GMQ20; GMQ20-RM16-25-OI-vers. 2.5 gb. 05.02.15

Table of contents:

1.0.0 Declaration of Incorporation Page 5

1.1.0 Declaration of Incorporation according to the Machinery Directive

2006/42/EG Page 5

2.0.0 Module Information Page 6

2.1.0 Transport and storage (packing and unpacking) Page 6

2.1.1 Possibilities of fastening GMQ 20 and GMQ 20/RM 16/25 Page 7

2.1.2 Hole matrix and centering bushings Page 8

2.1.3 Tightening torques for bolts Page 9

2.1.4 Diagramme GMK 20 Page 10

2.1.5 Diagramme GMQ 20 Page 11

2.1.6 Preferred combinations GMQ 20 Page 12

3.0.0 Montage Instructions Page 13

3.1.0 Manufacturer address Page 13

3.1.1 Symbols Page 14

3.1.2 General description GMQ 20 Page 14

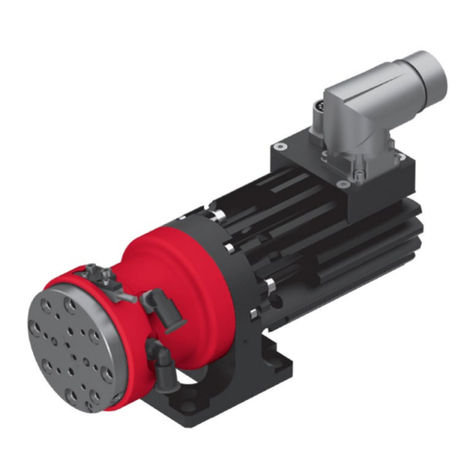

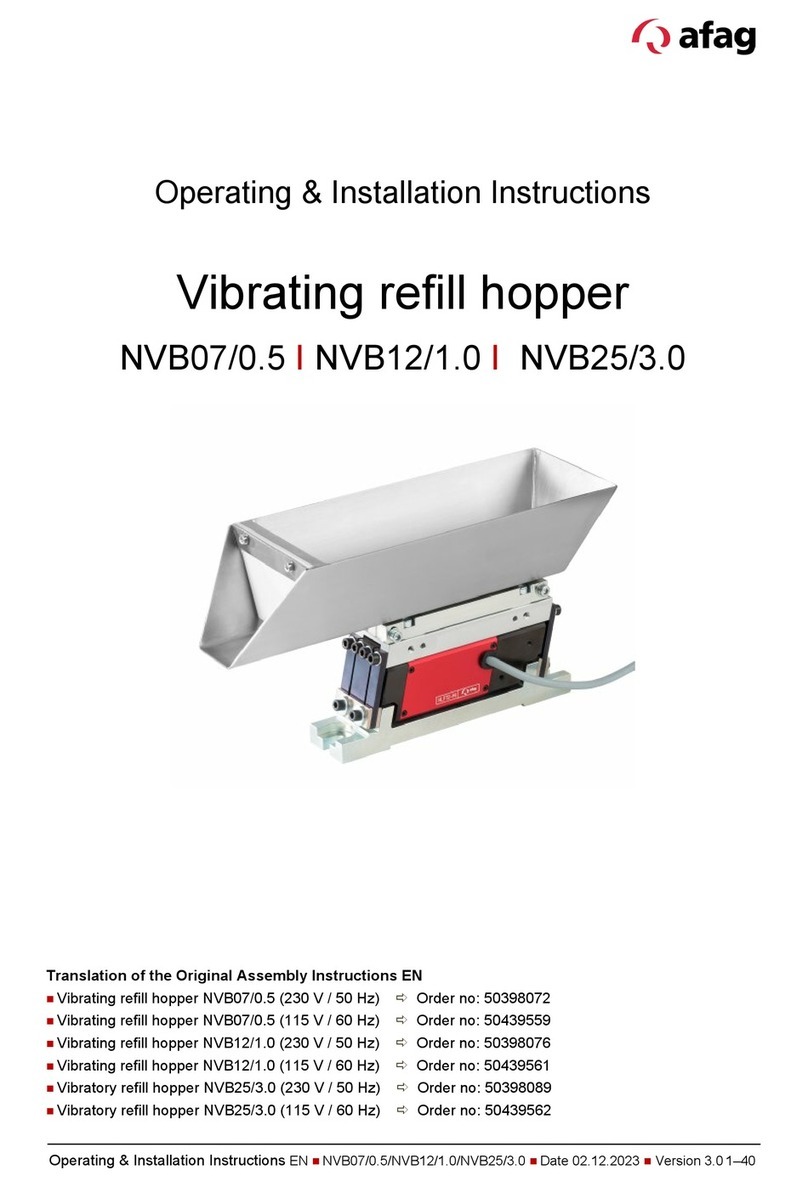

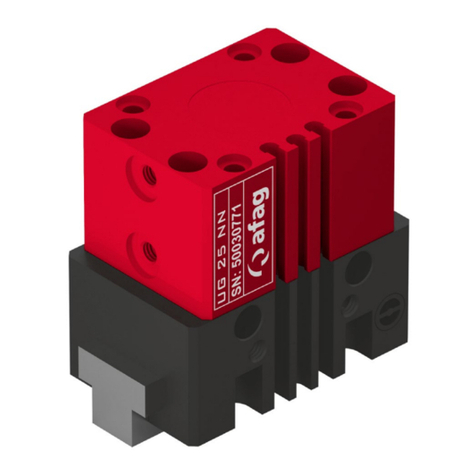

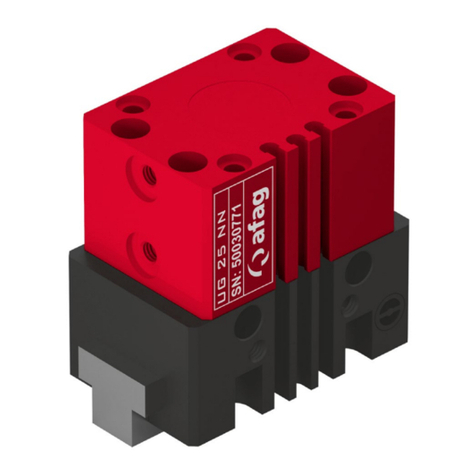

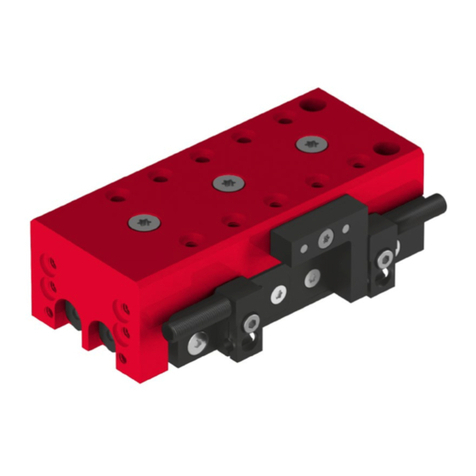

3.1.3 Description of the module GMQ 20 / GMK 20 Page 15

3.1.4 Description of the rotary gripper module GMQ 20/RM 16/25 Page 16

3.1.5 Included in the delivery GMQ 20 / GMK 20 Page 17

3.1.6 Intended use Page 17

3.1.7 Safety information GMQ 20 / GMK 20 Page 17

3.1.8 Included in the delivery GMQ 20/RM 16/25 Page 18

3.1.9 Intended use Page 18

3.2.0 Warranty Page 19

3.2.1 Areas of application Page 19

3.2.2 Dimensions drawing GMQ 20 / GMK 20 Page 20

3.2.3 Technical data of the GMK 20,GMQ 20 Page 21

3.2.4 Dimensions drawing GMK 20, GMQ 20/RM 16/25 Page 22

3.2.5 Pneumatic connection GMK 20, GMQ 20 Page 23

3.2.6 Pneumatic connection GMQ 20/RM 16/25 Page 23

3.2.7 Adjusting the GMK 20, GMQ 20 Page 24

3.2.8 Modifying the GMQ 20 to inner tension Page 25

3.2.9 Modifying the GMQ 20 double acting Page 26