to properly clean and maintain

these items could result in voiding your warranty!

VBA1443

VCD1464

VAF1471

VAL1472

VPF1452

VPL1453

VMR1450

VML1451

VTR1448

VTL1449

TRR652

TRO653

2611 Oakmont Drive • Round Rock • Texas • 78665

Toll Free USA & Canada: 800.334.1334

International: 512.388.7715 • Fax: 512.388.4188

Email: sales@equalizer.com

www.equalizer.com

www.equalizer.com

© 2012 Equalizer Industries, Inc.

Revision 11/10/17

Additional Accessories

ROCK STAR™

Windshield Repair System

Part# RSR800

User Guide

VCB1454VPO1455 AVL209

DL1093 BNG418

BNL820

MS492VPT1489

RB497

VUV1447

Table of contents

Other Equalizer Automobile Accessories manuals