ERHARD ERU K1 User manual

BA46E042

Jul 2009

Rev. 11

ERHARD-Armaturen D-89502 Heidenheim PO box 1280

(+49-7321) 320-0 (+49-7321) 320 491 e-mail: info@erhard.de

Internet: http://www.erhard.de

Page 1 of 12

BA46E042

Operating instructions

ERHARD-ERU Knife Gate Valve

K1

DN 350 - 600

electric actuator

1 Product description and range of application

2 Design features - technical data

3 Function and mode of operation

4 Storage

5 Installation into the pipeline –mounting

6 First time operation

7 Operation and use

These operating instructions must always be used in connection with BA01E001!

1 Product and function description

ERU Knife Gate Valve K1

with rising stem

Design for automatic operation with electro actuator

Make no.: 4607 .... PN 4

4617 ... PN 6

4657 .... PN 10

Operating instruction ERU Knife Gate Valve K1 electric actuator

BA46E042

Jul 2009

Rev. 11

ERHARD-Armaturen D-89502 Heidenheim Postfach 1280

(07321) 320-0 (07321) 320 491 e-mail:info@erhard.de

Internet: http://www.erhard.de

Page 2 of 12

Size

Nominated pressure

Hydr. Test pressure in bars Max. admissible

DN PN

for

working pressure in bars at

body end seal working temperature < 60°C

Erz.-Nummer

350 10 17 11 10 4655....; 4657....

400-600 4 8 4,4 4 4605....; 4607....

400 - 600 6 12 6,6 6 4615....; 4617....

400 - 600 10 15 11 10 4655....; 4657....

Operating instruction ERU Knife Gate Valve K1 electric actuator

BA46E042

Jul 2009

Rev. 11

ERHARD-Armaturen D-89502 Heidenheim Postfach 1280

(07321) 320-0 (07321) 320 491 e-mail:info@erhard.de

Internet: http://www.erhard.de

Page 3 of 12

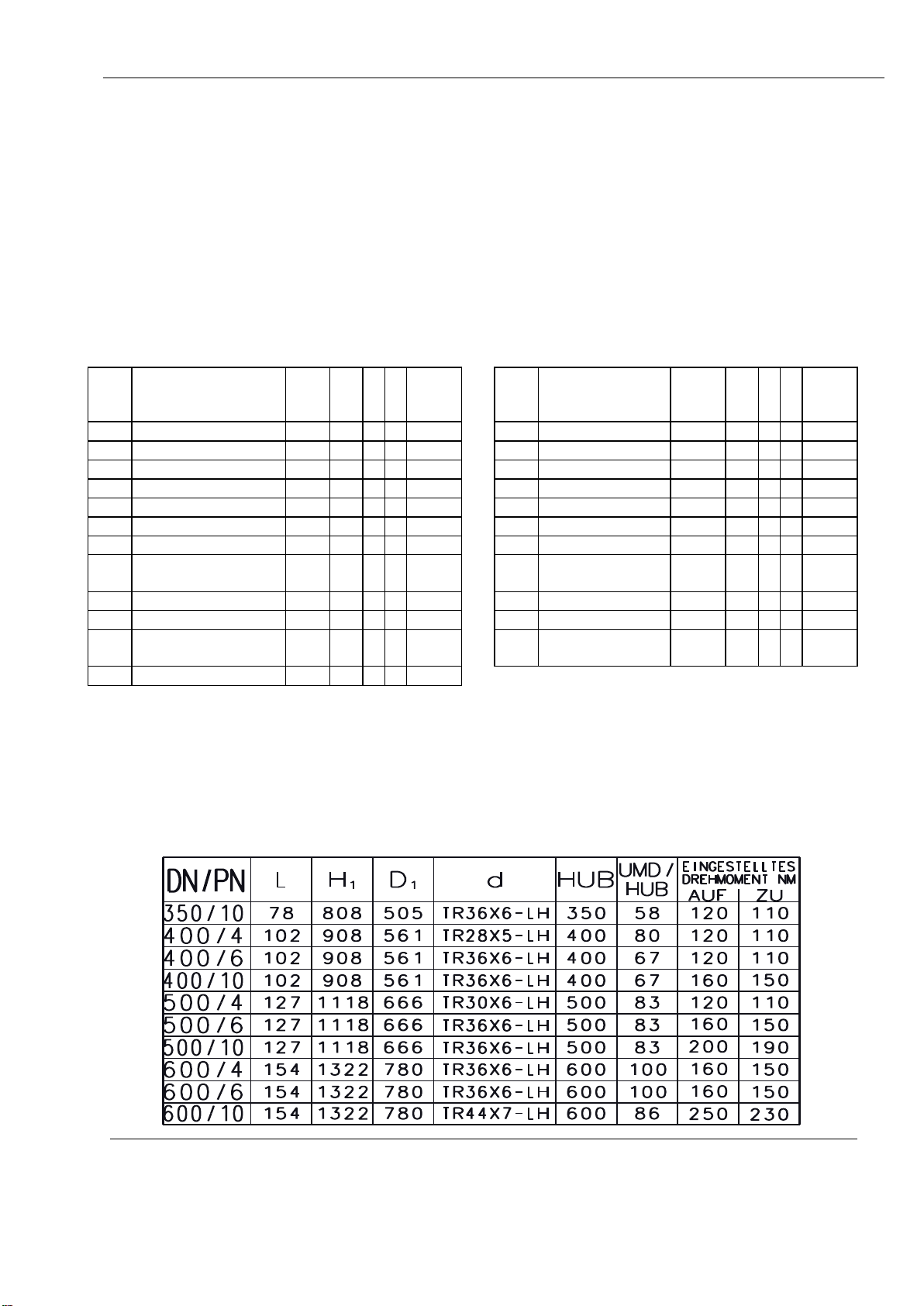

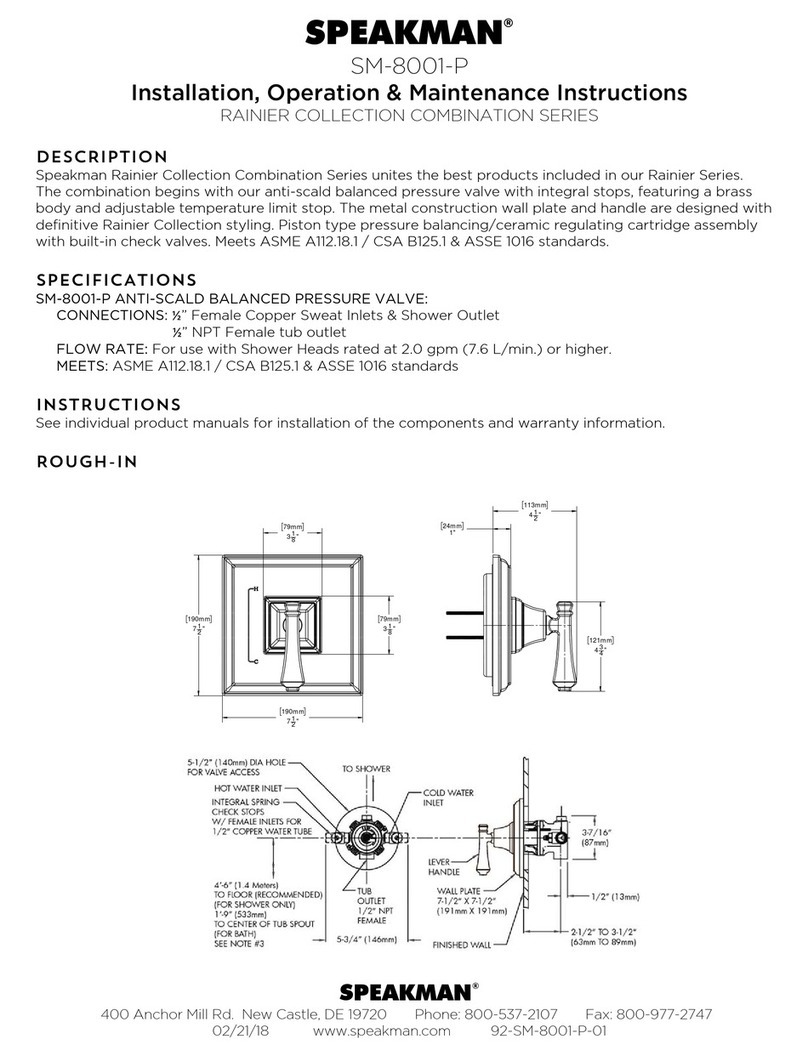

2 Design features –technical data

Drawing 3. 60796

ERU Knife Gate Valve K1 with electro actuator

- Flange connection dimensions according to DIN EN1092, PN10, previously DIN 2532 PN10

- Connection elements for flange connection according to drawing 4.131899

- Overall length EN558-1, Basis series I HE 20, previously DIN3202, part 3, series K1

Operating instruction ERU Knife Gate Valve K1 electric actuator

BA46E042

Jul 2009

Rev. 11

ERHARD-Armaturen D-89502 Heidenheim Postfach 1280

(07321) 320-0 (07321) 320 491 e-mail:info@erhard.de

Internet: http://www.erhard.de

Page 4 of 12

Parts list to drawing: 3. 60796

ERU Knife Gate Valve K1 with electro actuator

In the column "E/V" are marked

spare parts or sets, respectively, e.g. E1 = spare parts set No. 1

or

wearing parts, spare parts or sets, respectively, e.g. V1 = wearing parts

set No. 1

and in column 2j (for 2 years of operation or as needed, respectively)

Part

Name

eac

h

2

j

E / V

Part

Name

each

2

j

E / V

1

Body part

2

13

Washer

*)

2

Bow cpl.

1

x

V1

14

Bow attachment

1

3

Round key

*)

15

Bushing

1

x

E2

4

Pressure piece

2

16

Stem

1

x

E1

5

Gaskets 4kt

4

x

V1

17

Bolt

*)

x

E2

6

Profile rubber

2

x

V1

18

Retaining washer

*)

x

E2

7

Sliding plate

1

19

Washer

4

8

Washer

*)

20

Cheese head

screw

4

9

Hexagon bolt

*)

21

Electro actuator

1

10

Hexagon nut

*)

22

Washer

4

11

hexagon bolt

*)

23

Cheese head

screw

4

12

Hexagon nut

*)

*) according to DN varying quantities

Table of dimensions to drawing: 3. 60796

Stroke UMD / Set

stroke torque Nm

Operating instruction ERU Knife Gate Valve K1 electric actuator

BA46E042

Jul 2009

Rev. 11

ERHARD-Armaturen D-89502 Heidenheim Postfach 1280

(07321) 320-0 (07321) 320 491 e-mail:info@erhard.de

Internet: http://www.erhard.de

Page 5 of 12

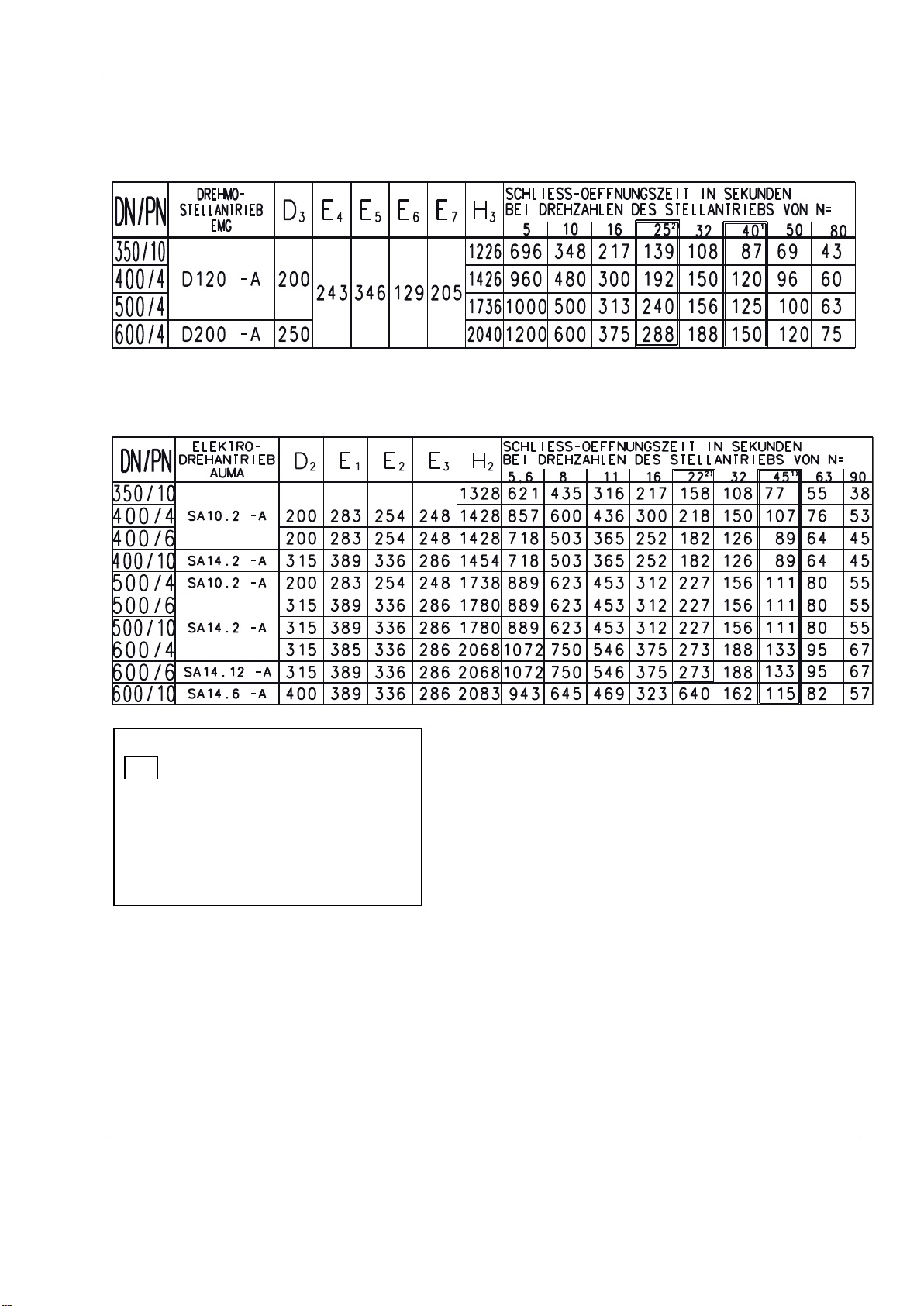

Table of dimensions to drawing:3. 60796

Torque actuator Closing-opening times in sec.

EMG at rotational speed of the actuator of N=

Electro Closing-opening times in sec.

rotational actuator at rotational speed of the actuator of N=

AUMA

Preferred series

1)

at standard actuator

2)

at control actuator

Operating instruction ERU Knife Gate Valve K1 electric actuator

BA46E042

Jul 2009

Rev. 11

ERHARD-Armaturen D-89502 Heidenheim Postfach 1280

(07321) 320-0 (07321) 320 491 e-mail:info@erhard.de

Internet: http://www.erhard.de

Page 6 of 12

3 Function and mode of operation

ERU Knife Gate Valves K1 are single plate knife gate valves with clamping installation

design featuring short overall lengths, suitable also for control purposes due to special

design e.g. with regulating piece. Between two body sections the solid sliding plate is

moving in a long plate guide. Its perimeter seals against a rubber elastic steel

reinforced chambered U-bow. At the exit of the sliding plate from the body the sliding

plate seals by an elastically biased profile gasket to the outside. This profile gasket is

adjustable. For reducing wear of the profile gasket and the actuator elements the bias

can be reduced to the value needed for actual operation.

The slides have been tested at the manufacturers for strength and tightness according

to DIN EN 12266 and DIN EN 1074. They allow operation in both flow directions.

4 Storage

ERU Knife Gate Valves K1 must be stored in closed condition. Rubber lined parts,

such as bows between body sections must be protected against direct sun radiation.

Influence of radiant heat e.g. from radiators should be avoided.

5 Installation into the pipeline - mounting

All packaging material must be removed from the valve. Prior to installation, the

pipeline must be inspected for pollutions and foreign parts and be cleaned if

necessary.

Care should be taken that the valve is accessible from all sides for

operation and maintenance.

At operating media with solids, such as sand etc. and installations in horizontal lines

the stem or piston rod, respectively, should not be installed inclined more than 30º

to the horizontal position. Thus rinsing free of the stroke area of the sliding plate

becomes possible.

At different installation positions, especially at hanging stem or piston rod,

respectively, deposits may be built-up around the sliding plate. That could cause

functional failures and maintenance could become more extensive.

During the mounting process the valve should have a distance between the pipeline

flanges which is at least 20 mm larger than the overall length of the valve, in order

not to damage the work strips and allow gaskets to be put in. As flange gaskets

steel reinforced flat gaskets are recommended (rubber gaskets) according to DIN

EN 1514-1. At lap-joint flanges mandatory required. Media and temperature

compatibility of the gaskets must be observed and to be checked.

The pipeline counter flanges must be plane parallel and concentric.

Operating instruction ERU Knife Gate Valve K1 electric actuator

BA46E042

Jul 2009

Rev. 11

ERHARD-Armaturen D-89502 Heidenheim Postfach 1280

(07321) 320-0 (07321) 320 491 e-mail:info@erhard.de

Internet: http://www.erhard.de

Page 7 of 12

Connection screws must be tightened equally (tension free) and crosswise. In no

case the pipeline may be pulled to the valve.

Should the distance between the flanges be too large for the valve the difference

must be compensated by thicker flat gaskets.

ERU Knife Gate Valves K1 are either

- clamped between two flanges of the pipeline, or

- screwed as end-of-line valve on the end flange.

When installing into the pipeline, the special flange bore pattern must be observed

at this type of valve. One part of the screws connects the pipeline flange with the

body. The other part is located alongside the body from pipeline flange to pipeline

flange.

6 First time operation

Attention: prior to first time operation stem and stem nut must be greased (for

recommended grease see section „Operation and use“).

The electro actuator is mounted concentrically on the bock attachment of the ERU

Knife Gate Valve K1. The stem of the valve is moved by the threaded bushing of the

electro actuator in vertical direction (ON - OFF). The actuators are equipped in the

standard version with:

Torque and travel switch with 1 open + 1 close contact each per rotational direction,

flasher unit for indicating the run,

heater in the switching room,

thermal switch in the motor winding.

ERU Knife Gate Valves K1 are switched off in both end positions depending on

travel.

The switching points of the end position switches are set in the factory during leakage

tests at nominal pressure. It will be considered that blocking of the sliding plate against

the upper mechanical end caused by motor run-on will be avoided and starting from

there will be no problem. The torque switches serve as safety switches, e.g. at

intermediate positions.

If the valve is supplied without attached electro actuator the travel switches should be

set after mounting the electro actuators.

See also section 6.2 "First time operation of the electro actuator", paragraph

"Resetting of travel switch".

The relevant safety regulations (VDE/TAB etc.) and instructions of the electro actuator

manufacturer for transport, storage and first time operation must be observed.

Operating instruction ERU Knife Gate Valve K1 electric actuator

BA46E042

Jul 2009

Rev. 11

ERHARD-Armaturen D-89502 Heidenheim Postfach 1280

(07321) 320-0 (07321) 320 491 e-mail:info@erhard.de

Internet: http://www.erhard.de

Page 8 of 12

Electrical connections must be made according to operating instructions as well as

switching and connection plan of the electro actuator manufacturer (travel distance,

torque and thermal switches, heater motor). Prior to installation the isolation resistance

of the motor must be measured. In case it is below 500 kΩit means there is humidity

in the winding. The motor must be removed for drying and be warmed up by means of

a hot-air blower or in a heated chamber: maximum admissible temperature = 100°C.

Inching and emergency manual operation

Attention:

If a foreign part will be trapped during operation of the valve the torque switch for the

corresponding direction will trip and switch off the motor.

The time between tripping of the torque switch and separation of the motor from mains

depends on signal travelling time. If now a new command will be given for the previous

direction without having rotated the valve sufficiently far enough into the opposite

direction, the torque will rise. If this procedure will be repeated several times the

momentum will be cumulated. The valve and its actuator parts are not designed for

such a case of failure and may be damaged.

We point express to the fact that such an "Inching" is not admissible.

Inching is admissible as follows:

If the torque switch trips at an intermediate position, first, it must be travelled far

enough into the counter direction until the torque switch reaches completely its home

position. Only then, restart into that direction in which the failure has occurred is

admissible. At this procedure torques will be reached which correspond with the set

momentum on the torque switch. Moreover, the foreign part can loosen and be flooded

out from the seat area.

Operating by emergency manual operation (hand wheel):

If the valve will be operated by hand wheel of the electric actuator the torque switches

have no securing effect.

If a foreign part is trapped at an intermediate position, excessive force may lead to

damages on the actuator parts - especially at heavy geared down equipment.

Therefore it must be observed:

If during emergency manual operation a resistance will be noticed, one turn into the

counter direction must be performed prior to rotating into that direction in which the

failure has been detected (rinsing out the foreign part). Operation should be performed

at utmost care, in no case use excessive force, if required rinsing should be repeated.

The profile gasket has been set to nominal pressure in the factory (biased). At low

operating pressures the profile gasket can be released after the pressure test of the

pipeline according to actual operating pressure. For doing this, the screws on the

Operating instruction ERU Knife Gate Valve K1 electric actuator

BA46E042

Jul 2009

Rev. 11

ERHARD-Armaturen D-89502 Heidenheim Postfach 1280

(07321) 320-0 (07321) 320 491 e-mail:info@erhard.de

Internet: http://www.erhard.de

Page 9 of 12

cover plate shall be loosened accordingly. By this measure wear of components

involved in movements can be reduced.

ATTENTION ! Operating media may escape. In case of poisonous or corroding media

wear protective clothing (goggles).

First time operation of the electro actuators

For first time operation of the valve the operating instructions of the electro actuator

manufacturer must be referenced to.

6.1.1 Rotate ERU Knife Gate Valve K1 manually into intermediate position.

6.1.2 By short time electrically starting the plate movement and thus direction of

rotation of the actuator has to be checked.

valve closes = actuator direction RIGHT (clockwise)

valve opens = actuator direction LEFT

6.1.3 At wrong direction of rotation change poles on the motor connection

6.1.4 Check direction of rotation by short time electrically starting

6.1.5 Check correct switching sequence of the torque switches in "OPEN-CLOSED"

direction by manual operation

6.1.6 Change poles if required

6.1.7 Only after the direction of rotation "RIGHT for valve closes" is met you may

travel over the complete stroke.

At wrong direction of rotation travel and torque switches do not have any

effect !

6.2 Resetting of the travel switches:

6.2.1 Rotate valve manually to end position "OPEN"

6.2.2 Reverse by approx. 5mm stroke

6.2.3 Adjust travel switch "OPEN" according to operating instructions of the electro

actuator manufacturer

6.2.4 Rotate valve manually into closed end position "CLOSED"

6.2.5 Adjust travel switch "CLOSED" according to operating instructions of the

electro actuator manufacturer

If these suggested measures will not be adhered to we will not accept any

liability for possibly occurring damages.

Operating instruction ERU Knife Gate Valve K1 electric actuator

BA46E042

Jul 2009

Rev. 11

ERHARD-Armaturen D-89502 Heidenheim Postfach 1280

(07321) 320-0 (07321) 320 491 e-mail:info@erhard.de

Internet: http://www.erhard.de

Page 10 of 12

7 Operation and use

Prior to first time operation stem and stem nut must be greased.

At operating media water the recommended lubricant is Klüber Unisilikon L641.

At operating media water silicon free types the recommended lubricant is Klüber Synth

VR 69-252.

At the electro actuator a gap between sliding plate and bearing plate remains visible

(run-on).

The cross gaskets are set to nominal pressure in the factory (biased). They can be

adapted to the actual operating over pressure: by loosening the counter nut and

screws the bias of the gasket will be reduced.

ATTENTION ! Operating media may escape. In case of poisonous or corroding

media wear protective clothing (goggles).

The valve plate (gate) should be always cleaned and lubricated depending on the

operating and environmental conditions.

ERU Knife Gate Valves K1 should be operated in regular short intervals (every six

months) over the complete stroke (OPEN-CLOSED). Depending on operating media

and the conditions at place of use the maintenance intervals could be shorter or

longer.

As soon as a minor leakage will be detected the cross gaskets must be brought into

tight condition by equally tightening the screws.

Tighten counter nuts. By this adaptation to the actual operating conditions the

operating force will be reduced and service life of the cross gaskets will be increased.

If re-tightening of the cross gasket should be no more possible they must be

replaced.

Sliding plate and stem must be inspected for pollution in regular intervals and be

cleaned if required and be treated with lubricants (thin application).

ERU Knife Gate Valves K1 which are equipped with grease nipple in the area of the

stem bearing must be re-greased with regards to usage conditions in regular

intervals.

If sluggishness will continue it should be checked if the valve has possibly been

pressed too hard between the flanges of the pipeline. The through flange screws

must be loosened equally and ease of movement should be re-checked.

Please see also section "Operating failures which can be solved by yourself "

Operating instruction ERU Knife Gate Valve K1 electric actuator

BA46E042

Jul 2009

Rev. 11

ERHARD-Armaturen D-89502 Heidenheim Postfach 1280

(07321) 320-0 (07321) 320 491 e-mail:info@erhard.de

Internet: http://www.erhard.de

Page 11 of 12

7.1 Not admissible modes of operation

For inspections or maintenance works the valve - or parts of the valve - may only be

dismantled after the line section in which they are installed is blocked and be made

pressure less. If works are performed in the vicinity of the valves which may lead to

pollutions (concrete, brick laying, painting works, sand blasting and the like) valves

must be covered appropriately.

At equipping the ERU Knife Gate Valves K1 with EPDM profile gaskets the EPDM

parts may not be greased with oil or come into contact with grease, since EPDM

swells. For the recommended grease see section 7.

The ERU Knife Gate Valves K1 of this type are not suitable for control purposes. For

extensive control operation special types, e.g. with regulating piece should be used.

Elongation of operating elements by levers or the like is not admissible, Risk of

damages !

Operating instruction ERU Knife Gate Valve K1 electric actuator

BA46E042

Jul 2009

Rev. 11

ERHARD-Armaturen D-89502 Heidenheim Postfach 1280

(07321) 320-0 (07321) 320 491 e-mail:info@erhard.de

Internet: http://www.erhard.de

Page 12 of 12

7.2 Operating failures which can be solved by yourself:

Failure

Possible cause

Remedy

Leakage at the

cross gasket

Not enough bias,

possibly higher

operating pressure than

set

Re-adjustment of the cross gasket: see

"6. First time operation".

Wear of the PTFE

gaskets

Replace gaskets

Pollution (residues) on

the sliding plate

At valve open position: clean plate on both

sides and grease

Leakage at the

plate face

Bias of the upper body

screws

Tighten body screws at installed valve

Leakage at

body girth

Bias of the

body screws

First tighten through screws from flange to

flange and as far as can be reached body

screws. If no success: replace bow

Leakage at end

seal

Pollution of the plate,

defective bow

Clean plate and grease,

replace bow

Sliding plate runs on

one side onto the body

Loosen bias of the cross gasket on both

sides. Renew bias setting on both sides

equally, in order to let the sliding plate run

centrically.

Operating force

too high

Bias of the cross gasket

too high

Loosen cross gasket

see "First time operation".

Pollution (residues) on

the sliding plate

At valve open position: clean plate on both

sides and grease

Spindle

runs dry

Re-grease thread

Actuation

blocks

Operating media

residues became

hardened

Line section pressure less. Clean all

accessible surfaces of plate and stem and

grease. Loosen cross gasket on both sides.

Loosen upper body screws slightly. Beat

with rubber hammer on the valve and try to

operate the valve at the same time. In case

of no success, remove, dismantle, clean,

replace damaged parts.

Other manuals for ERU K1

1

Table of contents

Other ERHARD Control Unit manuals

Popular Control Unit manuals by other brands

Speakman

Speakman CPV-P-IS Installation, operation & maintenance instructions

Vertiv

Vertiv Geist Replacement guide

Pentair

Pentair HI FLOW SIX-WAY 1-1/2 INCH TOP MOUNT VALVE Installation and user guide

Satel

Satel ETHM-1 manual

Atmel

Atmel ATBTLC1000 BluSDK user guide

iSmartHome

iSmartHome id Smart Box Operation manual