ErgoAV ERDHM2-01B User manual

1 2 3 4

2 431

D

E

C

B

A

F

E

D

C

B

A

(.XXX)

##

.XXX

##

ERDHM2-01B-

Manual(英法西)-XX

0-30 ±1

30-150 ±2

150-300 ±3

300-450 ±4

>450 ±5

00

XXX-XXXXX-XX

1 1

技术要求:

1、材质:封页105g 铜板纸;内页80g双胶纸

2、展开尺寸:A4,如图所示装订成型为A5,44P

3、颜色:单色

4、印刷:印刷图档见后续页,双面印刷

5、装订方式:骑马钉

Lia

2023/06/01

刀模线:

内折线:

注:此页为技术说明,非印刷内容

297mm

210mm

装订效果图:

展开尺寸图:

深圳市倍思奇创

新科技有限公司

封

面

封

底

(A)

Dual Monitor Desk Mount Instruction Manual

Thank You for Choosing this ErgoAV Product!

At ErgoAV, we want to add value to your AV experience by providing the highest

quality products and services in the industry. If you have any concerns or

comments, please contact us.

ErgoAV Customer Care

phone: (877) 419-7832

email: [email protected]

website: www.ergoav.com

address: 9501 Louisiana Ave N, #200, Brooklyn Park, MN 55445

Model: ERDHM2-01B

English pages French pages Spanish pages

• Please carefully read all instructions before attempting installation. If you do not understand the

instructions or have any concerns or questions, please contact Technical Support at

CAUTION: Avoid potential personal injuries and property damage!

• Do not use this product for any purpose that is not explicitly specified in this manual. Do not exceed

weight capacity. We are not liable for damage or injury caused by improper mounting, incorrect

assembly or inappropriate use.

• This product contains gas assist arms which are under pressure. Do not puncture these arms or

expose the arms to high heat.

• If the product arrives defective or is missing parts, please contact ErgoAV Customer Support at

• Do Not use this product on desks made of particle board or other soft woods.

• The information contained in this manual does not cover all possible conditions or variables in

relation to the install of this product.

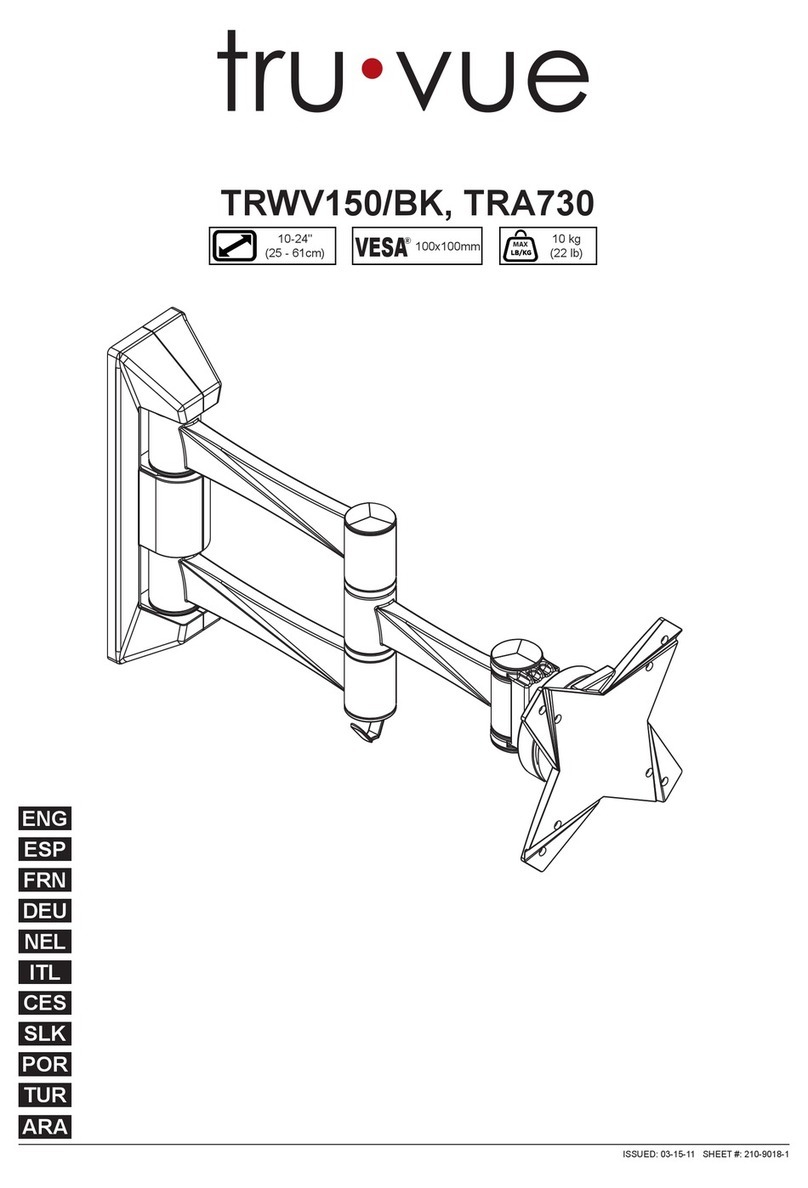

Check the VESA Pattern of Your Monitor before the Installation

Important Safety Information

If your monitor's VESA Pattern is smaller than 75mm x 75mm/3” x 3” or greater than

100mm x 100mm/4” x 4”, this mount is NOT COMPATIBLE with your monitor.

find a compatible mount.

Weight Restrictions

4.4~22 lbs.

MAX

Per Arm

(2.0~10.0 kg)

If your monitor weighs

more, this mount is

NOT compatible. Monitor

should not exceed

maximum listed weight.

WARNING

DO NOT exceed the maximum weight indicated. This mounting

system is intended for use only within the weight range listed. Use

with products heavier than the maximum weight limit may result in

failure of the mount, causing potential damage and or injury.

It is the responsibility of the installer to verify the total weight of

the monitors and any accessories attached. Do Not exceed the

weight limit listed.

W

HMinimum: 75mm x 75mm/3”x 3”(WxH)

Maximum: 100mm x 100mm/4”x 4”(WxH)

Measure Your Monitor's VESA Pattern:

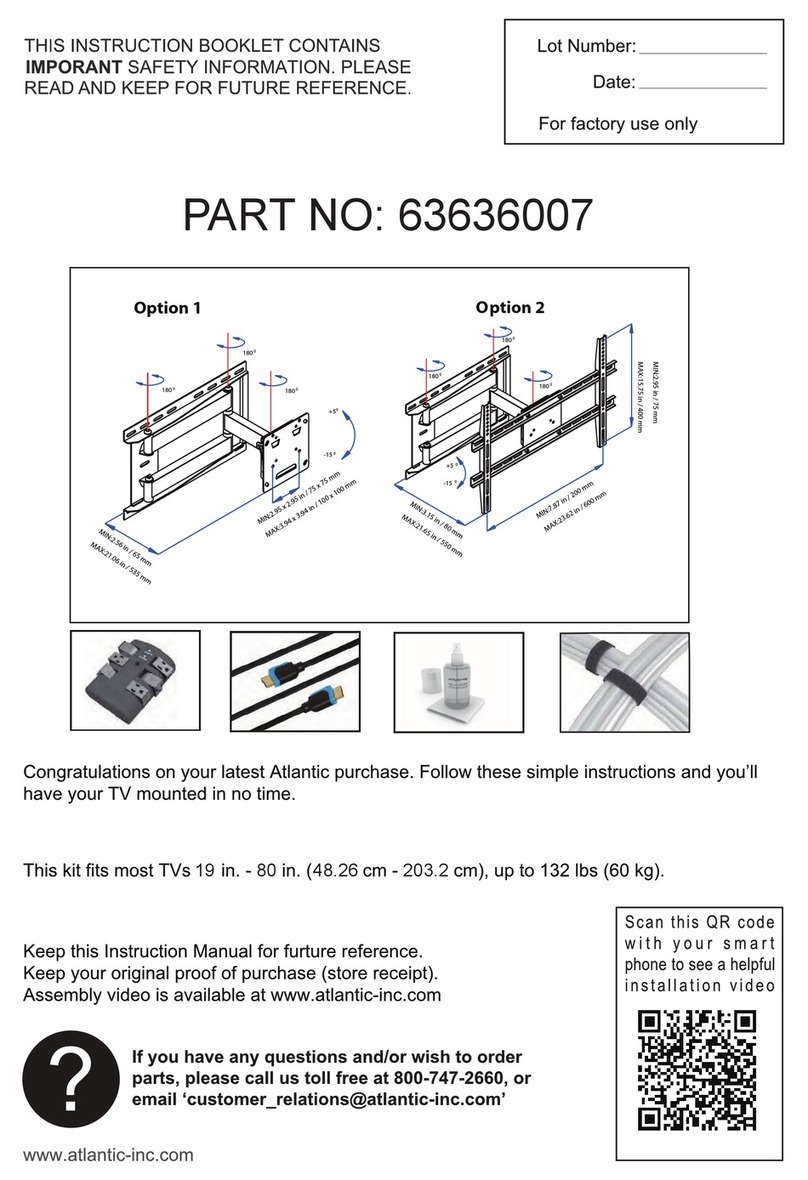

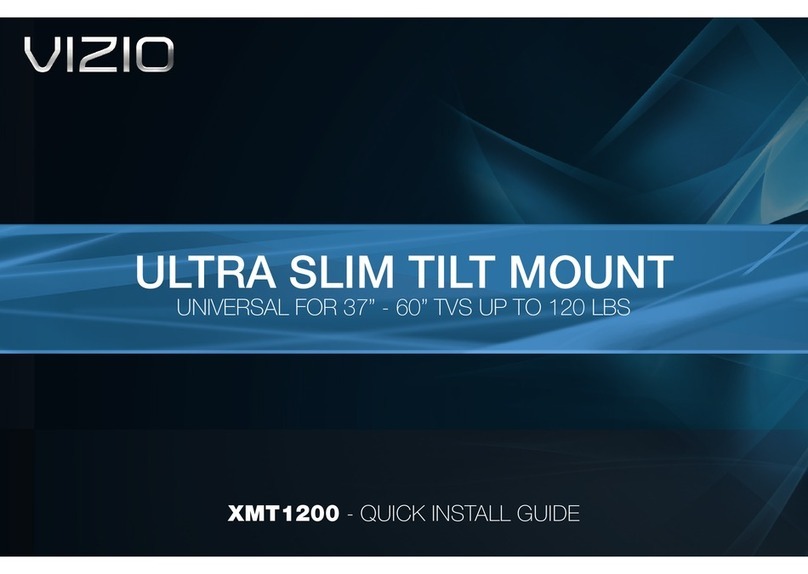

Product Features

Grommet Mounting

for grommet bolt

0.79” ~ 3.54”

(20~90mm)

360° 360°

15.2”

(385mm)

7.3”

(185mm)

+45°

180°

C-Clamp Mounting for table edge

0.79” ~ 3.54” (20–90mm)

DO NOT adjust tension without monitor attached.

1. Verify the weight of your monitor (including accessories) is between

4.4 ~ 22 Ibs (2.0~10.0 kg).

2. Monitor weight information can be found within its box or manual.

3. Ensure monitor has been securely attached to the mount.

TENSION ADJUSTMENT SHOULD BE DONE ONLY

AFTER MOUNT INSTALLATION

Attention

WARNING:

Gas Spring Arm is under pressure and should be handled with care.

Failure to follow the instructions may result in damage to the mount and/or

personal injury.

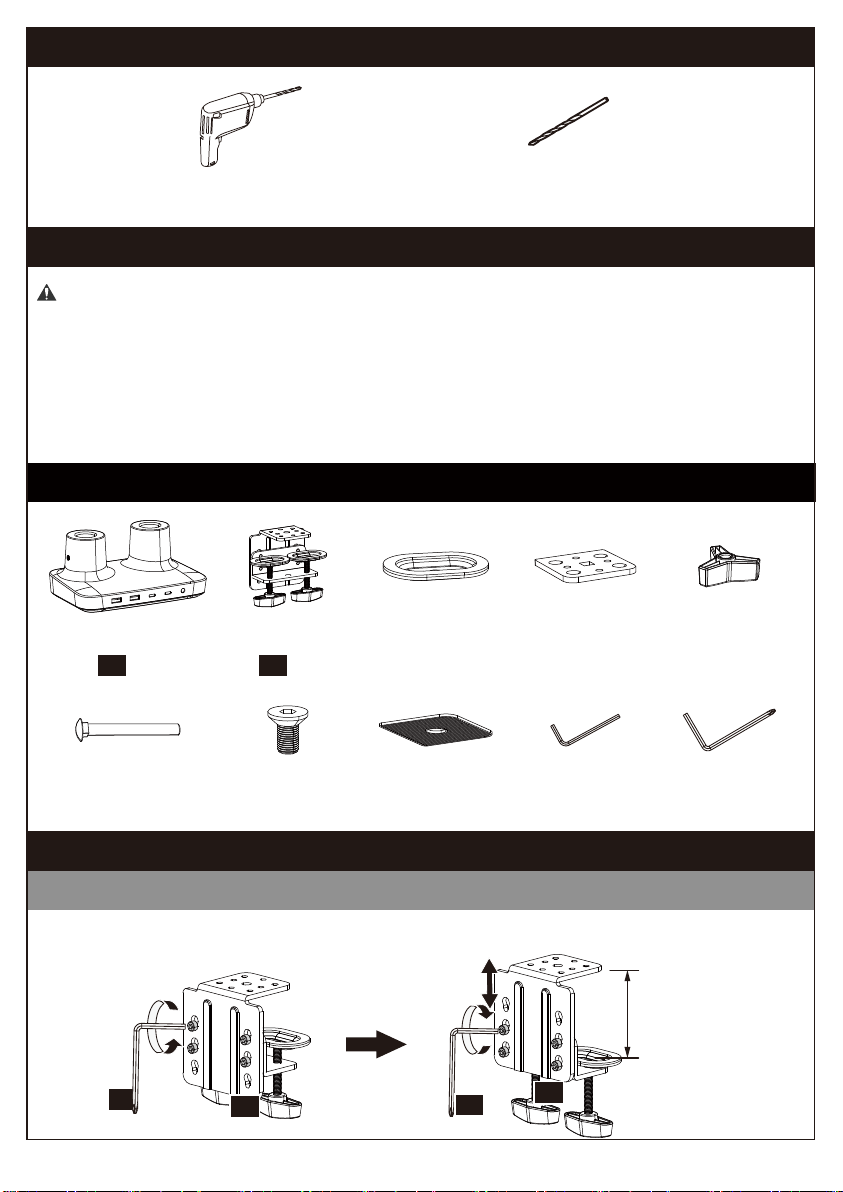

Supplied Parts and Hardware

WARNING: This product contains small items that may pose a choking hazard.

Before starting assembly, verify all parts are included and undamaged. Do not use

damaged or defective parts. lf you require replacement parts, please contact Technical

Support at (877) 419-7832 or Customer Service at [email protected] to find a

compatible mount.

• NOTE: Not all hardware included in this package will be used.

Supplied Parts and Hardware for Step 1

Electric Drill (Optional)

Drill Bit (Optional)

3/8–1 1/16" (10–27mm)

Tools Needed (Not lncluded)

Base

01

x 1

Step 1 Attach to Desk Mounting Surface

C-Clamp

02

x 1

Bolt M6 x 12mm

[B1] x 4

Rubber Pad

[C] x 1

Medium Allen Key

5/32” (4mm)

[L1] x 1

Locking Plate

[A1] x 1

Locking Plate

[A2] x 1

Butterfly Nut

[A3] x 1

Grommet Bolt

[A4] x 1

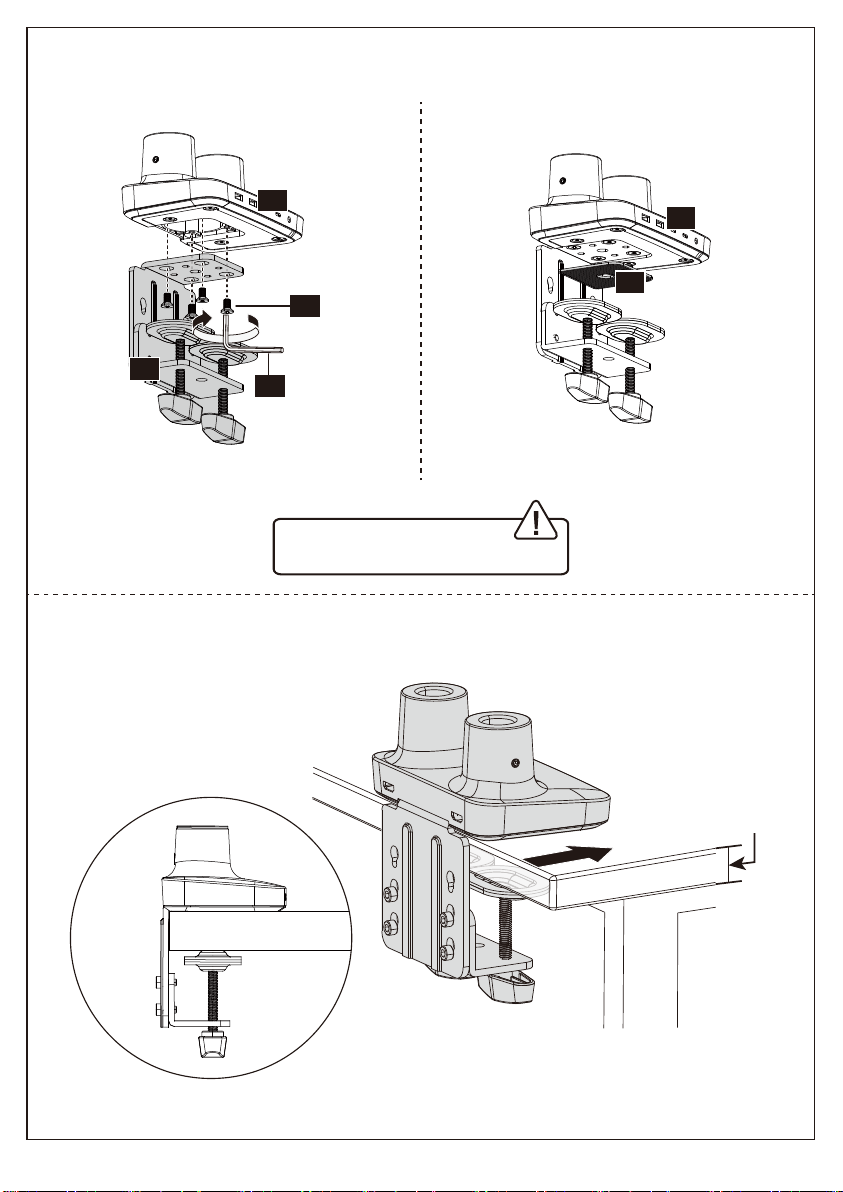

Option A: For Clamp Mounting

1A-1 Remove the pre-installed bolts and detach the C-clamp from the brace. Reattach through

the pair of holes with the best clamping range for your desk thickness.

Large Allen Key

3/16” (5mm)

[L2] x 1

Maximum

thickness:

3.54” (90mm)

L2 L2 02

02

1A-2 Attach the C-clamp brace to the

Base [01] using Bolts [B1].

1A-3 Install the Rubber Pad [C] on the

Base [01].

WARNING:

Ensure bolts are secured firmly.

1A-4 After pushing the clamp fully onto the desk, rotate the knob until the C-Clamp [02]

is secured firmly to the underside of desktop.

0.79”–3.54”

(20–90mm)

0.79”–3.54”

(20–90mm)

L1

B1

02

01

01

C

Option B: Existing Grommet Hole Installation

A4

A2 C

ATTENTION:

Ensure the grommet

bolt is threaded

securely to the base.

L1

B1

3/4" ~ 3 1/2"

20~90mm

0.79”–3.54”

20~90mm

NOTE: If your desk has an existing grommet

hole with a plastic cover, remove it before

installation.

A1

A4

A3

Rotate Butterfly Nut [A3] until the Locking Plate [A1] is firmly secured to the underside of

your desk.

L1

B1

A4

A2 C

ATTENTION:

Ensure the grommet

bolt is threaded

securely to the base.

Rotate Butterfly Nut [A3] until the Locking Plate [A1] is firmly secured to the underside of

your desk.

Option C: Self Drilled Grommet Hole Installation

If a hole is needed for grommet installation, be sure to leave at least 2” from the edge

of desktop and mark where the hole will be drilled. Use either a 7/16” or 7/8” drill bit

for this step.

7/16" ~ 7/8"

11-22cm

Electric Drill

(Not Included)

NOTE: The hole

should be at least

50mm (2") from

the edge of the

desk.

NOTE: The hole

should be at least

50mm (2") from

the edge of the

desk.

3/4" ~ 3 1/2"

20~90mm

0.79" ~ 3.54"

20~90mm

A1

A4

A3

Supplied Parts and Hardware for Step 2

Small Allen Key

1/8” (3mm)

[L3] x 1

Arm Extender

03

x 2

Arm

04

x 2

2-1 Push the Arm Extender [03] into the base, and then the Arm [04] onto the Arm

Extender [03].

2-2 Tighten the set screws on both sides of the arm joints. Do not overtighten the set

screws as this may affect the rotation of the arm.

Step 2 Attach the Arm Sections

Supplied Parts and Hardware for Step 3

Large Allen Key

3/16” (5mm)

[L2] x 1

Monitor Plate

05

x 2

Bolt

M8 x 38mm

[D1] x 2

Washer

16 x 8.2 x 1.5mm

[D2] x 2

03

04

04

03

03

L3

L3

Supplied Parts and Hardware for Step 4

Slide the Monitor Plate [05] sideways into the slot at the end of the Arm [04]. Fasten with

Bolt [D1] and Washer [D2].

Step 3 Attach the Monitor Plate

L2

05

04

Washer

10 x 4.5 x 1.0mm

[E1] x 8

Spacer

L13mm

[H1] x 8

Bolt

M4 x 12mm

[F1] x 8

Bolt

M4 x 30mm

[G1] x 8

Large Allen Key

3/16” (5mm)

[L2] x 1

D2

D1

Step 4 Attach the Monitor to the Arm

Only one size bolt fits your monitor.

Select Monitor Bolts

M4

L3

F1

F1

E1 E1 0.1–0.2" (3–5mm)

spacing left

Option A (For Flat Back Monitor)

4A-1 Thread two Bolts [F1] with Washers [E1] into the top holes until about 0.1–0.2"

(3–5mm) of space is left between monitor back and washer.

4A-2 Hang the monitor from the monitor plate with the top two Bolts [F1] (see Fig. A or

Fig. B). Screw the remaining two Bolts [F1] into the bottom holes (see Fig.C).

Tighten all Bolts [F1] evenly.

Fig. A

For Monitor Hole Pattern:

100 x 100mm (3.9 x 3.9”)

For Monitor Hole Pattern:

75 x 75mm (3 x 3”)

Fig. B

Fig. C

F1

F1

E1 E1

F1 E1

F1 E1

Turn clockwise to thread

Bolt length: Verify adequate thread engagement with bolts or bolts / spacers combination.

We recommend thread engagement of at least 5 turns.

-Too short will NOT hold the monitor.

-Too long will damage the monitor.

Too Long

Correct Correct

Too Short

Fig. C

H1

E1

G1 E1

L3

G1

Fig. A

For Monitor Hole Pattern:

100 x 100mm (3.9 x 3.9”)

For Monitor Hole Pattern:

75 x 75mm (3 x 3”)

Fig. B

Option B (For Curved Back Monitor)

4B-1 Slide the Washers [E1] and Spacers [H1] over the Bolts [G1]. Turn the top two

Bolts [G1] CLOCKWISE until about 0.1–0.2" (3–5mm) of space is left between the

Washer [E1] and the Spacer [H1].

4B-2 Hang the monitor from the monitor plate with the top two Bolts [G1] (see Fig. A or

Fig. B). Place the Spacers [H1] between the monitor plate and back of monitor.

Screw the remaining two Bolts [G1] into the bottom holes (see Fig.C). Tighten all

bolts evenly.

0.1–0.2" (3–5mm)

spacing left

G1 H1

E1

G1

E1 H1

G1

E1 H1

WARNING!

Gas Spring arm is under pressure and should

be handled with care. Failure to follow the

instructions may result in damage to the

mount and/or personal injury.

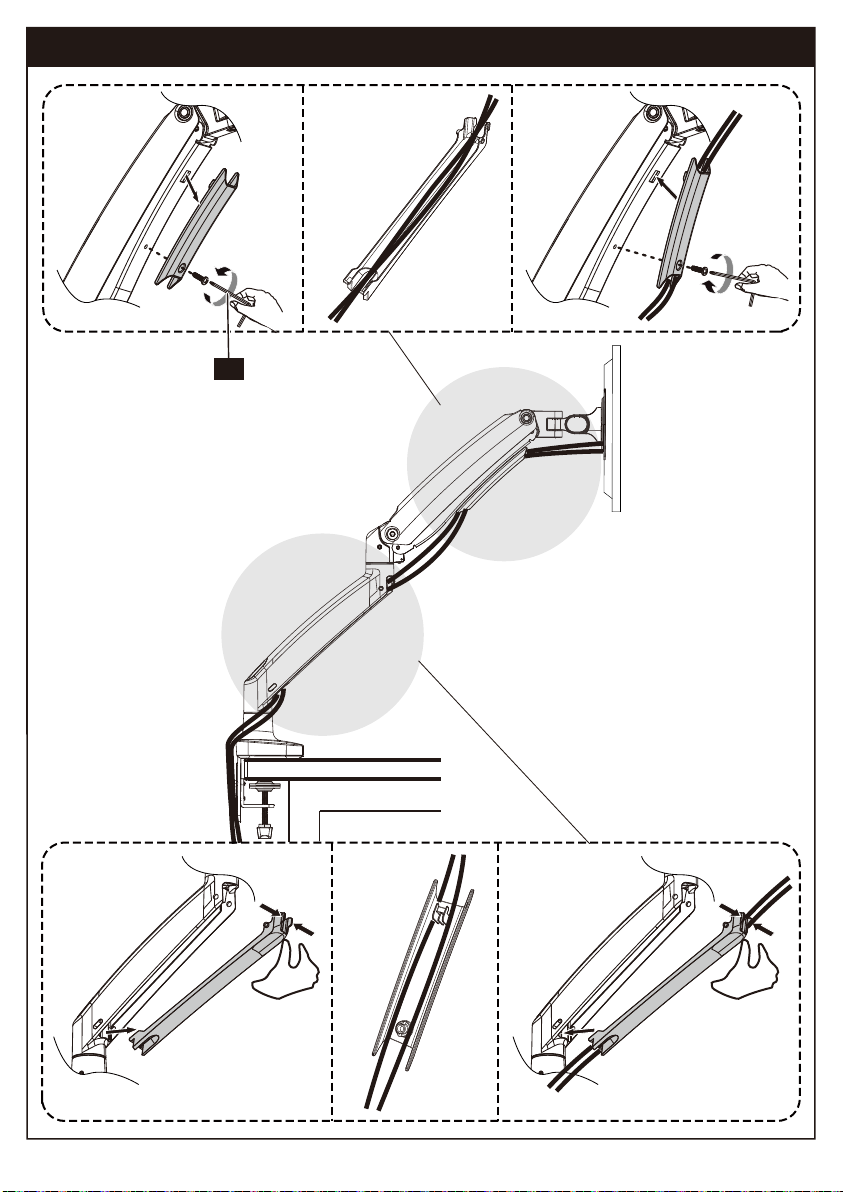

Step 5 Adjust the Gas Spring Tension

Note: Ensure the arm is held in a

horizontal position (parallel to desktop)

during adjustment. Failing to do so may

result in difficulty adjusting or potential

damage to the mount.

5-1 If the gas spring arm RISES with the monitor

attached, hold the arm in a horizontal position

while using the large Allen Key [L2] to turn the

adjustment bolt CLOCKWISE, REDUCING the

arm tension.

5-2 If the gas spring arm LOWERS with the

monitor attached, hold the arm in a horizontal

position while using the large Allen Key [L2] to

turn the adjustment bolt COUNTER-clockwise,

INCREASING the arm tension.

Supplied Hardware for Step 5

L2

Clockwise to

REDUCE tension

Counter-clockwise

to INCREASE tension

Large Allen Key

3/16” (5mm)

[L2] x 1

Incorrect orientation Correct orientation

Supplied Hardware for Step 7

Step 7 Adjust the Monitor to Proper Tilt Angle

Use fingernail or tool to open the cover easily. Slightly loosen the bolt with large Allen Key

[L2]. Tilt monitor to your desired position. Re-tighten the bolt with large Allen Key [L2] to

hold monitor in desired position.

Step 6 Rotation Restriction

To ensure proper stability, do not position monitor behind base. Monitor and arms should

remain over the desktop. Failure to do so may cause instability, resulting in property

damage or injury.

Large Allen Key

3/16” (5mm)

[L2] x 1

L2

Supplied Hardware for Step 8 and Step 10

Small Allen Key

1/8” (3mm)

[L3] x 1

Large Allen Key

3/16” (5mm)

[L2] x 1

Step 9 Rotation Adjustment

Step 8 Swivel Adjustment

Turn adjustment set screw

CLOCKWISE to INCREASE

the swiveling tension.

Turn adjustment set screw

COUNTER-CLOCKWISE to

REDUCE the swiveling

tension.

L3

180°180°

360°360°

360°360°

Firmly hold monitor at

edges and rotate from

Landscape to Portrait mode.

360° Rotation

WARNING:

Ensure bolts are secured firmly

before rotation.

WARNING:

Do not overtighten or

overloosen the bolts.

L3

Step 10 Route Cables along the Arm

①

②

⑤

④

③

①

②

⑤

④

③

L2

1&2

3

4

5

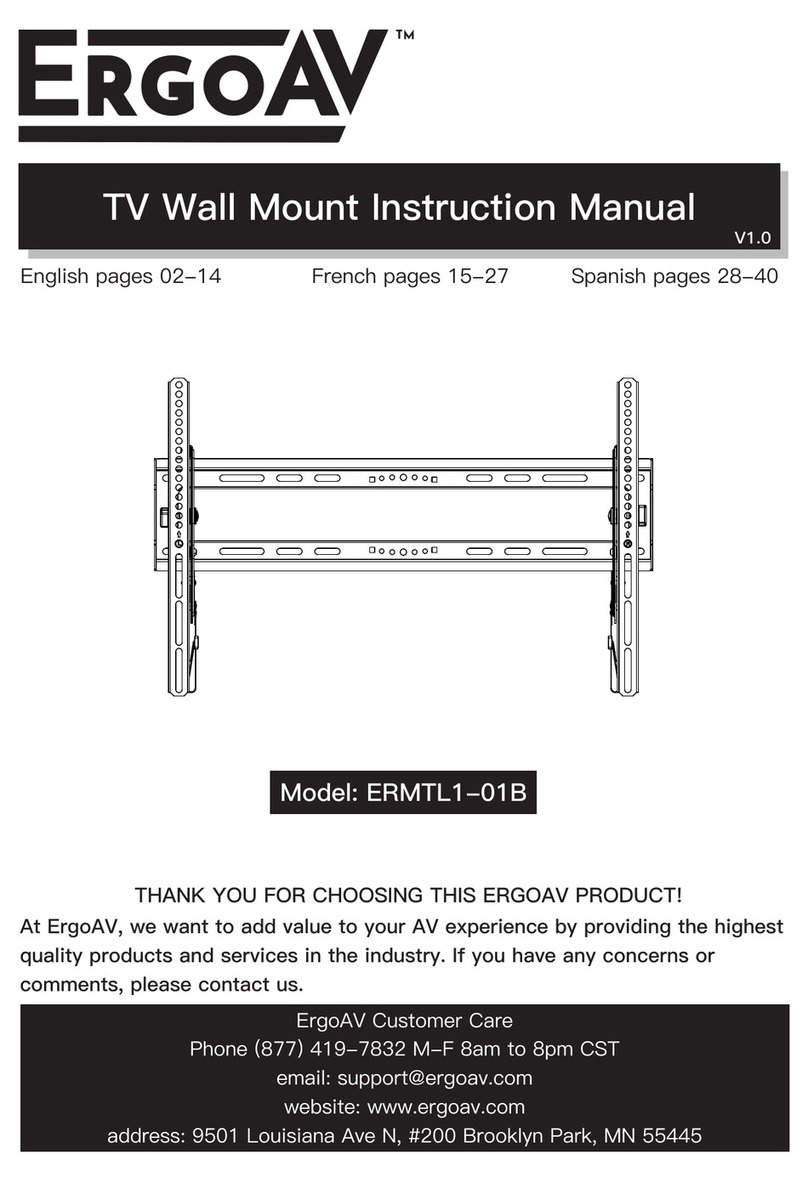

Introduction of the Docking Station

• USB-A 3.0. Used to connect to USB Devices to transfer files.

• Output 900mA, USB2.0 500mA.

• Ability to charge smaller devices.

• 3.5 mm AUX output. Connect earphones or other audio devices.

7

8

9

• 1x RJ45 Ethernet Port. Connection speeds of up to 1Gbps.

• Uses CAT5 or CAT6 cable.

6

• Media streaming up to 4k resolution via HDMI.

• This port is capable of up 4k streaming at 60Hz. (HDMI-1 is HDMI 2.0.)

• Media streaming up to 4k resolution via HDMI.

• This port is capable of up 4k streaming at 30Hz. (HDMI-2 is HDMI 1.4.)

• The 30HZ HDMI port needs to install the drive to use two screens.

• Supports up to 75W USB-C for Laptops, Tablets and Phones.

• UBS C port referenced as port No. 4 is where your laptop/tablet should be

plugged in to utilize the hub.

• After connecting your USB C cable to the Hubs corresponding port, your

computer will automatically detect the file ErgoAV by displaying an external

drive on your desktop.

• USB-C Data Port (7.5W). Transfer files up to 5Gbps.

• Charge devices via the 7.5W USB-C port.

• 100W PD Input Port.

• 100W PD input is the max power this port can accept.

Power Distribution of the Docking Station

System Requirements for Monitor Mounts with Dock

4k@60Hz Operating System(Port 8):

• Win10, Win11 or later

• Mac OS 10.12~13.3.1 versions (support M1 & M2 & Intel chip) or later

• Chrome OS 48.0.2564.82 or later

• iPad OS 12 or later

• Android 9.0 or later

• Linux Kernel 4.6 or later

(Apples website that clearly describes your Apple Intel/Silicon computers capabilities: https://sup-

port.apple.com/en-us/HT213503)

4k@30Hz Operating System(Port 9):

• Win10, Win11 or later

• Mac OS 10.12~13.3.1 versions (support M1 & M2 & Intel chip) or later

(Windows and macOS require driver installation to use this port.)

Compatible Devices Include:

Only compatible with laptops/computers and tablets that have a USB type C connection.

Environment:

32° to 104° F / 0° to 40° C

A1 A2 C1 C2

Two Ports:

C1: 7.5W Max

A1 or A2: 7.5W Max

C2: 75W Max

A1 or A2: 7.5W Max

C1: 7.5W Max

C2: 75W Max

A1 & A2:

One of the ports 7.5W Max,

total 10.8W Max

Single Port:

C1: 7.5W Max C2: 75W MaxA1:7.5W Max A2: 7.5W Max

Three Ports:

C1: 7.5W Max C2: 75W Max

A1 or A2: 7.5W Max

C1: 7.5W Max

A1 & A2: One of the ports 7.5W

Max, total 10.8W Max

C2: 75W Max

A1 & A2: One of the ports 7.5W

Max, total 10.8W Max

C1: 7.5W Max C2: 75W Max A1 & A2: One of the ports 7.5W Max, total 10.8W Max

Four Ports:

9501 Louisiana Ave N, #200, Brooklyn Park, MN 55445

ErgoAV Customer Care

Phone (877) 419-7832

At ErgoAV, we strive to provide the highest value products.

We want to support your purchase.

If you have questions, concerns,

or feedback please let us know!

www.ergoav.com

XXX-XXXXX-XX Rev00(A)

Electric Standing Desk Tabletop TV StandsTV Mount

Table of contents

Other ErgoAV TV Mount manuals

ErgoAV

ErgoAV ERTSS2-01B User manual

ErgoAV

ErgoAV ERTSM2-01B User manual

ErgoAV

ErgoAV ERMTL1-01B User manual

ErgoAV

ErgoAV ERDHM1-01B User manual

ErgoAV

ErgoAV ERMTS1-01B User manual

ErgoAV

ErgoAV ERMMS1 -01 B User manual

ErgoAV

ErgoAV ERMTM2-01B User manual

ErgoAV

ErgoAV ERMCM1-01B User manual

ErgoAV

ErgoAV ERMTM2-01B User manual

ErgoAV

ErgoAV ERMTM1-01B User manual

Popular TV Mount manuals by other brands

Rapid video mounts

Rapid video mounts RVM-75FM150 instruction manual

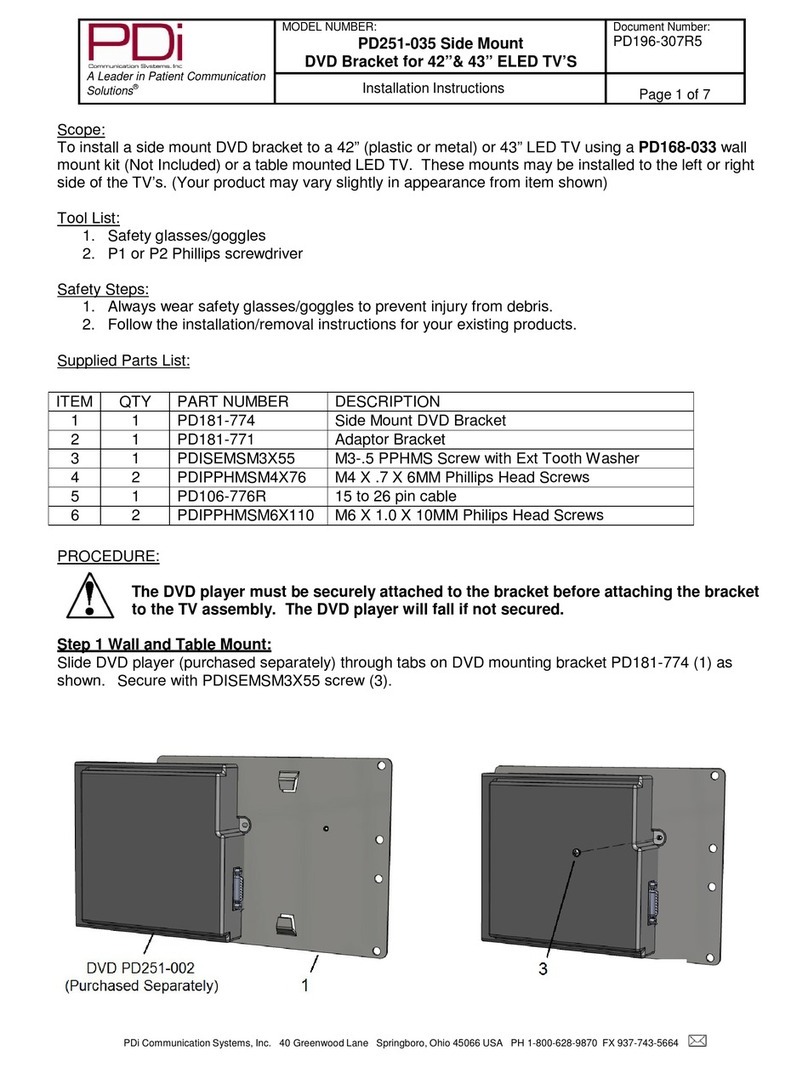

PDi

PDi PD251-035 installation instructions

Sony

Sony KDL-32ML130 - 32" Bravia M-series Digital Lcd... instructions

Philips

Philips SQM6375/27 user manual

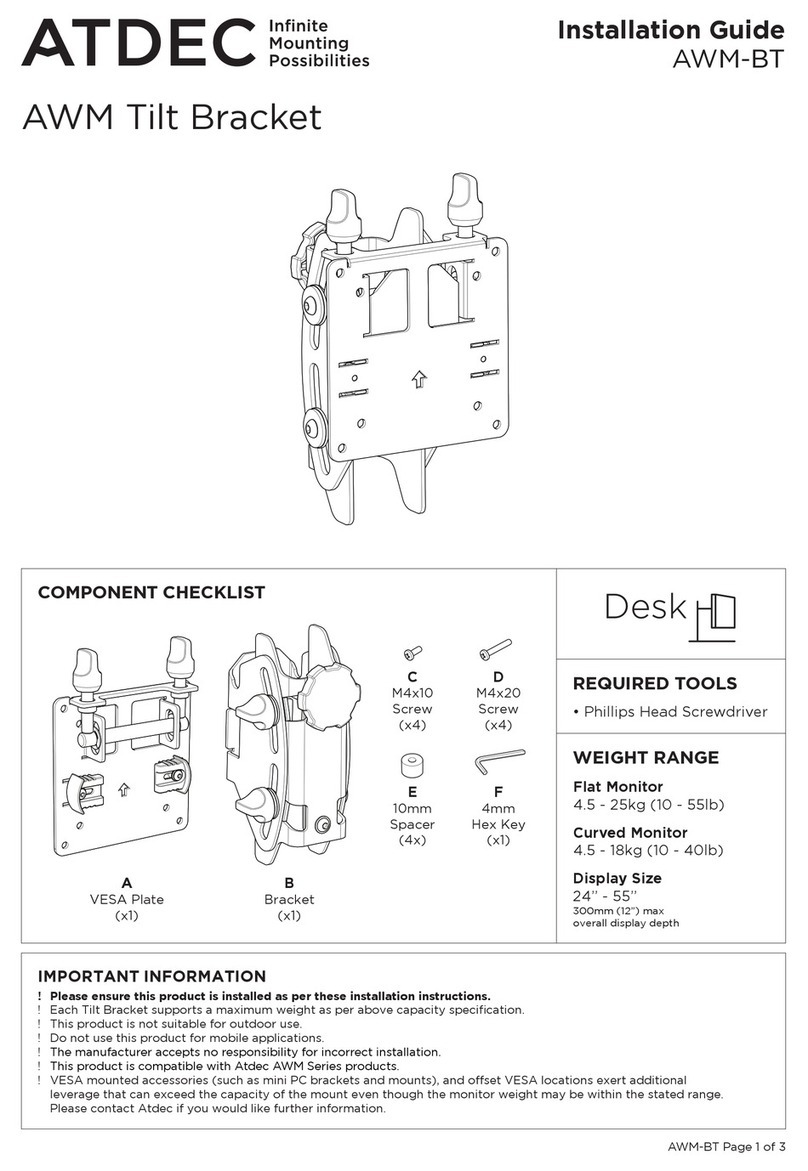

Atdec

Atdec AWM-BT installation guide

cabstone

cabstone CAB EASYFIX U-Slim XL user manual